Claas Scorpion 7045 7040 (K14) Telehandlers Assembly Instruction EN

$50.00

- Model: Scorpion 7045 7040 (K14) Telehandlers

- Type Of Manual: Assembly Instruction

- Language: EN

- Format: PDF(s)

- Size: 34.8 MB

File List:

00 0290 143 2.pdf

00 0292 437 0.pdf

00 0300 131 0 2.pdf

00 0300 131 0.pdf

00 0300 132 0.pdf

00 0300 134 0.pdf

00 0300 137 0.pdf

00 0300 139 0.pdf

00 0300 143 0.pdf

00 0300 164 0.pdf

00 0300 176 0.pdf

00 0300 374 1.pdf

00 1325 214 4.pdf

SCORPION retrofitting a front hydraulic port (external installation).pdf

00 0300 131 0 2.pdf:

Montageanleitung – Schnellganggetriebe Version I+II mit constant Zusatzmotor, durch Schnellganggetriebe Version III austauschen

Qualification

Benötigte Werkzeuge

Schnellganggetriebe Version I, durch Schnellganggetriebe Version III austauschen

Schnellganggetriebe Version II, durch Schnellganggetriebe Version III austauschen

Vorbereitungsarbeiten

Getriebe dismantling

Overview: Getriebe

Vormontage Getriebe (new)

Assembly Verschraubungen Prüfanschlüsse

Zusatzmotor mounted

Getriebe assembly (new)

Inbetriebnahme

Assembly instructions for replacement of version I + II high-speed gearbox with auxiliary fdsplacement motor, by version III high-speed gearbox

Qualification

Necessary tools

Replacement of version I by version III high-speed gearbox

Replacement of version II by version III high-speed gearbox

Preparatory work

Removing the gearbox

Gearbox overview

Pre-assembly the gearbox (new)

Installing the threaded fittings of the test connections

Install the auxiliary motor

Installing the new gearbox

Putting into operation

Assembly instructions for replacing a version I + II of the overdrive gearbox with additional constant displacement motor, with a version III

Qualification

Necessary tools

Replacement of a version I by a version III of the overdrive gearbox

Replacement of a version II by a version III of the overdrive gearbox

Preliminary activities

Removing the box

Box Overview

Box pre-assembly (new)

Mounting the screw connections of the measuring sockets

Mount the additional motor

Assembly of the box (new)

Start-up

00 0300 131 0.pdf:

Montageanleitung – Schnellganggetriebe Version I+II mit constant Zusatzmotor, durch Schnellganggetriebe Version III austauschen

Qualification

Benötigte Werkzeuge

Schnellganggetriebe Version I, durch Schnellganggetriebe Version III austauschen

Schnellganggetriebe Version II, durch Schnellganggetriebe Version III austauschen

Vorbereitungsarbeiten

Getriebe dismantling

Overview: Getriebe

Vormontage Getriebe (new)

Assembly Verschraubungen Prüfanschlüsse

Zusatzmotor mounted

Getriebe assembly (new)

Inbetriebnahme

Assembly instructions for replacement of version I + II high-speed gearbox with auxiliary fixed-displacement motor, by version III high-speed gearbox

Qualification

Necessary tools

Replacement of version I by version III high-speed gearbox

Replacement of version II by version III high-speed gearbox

Preparatory work

Removing the gearbox

Gearbox overview

Pre-assembly the gearbox (new)

Installing the threaded fittings of the test connections

Install the auxiliary or

talling the new gearbox

Putting into operation

Assembly instructions for replacing a version I + II of the overdrive gearbox with additional constant displacement motor, with a version III

Qualification

Necessary tools

Replacement of a version I by a version III of the overdrive gearbox

Replacement of a version II by a version III of the overdrive gearbox

Preliminary activities

Removing the box

Box Overview

Box pre-assembly (new)

Mounting the screw connections of the measuring sockets

Mount the additional motor

Assembly of the box (new)

Start-up

00 0300 132 0.pdf:

Montageanleitung Schnellganggetriebe Version I+II durch Schnellganggetriebe Version III austauschen

Qualification

Benötigte Werkzeuge

Übersicht: Schnellganggetriebe

Schnellganggetriebe Version I, durch Schnellganggetriebe Version III austauschen

Schnellganggetriebe Version II, durch Schnellganggetriebe Version III austauschen

Vorbereitungsarbeiten

Getriebe dismantling

Vorntage Getebe (new)

Getriebe assembly

Inbetriebnahme

Assembly instructions for replacement of version I + II by version III high-speed gearbox

Qualification

Necessary tools

High-speed gearbox (overview)

Replacement of version I by version III high-speed gearbox

Replacement of version II by version III high-speed gearbox

Preparatory work

Removing the gearbox

Pre-assembly the gearbox (new)

Installing the gearbox

Putting into operation

Assembly instructions for replacing a version I + II with a version III of the overdrive box

Qualification

Necessary tools

Overview of the overdrive box

Replacement of a version I by a version III of the overdrive gearbox

Replacement of a version II by a version III of the overdrive gearbox

Preliminary activities

Removing the box

Box pre-assembly (new)

Box assembly

Start-up

00 0300 134 0.pdf:

MA Umrüstung Steuergerät von 5310 auf HDS34

Qualification

Benötigte Werkzeuge

Steuergerät ersetzt durch:

Pie: Disassemborhandenes Steuergerät

Picture: Steuergerät Oberseite (Verschraubungen montiert)

Picture: Steuergerät Oberseite (verschlaucht)

Picture: Steuergerät Oberseite (verschlaucht)

Mounting Steuergerät Unterseite (Ausführung: Hydraulischer Anschluss Heck)

Assembly Steuergerät Unterseite

Instructions Assembly

Disassembly: Steuergerät

Assembly: Steuergerät

Inbetriebnahme

Assembly instructions for replacing a 5310 control by an HDS34 control valve

Qualification

Necessary tools

Control valve replaced by:

Figures: removing the existing control valve

Figures: control valve top side (screw connections fitted)

Figures: control valve top side (hoses fitted)

Figures: control valve top side (hoses fitted)

Control valve assembly, lower side (rear hydraulic port version)

Assembly, control valve lower side

Preparatory work

Removing the control valve

Installing the control valve

Putting into operation

Assembly instructions for replacing a 5310 distributor with an tributor

Quali Necessary tools

Distributor replaced by:

Figures: removal of the existing distributor

Figures: upper face of the distributor (mounted screws)

Figures: upper face of the distributor (hoses installed)

Figures: upper face of the distributor (hoses installed)

Mounting the distributor, underside (version: rear hydraulic connection)

Assembly, underside of the distributor

Preliminary activities

Removing the distributor

Mount the distributor

Start-up

00 0300 137 0.pdf:

Montageanleitung Anbau Bolzen Schnellwechselplatte

Beschreibung

Qualifikation

Benötigte Werkzeuge

Vorbereitung Montage

Demontage: Schnellwechselplatte

Inbetriebnahme

Assembly instructions: Installing the quickhitch pin

Description

Qualification

Necessary tools

Preparatory work

Removing the quickhitch

Putting into operation

Instructions d’assemblage : montage d’un axe sur l’attache rapide

Description

Qualification

Outils nécessaires

Travauatoires

Dépose de l’ade

Mise en marche

00 0300 139 0.pdf:

Montageanleitung: Schutzblech für Sitzventil an Schnellwechselplatte

Instructions

Qualification

Benötigte Werkzeuge

Instructions Assembly

Inbetriebnahme

Assembly instructions: protective plate for seat valve on quickhitch

Description

Qualification

Necessary tools

Preparatory work

Putting into operation

Assembly instructions: protective plate for the seat valve on the quick coupler

Description

Qualification

Necessary tools

Preliminary activities

Start-up

00 0300 143 0.pdf:

Montageanleitung Druckschalter für Laststabilisator

Beschreibung

Qualifikation

Benötigte Werkzeuge

Vorbereitung

Übersicht 400-404

Übersicht 407

Übersicht 408

Übersicht 346-11 (750T)

Übersicht 352-10 (680T)

Inbetriebnahme

Assembly instructions for load stabilizer pressure switch

Description

Qualification

Necessary tools

Preparatory work

verview 400-404

Overview 407

OverviOverview 346-11 (750T)

Overview 352-10 (680T)

Putting into operation

Instructions d’assemblage : manocontact pour système antitangage

Description

Qualification

Outils nécessaires

Travaux préparatoires

Vue d’ensemble 400-404

Vue d’ensemble 407

Vue d’ensemble 408

Vue d’ensemble 346-11 (750T)

Vue d’ensemble 352-10 (680T)

Mise en marche

00 0300 164 0.pdf:

1 Spülanleitung

1.1 Hydraulic system instructions

Documentation:

Instructions for vehicle type:

Instructions

Qualification

Overview: Hilfsmittel Filter

Vorbereitungsarbeiten

Spülsatz-Nr.

Overview

Assembly

Eingebaute Filter prüfen

Leitungsfilter in Leckölleitung der Fahrpumpe montieren

Leitungsfilter-Montage in Lecköl-Leitung vom Sammelblock

Leitungsfilter-Montage in Tankleitung von dem Fahrmotor zum Kühler

Leitungsfilter-Montage in Leckölleitung von Axialkolben-Pumpe Arbeitshy

Abschluss Spüllauf

Inbetriebnahme

1 Rininse instructions for hydraulic system

Document:

Valid for machine model:

Description

Qualification

Tools for filter (overview)

Preparatory work

Rinsing set no.

Overview

Assembly

Checking the installed filters

Installing the line filter in the leak-oil line of the hydraulic pump

Installing the line filter in the leak-oil line of the manifold block

Installing the line filter in the reservoir line from the hydraulic motor toward the radiator

Installing the line filter in the leak-oil line from the axial-piston pump of the operating hydraulics

End of rinsing

Putting into operation

1 Rinsing Instructions

1.1 Instructions for flushing the hydraulic system

Document :

Valid for model:

Description

Qualification

Overview of filter tools

Preliminary activities

Rinse set no.

Overview

Assembly

Check installed filters

Install the lne filter in the transmission pump leak line

Install the line filter in the leak oil line of the collector block

Install the line filter in the tank line from the transmission motor to the radiator

Install the line filter in the leak line from the axial piston pump of the working hydraulics

End of rinsing

Start-up

00 0300 176 0.pdf:

MA Nachrüstung Spiegel rechts el. verstellbar + Heizung

Instructions

Qualification

Benötigte Werkzeuge

Reference: Einbau Kabelbaum 100 015 59 43 im Rahmen

Reference: Einbau Kabelbaum 100 015 52 44 in der Kabine

Editing: Vorbereitung

Installation: Kabelbaum 100 015 59 43 Rahmen

Editing: Spiegel

Installation: Kabelbaum 100 015 52 44 Kabine

Editing: Schalter Spiegelheizung

Editing: Kreuzschalter Spiegelverstellung

Inbetriebnahme

Assembly instructions for retrofitting a right-hand side mirror with electric adjustment and heating

Description

Qualification

Necessary tools

Installation of wiring rness 100 015 59 43 in frame: overview

Installation of wiring harness 1 015 52 44 in cab: overview

Preparatory work

Installing wiring harness 100 015 59 43 in the frame

Installing the rearview mirror

Installing wiring harness 100 015 52 44 in the cab

Installing the mirror heating switch

Installing the four-way switch for mirror adjustment

Putting into operation

Assembly instructions for retrofitting a right side mirror with electrical adjustment and heating

Description

Qualification

Necessary tools

Overview of mounting wiring harness 100 015 59 43 in the chassis

Overview of mounting wiring harness 100 015 52 44 in the cabin

Preliminary activities

Install the wiring harness 100 015 59 43 in the chassis

Mount the mirror

Install wiring harness 100 015 52 44 in the cabin

Install the mirror heating switch

Mount 4-way switch for rearview mirror adjustment

Commissioning

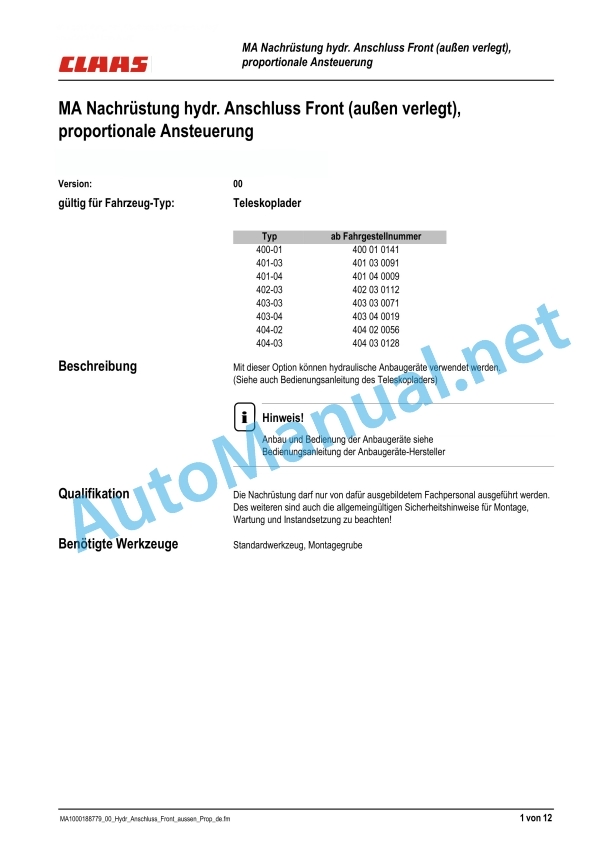

SCORPION retrofitting a front hydraulic port (external installation).pdf:

MA Nachrüstung hydr. Anschluss Front (außen verlegt), proportional Ansteuerung

Instructions

Qualification

Benötigte Werkzeuge

Hinweis: Steuergerät / Kabelbaum

Übersicht: Steuergerät

Overview: Führungskette

Overview: Führungskette

Overview: Elektrik in Fahrerkabine

Overview: Electricity in the Rahmen

Instructions Assembly

Assembly: Führungskette

Installation: Steuergerät, Steuerventil

Installation: Kabelbaum Fahrerkabine

Editing: Kabelbaum Rahmen

Inbetriebnahme

Assembly instructions for retrofitting a front hydraulic port (outside), proportional control

Description

Qualification

Necessary tools

Important: control valve/wiring harness

Control valve: overview

Guide chain overview

Guide chain overview

Overview of electric system in cab

Overview of electrics in frame

Preparatory work

Installing the guide chain

Mounting the control valve and the solenoid valve

Installing the wiring harness in the cab

Installing the wiring harness in the frame

Putting tion

Assembly instructions for retrofitting a front (external) hydraulic conneroportional control

Description

Qualification

Necessary tools

Important: Distributor/Wiring Harness

Dispenser Overview

Guide chain overview

Guide chain overview

Overview of electrics in the cabin

Overview of the electrics in the chassis

Preliminary activities

Install the guide chain

Install the distributor and the magnetic valve

Install the wiring harness in the cabin

Mount the wiring harness into the chassis

Commissioning

New Holland Service Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF