Claas Scorpion 960 (K38) Telehandlers Repair Manual FR

$100.00

- Model: Scorpion 960 (K38) Telehandlers

- Type Of Manual: Repair Manual

- Language: FR

- Format: PDF(s)

- Size: 183 MB

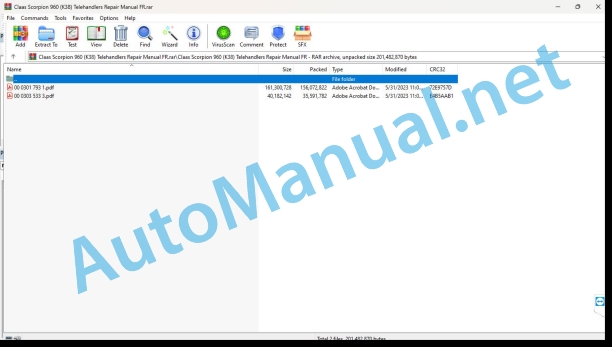

File List:

00 0301 793 1.pdf

00 0303 533 3.pdf

00 0301 793 1.pdf:

Deutz TCD 4.1 L4

Contents

Introduction

General informations

Validity of the notice

Use of the instructions

Texts and illustrations

Plan with module structure

Seek and find

Steering Specifications

Abbreviations

Specialized terminology

General repair tips

Technical characteristics

Proper repair advice

Self-locking screws

Liquid screw brake

Steel roller chains

Quick hitch

Type E quick coupler with spring

Type G quick coupler with wire

Type S quick coupler with pins

Assemblies using conical ring

Assembly

Heel pin assemblies

Assembly

Clamp ring bearing

Disassembly

Assembly

Clamp sleeve bearing

Assembly

Clamping sleeve

Removal of version A

Submission of version B

To set down

Clamping sleeve version A

Clamping sleeve version B

Circlips

Cutting ring fittings

To screw

Leaky cutting ring fittings

Sealing Cone Fittings

Hydraulic flexible lines

Passage of hoses

Treatment of sealing surfaces

Spare parts

Operating consumables

Tightening torques

Tightening torques for metric ISO threads

Tightening torques for metric fine pitch threads

Tightening torques for hydraulic connections with cutting ring

Tightening torques for screw connections with bicone connection and hydraulic connections with flexible sealing gasket

Tightening torques for hydraulic screwed coupling SDS form B and E

Tightening torques for hydraulic screwed coupling SDE form H, adjustable

Tightening torques for hydraulic swivel screw connections

Tightening torques for hollow screws (with copper seal)

Tightening torques for brake line screw connections

Tightening torques for tubular structures with O-ring and union nuts

Tightening torques for tangent screw clamps

Tightening torques for hose clamps with round bolts

CCN explanation

CCN (CLAAS Component Number)

Electrical standard

Hydraulic standard

CCN (CLAAS Component Number)

Security

General informations

To respect

Signal word

General safety and accident prevention instructions

First aid measures

Risk of injury from hydraulic fluid

Exit the machine

Stop the machine

Place the machine on jack stands

Adjustment and maintenance work

Welding work

Notes for working on the diesel engine

Protection against accidents

Cleanliness

Assembly tips

Engine overhaul

01 Motor

0102 Complete set

Rated motor characteristic data

TCD 4.1 L4

Engine Description

Lighting order

Start the engine manually

Special tool

Install the rotation tool on the flywheel side

Place the rotation tool on the torsional vibration damper

0105 Engine suspension

Engine suspension

Technical characteristics

0110 Motor housing

Crankcase air bleeding

Technical characteristics

To set down

Crankshaft speed sensor

Technical characteristics

Preparing for work

Camshaft speed sensor

Technical characteristics

Flywheel housing

Technical characteristics

Special tool

To set down

Gear housing

Technical characteristics

Preparing for work

To set down

Crankshaft seal ring

Technical characteristics

Special tool

To set down

Front cover

Technical characteristics

To set down

Crankshaft seal ring

Technical characteristics

Special tool

To set down

Replace shaft liner

Technical characteristics

Preparing for work

Special tool

To set down

Crankcase

Technical characteristics

Preparing for work

Check cylinder bore

0115 Powertrain

Technical characteristics

Special tool

Assembly advice

Check the piston

Remove the piston rings

Install the piston rings

Check piston rings

Measure the piston protrusion

Connecting rod

Technical characteristics

Special tool

Assembly advice

To set down

Torsional vibration damper

Technical characteristics

Preparing for work

Special tool

To set down

Crankshaft

Technical characteristics

To set down

Check axial play

Crankshaft bearing

Technical characteristics

Special tool

To set down

Flywheel

Technical characteristics

Preparing for work

Special tool

To set down

Remove the ring gear

Install the ring gear

0120 Cylinder head – Valves – Distribution

Upper valve cover

Technical characteristics

To set down

Cylinder head

Technical characteristics

Special tool

To set down

Rocker arm

Technical characteristics

Disassemble

To assemble

To set down

Camshaft

Technical characteristics

To set down

Technical characteristics

Special tool

To set down

Valve head and valve stem diameter

Valve guide diameter

Valve stem clearance

Valve Removal

Adjust valve clearance

Compression pressure

Special tool

0125 Injection system, fuel supply

Fuel feed pump

Technical characteristics

Fuel filter

Technical characteristics

Fuel lines

Technical characteristics

Special tool

To set down

Technical characteristics

Preparing for work

Special tool

Remove rail/fuel pressure sensor

Dismantle the pressure relief valve

Install the pressure relief valve

Install the fuel rail/pressure sensor

To set down

Injector

Technical characteristics

Special tool

Assembly advice

To set down

Injector socket

Technical characteristics

Preparing for work

Special tool

To set down

High pressure pumps

Technical characteristics

Preparing for work

Special tool

To set down

Command block

Technical characteristics

Preparing for work

Disassemble

To assemble

To set down

0130 Lubrication system

Oil suction tube

Technical characteristics

Lubricating Oil Cooler

Technical characteristics

Preparing for work

Lubricating oil cooler housing

Technical characteristics

To set down

Lubricating oil pump

Oil injection nozzle

Technical characteristics

Assembly tips

Oil level gauge

Technical characteristics

0135 Cooling system

Coolant lines

Technical characteristics

Preparing for work

Thermostat housing

Technical characteristics

Preparing for work

To set down

Thermostat

Technical characteristics

To set down

Check lifting stroke

Engine temperature sensor

Technical characteristics

Coolant pump

Technical characteristics

Preparing for work

To set down

Fan bearing

Technical characteristics

0140 Exhaust device

Exhaust gas turbocharger

Technical characteristics

Preparing for work

Special tool

To set down

Exhaust collector tube

Technical characteristics

Preparing for work

Special tool

To set down

Exhaust gas recirculation radiator

Technical characteristics

Preparing for work

Special tool

To set down

Special check valve

Technical characteristics

Preparing for work

To set down

Adjustment device

Technical characteristics

Preparing for work

Special tool

Assembly advice

To set down

Exhaust gas mass flow sensor

Technical characteristics

Assembly tips

0145 Air suction

Charge air pipe

Technical characteristics

Preparing for work

To set down

Heating flange

Technical characteristics

Preparing for work

Disassemble

To assemble

To set down

Mixing tube

Technical characteristics

To set down

Butterfly

Technical characteristics

To set down

0150 Engine assembly parts

Technical characteristics

Assembly advice

Generator

Technical characteristics

Disassemble

To assemble

To set down

Remove the console

Install the console

Protection plate

Technical characteristics

Air conditioning compressor

Technical characteristics

Assembly advice

Belt tensioner

Technical characteristics

Drive Belt Pulley

Technical characteristics

Compressor

Technical characteristics

Preparing for work

Assembly tips

0155 Engine controls

High current start relay

Technical characteristics

0165 Exhaust gas aftertreatment

Diesel particulate filter

Technical characteristics

Preparing for work

Special tool

Disassemble

To assemble

Diesel particulate filter differential pressure sensor

Technical characteristics

00 0303 533 3.pdf:

Repair instructions

Contents

Introduction

Notes on the instructions

Validity of the notice

Repair manual information

Use of the instructions

Classification in module/group structure

Seek and find

Directions

General repair instructions

Technical characteristics

Tips for correct repair

Self-locking screws

Liquid screw brake

Steel roller chains

Quick hitch

Type E quick coupler with spring

Type G quick coupler with wire

Type S quick coupler with pins

Assemblies using conical ring

Disassembly

Assembly

Heel pin assemblies

Assembly

Clamp ring bearing

Disassembly

Assembly

Clamp sleeve bearing

Assembly

Clamping sleeve

Removing version A

Removing version B

To set down

Clamping sleeve version A

Clamping sleeve version B

Circlips

Lip rings with spring

Hose clamps

Tightening speed

Tightening torques

Collar Alignment

Auxiliary mounting means

Assembly tools

Cutting ring fittings

To screw

Leaky cutting ring fittings

Sealing Cone Fittings

Hydraulic flexible lines

Passage of hoses

Diaphragm accumulator (pressure accumulator)

Consumable materials

Service and Assembly

Modification of gas filling

Special tool

Treatment of sealing surfaces

Spare parts

Glues, sealing pastes and assembly pastes

Consumable materials

ESD protective measures

Special tool

ESD protective measures

Inspection and repair advice

Tightening torques

Tightening torques for metric coarse and fine pitch threads

General tightening torques Bosch-Rexroth

General tightening torques Mannesmann-Rexroth

General tightening torques Dana / Spicer

Tightening torques for hydraulic screw connections with cutting ring

Tightening torques for pipe fittings with conical sealing fitting and hydraulic fittings with soft sealing gasket

Tightening torques for nuts for feed-through fitting, straight and angular

Tightening torques for hydraulic screwed coupling SDS form B and E

Tightening torques for hydraulic screwed socket SDS form F and sealing screw

Tightening torques for hydraulic screwed coupling SDS form H

Tightening torques for form E cover screws

Tightening torques for hydraulic screwed coupling form C, conical thread

Tightening torques for hydraulic screwed coupling SDE form F, adjustable

Tightening torques for hydraulic screwed coupling SDE form H, adjustable

Tightening torques for hydraulic swivel screw connections

Tightening torques for hollow screws (with copper seal)

Tightening torques for brake line screw connections

Tightening torques for tubular structures with O-ring and union nuts

Tightening torques for threaded rods / calibrated holes

Tightening torques for threaded bolts and special screws

Tightening torques for hydraulic components

Tightening torques for hexagonal sealing nuts

Hose clamp tightening torques

Assembly tips

Tangent screw clamps

Tangent screw clamps with spring washers

Hose clamps with round bolts

Security

Recognize the warnings

Warning pictogram

Signal word

Safety tips

Warning stickers and warnings

Requirements for specialized personnel

Children in danger

Dangerous areas of the machine

Passenger instructor during work

Risk of injury from rotating shafts

Construction modifications on the machine

Optional equipment and spare parts

Controlling the machine in operation

Technical condition

Respect the technical threshold values

Danger due to machine elements continuing to operate by inertia

Maintain safety devices in operational capacity

Personal protective equipment

Wear suitable clothing

Remove dirt and loose objects

Park and store the machine safely

Unsuitable operating consumables

Safe handling of operating consumables and secondary consumables

Environmental protection and disposal

Never put chemicals in the cabin

Avoiding fires

Fatal electrical discharges from overhead power lines and lightning strikes

Electrical discharge from the electrical system

Noise can harm your health

Machine parts under stress

Liquids under pressure

Pressurized air

Toxic exhaust gases

Hot surfaces

Safe ascent and descent

Work only when the machine is stopped

Risks during repair work

Machine elements recorded and loads

Risks due to welding work

Check and charge the battery

Preparations for emergency cases

CCN explanation

CCN (CLAAS Component Number – CLAAS part number)

Electrical standard

Hydraulic standard

CCN (CLAAS Component Number – CLAAS part number)

01 Motor

0102 Complete set

Diesel motor

Technical characteristics

Preparing for work

To set down

Diesel motor

Technical characteristics

Preparing for work

To set down

0125 Injection system, fuel supply

Fuel tank

Technical characteristics

To set down

Fuel pre-filter

Technical characteristics

To set down

0135 Cooling system

Compensation tank

Technical characteristics

To set down

Engine radiator

Technical characteristics

Preparing for work

To set down

Fan motor

Technical characteristics

To set down

Fan distribution block

Technical characteristics

To set down

Fan valve block

Technical characteristics

To set down

0140 Exhaust device

Exhaust pipe

Technical characteristics

To set down

Technical characteristics

To set down

0145 Air suction

Air filter housing

Technical characteristics

To set down

Intercooler

Technical characteristics

To set down

0150 Engine assembly parts

Belt cover

Technical characteristics

Preparing for work

To set down

To set down

To set down

Generator

To set down

Compressed air compressor

Technical characteristics

To set down

0155 Engine controls

Accelerator pedal

Technical characteristics

To set down

0165 Exhaust gas aftertreatment

Exhaust gas post-treatment, general

Preparing for work

Special tool

Check the purity of the urea solution

Check the density of the urea solution

Diesel Oxidation Catalytic Converter

Technical characteristics

To set down

Diesel particulate filter

Technical characteristics

To set down

Mixing section

Technical characteristics

To set down

Dosing valve

Technical characteristics

To set down

SCR catalyst

Technical characteristics

To set down

Urea tank

Technical characteristics

Special tool

To set down

Urea sampling unit

Technical characteristics

Special tool

To set down

Urea pump

Technical characteristics

To set down

02 Gearbox – Clutch – Cardan shaft

0210 Vibration damper

Vibration damper

Technical characteristics

To set down

0230 Mechanical gearbox

Overdrive gearbox

Technical characteristics

Preparing for work

To set down

Replace control flange

Overdrive gearbox

Technical characteristics

Preparing for work

To set down

Replace control flange

0238 Gearbox controls

Control cover

Technical characteristics

To set down

0260 Cardan shaft

Cardan shafts

Technical characteristics

Preparing for work

To set down

To set down

03 Chassis

0305 Axle suspension

Level compensation valve block

Technical characteristics

To set down

Hydraulic level compensation cylinder

Technical characteristics

To set down

Hydraulic cylinder pendulum axle lock

Technical characteristics

To set down

Axle bearing

Technical characteristics

To set down

0325 Drive axle, front

Front wheel steering axle

Technical characteristics

To set down

Planetary gear

Technical characteristics

Preparing for work

Disassemble

To assemble

Technical characteristics

Preparing for work

To set down

Half shaft

Technical characteristics

Preparing for work

Disassemble

To assemble

To set down

Axle body

Technical characteristics

Preparing for work

To set down

Bevel gear drive

Technical characteristics

Preparing for work

To set down

Differential

Technical characteristics

Preparing for work

Disassemble

To assemble

To set down

0330 Drive axle, rear

Rear-wheel steering axle

Technical characteristics

To set down

Planetary gear

Half shaft

Bevel gear drive

Differential

0335 Transmission

Transmission hydraulic pump

Technical characteristics

To set down

Transmission hydraulic pump

Technical characteristics

To set down

Transmission auxiliary variable displacement motor

Technical characteristics

To set down

04 Brake

0405 Service brake

Service brake

Technical characteristics

Preparing for work

To set down

Bleed air from service brake

Hydraulic service brake cylinder

Technical characteristics

To set down

0415 Parking brake

Parking brake

Assembly tips

Mechanically release the parking brake

Adjust the parking brake

0420 Air trailer brake

Compressed air tank

Technical characteristics

To set down

05 Management

0505 Steering

Steering column

Technical characteristics

Preparing for work

To set down

Steering column

Technical characteristics

Preparing for work

To set down

Management unit

Technical characteristics

To set down

Hydraulic steering cylinder

Technical characteristics

Preparing for work

Disassemble

To assemble

To set down

Set the track

Adjust the steering angle

Blocking block

Technical characteristics

To set down

Bleed the air from the steering hydraulics

06 Lifting device

0620 Telescopic arm

Telescopic arm

Technical characteristics

Special tool

To set down

Telescopic boom

Technical characteristics

To set down

Tread sensor

Technical characteristics

Telescopic lines

To set down

To set down

Technical characteristics

To set down

Sliding plates

Technical characteristics

Preparing for work

Assembly tips

To set down

CLAAS tool holder, mechanical

Technical characteristics

Special tool

To set down

CLAAS tool holder, hydraulic

Technical characteristics

Special tool

To set down

JCB tool holder, hydraulic

Technical characteristics

Special tool

To set down

Manitou tool holder, mechanical

Technical characteristics

Special tool

To set down

Manitou tool holder, hydraulic

Technical characteristics

Preparing for work

Special tool

To set down

Volvo tool carrier, hydraulic

Technical characteristics

Special tool

To set down

Hydraulic cylinder mount

Technical characteristics

Special tool

To set down

Hydraulic cylinder mount

Technical characteristics

Special tool

To set down

Hydraulic compensation cylinder

Technical characteristics

Special tool

To set down

Hydraulic thrust cylinder

Technical characteristics

To set down

Hydraulic cylinder tilt

Technical characteristics

Special tool

To set down

Hydraulic cylinder quick change lock

Technical characteristics

Special tool

To set down

Hydraulic cylinder quick change lock

Technical characteristics

To set down

Hydraulic cylinder quick change lock

Technical characteristics

To set down

Hydraulic cylinder quick change lock

Technical characteristics

To set down

Lift angle sensor

Technical characteristics

To set down

Tilt angle sensor

Technical characteristics

To set down

07 Hitch device

0705 Hitch

Hitch clevis

Technical characteristics

Height-adjustable hitch clevis

Technical characteristics

To set down

0720 Towing hook

Hitch drawbar

Technical characteristics

To set down

Remove sensor B67-LWT

Install the B67-LWT sensor

Remove the axle

Install the axle

08 Orders

0800 Drive scheme

Training scheme

09 Hydraulic system

0900 Hydraulic system General

Flush the hydraulic system

Assemble the filter elements

Install the line filter

Install the filter elements

Complete the rinsing process

0905 Hydraulic oil tank

Hydraulic oil tank

Technical characteristics

Special tool

To set down

Generate a vacuum in the hydraulic oil tank

No longer generate vacuum in the hydraulic oil tank

0907 Hydraulic oil cooler

Hydraulic Oil Cooler

0910 Pumps

Hydraulic pump of working hydraulic system

Technical characteristics

To set down

Hydraulic pump of working hydraulic system

Technical characteristics

To set down

Hydraulic pump, gear pump

Technical characteristics

To set down

0915 Hydraulic circuit

Forward control circuit (HIGHFLOW)

Technical characteristics

Preparing for work

To set down

Multicoupler

Technical characteristics

To set down

Multicoupler

Technical characteristics

To set down

0920 Valves

Hydraulic braking

Technical characteristics

Remove the brake hydraulic valve block

Install the brake hydraulic valve block

Remove the accumulator charging valve valve block

Install the accumulator charging valve valve block

Remove differential lock valve block

Install the differential lock valve block

Trailer brake valve block

Technical characteristics

To set down

Steering mode valve

Technical characteristics

To set down

Control circuit valve block 3

Technical characteristics

To set down

Hitch Hitch Valve Block

Technical characteristics

To set down

Working hydraulic system valve block

Technical characteristics

To set down

Working hydraulic system valve block

Technical characteristics

To set down

Compensation cylinder distribution block

Technical characteristics

To set down

Priority valve distribution block

Technical characteristics

To set down

Emergency lowering valve block

Technical characteristics

Assembly tips

10 Electrical and electronic systems

1005 Power supply

Technical characteristics

To set down

Battery cut-off switch

Technical characteristics

To set down

1010 Central electrical system

Central electrical system

Technical characteristics

To set down

Technical characteristics

Drop A30-LWT and A40-LWT

Install A30-LWT and A40-LWT

Drop A50-LWT

Lay A50-LWT

Load sensor

Technical characteristics

Preparing for work

To set down

1035 Control / multifunction handle

Control lever

Technical characteristics

To set down

Manual slow approach monolever

Technical characteristics

To set down

Manual throttle monolever

Technical characteristics

To set down

Monolever control circuit 4

Technical characteristics

To set down

Display unit

Technical characteristics

To set down

7 screen

Technical characteristics

To set down

Steering mode distribution table

Technical characteristics

To set down

DMS evaluation electronics

Technical characteristics

To set down

12 Cabin, driving position

1210 Cabin

Technical characteristics

To set down

Front interior trim

To set down

Front interior trim

To set down

Front wiper

Technical characteristics

To set down

Back windshield wiper

Technical characteristics

To set down

Side wiper

Technical characteristics

To set down

Windshield washer fluid reservoir

Technical characteristics

To set down

1230 Headquarters

Driver’s seat

Technical characteristics

To set down

1235 Cabin heater

Heating and air conditioning box

Technical characteristics

To set down

Heat exchanger

Technical characteristics

To set down

Technical characteristics

To set down

Cabin air filter

Technical characteristics

To set down

1240 Air conditioning

Air conditioning, general

Empty the air conditioning

Fill the air conditioning

Heating and air conditioning box

Technical characteristics

To set down

Air conditioning compressor

Technical characteristics

To set down

Evaporator

Technical characteristics

To set down

Capacitor

Technical characteristics

To set down

Filter dryer

Technical characteristics

To set down

75 Central lubrication system

7500 Central lubrication, general

Central lubrication, general

Special tool

7505 Tank, pump

Tank and pump

Technical characteristics

To set down

Remove the feed piston

Install the feed piston

7515 Lubrication system / lines

Lubrication lines

Special tool

80 Assembly parts, bodywork

8005 Chassis

Crankcase

Technical characteristics

Assembly tips

Tank console

Technical characteristics

To set down

8020 Balustrades / Safety devices

Underbody protection

Technical characteristics

Preparing for work

To set down

8025 Covering sheets / covers

Technical characteristics

To set down

8030 Wings

Technical characteristics

To set down

95 Overview of maintenance parts

9599 Maintenance work

Place the machine in maintenance position

Checking the leaks of the diesel engine

Check the fixing of the diesel engine consoles

Adjust valve clearance

Replace fuel filter filter cartridges

Preparing for work

Fuel pre-filter

Fine fuel filter

Bleed the air from the fuel system

Replace diesel engine oil

Preparing for work

Replace diesel engine oil filter

Preparing for work

Check the belt (R01) of the diesel engine

Replace the belt (R01) of the diesel engine

Check the tightness and condition of the cooling system

Replace the coolant

Preparing for work

Check the coolant antifreeze

Preparing for work

Correct antifreeze concentration

Check the suction system and exhaust gas system

Check the correct attachment of the compressed air compressor

Check the cable connection of the diesel engine sensor system

Replace the urea pump filter

Replace travel gear oil

Preparing for work

Control and measure transmission

Check the axle oil level

Differential gear

Wheel hub

Replace axle oil

Preparing for work

Differential gear

Wheel hub

Check the tightening torque of the axle fixing screws

Check brake lining wear

Clean the external compressed air tank

Check the tightness of the air brake system

Check the filling level of the antifreeze pump of the air brake system

Check and measure the braking system

Check and measure the steering system

Check the absence of wear and the correct positioning and tightening of the rear sliding plates

Replace hydraulic oil

Preparing for work

Replace the filter element of the filter on the return of the hydraulic tank

Replace the hydraulic tank air filter

Check the tightness of the hydraulic system

Replace the fuel circuit pressure filter

Check and measure working hydraulics

Check the correct fixation of the battery terminals

Check the battery fluid level

Check the condition and rout

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF