Claas Variant 280 Rc (730) Baler Operator Manual ES

$50.00

- Model: Variant 280 Rc (730) Baler

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 20.4 MB

File List:

00 0298 453 6.pdf

00 0299 040 2.pdf

00 0299 439 1.pdf

00 0304 379 0.pdf

00 0298 453 6.pdf:

Introduction

Introduction

General indications

Road Traffic

Observe especially

Type indicator plate

Machine number

For security

For security

Warning and indication signs

Proper use

General safety and accident prevention requirements

Trailed machines

Service with PTO shaft

Hydraulic system

Maintenance

Machine working noises, information “D”

wheel chock

Fire extinguisher (Optional depending on country)

Main gear protective cover

Safety stickers with warning symbols

Technical characteristics

CLAAS Variant_x0011_260/280 / Variant_x0011_260/280_x0011_RC

Admission bodies

cutting device

Compaction of the pressed good

Tying mechanism

rolling wheels

Hydraulic system

Tractor hydraulic system required

Hydraulic pressure

Electric system

CLAASiant 260/280 / Vari260/280 RC

Dimensions of the round bale baler

CLAAS Variant 260/280 / Variant 260/280 RC

Safety devices

Cutting screws

Overload clutch

Configuration and way of working

Machine overview

Force transmission

Cutting coupling and free-running articulated shaft

Cam clutch articulated shaft

collecting drum

cutting device

Blind blade support (option)

pressing chamber

Tying the bales

bale ejector

Storage of round bales

Rotor Disengage Clutch

Rotor reverse turning device, manual

yarn drawer

Fire extinguisher (Optional depending on country)

Active hydraulics

Automatic chain lubrication

Address indication (option)

control box

Before commissioning

Check and observe before first start-up

Hook up the baler

Install the drive shaft on the machine side

Transmission shaft with tightening cone closure

Assemble the drive shaft with clamping cone lock

Stop support

Before unhitching the round baler

After attaching the round baler

Hook on the traction pendulum

Grease the traction eye

Mount the transmission shaft on the tractor side (by coupling with a traction pendulum)

Check the meshing of the drive shaft halves:

Reduce drive shaft

Secure the drive shaft protection tubes against simultaneous rotation

Hitch in the hitch mouth

Install the drive shaft on the tractor side

Attachment to the labeled pivot

Splice the pipes

handling box

Power supply

Translation lighting

Splice the hydraulic oil hoses

Back cover opening speed

Before transportation

Arrange the press

Collected

Pickup height adjustment

Adjust the working height of the pickup (pickup without support wheels)

Pickup with training wheels

Support wheels

Cutting device (VARIANT 260/280 RC)

blind blade

Assembling and disassembling the blades

Insert the blades into the blade holder

Fit the blade

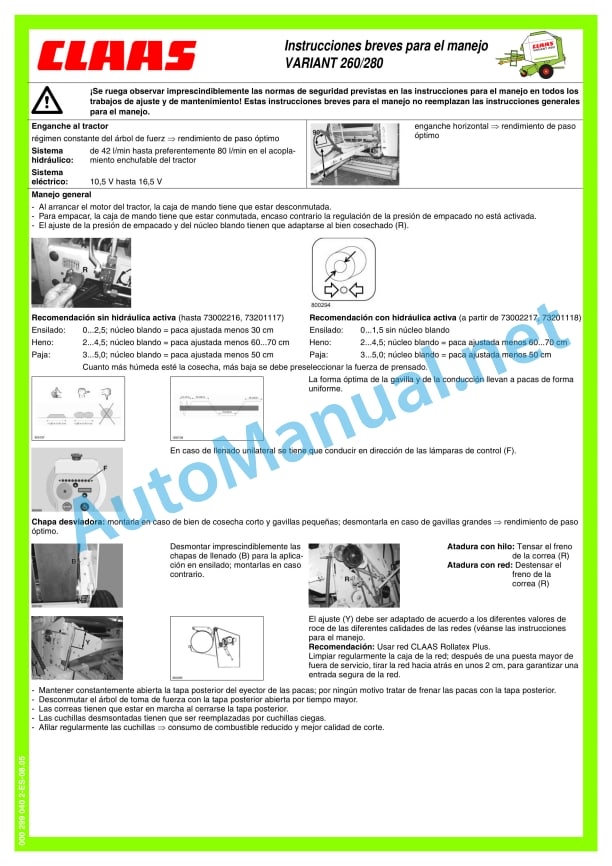

Bale compaction

Pressing pressure regulation

Adjust the diameter of the bale

Adjust the diameter of the soft core

Net binding

Put the network

Regulate the number of network wraps

Tying with thread

Thread the thread

Regulate the number of thread wraps

Adjust the twine wraps on the outer edges of the bale

Tie with three threads

Prepare the eyelet for the thread

Introduce the three wires

Press adjustment for extreme silage cases

Removing the belt guides

Assembling the belt guides

Round bale press with twine and net tying

Switch to thread tying

Drive for tying with thread

Put the V-belt brake on

Switch to net tethering

Adjust the drive for tying with net

Release the V-belt brake

Silage pressing

Mount the blind knife holder (option) on VARIANT ROTO_x0011_CUT

Commissioning the round baler

Filling the pressing chamber

Indication of the direction of travel

Automatic binding

Tether delay

delay function

Thread Tying: Delay Adjustment

Net Tying: Delay Adjustment

Tying and ejecting the bales.

Deposit the bales

Ejecting bales without the bale ejector

bale counter

Round baler with net tying

Baler for round bales with twine and net tying

Round baler with twine tying

Manual overregulation of automatic fastening

Activate the binding process early

Slow down the binding process

Cutting device (ROTO CUT)

Turn the blades inward

Rotate the blades outward

Adjust the volume of the acoustic warning signal

Blockages in the round bale baler

Cam clutch articulated shaft

Rotor reverse turning device (VARIANT_x0011_260/280 / 260/280_x0011_RC)

Fault, reason or solution

Tying with thread

Net binding

After service

Uncouple the baler

wheel chocks

Stop support

control box

Hydraulic oil hoses and electrical connection cables

Transmission tree

Support wheels

Dirt cleaning

Maintenance

Important maintenance instructions

General maintenance instructions

Maintenance and lubrication tables

Maintenance tables

Lubricant table

Cutting screw, main drive

Cutting screw, collector drive

angular gear

Retension drive chains

Tension the collector drive chain

Tension the drive chain of the transverse conveyor thread

Adjust compression springs for pressure roller

Adjust the clamping device for the network meter

Adjust disc brakes

Tension the tension spring for the chain drive (belts and rotor)

Tension the tension spring for the chain drive on the rear cover

Adjust tension springs for clamping arm

Adjust the tension springs for the lower clamping arm

Tension the tension spring of the net roll braking bracket

Adjust spring cylinder for freewheel drive

Adjust the bale ejector tension springs

Adjust linkage to bale ejector end switch

Drive brake on twine tie

Adjust compression springs on disengagement clutches

Adjust the compression springs on the slip coupling (ratchet wheel) (attachment…

Adjust the thread tensioners

Inductive sensor settings

Inductive sensor “maximum ball diameter”

Inductive “door closed” sensor

Hydraulic oil filter (machines with filter installation)

Automatic chain lubrication

Adjust the Linatex guide plate

Fire extinguisher (option)

flat strap

Release the flat belt

Check flat belts

Repair flat belts

Lay the straps flat

Adjust the belt travel

Adjust the lower roller scraper

Check the seat of the wheel nuts

Check the wheel hub bearing clearance

Adjust bearing clearance

Proposals for preparing for winter

Lubrication plan

Lubricants and information

Reference word index

Reference word index

00 0299 439 1.pdf:

Notice de montage eton

Kit « lin – lin court » and Kit « Li Introduction

Introduction

Consignes de sécurité

Important

Characterization of indications sur les dangers

Consignes générales de sécurité et de prévention des accidents

Stationnement de la machine

Utilization conforme à la destination

Installation notice

Kit lin et lin court

Introduction

Lot de pièces (0843 001.0)

Reduction of the number of belts

Détente des courroies

Coupe des courroies

Ajustage de la longueur des corroies

Agrafage des courroies

Préparation du pick-up

Démontage du tasseur

Démontage du carter de protection du pick-up

Montage de la roue à chain « Kit lin »

Démontage des vis de recentrage

Remontage du carter du pick-up

Démontage des dents du pick-up

Préparation des parois du pick-up

Prémontage du kit lin

Mounting the wheel on the frame

Montage des guides-fourrage sur le cadre

Graisseur

Montage du kit lin

Fixation du c presse

Montage du ski sur le cadre

Fixation du crochet sur la machine

Preparation of the Lin court kit

Variant 260

Perçage de la chambre de pressage

Prémontage du kit lin court

Variant 280

Perçage de la chambre de pressage

Prémontage du kit lin court

Guides-ficelle et couteau

Montage des guides-ficelle « Lin »

Montage du knife Lin

Démontage du couteau d’origine

Montage du knife «Lin»

Électrique

Montage de l’interrupteur

Préparation de la tôle

Fixation de l’interrupteur

Configuration du module pour le lin

Verification of information

Fixation du module lin sur le support

Montage du support sur la presse

Montage du faisce électrique

Fixing the cable on the chassis

Setting the proximity detector

Mise en place du capot

Installation notice

Kit lin trèsduction

Lot de pièces (0843 592.0)

Préparation du kit « lin très cour260

Perçage de la chambre de pressage

Prémontage du kit « lin très court »

Variant 280

Perçage de la chambre de pressage

Prémontage du kit « lin très court »

Notice d’utilisation

Introduction

Principle and function

Vitesse de la prise de force

Pressage

Sens de pressage

Pressure de pressage

Liage des tiges de lin

Principle

Vitesse d’avancement et rapport de nappe

Avant utilization

Adjustment of the frame before the kit lin

Hauteur de la roue centrale

Hauteur des guides-fourrage

Hauteur du ski

Adjustment of the press

Nombre de tours de ficelle

Guides-ficelle « Lin »

Mise en place de la ficelle

Pressure de pressage

Diamètre de balls

Utilization pour le pressage du lin

Generalities

Pisur terrain non pierreux

Récolte sur terrain pierreux

Utilization pour le pressage du lineralities

Preparation of the pressing chamber

Montage des glissières sur la paroi – Variant 260

Montage des glissières sur la paroi – Variant 280

Mise en place de la tôle lin court

Fixation de la tôle lin court

Adjustment of the slide mobile

Récolte sur terrain non pierreux

Récolte sur terrain pierreux

Utilization pour le pressing du lin très court

Generalities

Preparation of the pressing chamber

Montage des glissières sur la paroi – Variant 260

Montage des glissières sur la paroi – Variant 280

Mise en place de la tôle lin très court

Fixation de la tôle lin très court

Adjustment of the slide mobile

Récolte sur terrain non pierreux

Récolte sur terrain pierreux

Use of the press for other harvests

Chambre de pressage

iintenance

Graisseur

Assembly and operating instructions

Set linen – short line and set very short line

Introroduction

Safety instructions

The important information

Description of warning signs

General instructions on safety techniques and accident prevention

Car parking

Use as intended

Assembly instruction

Set for linen and short linen

Introduction

Lot of parts (0843 001.0)

Reducing the number of drive belts

Belt slack

Trimming belts

Belt length adjustment

Belt fastening

Preparing the baler

Dismantling the rammer

Dismantling the baler protection casing

Assembly of stars from the Len set

Dismantling of centering screws

Installation of the baler crankcase

Dismantling fingers with the baler

Preparing the on-board baler

Pre-assembly of the Len set

Installing wheels on a frame

Installation of feed guides on the frame

Setting the proximity detector

Lubrication hole

Assembling the Len set

Fastening the assembled frame to the press

Installing skis on a shoulder

Fixing the grip on the car

Preparation of the set «Short linen»

Variant 260

Perforating press camera

Pre-assembly of the «Short Linen» set

Variant 280

Perforating press camera

Pre-assembly of the «Short Linen» set

String guide and knife

Installation of the guide string of the Len set

Installation of the Len knife

Dismantling the standard blade

Installation of the Len knife

Electronics

Installation of the circuit breaker

Preparation sheet

Mounting the circuit breaker

Cleaning module setting

Check information

Fixation of the «Len» module on a support

Press support installation

Installation of electrical wiring

Fixing the cable to the casing

Setting detector approximations

Hood installation

Assembly instruction

Set «very sh?

Introduction

Lot of parts (0843 592.0)

Preparation of the set ?Very short linen?

Variant 260

Perforatinamera

Pre-assembly of the set ?Very Short Linen?

Variant 280

Perforating press camera

Pre-assembly of the set ?Very Short Linen?

Operating instructions

Introduction

Principle and operation

Power take-off speed

Pressing

Making presses

Pressure presses

Bundle of stems

A principle

Speed _x000B__x000B_advances and layer coefficient

Preparation for use

Adjusting the front frame of the Len kit

Center wheel height

Height of feed guides

Ski height

Press setup

Number of windings

Guide cords Flax

Seasoning strings

Pressure presses

Bundle diameter

Use for pressing flax

General information

Baler picker

Harvesting of non-rocky soil

Harvesting stony soil

Use for pressing short flax

General information

Preparation of the press camera

Installation of guides on the wall – Variant 260

Installation of guides on the wall – Variant 280

Installation of welded sheet Short linen

Fixation of welded sheet Short flax

Adjustment of the movable guide

Harvesting of non-rocky soil

Harvesting stony soil

Use for pressing short flax

General information

Preparation of the press camera

Installation of guides on the wall – Variant 260

Installation of guides on the wall – Variant 280

Installation of welded sheet «Very short linen»

Fixation of welded sheet «Very short linen»

Adjustment of the movable guide

Harvesting of non-rocky soil

Harvesting stony soil

Using a press for harvesting other crops

Baler picker

Connection

Press camera

Electric current

Technical service

Lubricat

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)