Claas Variant 485 480 385 380 Rc Rf (752) Balers Operator Manual EN

$50.00

- Model: Variant 485 480 385 380 Rc Rf (752) Balers

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 193 MB

File List:

00 0288 014 3.pdf

00 0290 518 0.pdf

00 0292 625 4.pdf.crdownload

00 0294 278 6.pdf

00 0294 601 0.pdf

00 0301 051 0.pdf

00 0301 092 0.pdf

00 0301 388 7.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0288 014 3.pdf:

EASY on board app

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Qualified specialist workshop

1.1.5 Maintenance notes

1.1.6 Notes on warranty

1.1.7 Spare parts and technical questions

1.1.8 Technical requirements

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Requirements made on all persons working with the product

2.2.3 Hazard areas

2.2.4 Check interactions with self-propelled machines / tractors and implements

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Technical status

2.2.8 Hazard caused by damage to the product

2.2.9 Visibility of work area

2.2.10 Glare and reflections

2.2.11 Unintentional triggering of functions

2.2.12 Hazards caused by signal tones

2.2.13 Unauthorised use

2.2.14 Use of mobile terminal outside the cab

2.2.15 Follow the safety instructions

2.2.16 Respecting technical limit values

2.2.17 Preparing the product for road travel

2.2.18 Hazards when driving on the road and on the field

2.2.19 Hazards when driving on the road with an ISOBUS implement

2.2.20 Switching off the mobile terminal while driving

2.2.21 Hazards from disturbance of WLAN environment

2.2.22 Hazards from covering up the App

2.2.23 Hazards caused by malfunctions of the app

2.2.24 Raised machine parts and loads

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CWI

3.1.2 Functions of CWI

3.2 Identification plates and identification numbers

3.2.1 CWI identification plate

3.3 Information on the product

3.3.1 Factory settings

3.3.2 Software and hardware version

3.3.3 Seal on the CWI

4 Operating and display elements

4.1 CLAAS Wireless Interface (CWI)

4.1.1 CWI operating elements

4.2 CWI Setup App

4.2.1 Overview of screen

4.2.2 Buttons

4.2.3

4.2.4

4.2.5

5 Technical specifications

5.1 CLAAS Wireless Interface (CWI)

5.1.1 Specification

6 Preparing the product

6.1 Installing the product

6.1.1 Installing the CWI Setup app

6.1.2 Installing the EASY on board app

6.1.3 Connecting the tablet

7 Operation

7.1 Initial operation

7.1.1 Establishing the WLAN connection for the first time

7.1.2 Changing factory settings

7.1.3 Establishing the WLAN connection

7.2 CWI Setup App

7.2.1 Calling up menus

7.2.2 Establishing a secure data connection

7.2.3 Deleting a secure data connection

7.2.4 Displaying the software version

7.3 CWI Setup – Settings

7.3.1 Changing settings

7.3.2 Switching LEDs on and off

7.4 CWI setup – Advanced settings

7.4.1 Deleting the connection partner in CWI

7.4.2 Deleting the connection partner on the tablet

7.4.3 Resetting the CWI to factory settings

7.4.4 Resetting the tablet to factory settings

7.4.5 Switching the CAN filter on and off

7.5 EASY on board App

7.5.1 Launching Operator’s Manual

8 Faults and remedies

8.1 Overview of problems

8.1.1 CWI faults

8.1.2 Fault message: USB charging connection was disconnected

8.1.3 Fault message: Tablet outside WLAN reception area

8.1.4 Fault message: Screen locked

9 Maintenance

9.1 Maintenance schedules

9.1.1 Daily

9.2 Tablet

9.2.1 Cleaning the tablet

9.2.2 Downloading software updates

9.2.3 Updating the operating system

10 Putting out of operation and disposal

10.1 General information

10.1.1 Decommissioning and disposal

11 EC declaration of conformity

11.1 CLAAS Wireless Interface (CWI)

11.1.1 EU Declaration of conformity

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Abbreviations

12.1.2 Technical terms

00 0290 518 0.pdf:

1 Introduction

1.1 Generalities

1.2 Machines to equip

2 Safety instructions

2.1 Important

2.1.1 Generalities

2.1.2 Use according to destination

2.2 Safety instructions

2.2.1 Characterization of indications on the dangers

2.2.2 General safety and accident prevention instructions

2.2.3 Parking the machine

3 Lot of pieces

3.1 VARIANT 3XX – 00 0857 722 0

3.1.1 Garde-corps et visserie

4 Montage du garde-corps

4.1 Description

4.1.1 Press security

4.2 Press preparation

4.2.1 Moving the hydraulic brake flexible support (depending on equipment)

4.2.2 Drilling the fixing holes

4.3 Mise en place du garde-corps

1 Introduction

1.1 General

1.2 Auszurustende Maschinen

2 Sicherheitsvorschriften

2.1 Important

2.1.1 General

2.1.2 Benutzung gemäß Zweckbestimmung

2.2 Sicherheitsvorschriften

2.2.1 Kennzeichnung der Gefahrenhinweise

2.2.2 Allgemeine Vorschriften zur Sicherheit und Accidentverhütung

2.2.3 Parking the machine

3 parts list

3.1 VARIANT 3XX – 00 0857 722 0

3.1.1 Railing and fastening material

4 Montage des Geländers

4.1 Description

4.1.1 Sichern der Presse

4.2 Vorbereiten der Presse

4.2.1 Verlegen des Halters für die hydraulic Bremsleitung (je nach Ausrüstung)

4.2.2 Durchführen der Befestigungsbohrungen

4.3 Installation of Railings

1 Introduction

1.1 General points

1.2 Machines that can be fitted

2 Safety advice

2.1 Important

2.1.1 General points

2.1.2 Use in accordance with original specifications

2.2 Safety instructions

2.2.1 Definition of hazard information

2.2.2 General safety and accident prevention advice

2.2.3 Parking the machine

3 parts kit

3.1 VARIANT 3XX – 00 0857 722 0

3.rd rail and bolts

4 Fitting the guard rail

4.1 Description

4.1.1 Securing the baler

4.2 Preparing the baler

4.2.1 Moving the hydraulic brake hose support (depending on equipment)

4.2.2 Drilling the mounting holes

4.3 Fitting the guard rail

1 Introduction

1.1 Generality

1.2 Equipment machine

2 Safety instructions

2.1 Important

2.1.1 Generality

2.1.2 Use as intended

2.2 Safety instructions

2.2.1 Characterization of the indications relative to danger

2.2.2 General safety and incident prevention instructions

2.2.3 Parking the machine

3 Lotto di pezzi

3.1 VARIANT 3XX – 00 0857 722 0

3.1.1 Protection and fittings

4 Installation of the protection

4.1 Description

4.1.1 Rush security

4.2 Press preparation

4.2.1 Displacement of the hydraulic brake hose support (depending on equipment)

4.2.2 Execution of the fixing forum

4.3 Installation of the protection

1 Introduction

1.1 General information

1.2 Applicable machines

2 Safety rules

2.1 Important

2.1.1 General information

2.1.2 Use according to the application

2.2 Security rules

2.2.1 Symbols applicable to danger indications

2.2.2 General safety and accident prevention rules

2.2.3 Fixing the machine

3 Lot of pieces

3.1 VARIANT 3XX – 00 0857 722 0

3.1.1 Body protection and screws

4 Assembling the body protection

4.1 Description

4.1.1 Fixation of the press

4.2 Preparation of the press

4.2.1 Displacement of the hydraulic brake flexible support (depending on the equipment)

4.2.2 Drilling of the fixing holes

4.3 Placement of body protection

1 Ââåäåíèå

1.1 Îáùèå ñâåäåíèØ

1.2 Îáî²óäóåìûå ìàøèíû

2 ÓêàçàíèØ ïî ìå²àì áåçîïàñíîñòè

2.1.1 Îáùèå ñâåäåíèØ

2.1.2 Èñïîëüçîâàíèå ïî íàçíà÷åíè

2.2 ÓêàçàíèØ ïî ìå²àì áåçîïàñíîñòè

2.2.1 Âûäåëåíèå óêàçàíèé íà îïàñíîñòè

2.2.2 Îáùèå óêàçàíèØ t??

4 ?????? ????

4.1 ????????

4.1.1 ϲ???????? ????-????????? ? ?????????? ?????????

4.2 ?????????? ????-?????????

4.2.1 ?????????? ???? ?????? ????????????? ???????? ??????? (? ??????????? ?? ???????????)

4.2.2 ???????? ???????? ????????

4.3 Disclaimer

00 0292 625 4.pdf.crdownload:

COMMUNICATOR II

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Requirements made on all persons working with the product

2.2.3 Hazard areas

Hazard areas

2.2.4 Interaction between the control terminal and the machine or tractor

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Technical status

2.2.8 Danger from damage to the machine

2.2.9 Complying with technical limit values

2.2.10 Preparing the product for road travel

2.2.11 Hazards when driving on the road and in the field

2.2.12 Hazards when driving on the road with an ISOBUS implement

2.2.13 Switching off the terminal while driving

2.2.14 Electrocution by electrical system

2.2.15 Only carry out work on the machine when it is stopped

2.2.16 Maintenance operations and repair work

2.2.17 Raised machine parts and loads

2.2.18 Welding work prohibited

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of COMMUNICATOR II

3.1.2 Function of COMMUNICATOR II

3.2 Identification plates and identification numbers

3.2.1 Identification plate of COMMUNICATOR II

4 Operating and display elements

4.1 COMMUNICATOR II

4.1.1 Terminal

4.1.2 Terminal program

4.2 Universal terminal menu structure (service)

4.2.1 Main menu of universal terminal

4.2.2

4.2.3

4.2.4

4.2.5

4.3 Job processing (task) menu structure

4.3.1 Job processing main menu

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

5 Technical specifications

5.1 COMMUNICATOR II

5.1.1 Specification

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Shut down and secure the machine

7 Operation

7.1 Switching COMMUNICATOR II on/off

7.1.1 Switching COMMUNICATOR II on

7.1.2 Selecting the application

7.1.3 Switching off COMMUNICATOR II

7.2 Programmable keys

7.2.1 Displaying the key assignment

7.2.2 Creating a key assignment

Step 1: Selecting the control and the key

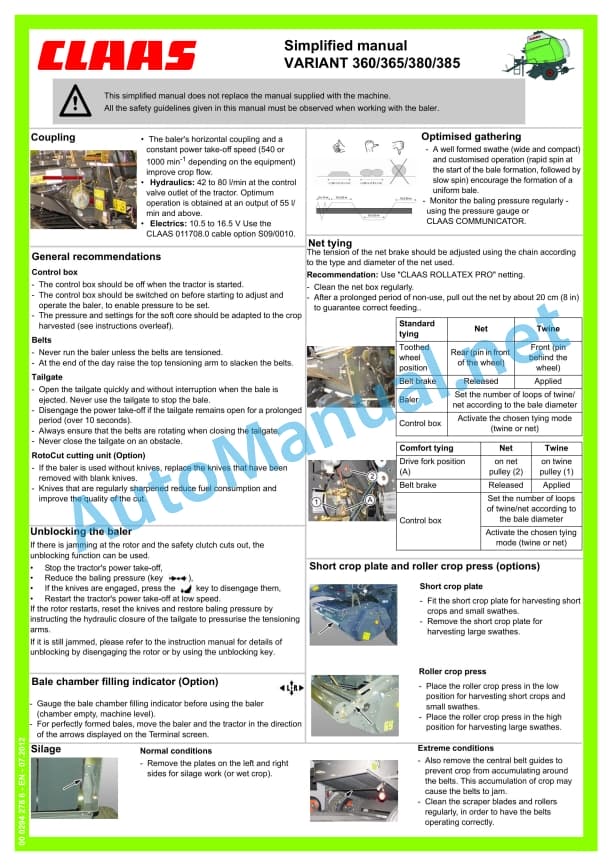

00 0294 278 6.pdf:

Short crop plate

Roller crop press

Short crop plate and roller crop press (options)

Settings (recommended values)

Optimised gathering

General recommendations

Unblocking the baler

Bale chamber filling indicator (Option)

00 0294 601 0.pdf:

FR_0100.pdf

Assembly and use instructions

“Linen – short linen” kit and “Very short linen” kit

FR_0001.pdf

Introduction

FR_0002_V2.pdf

Introduction

FR_0101.pdf

Safety instructions

FR_0102b_V2.pdf

Characterization of hazard indications

General safety and accident prevention instructions

Machine parking

Use as intended

FR_0200.pdf

Installation instructions

Linen and short linen kit

FR_0508_V2.pdf

Use of the press for other crops

Pressing chamber

FR_0507_V2.pdf

Use for pressing very short linen

Preparing the pressing chamber

Mounting the slides on the wall – Variant 360

Mounting the slides on the wall – Variant 380

Installation of the very short linen sheet

Fixing the very short linen sheet

“Moveable” slide adjustment

Harvesting on non-stony ground

Harvesting on stony ground

FR_0506_V2.pdf

Use for pressing short linen

Preparing the pressing chamber

Mounting the slides on the wall – Variant 360

Mounting the slides on the wall – Variant 380llation of the short linen sheet

Fixing the short linen sheet

“Moveable” slide adjustment

Harvesting on non-stony ground

Harvesting on stony ground

FR_0505_V2.pdf

Use for pressing linen

Harvesting on non-stony ground

Harvesting on stony ground

FR_0504_V2.pdf

Before use

Linen kit front frame adjustment

Center wheel height

Height of forage guides

Setting the proximity sensor

Ski height

Press adjustment

Number of turns of string

“Linen” twine guides

Flax harvest

Harvesting short flax and very short flax

Setting up the string

Setting using the Terminal

Pressing pressure adjustment

Bale diameter adjustment

Binding adjustment

FR_0503_V2.pdf

Principle and operation

Pressing direction

Pressing pressure

Tying flax stems

Forward speed and slick ratio

FR_0502_V2.pdf

Introduction

FR_0500.pdf

Instructions for use

FR_0404_V2.pdf

Preparation of the “very short line Variant 360

Drilling the pressing chamber

Pre-assembly of the “very short linen” kit

Variant 380

Drilling the pressing chamber

Pre-assembly of the “very short linen” kit

FR_0402_V2.pdf

Parts set (0844 809.0)

FR_0401_V2.pdf

Introduction

FR_0400.pdf

Installation instructions

Very short linen kit

FR_0210_V2.pdf

Module configuration for linen

Verification of information

Fixing the cable to the chassis

Setting the proximity sensor

Installing the cover

FR_0209_V2.pdf

Twine and knife guides

Fitting the “Linen” twine guides

Assembly of the “Lin” knife

Disassembly of the original knife

Assembly of the “Lin” knife

FR_0208_V2.pdf

Preparation of the “Short linen” kit

Variant 360

Drilling the pressing chamber

Pre-assembly of the “short linen” kit

Variant 380

Drilling the pressing chamber

Pre-assembly of the “short linen” kit

FR_0207_V2.pdf

Assembly of the linen kit

Fixingpress

Mounting the ski on the frame

Attaching the hook to the machine

FR_0206_V2.pdf

Pre-assembly of the linen kit

Mounting the wheel on the frame

Mounting the forage guides on the frame

Mounting the proximity sensor

Lubricator

FR_0205_V2.pdf

Preparing the pick-up

Dismantling the packer

Removing the pick-up protective cover

Assembly of the “Linen Kit” chain wheel

Removing the centering screws

Reassembly of the pickup housing

Removing Pickup Teeth

Preparing the walls of the pick-up

FR_0204_V2.pdf

Reduction in the number of belts

Relaxing the belts

Belt cutting

Belt length adjustment

Stapling the belts

FR_0202_V2.pdf

Parts set (0844 801.0)

FR_0201_V2.pdf

Introduction

FR_0509_V2.pdf

Maintenance

Lubricator

RU_0100.pdf

Èíñò²óêöèØ ïî ñáî²êå è Æêñïëóàòàöèè

Êîìïëåêò «ëåí – êî²îòêèé ëåí» è êîìïëåêò «î÷åíü êî²îòêèé ëåí»

RU_0001.pdf

RU_0002_V2.pdf

R ϲåññ-êàìå²à

Åëåêò²è÷åñêèé òîê

RU_0507_V2.pdf

Èñïîëüçîâàíèå äëØ ï²åññîâêè êî²îòêîãî ëüíà

Îáùèå ñâåäåíèØ

Ïîäãîòîâêà ï²åññ-êàìå²û

Ìîíòàæ íàï²àâëØ ùèõ íà ñòåíêó – Variant 360

Ìîíòàæ íàï²àâëØ ùèõ íà ñòåíêó – Variant 280

Óñòàíîâêà ñâà²íîãî ëèñòà «Î÷åíü êî²îòêèé ëåí»

ÔèêñàöèØ ñâà²íîãî ëèñòà «Î÷åíü êî²îòêèé ëåí»

Ãåãóëè²îâêà «ïîäâèæíîé» íàï²àâëØ ùåé

Óáî²êà íà íåêàìåíèñòîé ïî÷âå

Óáî²êà íà êàìåíèñòîé ïî÷âå

RU_0506_V2.pdf

Èñïîëüçîâàíèå äëØ ï²åññîâêè êî²îòêîãî ëüíà

Îáùèå ñâåäåíèØ

Ïîäãîòîâêà ï²åññ-êàìå²û

Ìîíòàæ íàï²àâëØ ùèõ íà ñòåíêó – Variant 360

Ìf

Ïîäãîòîâêà ê èñïîëüçîâàíè

Íàëàäêà ïå²åäíåé ²àìû êîìïëåêòà «Ëåí»

Âûñîòà öåíò²àëüíîãî êîëåñà

Âûñîòà íàï²àâëØ ùèõ ôó²àæà

Íàñò²îéêà äåòåêòî²à ï²èáëèæåíèØ

Âûñîòà ëûæè

Íàëàäêà ï²åññà

°èñëî îáî²îòîâ áå÷åâêè

Íàï²àâëØ ùèå áå÷åâêè «Ëåí»

Óáî²êà ëüíà

Óáî²êà êî²îòêîãî è î÷åíü êî²îòêîãî ëüíà

Çàï²àâêà áå÷åâêè

Ãåãóëè²îâêà ñ èñïîëüçîâàíèåì òå²ìèíàëà

Ãåãóëè²îâêà äàâëåíèØ ï²åññîâàíèØ

Ãåãóëè²îâêà äèàìåò²à ò êîâ

Ãåãóëè²îâêà îáâØçêè

RU_0503_V2.pdf

ϲèíöèï è ôóíêöèîíè²îâàíèå

Ñêî²îñòü îòáî²à ìîùíîñòè

Íàï²àâëåíèå ï??????? ????

RU_0402_V2.pdf

????? ??????? (0844 809.0)

RU_0401_V2.pdf

RU_0400.pdf

????????? ?? ?????

???????? ?????? ??????? ????

RU_0210_V2.pdf

?????????????????

???????? ?????? ?? ????? ????

ϲ????? ??????

ʲ??????? ?????? ?? ????

?????????? ?????????????? ???????

????????? ????????? ?????

RU_0209_V2.pdf

??????? ??? ??????? ? ???

?????? ??????? ??? ??????? ????????? ?????

?????? ???? ?????

???????? ??????????? ????

?????? ???? ?????

RU_0208_V2.pdf

?????????? ????????? ???????? ????

Variant 360

???????? ???????? ? ????? ??????????

ϲ???????????? ?????? ????????? ???????? ????

Variant 380

???????? ???????? ? ????? ??????????

ϲ???????????? ?????? ????????? ???????? ????

RU_0207_V2.pdf

????? ????????? ?????

ʲ??????? ????????????? ???? ? ?????

????????? ???? ?? ????

ʲ??????? ??????? ?? ??????

RU_0206_V2.pdf

ϲ???????????? ????? ????????? ?????

????????? ?????? ?? ????

Óñòàíîâêà íàï²àâëØ ùèõ ôó²àæà íà ²àìó

Óñòàíîâêà äåòåêòî²à ï²èáëèæåíèØ

Ñìàçî÷íîå îòâå²ñòèå

RU_0205_V2.pdf

Ïîäãîòîâêà ï²åññ-ïîäáî²ùèêà

Äåìîíòàæ ò²àìáîâùèêà

Äåìîíòàæ êà²òå²à çàùèòû ï²åññ-ïîäáî²ùèêà

Ìîíòàæ çâåçäî÷êè èç íàáî²à «Ëåí»

Äåìîíòàæ öåíò²îâî÷íûõ âèíòîâ

Óñòàíîâêà êà²òå²à ï²åññ-ïîäáî²ùèêà

Äåìîíòàæ ïàëüöåâ ñ ï²åññ-ïîäáî²ùèêà

Ïîäãîòîâêà áî²òîâ ï²åññ-ïîäáî²ùèêà

RU_0204_V2.pdf

Óìåíüøåíèå ÷èñëà ï²èâîäíûõ ²åìíåé

Îñëàáëåíèå ²åìíåé

Îá²åçêà ²åìíåé

Ãåãóëè²îâêà äëèíû ²åìíåé

Ñê²åïëåíèå ²åìíØ

RU_0202_V2.pdf

Ïà²òèØ äåòàëåé (0843 001.0)

RU_0201_V2.pdf

RU_02df

Parts set (0844 801.0)

FR_0204_V2.pdf

Reduction in the number of belts

Relaxing the belts

Belt cutting

Belt length adjustment

Stapling the belts

FR_0205_V2.pdf

Preparing the pick-up

Dismantling the packer

Removing the pick-up protective cover

Assembly of the “Linen Kit” chain wheel

Removing the centering screws

Reassembly of the pickup housing

Removing Pickup Teeth

Preparing the walls of the pick-up

FR_0206_V2.pdf

Pre-assembly of the linen kit

Mounting the wheel on the frame

Mounting the forage guides on the frame

Mounting the proximity sensor

Lubricator

FR_0207_V2.pdf

Assembly of the linen kit

Fixing the pre-assembled frame on the press

Mounting the ski on the frame

Attaching the hook to the machine

FR_0208_V2.pdf

Preparation of the “Short linen” kit

Variant 360

Drilling the pressing chamber

Pre-assembly of the “short linen” kit

Variant 380

Drilling the pressing chamber

Pre-assemshort linen” kit

FR_0209_V2.pdf

Twine and knife guides

Fitting the “Linen” twine guides

Assembly of the “Lin” knife

Disassembly of the original knife

Assembly of the “Lin” knife

FR_0210_V2.pdf

Module configuration for linen

Verification of information

Fixing the cable to the chassis

Setting the proximity sensor

Installing the cover

FR_0400.pdf

Installation instructions

Very short linen kit

FR_0400.pdf

Installation instructions

Very short linen kit

FR_0401_V2.pdf

Introduction

FR_0402_V2.pdf

Parts set (0844 809.0)

FR_0404_V2.pdf

Preparation of the “very short linen” kit

Variant 360

Drilling the pressing chamber

Pre-assembly of the “very short linen” kit

Variant 380

Drilling the pressing chamber

Pre-assembly of the “very short linen” kit

FR_0500.pdf

Instructions for use

FR_0502_V2.pdf

Introduction

FR_0503_V2.pdf

Principle and operation

Pressing direction

Pressing pressure

Tyinpeed and slick ratio

FR_0504_V2.pdf

Before use

Linen kit front frame adjustment

Center wheel height

Height of forage guides

Setting the proximity sensor

Ski height

Press adjustment

Number of turns of string

“Linen” twine guides

Flax harvest

Harvesting short flax and very short flax

Setting up the string

Setting using the Terminal

Pressing pressure adjustment

Bale diameter adjustment

Binding adjustment

FR_0505_V2.pdf

Use for pressing linen

Harvesting on non-stony ground

Harvesting on stony ground

FR_0506_V2.pdf

Use for pressing short linen

Preparing the pressing chamber

Mounting the slides on the wall – Variant 360

Mounting the slides on the wall – Variant 380

Installation of the short linen sheet

Fixing the short linen sheet

“Moveable” slide adjustment

Harvesting on non-stony ground

Harvesting on stony ground

FR_0507_V2.pdf

Use for pressing very short liPreparing the pressing chamber

Mounting the slides on the wall – Variant 360

Mounting the slides on the wall – Variant 380

Installation of the very short linen sheet

Fixing the very short linen sheet

“Moveable” slide adjustment

Harvesting on non-stony ground

Harvesting on stony ground

FR_0508_V2.pdf

Use of the press for other crops

Pressing chamber

FR_0509_V2.pdf

Maintenance

Lubricator

RU_0100.pdf

Èíñò²óêöèØ ïî ñáî²êå è Æêñïëóàòàöèè

Êîìïëåêò «ëåí – êî²îòêèé ëåí» è êîìïëåêò «î÷åíü êî²îòêèé ëåí»

RU_0001.pdf

RU_0002_V2.pdf

RU_0101.pdf

ÓêàçàíèØ ïî òåõíèêå áåçîïàñíîñòè

RU_0102b_V2.pdf

ÂàæíàØ èíôî²ìàöèØ

Îïèñàíèå ï²åäóï²åäèòåëüíûõ çíàêîâ

Îáùå óêàçàíèØ ïî òåõíèêå áåçîïàñíîñòè è ï²åäîòâ²àùåíè íåñ÷àñòíûõ ñëó÷àåâ

ÑòîØíêà ìàøi

Îá²åçêà ²åìíåé

Ãåãóëè²îâêà äëèíû ²åìíåé

Ñê²åïëåíèå ²åìíØ

RU_0205_V2.pdf

Ïîäãîòîâêà ï²åññ-ïîäáî²ùèêà

Äåìîíòàæ ò²àìáîâùèêà

Äåìîíòàæ êà²òå²à çàùèòû ï²åññ-ïîäáî²ùèêà

Ìîíòàæ çâåçäî÷êè èç íàáî²à «Ëåí»

Äåìîíòàæ öåíò²îâî÷íûõ âèíòîâ

Óñòàíîâêà êà²òå²à ï²åññ-ïîäáî²ùèêà

Äåìîíòàæ ïàëüöåâ ñ ï²åññ-ïîäáî²ùèêà

Ïîäãîòîâêà áî²òîâ ï²åññ-ïîäáî²ùèêà

RU_0206_V2.pdf

ϲåäâà²èòåëüíàØ ñáî²êà êîìïëåêòà «Ëåí»

Óñòàíîâêà êîëåñà íà ²àìó

Óñòàíîâêà íàï²àâëØ ùèõ ôó²àæà íà ²àìó

Óñòàíîâêà äåòåêòî²à ï²èáëèæåíèØ

Ñìàçî÷íîå îòâå²ñòèå

RU_0207_V2.pdf

Ñáî²êà êîìïëåêòà «iong>

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0301 092 0.pdf:

VARIANT 360 / 360 RotoCutVARIANT 365 RotoCutVARIANT 380 / 380 RotoCutVARIANT 385 RotoCut

Table of contents

1 To this Operator’s Manual

1.1 General information

1.1.1 Manual validity

1.1.2 Using the manual

1.1.3 Symbols and notes

1.1.4 Technical specifications

2.1 General information

2.1.1 General points

2.1.2 Using in line with intended usage

2.1.3 Reasonably foreseeable improper usage

2.1.4 Driving on the road

2.1.5 Definition of hazard information

2.1.6 Safety advice

2.1.7 Accident prevention

2.1.8 Waste disposal

2.1.9 Residual risks

2.2 Safety decals

2.2.1 Description

2.2.2 Location of safety stickers

2.3 Safety equipment

2.3.1 Indicator lights

2.3.2 Reflective equipment

2.3.3 Jack stand

2.3.4 Chocks

2.3.5 Retaining cable (machine not equipped with brake and which can be used in France)

2.3.6 Parking brake

2.3.7 Locking the tailgate

2.3.8 Locking the pick-up

2.3.9 Extinguisher

2.3.10 Main gearbox output protection, without twine tying

3 Machine description

3.1 Existing models

3.1.1 Machine description

3.2 Overview and functions

3.2.1 Left-hand side

3.2.2 Right-hand side

3.2.3 Roller identification

3.3 Working and service areas

3.3.1 General points

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF