Clark C500 Y 950 CH Service Manual SM-580

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-580

- Format: PDF

- Size: 120.1MB

- Number of Pages: 609

Category: Clark Service Manual PDF

-

Model List:

- C500 Y 950 CH

- 1. Service Manual SM580

- 2. PICTORIAL INDEX

- 3. TABLE OF CONTENTS

- 4. INTRODUCTION

- 5. PM PLANNED MAINTENANCE PROGRAM

- 6. ENGINE

- 6.1. Section 1 Troubleshooting

- 6.2. Section 2 Cummins LTAIOC325 Diesel Engine Removal

- 7. COOLING SYSTEM

- 7.1. Section 1 Troubleshooting

- 7.2. Section 2 Radiator Removal

- 7.3. Section 3 Cooling System Testing and Maintenance

- 7.4. Section 4 Radiator Repair

- 8. FUEL SYSTEM

- 8.1. Section 1 Troubleshooting

- 8.2. Section 2 Air Induction System

- 8.3. Section 3 Accelerator Linkage

- 9. TRANSMISSION

- 9.1. Section 1 Troubleshooting

- 9.2. Section 2 Transmission Stall Test

- 9.3. Section 3 Transmission Removal

- 9.4. Section 4 Torque Converter Removal

- 9.5. Section 5 Drive Gear Replacement

- 9.6. Section 6 Linkage and Controls

- 9.7. Section 7 Transmission Filter

- 10. BATTERY ELECTRICAL CHECKS

- 10.1. Section 1 Battery Electrical Checks

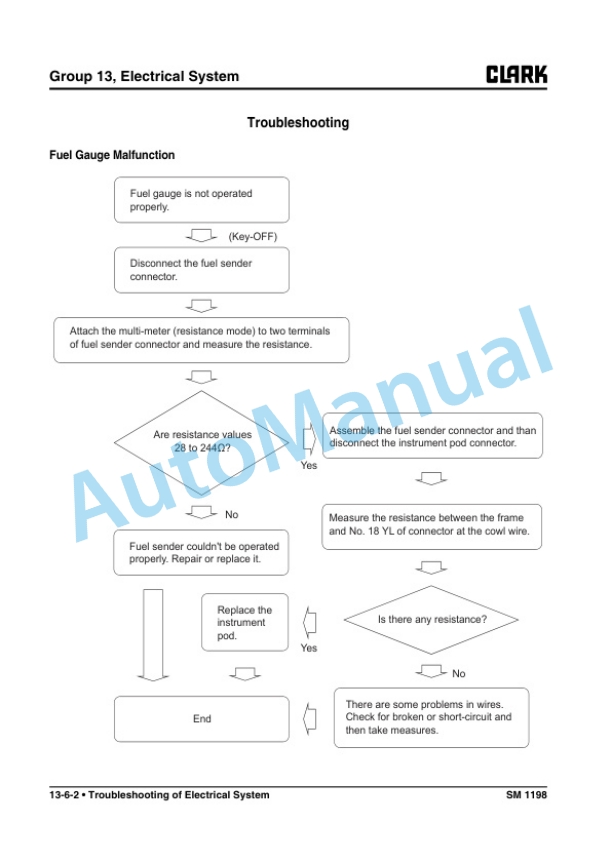

- 11. ELECTRICAL WIRING WIRING DIAGRAMS

- 11.1. Section 1 Troubleshooting

- 11.2. Section 2 Electrical Wiring Wiring Diagrams

- 11.2.1. Backup Alarm Installation

- 11.2.2. Cab Lights and Horns

- 11.2.3. Signal Light Installation

- 11.2.4. Container Handler Wiring

- 11.2.5. Front Light Installation

- 11.2.6. Instrument Panel Wiring

- 11.2.7. Tail Light Installation

- 12. DRIVE AXLE

- 12.1. Section 1 Troubleshooting

- 12.2. Section 2 Drive Axle Disassembly

- 13. UNIVERSAL JOINT

- 13.1. Section 1 Troubleshooting

- 13.2. Section 2 UJoint Removal Repair

- 14. TIRES WHEELS

- 14.1. Section 1 Tire Wheel Safety

- 14.2. Section 2 Tires Wheels

- 15. PARKING BRAKE

- 15.1. Section 1 Troubleshooting

- 15.2. Section 2 Parking Brake

- 15.3. Section 3 Parking Brake Head

- 16. SERVICE BRAKE

- 16.1. Section 1 Troubleshooting

- 16.2. Section 2 Service Brake System

- 16.3. Section 3 Service Brake Head

- 17. STEERING

- 17.1. Section 1 Troubleshooting

- 17.2. Section 2 Steer Column Gear Removal

- 17.3. Section 3 Steer Gear Overhaul

- 18. STEER AXLE CYLINDER

- 18.1. Section 1 Troubleshooting

- 18.2. Section 2 Steer Axle Removal

- 18.3. Section 3 Dual Steer Cylinder Removal

- 18.4. Section 4 Dual Steer Cylinder Overhaul

- 18.5. Section 5 Single Steer Cylinder Removal

- 18.6. Section 6 Single Steer Cylinder Overhaul

- 18.7. Section 7 Dual Steer Cylinder Axle Overhaul

- 18.8. Section 8 Steer Wheel Bearing Adjustment Replacement

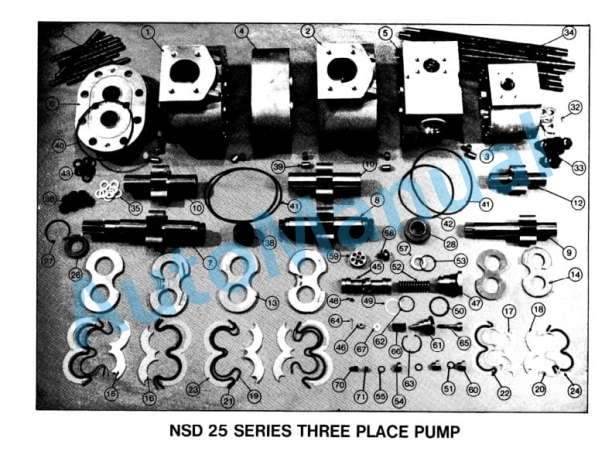

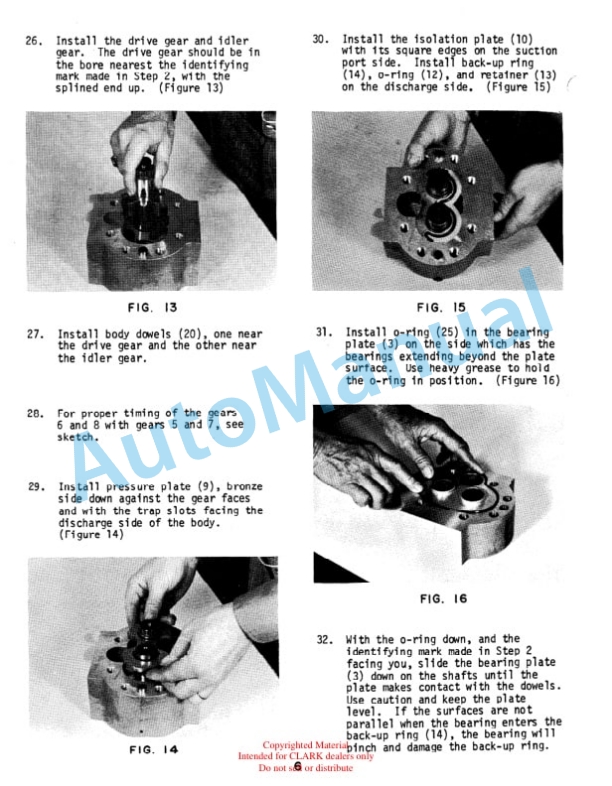

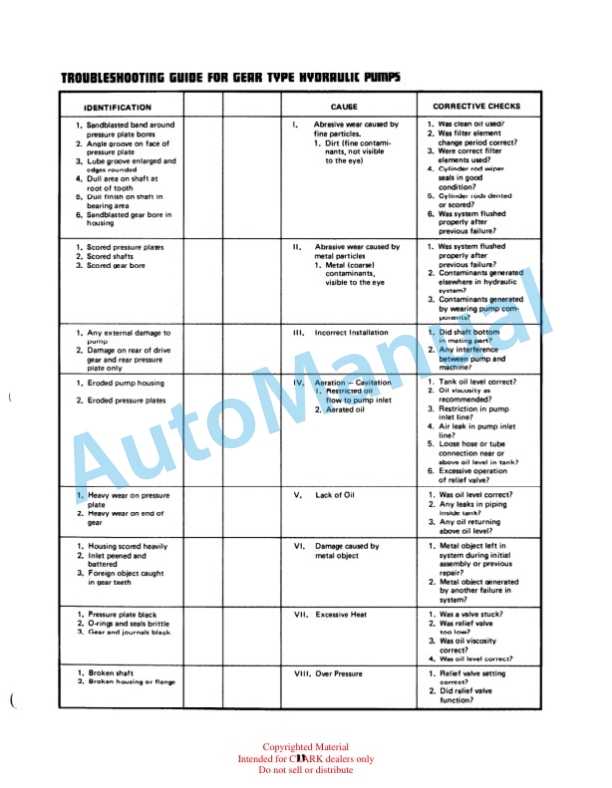

- 19. HYDRAULIC SUMP, FILTERS PUMPS

- 19.1. Section 1 Hydraulic Filters

- 19.2. Section 2 Hydraulic Pumps Removal

- 20. HYDRAULIC VALVES LIFT CIRCUIT

- 20.1. Section 1 Troubleshooting

- 20.2. Section 2 Hydraulic System

- 20.3. Section 3 Hydraulic Valve Controls

- 21. TILT CYLINDERS

- 21.1. Section 1 Tilt Cylinder Removal Reinstallation

- 22. UPRIGHT

- 22.1. Section 1 Troubleshooting

- 22.2. Section 2 Upright Removal

- 22.3. Section 3 Top Pickup Removal

- 22.4. Section 4 Lift Cylinder Removal

- 22.5. Section 5 Cylinder Overhaul

- 22.6. Section 6 Lift Chain Inspection, Lubrication and Replacement

- 23. COUNTERWEIGHTS

- 23.1. Section 1 Counterweight Removal and Installation

- 24. DECALS

- 24.1. Section 1 Decal Replacement

- 25. SPECIFICATIONS

- 25.1. Section 1 General Specifications

- 25.1.1. Capacity

- 25.1.2. Service Weight

- 25.1.3. Axle Weights

- 25.1.4. Parking Brake Test

- 25.1.5. Travel Speeds

- 25.1.6. Turning Radius

- 25.1.7. Wheels Tires

- 25.1.8. Drift Lift and Tilt

- 25.1.9. Lift Speeds, Upright

- 25.1.10. Lowering Speeds, Upright

- 25.1.11. Drive Axle

- 25.1.12. Service Brakes

- 25.1.13. Parking Brake

- 25.1.14. Cooling System

- 25.1.15. Electrical

- 25.1.16. Engine Specifications

- 25.1.17. Engine TuneUp

- 25.1.18. Fuel Recommendations

- 25.1.19. Tank Capacity Fuel

- 25.1.20. Hydraulic System

- 25.1.21. Hydraulic Filters

- 25.1.22. Transmission

- 25.1.23. Critical Fastener Torque Specifications

- 25.2. Section 2 PM Inspection Daily Inspection Forms

- 25.3. Section 3 Recommended Lubricants Lubricant Specifications

- 25.4. Section 4 Lubricants Shop Supplies

- 25.4.1. Lubricants

- 25.4.2. Sealants

- 25.4.3. Gasket Materials

- 25.4.4. Threadlocks and Threadsealers

- 25.4.5. Adhesives

- 25.4.6. Cleaners

- 25.4.7. Miscellaneous Shop Supplies

- 26. EXTENDABLE LIFT FRAME

- 26.1. Section 1 Extendable Lift Frame Maintenance and Repair

- 26.1.1. Lubrication

- 26.1.2. Replacement of Bushings

- 26.1.3. Land Pin Block Up

- 26.1.4. Adjustment of Twist Locks

- 26.1.5. Adjustment of Limit Switches

- 26.1.6. Hydraulic HookUp for Test Procedures

- 26.1.7. Extendable Lift Frame Straightness Check

- 26.1.8. SIDE SHIFTING AND SKEWING CHAIN ASSEMBLY

- 26.1.9. Container Handler Main Support Chains

- 26.1.10. Cleaning and Inspection Of NonHydraulic Parts

- 26.1.11. Extendable Lift Frame Removal

- 26.1.12. Twist Lock Cylinder Removal

- 26.1.13. Twist Lock Cylinder Overhaul

- 26.1.14. Cleaning and Inspection

- 26.1.15. Reassembly of Cylinder

- 26.1.16. Extendable Lift Frame Cylinder Removal

- 26.1.17. Extendable Lift Frame Cylinder Overhaul

- 26.1.18. Cleaning and Inspection

- 26.1.19. Reassembly of Cylinder

- 26.1.20. Land Pin Removal

- 26.1.21. Installation of Twist Lock

- 26.1.22. Removal of Extendable Beam

- 26.1.23. Installation of Extendable Beams

Rate this product

You may also like

Clark Service Manual PDF

Clark C500-355, C500-H355, C500-Y355, C500-HY355 Gasoline, LPG Service Manual SM-333

$30.00

Clark Service Manual PDF

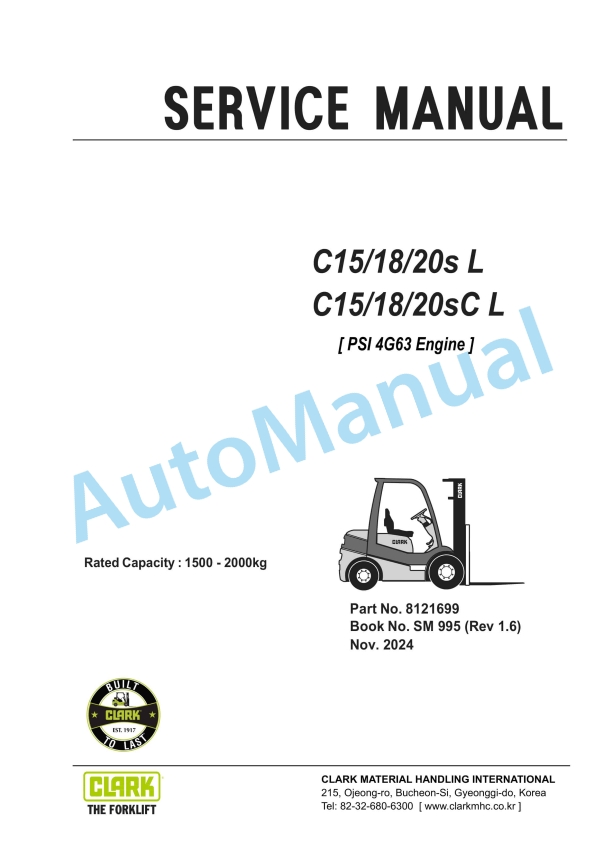

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-1198

$30.00

Clark Service Manual PDF

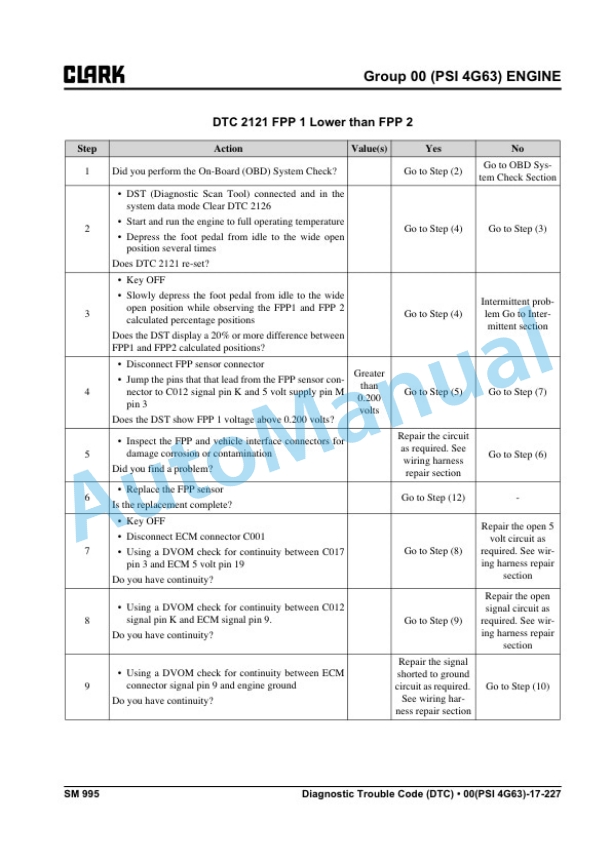

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-995

$30.00

Clark Service Manual PDF

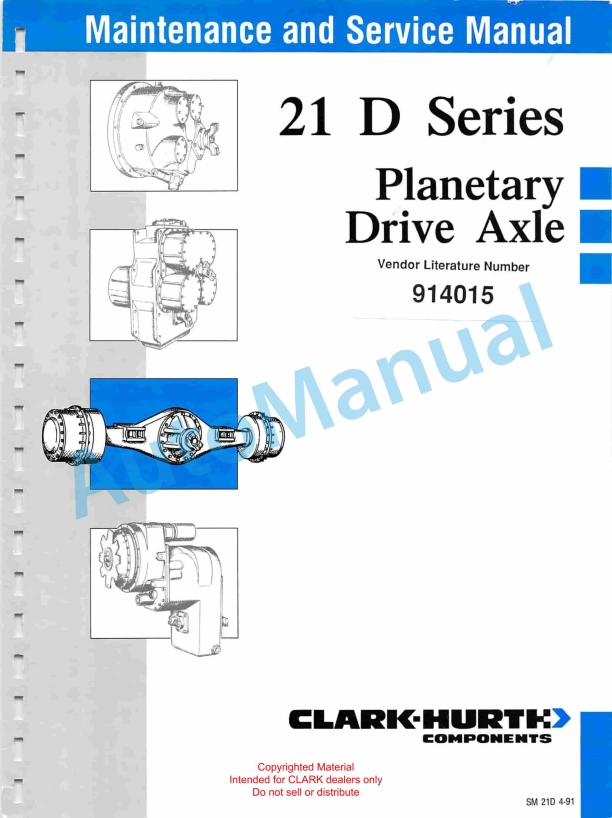

Clark 21 D Series Planetary Drive Axle Maintenance and Service Manual SM-21D

$30.00

Clark Service Manual PDF

$30.00