Clark CMP15-20sD, CMP15-20sL Service Manual SM-710

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-710

- Format: PDF

- Size: 22.3MB

- Number of Pages: 466

Category: Clark Service Manual PDF

-

Model List:

- CMP15-20sD

- CMP15-20sL

- 1. GENERAL

- 1.1. REVISION HISTORY

- 1.2. FOREWORD

- 1.2.1. FOREWORD

- 1.2.2. HOW TO READ THIS MANUAL

- 1.3. SAFETY

- 1.3.1. GENERAL PRECAUTIONS

- 1.3.2. PREPARATIONS FOR WORK

- 1.3.3. CAUTIONS DURING OPERATION

- 1.4. STANDARDS

- 1.4.1. STANDARD TIGHTENING TORQUE

- 1.4.2. MEASUREMENT CONVERSIONS

- 2. SPECIFICATIONS

- 2.1. GENERAL

- 2.1.1. LOCATION OF COMPONENTS

- 2.1.2. INSTRUMENT PANEL

- 2.1.3. DIMENSION AND WEIGHT

- 2.2. LOAD CAPACITY

- 2.2.1. CAPACITY CHARTS

- 2.3. COOLANT / FUEL / LUBRICATION

- 2.4. PERIODIC MAINTENANCE

- 2.5. TIGHTENING TORQUE

- 3. ENGINE (FOR LPG) (MMC 4G63)

- 3.1. GENERAL INFORMATION

- 3.1.1. Periodic inspection chart

- 3.1.2. How to read this chapter

- 3.1.3. Engine model and numbers

- 3.2. SPECIFICATION

- 3.2.1. General specifications

- 3.2.2. Service specifications

- 3.2.3. Tightening torque

- 3.2.4. Special tools

- 3.3. ADJUSTMENT

- 3.3.1. Valve clearance adjustment

- 3.3.2. Ignition timing adjustment

- 3.3.3. Idling speed adjustment

- 3.3.4. Air governor (high speed)

- 3.4. TIMING BELT

- 3.4.1. Removal

- 3.4.2. Inspection

- 3.4.3. Installation

- 3.5. ELECTRIC COMPONENT

- 3.5.1. Inspection

- 3.5.2. Distributor

- 3.5.3. Alternator

- 3.5.4. Starter

- 3.6. FUEL SYSTEM

- 3.6.1. Removal

- 3.6.2. Installation

- 3.6.3. Carburettor . LPG

- 3.6.4. Air governor

- 3.6.5. Other components . LP

- 3.7. COMPONENTS

- 3.7.1. Rocker arms and camshaft

- 3.7.2. Cylinder head and valves

- 3.7.3. Front case and oil pan

- 3.7.4. Piston and connecting rod

- 3.7.5. Crankshaft and cylinder block

- 3.8. TROUBLESHOOTING

- 3.8.1. By symptom

- 3.8.2. By component

- 4. DIESEL ENGINETIER2 (4TNV88/94L)

- 4.1. SAFETY

- 4.1.1. PREFACE

- 4.1.2. SAFETY PRECAUTIONS

- 4.1.3. PRECAUTIONS FOR SERVICE WORK

- 4.1.4. HOW TO READ THIS MANUAL

- 4.2. GENERAL

- 4.2.1. ENGINE NOMENCLATURE

- 4.2.2. SPECIFICATIONS

- 4.2.3. FUEL OIL, LUBRICATING OIL AND COOLING WATER

- 4.2.4. EXHAUST GAS EMISSION REGULATION

- 4.2.5. EXHAUST GAS EMISSION REGULATION

- 4.3. INSPECTION AND ADJUSTMENT

- 4.3.1. PERIODIC MAINTENANCE SCHEDULE

- 4.3.2. PERIODIC INSPECTION AND MAINTENANCE PROCEDURE

- 4.3.3. ADJUSTING THE NOLOAD MAXIMUM OR MINIMUM SPEED

- 4.3.4. SENSOR INSPECTION

- 4.3.5. WATER LEAK CHECK IN COOLING WATER SYSTEM

- 4.3.6. RADIATOR CAP INSPECTION

- 4.3.7. THERMOSTAT INSPECTION

- 4.3.8. ADJUSTING OPERATION

- 4.3.9. LONG STORAGE

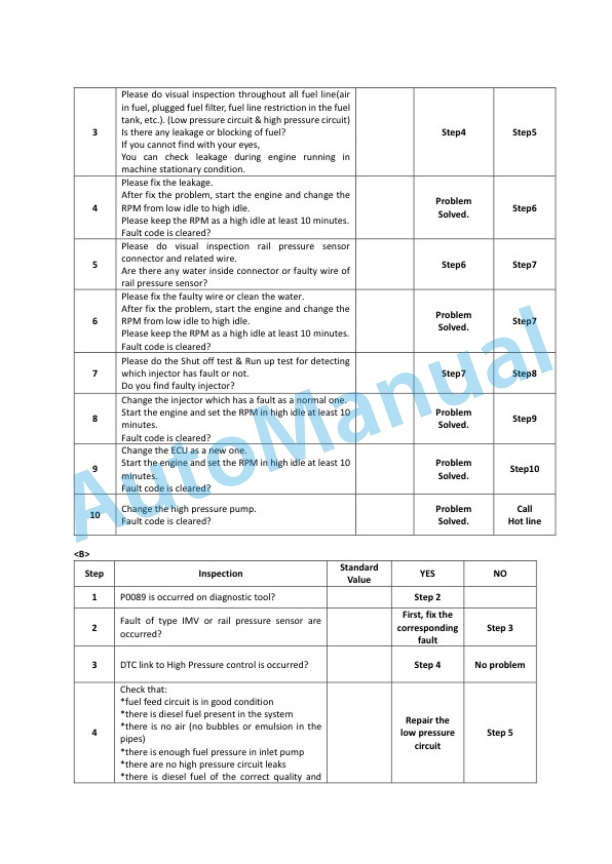

- 4.4. TROUBLESHOOTING

- 4.4.1. PREPARATION BEFORE TROUBLESHOOTING

- 4.4.2. QUICK REFERENCE TABLE FOR TROUBLESHOOTING

- 4.4.3. TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE

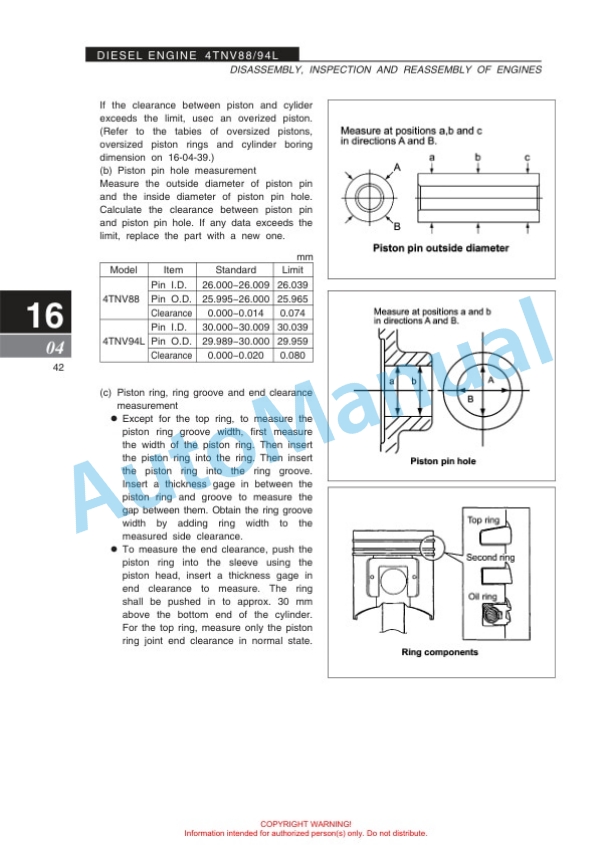

- 4.5. DISASSEM BLY, INSPECTION AND REASSEMBLY OF ENGINES

- 4.5.1. COMPLETE DISASSEMBLY AND REASSEMBLY

- 4.5.2. CYLINDER HEAD DISASSEMBLY, INSPECTION AND REASSEMBLY

- 4.5.3. GEAR TRAIN AND CAMSHAFT

- 4.5.4. CYLINDER BLOCK

- 4.6. LUBRICATION STSTEM

- 4.6.1. LUBRICATION SYSTEM DIAGRAM

- 4.6.2. TROCHOID PUMP COMPONENTS

- 4.6.3. DISASSEMBLY(REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 4.6.4. SERVICING POINTS

- 4.6.5. PARTS INSPECTION AND MEASUREMENT

- 4.7. COOLING SYSTEM

- 4.7.1. COOLING WATER SYSTEM

- 4.7.2. COOLING WATER PUMP COMPONENTS

- 4.7.3. DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)

- 4.7.4. SERVICING POINTS

- 4.8. FUEL INJECTION PUMP/GOVERNOR

- 4.8.1. INTRODUCTION

- 4.8.2. FUEL INJECTION PUMP

- 4.9. ALTERNATOR

- 4.9.1. THE 40A ALTERNATOR FOR 3TNV84 AND OTHER MODELS

- 4.10. ELECTRIC WIRING

- 4.10.1. ELECTRIC WIRING DIAGRAM

- 4.10.2. PRECAUTION ON ELECTRIC WIRING

- 4.11. SERVICE STANDARDS

- 4.11.1. ENGINE TUNING

- 4.11.2. ENGINE BODY

- 4.11.3. LUBRICATING OIL SYSTEM (TROCHOID PUMP)

- 4.12. TIGHTENING TORQUE FOR BOLTS AND NUTS

- 4.12.1. TIGHTENING TORQUES FOR MAIN BOLTS AND NUTS

- 4.12.2. TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS

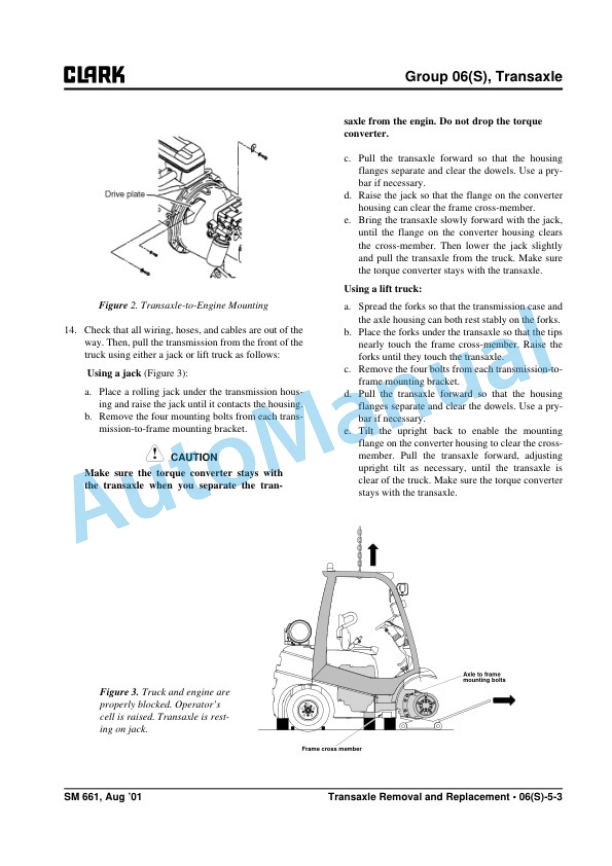

- 5. TRANSAXLE

- 5.1. STRUCTURE AND MAINTENANCE

- 5.1.1. CONSTRUCTION

- 5.1.2. HYDRAULIC CIRCUIT

- 5.1.3. SERVICE MAINTENANCE

- 5.1.4. SPECIFICATION

- 5.1.5. SERVICE BRAKE ADJUSTMENT

- 5.2. SERVICE BRAKE ADJUSTMENT

- 5.2.1. PRECAUTION

- 5.2.2. REMOVE AUXILIARY SUBASSEMBLIES

- 5.2.3. WHEEL END

- 5.2.4. BRAKE ASSEMBLY REMOVAL

- 5.2.5. SEPARATION OF CONVERTER HOUSING AND ADAPTOR PLATE

- 5.2.6. STATOR SUPPORT REMOVAL FROM ADAPTOR PLATE

- 5.2.7. CLUTCH ASSEMBLY, IDLER GEAR PINION SHAFT REMOVAL

- 5.3. ASSEMBLY

- 5.3.1. TRANSAXLE REASSEMBLY

- 5.3.2. DIFFERENTIAL

- 5.3.3. PINION GEAR SHIMMING

- 5.3.4. WHEEL END FINAL ASSEMBLY

- 5.3.5. CLUTCH ASSEMBLY

- 5.3.6. STATOR SUPPORT

- 5.3.7. TRANSMISSION ASSEMBLY

- 6. STEERING SYSTEM

- 6.1. FUNCTION AND MAINTENANCE

- 6.1.1. OUTLINE

- 6.1.2. OPERATING PRINCIPLE DURING LEFT/RIGHT TURN

- 6.1.3. STEERING UNIT

- 6.1.4. OPERATION

- 6.1.5. TROUBLESHOOTING TABLE

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.2.1. STEERING UNIT

- 6.2.2. PRIORITY VALVE

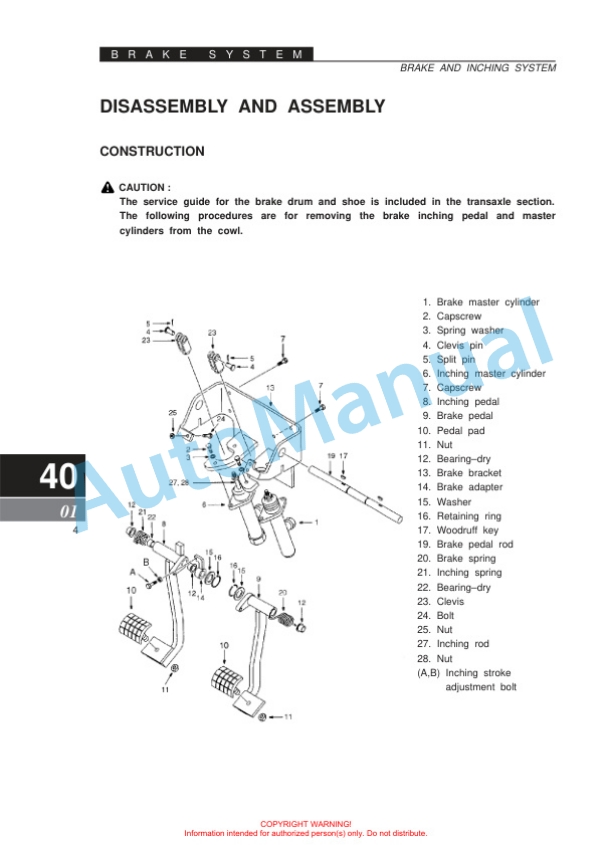

- 7. BRAKE SYSTEM

- 7.1. BRAKE AND INCHING SYSTEM

- 7.1.1. GENERAL

- 7.1.2. BRAKE / INCHING BLEEDING

- 7.1.3. DISASSEMBLY AND ASSEMBLY

- 8. HYDRAULIC STSTEM

- 8.1. MAIN PUMP(JP20)

- 8.1.1. SPECIFICATION

- 8.1.2. DISASSEMBLY AND ASSEMBLY

- 8.1.3. TROUBLESHOOTING

- 8.1.4. START.UP

- 8.2. MAIN HYDRAULIC VALVE (MC4)

- 8.2.1. OPERATION OF HYDRAULIC VALVE

- 8.2.2. TEST OF HYDRAULIC VALVE

- 8.2.3. DISASSEMBLY OF HYDRAULIC VALVE

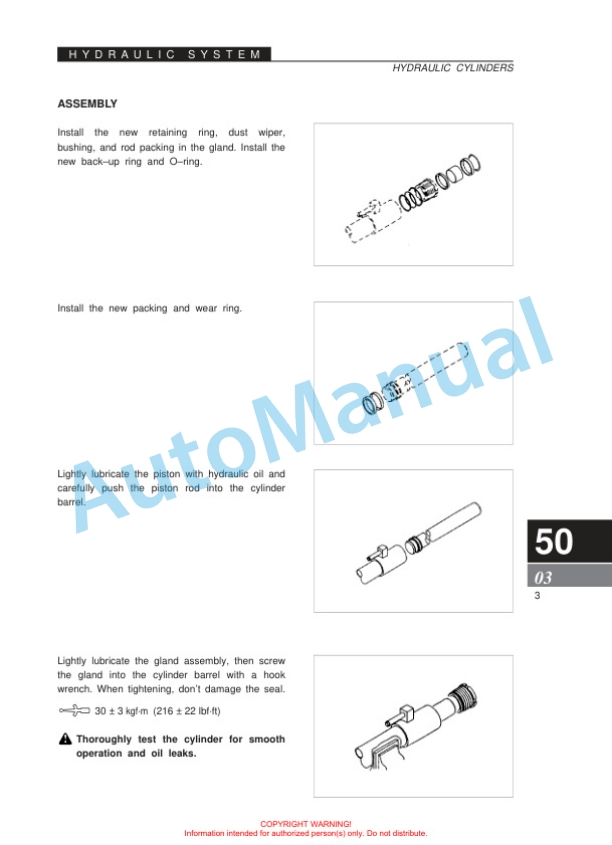

- 8.3. HYDRAULIC CYLINDERS

- 8.3.1. DISASSEMBLY AND ASSEMBLY

- 9. UPRIGHT(FOR FACELIFT)

- 9.1. UPRIGHT SPECIFICATIONS AND DESCRIPTION

- 9.1.1. GENERAL SPECIFICATIONS

- 9.1.2. DESCRIPTION

- 9.2. TROUBLESHOOTING

- 9.3. UPRIGHT INSPECTION

- 9.3.1. UPRIGHT INSPECTION

- 9.3.2. BASIC VISUAL INSPECTION

- 9.3.3. EXTENDED INSPECTION

- 9.4. CARRIAGE AND UPRIGHT ROLLER CLEARANCE CHECKS AND SHIM ADJUSTMENT

- 9.4.1. CARRIAGE AND UPRIGHT ROLLER CLEARANCE CHECKS AND SHIM ADJUSTMENT

- 9.4.2. INTRODUCTION

- 9.4.3. ROLLER SIDE CLEARANCE CHECKS

- 9.4.4. OVERSIZE ROLLERS

- 9.4.5. LIFT ROLLER SHIMMING

- 9.5. CYLINDER REMOVAL, SHIMMING, OVERHAUL, AND REPLACEMENT

- 9.5.1. CYLINDER TYPES

- 9.5.2. LIFT CYLINDER SHIMMING PROCEDURE

- 9.5.3. PRIMARY CYLINDER REMOVAL AND REPLACEMENT (TSU)

- 9.5.4. LIFT AND SECONDARY CYLINDER REMOVAL AND REPLACEMENT

- 9.5.5. CYLINDER OVERHAUL

- 9.6. UPRIGHT CHAIN INSPECTION, ADJUSTMENT, AND REPLACEMENT

- 9.6.1. UPRIGHT CHAIN INSPECTION, ADJUSTMENT, AND REPLACEMENT

- 9.6.2. PERIODIC INSPECTIONS

- 9.6.3. CHAIN LENGTH ADJUSTMENTS

- 9.6.4. CHAIN LUBRICATION

- 9.6.5. CHAIN REMOVAL AND REPLACEMENT

- 9.6.6. OTHER CHAIN SERVICE NOTES

- 9.7. FORK AND CARRIAGE REMOVAL AND REPLACEMENT

- 9.7.1. FORK REMOVAL

- 9.7.2. FORK REPLACEMENT

- 9.7.3. CARRIAGE REMOVAL

- 9.7.4. CARRIAGE REPLACEMENT

- 9.8. UPRIGHT REMOVAL AND REPLACEMENT

- 9.8.1. UPRIGHT REMOVAL AND REPLACEMENT

- 9.8.2. UPRIGHT REMOVAL

- 9.8.3. UPRIGHT REPLACEMENT

- 10. COUNTERWEIGHT

- 10.1. COUNTERWEIGHT

- 10.2. LIFTING, JACKING AND BLOCKING

- 11. CIRCUIT DIAGRAM

- 11.1. HYDRAULIC ELECTRIC CIRCUIT DIAGRAM

- 11.1.1. HYDRAULIC CIRCUIT DIAGRAM(FOR HANIL MC4)

- 11.1.2. ELECTRIC CIRCUIT DIAGRAM (FOR LPG ENGINEFACELIFT)

- 11.1.3. ELECTRIC CIRCUIT DIAGRAM (FOR DIESEL ENGINEEPA TIER2)

Rate this product

You may also like

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

Clark 5000 Series Powershift Transmission Maintenance and Service Manual SM-54

$30.00

Clark Service Manual PDF

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-995

$30.00