Clark E357 Service Manual SM-581

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-581

- Format: PDF

- Size: 15.3MB

- Number of Pages: 297

Category: Clark Service Manual PDF

-

Model List:

- E357

- 1. SERVICE MANUAL SM581

- 2. Main Table of Contents

- 3. FOREWORD

- 4. HOW TO USE THIS MANUAL

- 5. PICTORIAL INDEX

- 6. SAFETY AND OPERATIONAL CHECKS

- 7. RECOMMENDED PLANNED MAINTENANCE

- 8. SAFETY SIGNS AND SAFETY MESSAGES

- 9. USER SAFE MAINTENANCE PRACTICES

- 10. PM PLANNED MAINTENANCE

- 10.1. PM Report Form

- 10.2. Visual Inspection

- 10.3. Wheels and Tires

- 10.4. Pneumatic tires

- 10.5. Functional Tests

- 10.6. Battery Load Test

- 10.7. Test Drive The Truck

- 10.8. Air Cleaning

- 10.9. griti Fastener .Torque

- 10.10. LUBRICATION, FLUIDS AND

- 10.11. TRUCK CHASSIS INSPECTION AND

- 11. BATTERY REMOVAL

- 11.1. BAITERY MAINTENANCE

- 12. ACCELERATOR CONTROL

- 12.1. CONTROL DESCRIPTION

- 12.2. MAINTENANCE

- 12.3. CONTROL REMOVAL

- 12.4. CONTROL INSTALLATION

- 13. ELECTRIC MOTOR

- 13.1. ELECTRIC MOTOR MAINTENANCE

- 13.2. MOTOR CLEANLINESS

- 13.3. MOTOR INSULATION

- 13.4. TEST FOR MOTOR INSULATION

- 13.5. RESISTANCE TO GROUND

- 13.6. BRUSH AND COMMUTATOR INSPECTION

- 14. DRIVE MOTOR

- 14.1. MOTOR DESCRIPTION

- 14.2. MAINTENANCE

- 14.3. REMOVAL

- 14.4. DISASSEMBLY

- 14.5. COMPONENTS INSPECTION

- 14.6. ASSEMBLY

- 14.7. INSTALLATION

- 15. LIFT PUMP MOTOR

- 15.1. DESCRIPTION

- 15.2. MAINTENANCE

- 15.3. REMOVAL

- 15.4. DISASSEMBLY

- 15.5. INSPECTION

- 15.6. MOTOR RECONDITIONING

- 15.7. ASSEMBLY

- 15.8. INSTALLATION

- 16. STEER PUMP MOTOR

- 16.1. DESCRIPTION

- 16.2. MAINTENANCE

- 16.3. TROUBLESHOOTING

- 16.4. BRUSH REMOVAL AND INSPECTION

- 16.5. REMCVAL

- 16.6. DISASSEMBLY

- 16.7. ARMATURE REMOVAL

- 16.8. INSPECTION

- 16.9. ARMATURE AND BEARING REPAIR

- 16.10. ASSEMBLY

- 16.11. INSTALLATION

- 17. EV1 00s

- 17.1. SEQUENCE OF OPERATION

- 17.1.1. DRIVE CONTROL

- 17.1.2. Connect the battery.

- 17.1.3. BATTERY INDICATOR AND PUMP MOTOR

- 17.1.4. Hour meter and power steering operation, and S. R. 0.

- 17.1.5. Energizing the Directional Contactors

- 17.1.6. Contactor Closing and Capacitor Precharge

- 17.1.7. Turning on l and 5 RECS

- 17.1.8. C Capicitor Charging and Reactor Operation

- 17.1.9. 2 REC Turn On and l REC Turn Off

- 17.1.10. Flyback

- 17.1.11. Accelerator module, thenal protector and PMT

- 17.1.12. A Contactor Operation

- 17.1.13. Plugging

- 17.2. CHECKING COMPONENTS

- 17.2.1. SPECIFIC GRAVITY TEST

- 17.2.2. CHFCKING l . 3 5 RFCS CSCRS)

- 17.2.3. 2 AND 5 PRESS PACK RECS.

- 17.2.4. TESTING 3 AND 4 RECTIFIERS

- 17.2.5. TO CHECK CAPACITY (I. C

- 17.2.6. CHECKING 22,23,24,25 FILTER BLOCKS

- 17.2.7. CHECK FILTER MOUNTING TERMINAL BLOCK

- 17.2.8. CHECKING SENSOR

- 17.2.9. THERMAL PROTECTOR

- 17.2.10. REACTOR/CHOKE MODULE

- 17.3. CARD ADJUSTMENTS

- 17.4. CARD VOLTAGE CHECKS

- 17.5. CONNECTOR PLUG

- 17.6. 7 PLUG

- 17.7. RECOMMENDED TEST,

- 17.8. Troubleshooting

- 17.8.1. Symptom 1

- 17.8.2. Symptom 2

- 17.8.3. Symptom 3

- 17.8.4. Symptom 4

- 17.8.5. Symptom 5

- 17.8.6. Symptom 6

- 17.8.7. Symptom 7

- 17.8.8. Symptom 8

- 17.8.9. Symptom 9

- 17.8.10. Symptom 10

- 17.8.11. Symptom 11

- 17.8.12. Symptom 12

- 17.9. DESCRIPTION

- 17.10. MAINTENANCE

- 17.11. TROUBLESHOOTING

- 17.12. REMOVAL

- 17.13. DISASSEMBLY

- 17.14. CONTACTOR INSPECTION

- 17.15. ASSEMBLY

- 17.16. INSTALLATION

- 18. EVIOO LXT CONTROL PANEL

- 18.1. FUNCTION SETUP PROCEDURES

- 18.2. DESCRlPllON OF FUNCTION NUMBERS

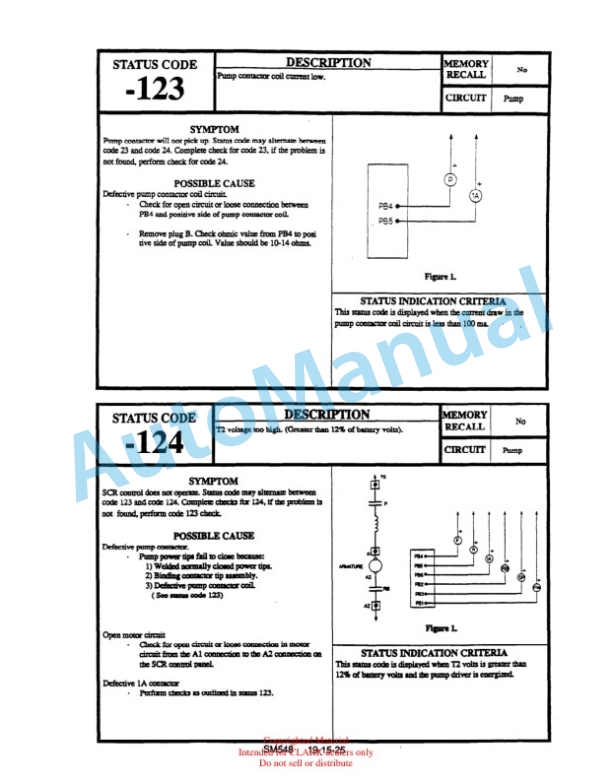

- 18.3. Status Codes

- 18.3.1. Blank, 01

- 18.4. Checking Components

- 18.4.1. Main Logic Card

- 18.4.2. Capacitor 1c

- 18.4.3. SCRS (IREC, 2REC5REC)

- 18.4.4. 4 RECs

- 18.4.5. Thermal Protector

- 18.4.6. Filter Block

- 18.4.7. Choke

- 18.5. REPLACEMENT OF EV100 COMFONENTS

- 18.5.1. lREC, 2REC or SREC

- 18.5.2. Capacitor

- 18.5.3. EC, 23REC and 25REC

- 18.6. Card Settings

- 18.6.1. E235 TRUCKS

- 18.6.2. ECS Std Pump Control

- 18.6.3. ECS Std

- 18.6.4. NP15/15D/20/22

- 19. DRIVE AXLE CCK

- 19.1. GENERAL DESCRIPTION

- 19.2. MAINTENANCE

- 19.3. DRIVE AXLE REMOVAL

- 19.4. DRIVE AXLE OVERHAUL

- 19.4.1. MOTOR ADAPTER

- 19.4.2. WHEEL END DISASSEMBLY

- 19.4.3. DISC BRAKE DISASSEMBLY

- 19.4.4. AXLE ADAPTER DISASSEMBLY

- 19.4.5. AXLE ASSEMBLY NOTES

- 19.4.6. DIFFERENTIAL AND BEARING

- 19.4.7. DRIVE MOTOR ADAPTER

- 19.4.8. AXLE END ASSEMBLY

- 19.5. AXLE INSTALLATION

- 20. DRIVE AXLE Speth

- 20.1. GENERAL DESCRIPTION

- 20.2. SERVICE NOTES

- 20.3. DRIVE AXLE MAINTENANCE

- 20.4. FLUID LEVEL CHECK

- 20.5. REMOVAL

- 20.6. DISASSEMBLY

- 20.7. ASSEMBLY

- 20.8. INSTALLATION

- 20.9. SPECIFICATIONS

- 20.9.1. DIFFERENTIAL BEARING ADJUST

- 20.9.2. PINION GEAR BEARING

- 20.9.3. RING GEAR PINION ADJUSTMENT

- 20.9.4. WHEEL HUB BEARING

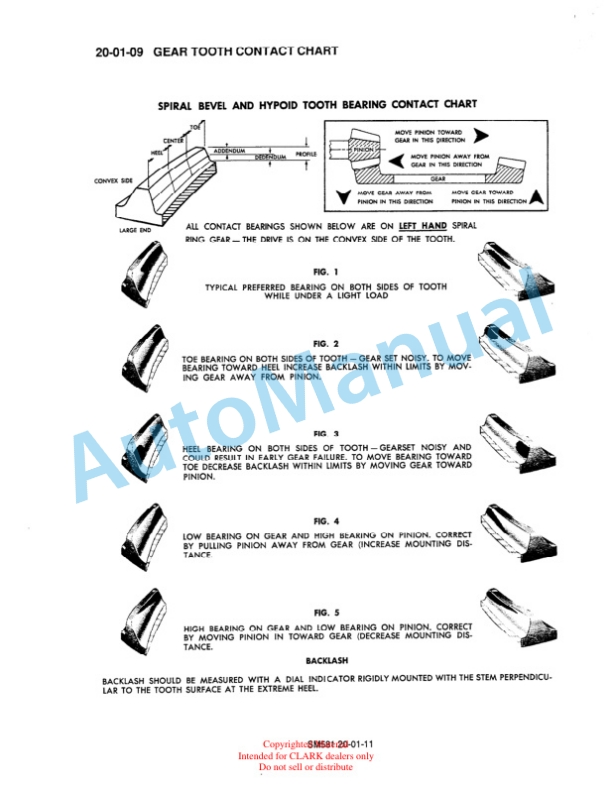

- 20.10. GEAR TOOTH CONTACT CHART

- 21. WHEELS TIRES

- 21.1. SPECIFICATIONS

- 21.2. DRIVE TIRE REPLACEMENT

- 21.3. DRIVE WHEEL i TIRE

- 21.4. STEER TIRE

- 22. BRAKE BLEEDING

- 23. STEERING GEAR

- 23.1. DESCRIPTION

- 23.2. RELIEF PRESSURE CHECK

- 23.3. TROUBLESHOOTING

- 23.4. REMOVAL

- 23.5. DISASSEMBLY

- 23.6. INSPECTION

- 23.7. REASSEMBLY

- 23.8. INSTALLATION

- 24. STEER AXLE

- 24.1. POWER STEERING SYSTEM

- 24.2. RELIEF PRESSURE CHECK

- 24.3. DESCRIPTION

- 24.4. STEER AXLE .REMOVAL

- 24.5. STEER AXLE OVERHAUL

- 24.5.1. STEER AXLE DISASSEMBLY

- 24.5.2. DISASSEMBLY

- 24.5.3. REASSEMBLY

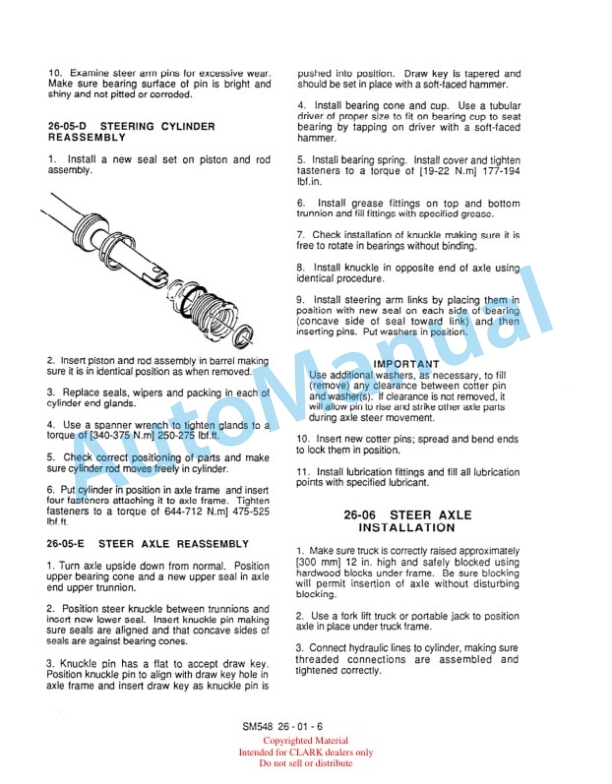

- 24.5.4. STEER AXLE REASSEMBLY

- 24.6. INSTALLATION

- 25. POWER STEERING PUMP

- 25.1. DESCRIPTION

- 25.2. PUMP RELIEF PRESSURE CHECK

- 25.3. TROUBLESHOOTING

- 25.4. PUMP REMOVAL

- 25.5. PUMP DISASSEMBLY

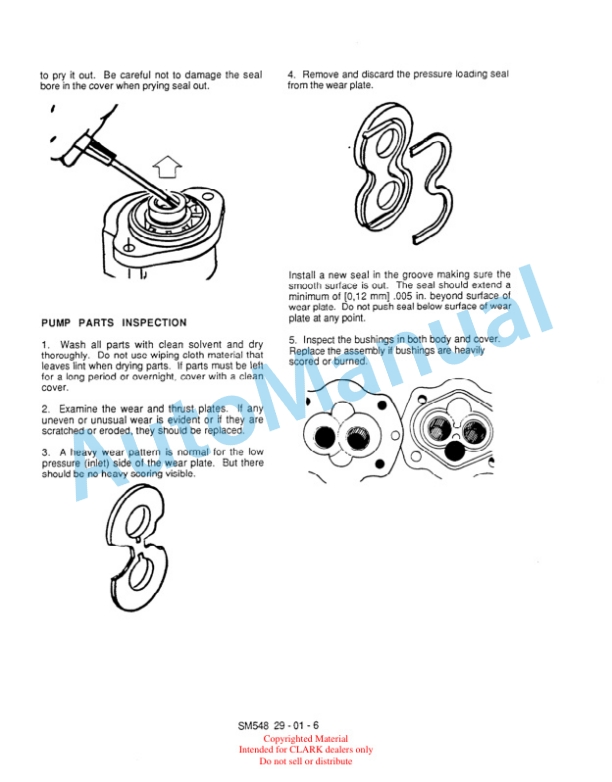

- 25.6. PARTS INSPECTION

- 25.7. PUMP ASSEMBLY

- 25.8. PUMP INSTALLATION

- 26. LIFT PUMP

- 26.1. DESCRIPTION

- 26.2. HYDRAULIC FLUID AND

- 26.3. MAIN HYDRAULIC PUMP

- 26.4. TROUBLESHOOTING

- 26.5. PUMP REMOVAL

- 26.6. PUMP DISASSEMBLY

- 26.7. PARTS INSPECTION

- 26.8. PUMP ASSEMBLY

- 26.9. PiJMP TEST PROCEDURE

- 26.10. PUMP INSTALLATION

- 27. MAIN HYDRAULIC VALVE

- 27.1. GENERAL DESCRIPTION

- 27.2. MAIN VALVE RELIEF

- 27.3. VALVE REMOVAL

- 27.4. VALVE DISASSEMBLY

- 27.5. VALVE INSPECTION

- 27.6. MAIN VALVE ASSEMBLY

- 27.7. INSTALLATION

- 28. TILT CYLINDER

- 28.1. ADJUSTMENT

- 28.2. REMOVAL

- 28.3. DISASSEMBLY

- 28.4. INSPECTION

- 28.5. ASSEMBLY

- 28.6. INSTALLATION

- 29. UPRIGHT

- 29.1. MAINTENANCE

- 29.2. TRIPPLE STAGE

- 29.2.1. SHIM INSPECTION TRIPPLE STAGE

- 29.2.2. CARRIAGE SHIM

- 29.2.3. SHIM INSPECTION

- 29.2.4. DISASSEMBLY

- 29.2.5. REASSEMBLY

- 29.2.6. TROUBLESHOOTING

- 29.2.7. HYDRAULIC CYLINDER

- 29.2.8. SEAL INSTALLATION TOOL

- 29.2.9. LIFT CHAIN

- 29.3. STANDARD UPRIGHT

- 29.3.1. CARRIAGE SHIM

- 29.3.2. INSPECTION STANDARD

- 29.3.3. DISASSEMBLY

- 29.3.4. REASSEMBLY

- 29.3.5. CYLINDER

- 29.3.6. SEAL INSTALLATION TOOL

- 30. COUNTERWEIGHT

- 30.1. MAINTENANCE

- 30.2. REMOVAL

- 30.3. INSTALLATION

- 31. MACHINE JACKING AND BLOCKING

- 31.1. RAISING DRIVE WHEELS

- 31.2. BLOCKING THE UPRIGHT

- 31.3. RAISING REAR OF TRUCK

- 31.4. RAISING ENTIRE TRUCK

- 31.5. RAISING TRUCK WITH A HOIST

- 32. TRUCK DATA PLATE AND DECALS

- 33. SPECIFICATIONS

- 33.1. FILL CAPACITIES

- 33.2. FLUID RECOMMENDATIONS

- 33.3. COUNTERWEIGHT WEIGHTS,

- 33.4. HYDRAULIC SYSTEM

- 33.5. UPRIGHT SPEEDS

- 33.6. MAXIMUM FORK DRIFT

- 33.7. TILT DRIFT

- 33.8. LUBRICANT SPECIFICATIONS

- 33.9. CRITICAL FASTENER TORQUE

- 33.10. CONTROL CARD SPECIFICATIONS

- 33.11. CURRENT DRAW

- 33.12. GROUND TEST

- 33.13. CONTACTORS

- 34. HYDRAULIC DIAGRAM

- 35. ELECTRICAL DIAGRAM

Rate this product

You may also like

Clark Service Manual PDF

Clark C40, 45, 50s, 55s D, C40, 45, 50s, 55s L Service Manual SM-810

$30.00

Clark Service Manual PDF

Clark C 20, 25, 30, 35 L-G, C 20, 25, 30, 32C L Service Manual SM-1044

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

Clark C500-355, C500-H355, C500-Y355, C500-HY355 Gasoline, LPG Service Manual SM-333

$30.00

Clark Service Manual PDF

Clark 5000 Series Powershift Transmission Maintenance and Service Manual SM-54

$30.00