Clark EWP45 Service Manual SM-719

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-719

- Format: PDF

- Size: 3.0MB

- Number of Pages: 178

Category: Clark Service Manual PDF

-

Model List:

- EWP45

- 1. IMPORTANT SAFETY NOTICE

- 2. Arrangement and Use of this Manual

- 3. Contents by Section

- 4. Section Locations

- 5. INTRODUCTION

- 5.1. Truck Presentation.

- 5.2. Truck Side Views

- 5.3. Intended Truck Application

- 5.4. Prohibited Truck Application

- 5.5. Truck Data

- 5.6. Truck Dimensions

- 5.7. Data Plate

- 5.8. Reverser switch

- 5.9. Travel speed/direction selection

- 5.10. Horn switch

- 5.11. Fork raise switch

- 5.12. Fork lower switch

- 5.13. Battery

- 5.14. Load wheel

- 5.15. Drive unit with brake

- 5.16. Electric panel

- 5.17. Circuit breaker

- 5.18. Steering pivot point

- 5.19. Hydraulic unit

- 5.20. Hydraulic electric solenoid valve

- 5.21. Steering control handle

- 5.22. Key switch (toggle switch)

- 5.23. Emergency Disconnect Switch

- 5.24. Battery Receptacle

- 6. GROUP PS PERIODIC SERVICE

- 6.1. SECTION 1 Maintenance ScheduleE

- 6.1.1. Periodic Service and Planned Maintenance

- 6.1.2. Determining Maintenance Intervals

- 6.1.3. CHECK SHEET

- 6.1.4. Visual Inspection

- 6.1.5. Operational Tests

- 6.1.6. Lubrication Chart

- 6.1.7. Oil and Grease Specifi cations

- 6.1.8. Jacking Truck Off the Floor

- 6.2. SECTION 2 The PM Inspection Form

- 6.2.1. PM Report Form

- 7. GROUP 12 BATTERY

- 7.1. SECTION 1 Battery

- 7.1.1. Battery Handling

- 7.1.1.1. Keeping Battery Records

- 7.1.1.2. Install Battery

- 7.1.1.3. REPLACEMENT BATTERIES

- 7.1.1.4. Clean Battery Compartment

- 7.1.1.5. Battery Electrolyte

- 7.1.1.6. Battery Charging

- 7.1.1.7. Battery Maintenance

- 7.1.1.8. Battery Cleaning

- 7.1.1.9. Battery Vents

- 7.1.1.10. Battery Removal

- 7.1.2. Swing Out Battery Pack

- 7.1.3. Battery Cable Routing Diagram

- 7.1.4. Battery Connector

- 7.1.5. Battery Controller/Hourmeter

- 7.1.6. Battery Safety

- 7.1.7. Battery

- 7.1.8. Battery Maintenance

- 7.1.9. Storage

- 7.1.10. Charger Diagram

- 7.1.11. Troubleshooting

- 7.1.12. Electrical

- 7.1.13. Pilot Cell

- 8. GROUP 13 ELECTRICAL CONTROLS

- 8.1. SECTION 1 Electrical Controls

- 8.2. Directional Control Housing

- 8.3. Driver Protection (Reverser) Assembly

- 8.4. Direction Control Switches

- 8.5. Raise, Lower, and Horn Switches

- 8.6. Potentiometer

- 9. GROUP 14 ELECTRICAL

- 9.1. Electrical Functions

- 9.2. Electrical Panel Components

- 9.3. Wiring Schematic

- 9.4. Start / Stop Switches

- 10. GROUP 16 ELECTRIC MOTORS

- 10.1. General Information

- 10.2. Pump Motor

- 10.3. Inspection and Troubleshooting

- 10.4. Brush Inspection

- 10.5. Drive Motor Brush

- 10.6. Drive Motor Removal

- 10.7. Component Repair

- 10.8. Motor Disassembly

- 10.9. Motor Inspection

- 10.10. Assembly/Testing

- 11. GROUP 19 MOTOR CONTROLS

- 11.1. OVERVIEW

- 11.2. CONNECTIONS

- 11.3. PROGRAMMER MENUS

- 11.4. PROGRAM MENU

- 11.5. MONITOR MENU

- 11.6. SYSTEM FAULTS MENU

- 11.7. DIAGNOSTICS AND TROUBLESHOOTING

- 11.7.1. Troubleshooting Chart

- 11.8. STATUS LED DIAGNOSTICS

- 11.9. CONTROLLER MAINTENANCE

- 11.10. VEHICLE DESIGN CONSIDERATIONS

- 11.11. ELECTROSTATIC DISCHARGE (ESD)

- 11.12. HANDHELD PROGRAMMER

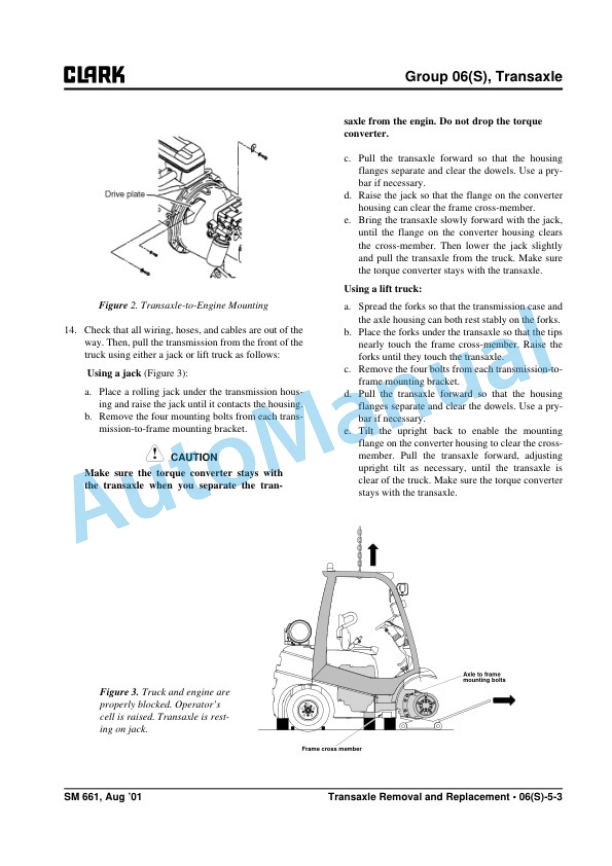

- 12. GROUP 20 DRIVE UNIT

- 12.1. System Description

- 12.2. Troubleshooting

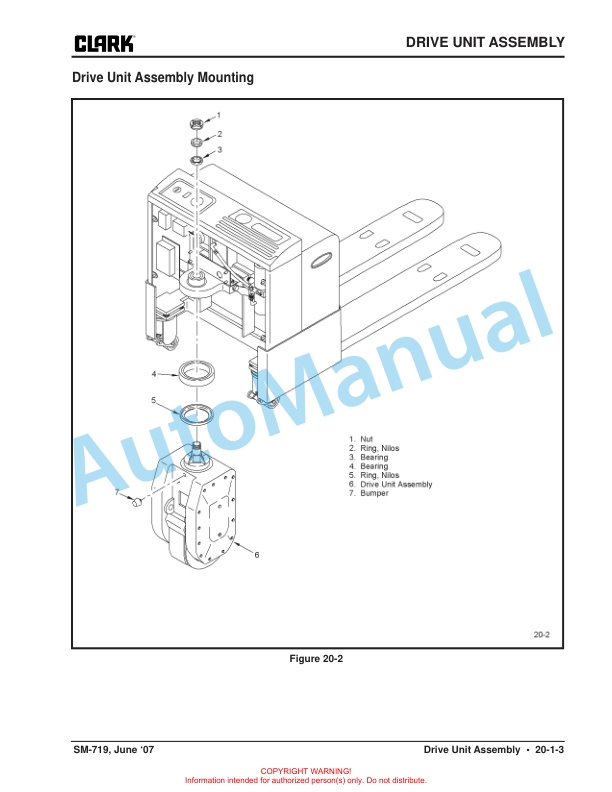

- 12.3. Drive Unit Assembly Mounting

- 12.4. Drive Unit Repair

- 12.4.1. Disassembly

- 12.4.2. Reassembly

- 12.5. Axle Seal

- 13. GROUP 23 BRAKE SYSTEM

- 13.1. Brake Theory of Operation

- 13.2. Brake System

- 13.3. Brake Adjustment

- 13.4. Brake Shoe Removal / Installation

- 13.5. Brake Switch

- 13.6. Drive Wheel

- 14. GROUP 25 CASTER ASSEMBLY

- 15. GROUP 26 STEERING

- 15.1. Steering Stem

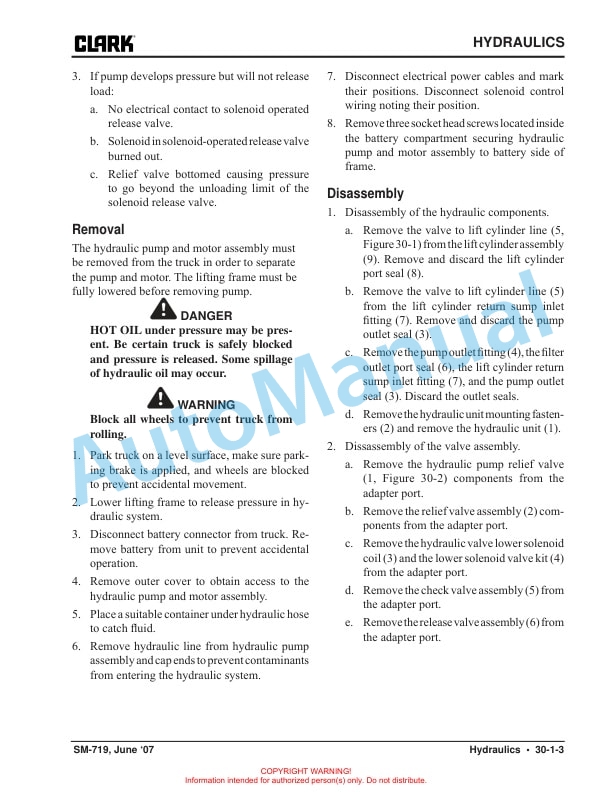

- 16. GROUP 30 HYDRAULICS

- 16.1. General

- 16.2. Adjustments

- 16.3. Installation

- 16.4. Assembly

- 16.5. Disassembly

- 16.6. Removal

- 16.7. Troubleshooting

- 17. GROUP 34 LIFT CYLINDER

- 17.1. Lift Cylinder Removal

- 17.2. Installation

- 18. GROUP 35 LIFT LINKAGE

- 18.1. Operational Check

- 18.2. Bearing Identifi cation

- 18.3. Lift Linkage Removal

- 18.3.1. Separate Lift Frame from Main Frame

- 18.3.2. Elevate and block truck as shown

- 18.3.3. Block Lift Frame and Main Frame

- 18.3.4. Remove Cylinder Pivot Shaft

- 18.3.5. Remove Upper Link Arms

- 18.3.6. Remove Left and Right Lower Link Arms

- 18.3.7. Disconnect Load Wheel Bracket

- 18.3.8. Bearing Removal

- 18.3.9. Cleaning and Inspections

- 18.3.10. Bearing Installation

- 18.4. Bearing Press Specifi cations

- 18.5. Lower Link Arms

- 18.6. Load Wheels

- 19. GROUP 39 SHEET METAL

- 20. GROUP 40 TRUCK SPECIFICATIONS

Rate this product

You may also like

Clark Service Manual PDF

Clark C500-355, C500-H355, C500-Y355, C500-HY355 Gasoline, LPG Service Manual SM-333

$30.00

Clark Service Manual PDF

Clark C20, 25, 30, 35 D, L, G, C20, 25, 30, 32C L Service Manual SM-996

$30.00

Clark Service Manual PDF

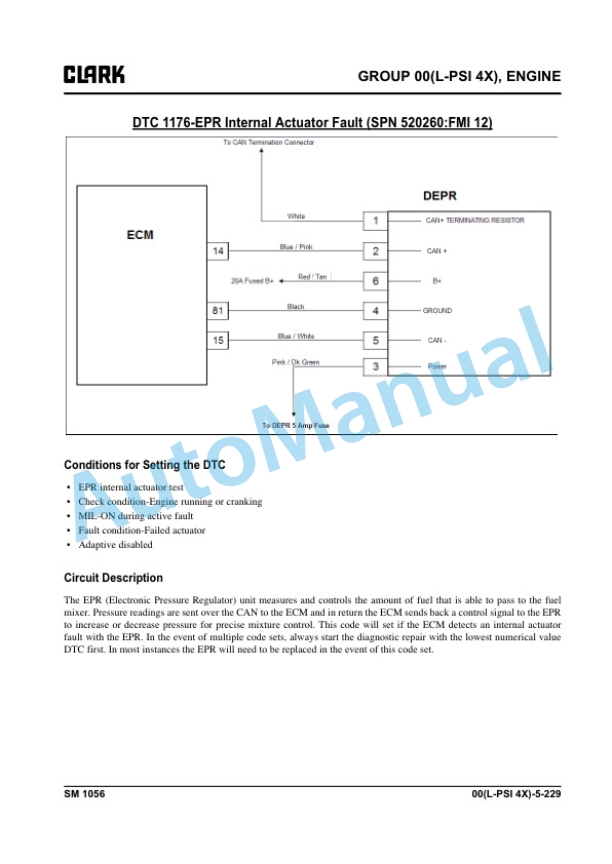

Clark C40, 45, 50s, 55s D, C40, 45, 50s, 55s L Service Manual SM-810

$30.00