Clark Fork Lift CER10-13, CER14-15-18, CER20-25 Operation and Maintenance Manual OM-694

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OM-694

- Format: PDF

- Size: 14.0MB

- Number of Pages: 92

Category: Clark Operator Manual PDF

-

Model List:

- Fork Lift CER10-13

- Fork Lift CER14-15-18

- Fork Lift CER20-25

- 1. CONTENTS

- 1.1. PREFACE

- 1.2. SAFETY

- 1.3. GENERAL

- 1.3.1. DESIGNATED WORKS

- 1.3.2. CHARACTERISTICS OF THE MACHINE

- 1.4. DRIVING LICENSE

- 1.5. NAME PLATE

- 1.5.1. LOCATION OF NAME PLATES

- 1.5.2. LOCATION OF MARKING PLATE

- 1.6. BASIC PRECAUTIONS

- 1.7. SAFETY TRAVELING

- 1.8. HOW TO USE THE BATTERY AND CAUTIONS FOR CHARGING

- 1.9. CAUTIONS WHEN OPERATING THE MACHINE

- 1.10. TRANSPOTATION

- 1.10.1. REACH CYLINDER PIN

- 1.10.2. MAIN LIFT TILT RETURN HOSE

- 1.10.3. FORK LOAD BACKREST

- 1.11. ATTACHED POSITION OF SAFETY DECALS

- 1.11.1. ATTACHED POSITION OF SAFETY DECALS

- 1.11.2. CONTENTS OF SAFETY DECALS

- 2. OPERATION

- 2.1. GENERAL LOCATIONS

- 2.2. DRIVING AND OPERATING

- 2.2.1. LCD DISPLAY PANEL AND CONTROLLER

- 2.2.2. OPERATING

- 2.3. BATTERY DHARGING

- 2.3.1. NORMAL CHARGING

- 2.3.2. EQUAL CHARGING

- 2.3.3. SUPPLEMENTARY CHARGING

- 2.3.4. CHARGING FOR LONG TERM STORAGE

- 2.3.5. CHARGING METHOD

- 2.4. STATIONARY BATTERY

- 2.4.1. CHARGING METHOD (NORMAL CHARGING)

- 2.5. BATTERY REPLACEMENT

- 2.6. LEVEL OF BATTERY ELECTROLYTE AND READING GRAVIMETER

- 2.6.1. LEVEL OF BATTERY ELECTROLYTE

- 2.6.2. HOW TO READ THE GRAVIMETER

- 2.6.3. SPECIFIC GRAVITY OF ELECTROLYTE AND CONVERSION TABLE OF TEMPERATURE COMPENSATION

- 2.7. SOUND INFORMATION

- 2.7.1. SOUND LEVEL

- 2.8. CHECK BEFORE WORKING

- 2.8.1. CHECKING POINTS

- 2.8.2. CHECKING METHODS BEFORE STARTING OPERATION

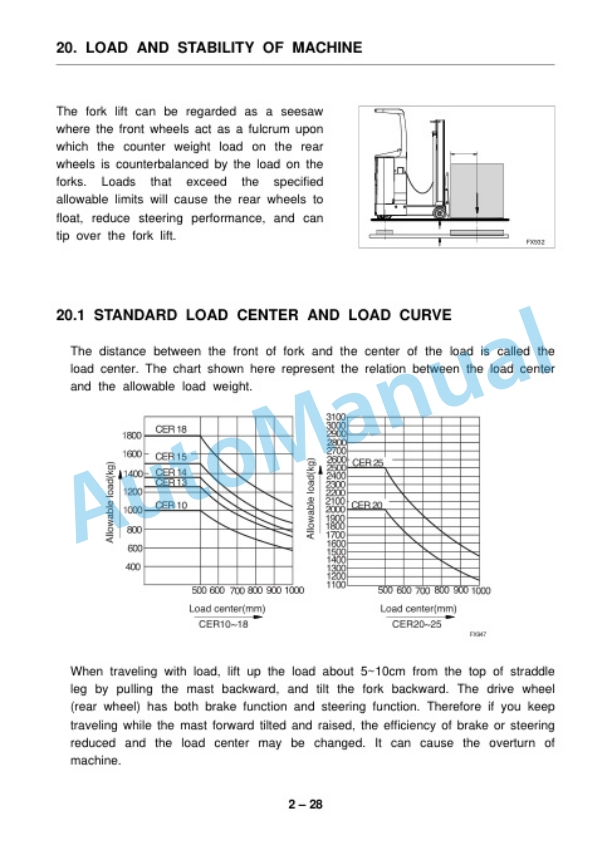

- 2.9. LOAD AND STABILITY OF MACHINE

- 2.9.1. STANDARD LOAD CENTER AND LOAD CURVE

- 2.9.2. STABILITY OF MACHINE

- 2.10. OPERATING AND UNLOADING

- 2.10.1. PREPARATION FOR STARTING

- 2.10.2. OPERATING

- 3. INSPECTIONMAINTENANCE

- 3.1. INSPECTION AND MAINTENANCE

- 3.1.1. GENERAL CAUTIONS FOR INSPECTION AND MAINTENANCE

- 3.1.2. INSPECTION EVERY WEEK (50HR)

- 3.1.3. MEASURING SPECIFIC GRAVITY

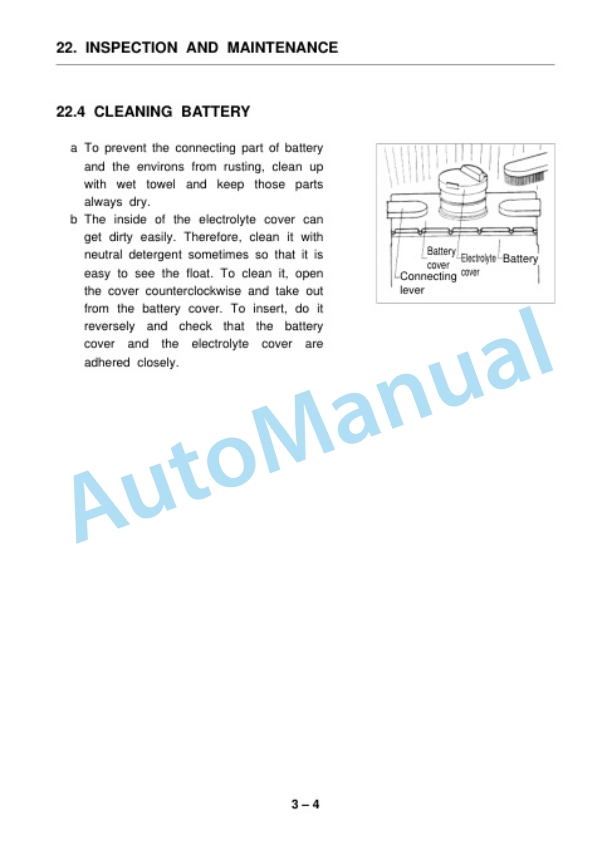

- 3.1.4. CLEANING BATTERY

- 3.1.5. INSPECTION EVERY MONTH (200HR)

- 3.1.6. INSPECTION EVERY 2 MONTHS (400 HR)

- 3.1.7. INSPECTON EVERY 3 MONTHS (600 HR)

- 3.1.8. INSPECTION OF CARBON BRUSH

- 3.2. LUBRICATION CHART

- 3.2.1. LUBRICATING POINT

- 3.2.2. SPECIFIED LUBRICATION CHART

- 3.3. GUIDE TO REPLACE AND REPAIR PARTS

- 3.3.1. HOW TO REPLACE THE CONTACTOR

- 3.3.2. HOW TO ADJUST THE BRAKE

- 3.4. REFRIGERATING SPECIFIED VEHICLE

- 3.4.1. COUNTERMEASURE FOR ANTICORROSION

- 3.4.2. COUNTERMEASURE FOR LOW TEMPERATURE

- 3.4.3. USAGE OF NO SLIP TIRE

- 4. SPECIFICATIONS

- 4.1. SPECIFICATIONS

- 4.1.1. DIMENSIONS

- 4.1.2. TRUCK SPECIFICATIONS

- 4.1.3. BATTERY SPECIFICATIONS

- 4.1.4. TIGHTENING TORQUE OF EACH PART

Rate this product

You may also like

Clark Operator Manual PDF

Clark C 60 B, C 70 B, C 80 B, CY 60 B, CY 70 B, CY 80 B Diesel Operator Manual O-255 2nd

$20.00

Clark Operator Manual PDF

Clark C 15-35 D, L, G, C 15-32 C L, G, C 40-55s D, L, C 60-80 D, C 60-75 L Operator Manual OM-663

$20.00

Clark Operator Manual PDF

Clark C500 Y 180-200-225S-225L-250S-250L-300S-300L-350 Operator Manual OM-575

$20.00

Clark Operator Manual PDF

$20.00

Clark Operator Manual PDF

$20.00