Clark GCS Service Manual SM-520R

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-520R

- Format: PDF

- Size: 124.0MB

- Number of Pages: 895

Category: Clark Service Manual PDF

-

Model List:

- GCS

- 1. SERVICE MANUAL SM520R

- 2. Foreword

- 3. Contents

- 4. About This Manual

- 5. Part 1 General Information

- 5.1. Safe Maintenance Practices

- 5.2. Safety Signs and Messages

- 5.3. General Precautions

- 5.4. Product Identification

- 6. Part 2 Specifications

- 6.1. Service Specifications

- 6.2. Product Specification Changes

- 7. Part 3 Planned Maintenance

- 7.1. PM Schedules

- 7.2. Planned Maintenance Procedures PM Program

- 7.3. Machine Jacking and Blocking

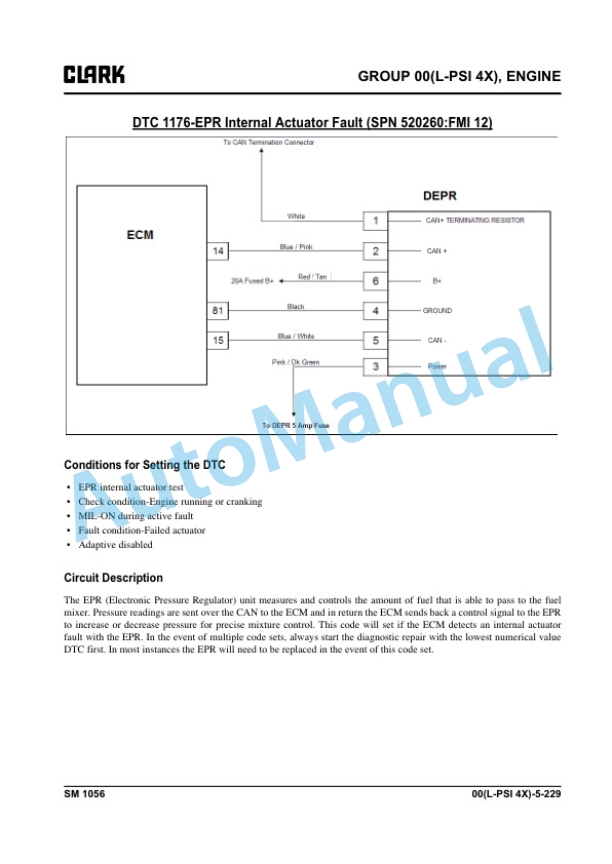

- 8. Part 4 Engine

- 8.1. Engine Maintenance Oil and Filter Change

- 8.2. Engine Troubleshooting Gasoline/LPG and Diesel

- 8.3. Engine TuneUp Gasoline/LPG n Diesel

- 8.4. Ignition Timing Procedures

- 8.5. Engine Valve Clearance Adjustment

- 8.6. Engine Compression Pressure Test (Gasoline/LPG Diesel)

- 8.7. Engine RPM, Vacuum Stall Tests

- 8.8. Cooling System

- 8.9. Engine Air Cleaner

- 8.10. Engine Adjustments

- 8.11. Engine Removal

- 8.12. Engine Components GC(P)X, MB, MC Models 4G54 2.6L Engine

- 8.13. Engine Components G(P)XC, I Models TM(D)27 2.7L Engine

- 8.14. Engine Components WC Models D176GA 2.9L Engine

- 9. Part 5 Fuel System

- 9.1. Fuel Tank Installation Gasoline/Diesel

- 9.2. Fuel Systems Maintenance

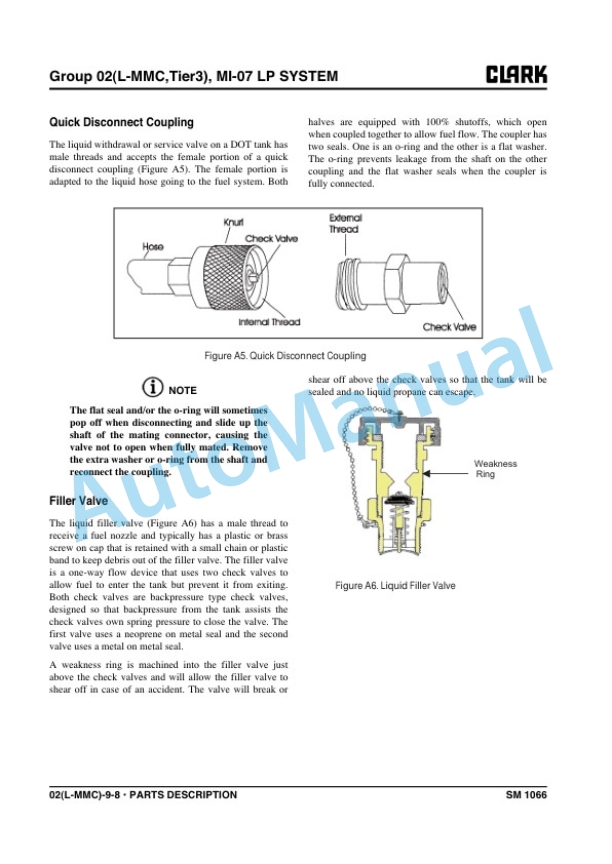

- 9.3. LPG Fuel System

- 9.4. Diesel Fuel Injection System TMD27 2.7L Diesel Engine

- 9.5. Carburetor Gasoline 4654 2.6L Engine

- 9.6. Carburetor Overhaul Gasoline TM27 2.7L Engine

- 9.7. Carburetor Overhaul Gasoline D176GA 2.9L Engine

- 9.8. LPG Carburetor IMPCO Model CA1 00 Carburetor Assemblies

- 9.9. LPG Carburetor IMPCO Model CA50 Carburetor Assembly

- 9.10. LPG VaporizerRegulator IMPCO Model J Converter

- 9.11. LPG Fuel LockOff Valve IMPCO Model VFF 30

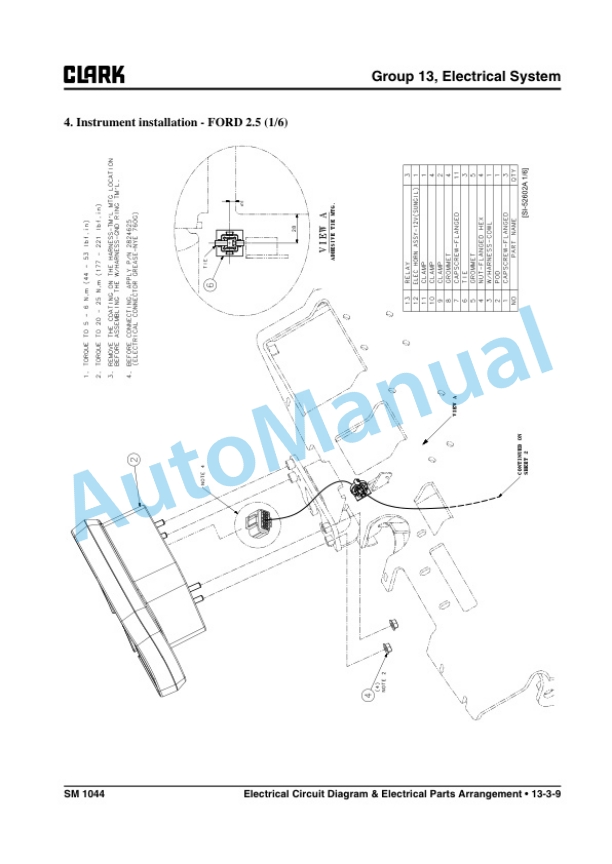

- 10. Part 6 Electrical System

- 10.1. Electrical System Wiring

- 10.2. Ignition System Troubleshooting

- 10.3. Ignition System Maintenance

- 10.4. Ignition System 4G54 2.6L Engine

- 10.5. Ignition System TM27 2.7L Engine

- 10.6. Ignition System D176GA 2.9L Engine

- 10.7. Electronic Ignition Conversion PerLux /gnito for D176GA 2.9L Engine

- 10.8. Alternator Maintenance

- 10.9. Alternator Delco 103

- 10.10. Alternator Motorola 9DB

- 10.11. Starting System Troubleshooting

- 10.12. Starter Motor Troubleshooting

- 10.13. Starter Maintenance Delco WC Model, D176GA 2.9L Engine

- 10.14. Starter Maintenance DirectDrive (Type 1) 4G54 2.6L Engine

- 10.15. Starter Maintenance ReductionType (Type 2) 4654 2.6L Engine

- 10.16. Starter Maintenance G( P)XC, I Models, TM(D)27 2.7L Engine

- 11. Part 7 Transaxle

- 11.1. SPIRAL BEVEL AND HYPOID TOOTH BEARING CONTACT CHART

- 11.2. Transaxle Maintenance Fluid and Filter Change

- 11.3. Transmission Troubleshooting

- 11.4. Transmission Pressure Checks

- 11.5. Transaxle Mounting Removal/Installation

- 11.6. Transaxle Overhaul General Procedures

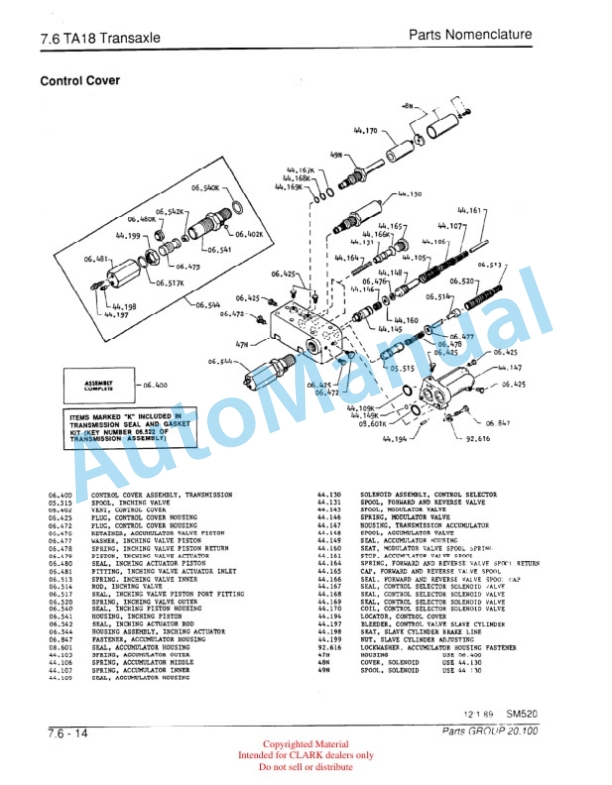

- 11.7. TAI 8 Transaxle

- 11.8. HR500 Transaxle 11FHR510/511 lSpeed

- 11.9. HR600 Transaxles 11 FHR61 O/61 l/61 2 1 Speed 11 FH R620/621 2Speed

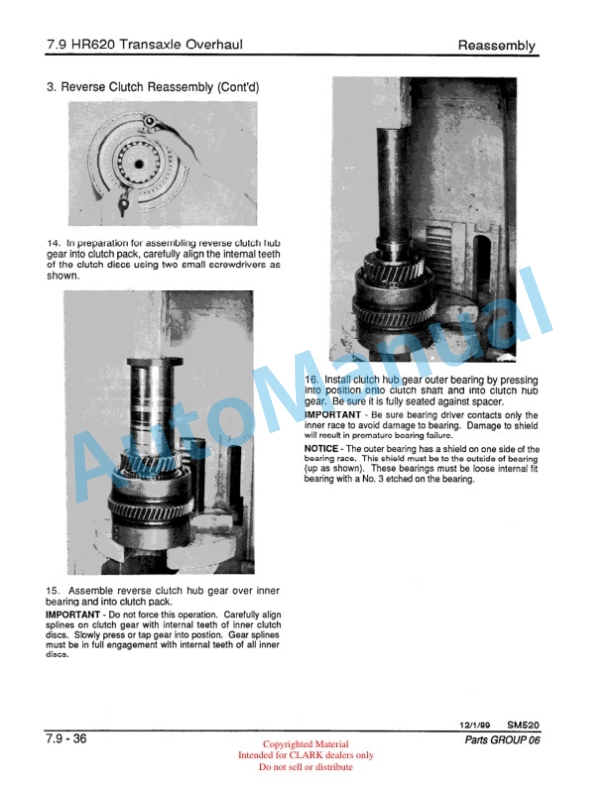

- 11.10. HR620 Transmission Overhaul 11 FHR620/621 2speed transaxle ()

- 11.11. HR610 Transmission Overhaul 11FHR610/611/612 lspeed transaxle

- 11.12. Drive Axle Overhaul HR600 Series Transaxles

- 11.13. Directional Control Linkage Transmission Shift Controls

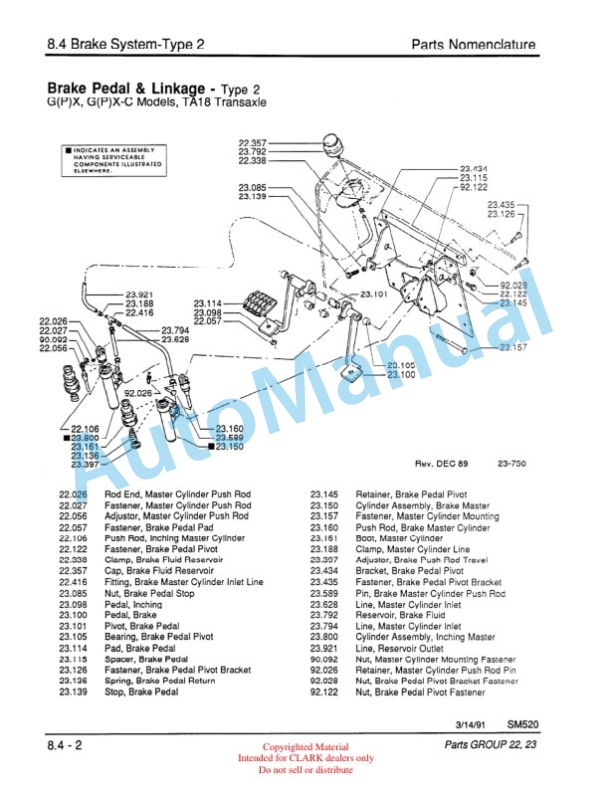

- 12. Part 8 Brakes

- 12.1. Service Brake Inching Systems

- 12.2. Brake Inching System Type 1 Single Master Cylinder

- 12.3. Brake Bleeding Procedures Type 1 Single Master Cylinder

- 12.4. Brake Inching System

- 12.5. Brake Bleeding Type 2 Dual Master Cylinders TA18 Transaxle

- 13. Part 9 Steering System

- 13.1. Power Steering Lines Installation MB, MC, WC, I Models (Type 1/7A) Steer Axle

- 13.2. Steering System/Main Hydraulic Lines HR500 HR600 Transaxle

- 13.3. Power Steering Lines Installation G(P)X, G(P)XC, MC, I Models (Type 2) Steer Axle

- 13.4. Power Steering System Relief Pressure Setting

- 13.5. Steering Column and Valve (Steering Gear)

- 13.6. Steering Column Removal/Installation

- 13.7. Steering Valve Overhaul (Steering Control Unit)

- 13.8. Steer Axles

- 13.9. Steer Axle Wheel Bearing Maintenance

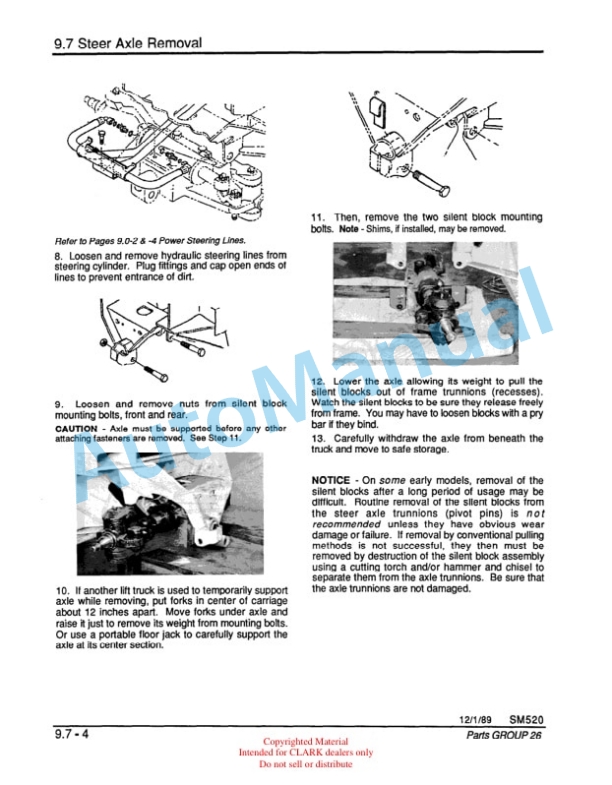

- 13.10. Steer Axle Removal/Installation

- 13.11. Steer Axle Overhaul Type 1)

- 13.12. Steering Cylinder Overhaul (Type 1 IA, Style 7,2 3)

- 13.13. Steer Axle Overhaul (Type 1A)

- 13.14. Steering Cylinder Overhaul (Type IA, Style 4)

- 13.15. Steer Axle Overhaul (Type 2)

- 13.16. Steering Cylinder Overhaul (Type 2 Steer Axle)

- 14. Part 10 Hydraulic System

- 14.1. Hydraulic System Schematic Diagram GC(P)X, GCS/GPS 1730

- 14.2. Main Hydraulic System

- 14.3. Description and Operation

- 14.4. Parts Nomenclature Steering Priority Demand (Flow Control) Valve

- 14.5. Parts Nomenclature Main Hydraulic Lines G(P)X, G(P)XC Models TA18 Transaxle

- 14.6. Parts Nomenclature Main Hydraulic/Steering Lines G(P)X, G(P)XC Models TA18 Transaxle

- 14.7. Parts Nomenclature Main Hydraulic Lines MB, MC, WC, I Models HR500,HR600Transaxle

- 14.8. Parts Nomenclature Main Hydraulic Lines MB, MC, WC, I Models HR500, HR600 Transaxle

- 14.9. Parts Nomenclature Lift and Tilt Lines

- 14.10. Hydraulic Sump Fluid and Filter Change

- 14.11. Hydraulic System Relief Pressure Check Adjustment

- 14.12. Main Hydraulic Pump Removal/Installation

- 14.13. Main Hydraulic Pump Overhaul

- 14.14. Main Hydraulic Control Valve Removal/Installation

- 14.15. Main Hydraulic Valve Overhaul

- 14.16. Tilt Cylinder Maintenance

- 15. Part 11 Wheels Tires

- 15.1. Cushion Tire Nomenclature

- 15.2. Pneumatic Tire Nomenclature

- 15.3. Pneumatic Tire Nomenclature

- 15.4. Cushion Tire and Wheel Maintenance

- 15.5. Pneumatic Tire and Wheel Maintenance

- 16. Part 12 Counterweight Chassis

- 16.1. Counterweight Maintenance

- 16.2. Chassis Components

- 17. Part 13 Uprights

- 17.1. Upright Maintenance

- 17.2. High Visibility Standard Upright (HIVIS Std)

- 17.3. Triple Stage Upright (TSU)

- 18. Part 14 Index

- 18.1. Listing by Section Contents

- 18.2. Subject Index

Rate this product

You may also like

Clark Service Manual PDF

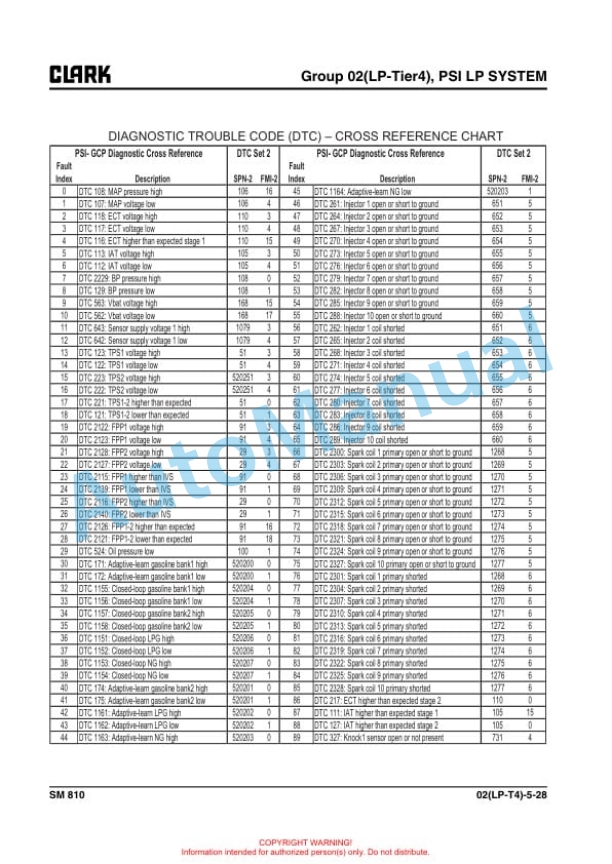

Clark C40, 45, 50s, 55s D, C40, 45, 50s, 55s L Service Manual SM-810

$30.00

Clark Service Manual PDF

Clark C20, 25, 30, 35 D, L, G, C20, 25, 30, 32C L Service Manual SM-996

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

Clark C15s D-L, C 18s D-L, C 20s D-L, C15s C-L, C 18s C-L, C 20s C-L Service Manual SM-1066

$30.00

Clark Service Manual PDF

Clark C 20, 25, 30, 35 L-G, C 20, 25, 30, 32C L Service Manual SM-1044

$30.00