Clark NS, NP 246 Service and Adjustment Manual SM-538

$30.00

- Type Of Manual: Service and Adjustment Manual

- Manual ID: SM-538

- Format: PDF

- Size: 11.3MB

- Number of Pages: 188

Category: Clark Service Manual PDF

-

Model List:

- NS 246

- NP 246

- 1. SERVICE MANUAL SM538

- 2. CONTENTS

- 3. FOREWORD

- 4. HOW TO USE THIS MANUAL

- 5. PICTORIAL INDEX

- 6. SAFETY AND OPERATIONAL CHECKS

- 7. RECOMMENDED PLANNED MAINTENANCE AND LUBRICATION SCHEDULE

- 8. SAFETY SIGNS AND SAFETY MESSAGES

- 9. USER SAFE MAINTENANCE PRACTICES

- 10. PM PLANNED MAINTENANCE PROGRAM

- 10.1. GENERAL

- 10.2. VISUAL INSPECTION

- 10.3. FUNCTIONAL TESTS

- 10.4. TEST DRIVE THE TRUCK

- 10.5. AIR CLEANING

- 10.6. CRITICAL FASTENER TORQUE CHECK

- 10.7. LUBRICATION, FLUIDS AND FILTERS

- 11. BATTERY HANDLING AND CARE

- 11.1. BATTERY HANDLING

- 11.2. BATTERY REMOVAL PROCEDURE

- 11.3. BATTERY MAINTENANCE

- 11.4. BATTERY RECORDS

- 11.5. FOR MAXIMUM BATTERY LIFE

- 11.6. BATTERY INSTALLATION

- 12. ACCELERATOR CONTROL SYSTEM

- 12.1. ACCELERATOR DESCRIPTION

- 12.2. ACCELERATOR TROUBLESHOOTING

- 12.3. CONTROL REMOVAL

- 12.4. HAND MASTER SWITCH (HMS) DISASSEMBLY.

- 12.5. MASTER SWITCH ASSEMBLY

- 12.6. CONTROL INSTALLATION

- 13. ELECTRIC MOTOR GENERAL MAINTENANCE

- 14. DRIVE MOTOR

- 14.1. MOTOR DESCRIPTION

- 14.2. DRIVE MOTOR MAINTENANCE

- 14.3. DRIVE MOTOR REMOVAL

- 14.4. DRIVE MOTOR DISASSEMBLY

- 14.5. DRIVE MOTOR INSPECTION

- 14.6. DRIVE MOTOR ASSEMBLY

- 14.7. DRIVE MOTOR INSTALLATION

- 15. LIFT PUMP MOTOR

- 15.1. LIFT PUMP MOTOR DESCRIPTION

- 15.2. LIFT PUMP MOTOR MAINTENANCE

- 15.3. LIFT PUMP MOTOR REMOVAL

- 15.4. LIFT PUMP MOTOR DISASSEMBLY

- 15.5. LIFT PUMP MOTOR INSPECTION

- 15.6. MOTOR ASSEMBLY

- 15.7. PUMP MOTOR INSTALLATION

- 16. STEER PUMP MOTOR

- 16.1. STEER PUMP MOTOR DESCRIPTION

- 16.2. STEER PUMP MOTOR MAINTENANCE

- 16.3. STEER PUMP MOTOR REMOVAL

- 16.4. STEER PUMP MOTOR DISASSEMBLY

- 16.5. STEER PUMP MOTOR INSPECTION

- 16.6. STEER PUMP MOTOR ASSEMBLY

- 16.7. STEER PUMP MOTOR INSTALLATION

- 17. SCR CONTROL, RECOMMENDED TEST, TEST EQUIPMENT AND PROCEDURES

- 18. SCR, SYMPTOM CHARTS

- 19. CONTROL PANEL

- 19.1. CONTROL PANEL DESCRIPTION

- 19.2. CONTROL PANEL MAINTENANCE

- 19.3. CONTROL TROUBLESHOOTING

- 19.4. SCR CONTACTOR PANEL AND RELAY PANEL REMOVAL

- 19.5. CONTROL PANEL DISASSEMBLY

- 19.6. CONTACTOR INSPECTION

- 19.7. CONTROL PANEL ASSEMBLY

- 19.8. CONTROL PANEL INSTALLATION

- 20. DRIVE UNIT

- 20.1. GENERAL DESCRIPTION

- 20.2. DRIVE UNIT MAINTENANCE

- 20.3. DRIVE UNIT REMOVAL

- 20.4. DRIVE UNIT DISASSEMBLY

- 20.5. DRIVE UNIT INSPECTION

- 20.6. DRIVE UNIT ASSEMBLY

- 20.7. DRIVE UNIT INSTALLATION

- 21. WHEELS AND TIRES

- 21.1. DRIVE TIRE SPECIFICATIONS

- 21.2. DRIVE TIRE REPLACEMENT

- 22. BRAKE

- 22.1. BRAKE DESCRIPTION

- 22.2. BRAKE ADJUSTING PROCEDURE

- 22.3. BRAKE REMOVAL

- 22.4. BRAKE DISASSEMBLY

- 22.5. BRAKE ASSEMBLY

- 22.6. BRAKE INSTALLATION

- 23. CASTER ADJUSTMENT PROCEDURE

- 23.1. CASTER DESCRIPTION

- 23.2. CASTER REMOVAL

- 23.3. CASTER SERVICE/ ADJUSTMENT

- 24. STEERING SYSTEM

- 24.1. POWER STEERING SYSTEM

- 24.2. TORQUE GENERATOR REMOVAL.

- 24.3. SHAFT/GEAR REMOVAL

- 24.4. TORQUE GENERATOR DISASSEMBLY

- 24.5. TORQUE GENERATOR INSPECTION

- 24.6. TORQUE GENERATOR ASSEMBLY

- 24.7. SHAFT/GEAR INSTALLATION

- 24.8. TORQUE GENERATOR INSTALLATION

- 25. POWER STEERING PUMP

- 25.1. GENERAL DESCRIPTION

- 25.2. RELIEF PRESSURE CHECK

- 25.3. PUMP TROUBLESHOOTING

- 25.4. PUMP REMOVAL

- 25.5. PUMP DISASSEMBLY

- 25.6. PUMP INSPECTION

- 25.7. PUMP ASSEMBLY

- 25.8. PUMP INSTALLATION

- 26. HYDRAULIC LIFT PUMP

- 26.1. PUMP OVERVIEW

- 26.2. PUMP MAINTENANCE

- 26.3. LIFT PUMP REMOVAL

- 26.4. PUMP DISASSEMBLY

- 26.5. PUMP PARTS INSPECTION

- 26.6. PUMP ASSEMBLY

- 26.7. PUMP INSTALLATION

- 27. MAIN HYDRAULIC VALVE

- 27.1. GENERAL DESCRIPTION

- 27.2. MAIN VALVE RELIEF PRESSURE CHECK ADJUSTMENT

- 27.3. MAIN VALVE TESTING

- 27.4. MAIN VALVE TROUBLESHOOTING

- 27.5. MAIN VALVE REMOVAL

- 27.6. VALVE DISASSEMBLY

- 27.7. MAIN VALVE INSPECTION

- 27.8. MAIN VALVE ASSEMBLY

- 27.9. MAIN VALVE INSTALLATION

- 28. TILT CYLINDER MODEL C

- 28.1. TILT CYLINDER ADJUSTMENT

- 28.2. TILT CYLINDER REMOVAL

- 28.3. TILT CYLINDER DISASSEMBLY

- 28.4. CYLINDER ASSEMBLY

- 28.5. TILT CYLINDER INSTALLATION

- 29. REACH CYLINDER MODEL C

- 29.1. REACH CYLINDER ADJUSTMENT

- 29.2. REACH CYLINDER REMOVAL

- 29.3. REACH CYLINDER DISASSEMBLY.

- 29.4. REACH CYLINDER ASSEMBLY

- 29.5. REACH CYLINDER INSTALLATION

- 30. LIFT CYLINDER MODEL D

- 30.1. LIFT CYLINDER REMOVAL (STANDARD UPRIGHT)

- 30.2. LIFT CYLINDER DISASSEMBLY (STANDARD UPRIGHT)

- 30.3. LIFT CYLINDER ASSEMBLY (STANDARD UPRIGHT)

- 30.4. LIFT CYLINDER INSTALLATION (STANDARD UPRIGHT)

- 30.5. LIFT CYLINDER REMOVAL (THREE STAGE UPRIGHT)

- 30.6. LIFT CYLINDER DISASSEMBLY (THREE STAGE UPRIGHT)

- 30.7. LIFT CYLINDER ASSEMBLY (THREE STAGE UPRIGHT)

- 30.8. LIFT CYLINDER INSTALLATION (THREE STAGE UPRIGHT)

- 31. TILT CYLINDER NP300D

- 31.1. TILT CYLINDER ADJUSTMENT

- 31.2. TILT CYLINDER REMOVAL

- 31.3. TILT CYLINDER DISASSEMBLY.

- 31.4. CYLINDER ASSEMBLY

- 31.5. TILT CYLINDER INSTALLATION

- 32. TILT CYLINDER NS300D

- 32.1. TILT CYLINDER ADJUSTMENT

- 32.2. TILT CYLINDER REMOVAL

- 32.3. TILT CYLINDER DISASSEMBLY.

- 32.4. CYLINDER ASSEMBLY

- 32.5. TILT CYLINDER INSTALLATION

- 33. REACH CYLINDER NP300D

- 33.1. REACH CYLINDER ADJUSTMENT

- 33.2. REACH CYLINDER REMOVAL

- 33.3. REACH CYLINDER DISASSEMBLY.

- 33.4. REACH CYLINDER ASSEMBLY

- 33.5. REACH CYLINDER INSTALLATION

- 34. UPRIGHT REMOVAL MODEL C

- 34.1. UPRIGHT REMOVAL

- 34.2. UPRIGHT INSTALLATION

- 35. UPRIGHT MAINTENANCE MODEL C

- 35.1. UPRIGHT MAINTENANCE

- 35.2. UPRIGHT ROLLER CHECK AND ADJUSTMENT PROCEDURES

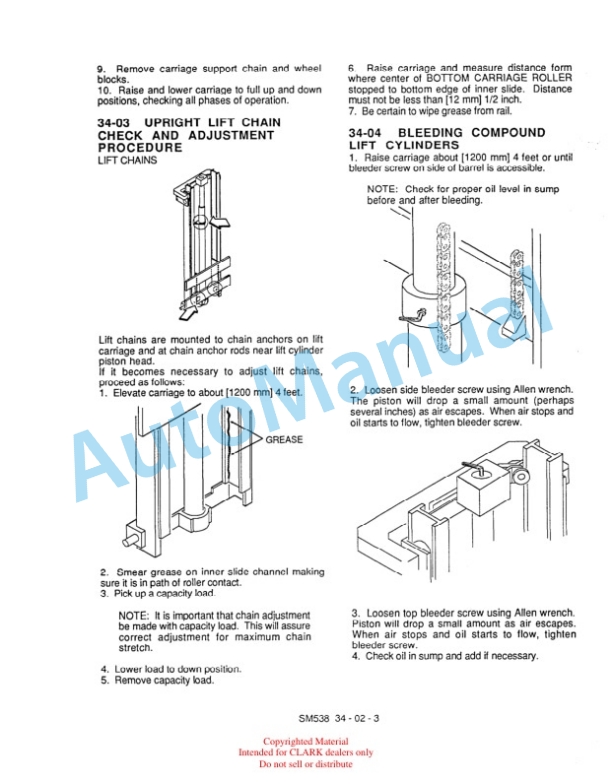

- 35.3. UPRIGHT LIFT CHAIN CHECK AND ADJUSTMENT PROCEDURE

- 35.4. BLEEDING COMPOUND LIFT CYLINDERS

- 35.5. UPRIGHT DOWNDRIFT TEST

- 35.6. UPRIGHT DESCRIPTION (TSU)

- 35.7. OPERATIONAL CHECKS AND ADJUSTMENTS (TSU)

- 35.8. LATCH OPERATION (TSU)

- 35.9. INTERMEDIATE RAILS (TSU)

- 35.10. CARRIAGE CHAIN ADJUSTMENT (TSU)

- 35.11. CHECKING ROLL PATTERN

- 35.12. CHECKING CYLINDER AND SEALS

- 35.13. LOAD TESTING

- 35.14. LIFT CYLINDER DRIFT TEST

- 35.15. TILT CYLINDER DRIFT TEST

- 35.16. CARRIAGE REMOVAL

- 35.17. ADJUSTING CARRIAGE ROLLERS

- 35.18. CARRIAGE INSTALLATION

- 35.19. UPRIGHT CLEARANCE (TSU)

- 35.20. ROLLER SHIM INSTALLATION (TSU)

- 36. UPRIGHT LIFT CYLINDER MODEL C

- 36.1. UPRIGHT CYLINDER DESCRIPTION

- 36.2. UPRIGHT MAINTENANCE TROUBLE SHOOTING

- 36.3. STANDARD CYLINDER DISASSEMBLY

- 36.4. STANDARD LIFT CYLINDER ASSEMBLY

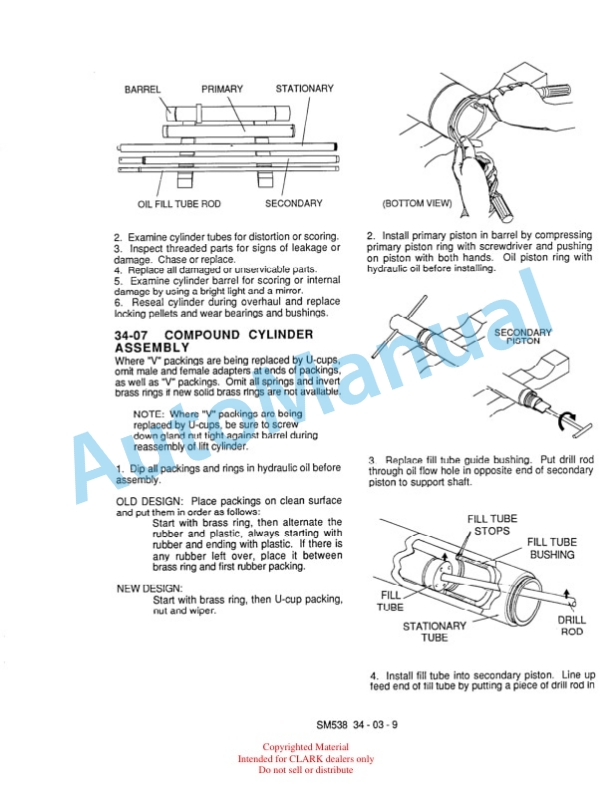

- 36.5. COMPOUND CYLINDER DISASSEMBLY

- 36.6. CYLINDER PARTS INSPECTION

- 36.7. COMPOUND CYLINDER ASSEMBLY

- 37. PANTOGRAPH MODEL C

- 37.1. PANTOGRAPH REMOVAL (WITH TILT)

- 37.2. PANTOGRAPH INSTALLATION (WITH TILT)

- 38. UPRIGHT REMOVAL MODEL D

- 38.1. UPRIGHT REMOVAL

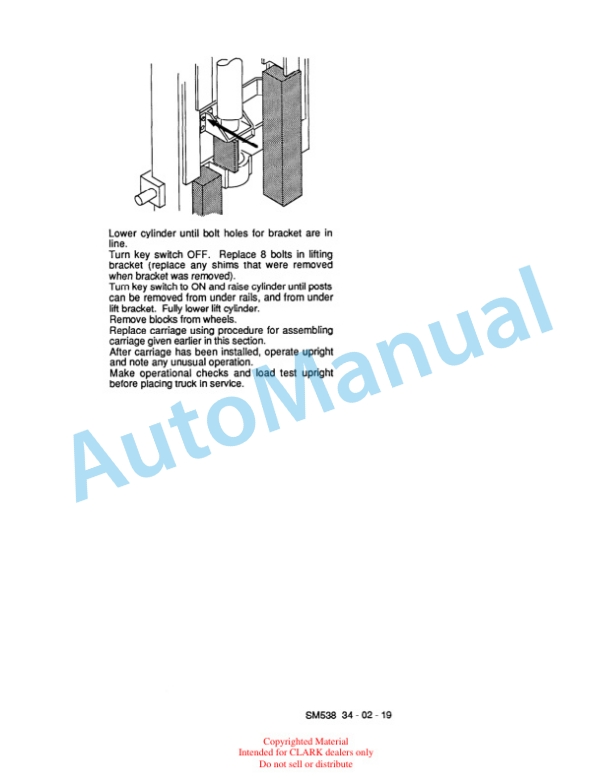

- 38.2. UPRIGHT INSTALLATION

- 39. UPRIGHT MAINTENANCE MODEL D

- 39.1. UPRIGHT MAINTENANCE

- 39.2. UPRIGHT ROLLER CHECK AND ADJUSTMENT PROCEDURES

- 39.3. UPRIGHT LIFT CHAIN CHECK AND ADJUSTMENT PROCEDURE

- 39.4. BLEEDING LIFT CYLINDERS

- 39.5. UPRIGHT DOWNDRIFT TEST

- 39.6. CHECKING ROLL PATTERN

- 39.7. CHECKING CYLINDER AND SEALS

- 39.8. LOAD TESTING

- 39.9. LIFT CYLINDER DRIFT TEST

- 39.10. TILT CYLINDER DRIFT TEST

- 39.11. CARRIAGE REMOVAL

- 39.12. ADJUSTING CARRIAGE ROLLERS

- 39.13. CARRIAGE INSTALLATION

- 40. PANTOGRAPH NP300D

- 40.1. PANTOGRAPH REMOVAL

- 40.2. PANTOGRAPH DISASSEMBLY

- 40.3. PANTOGRAPH INSTALLATION

- 41. MACHINE JACKING AND BLOCKING

- 41.1. RAISING DRIVE WHEEL

- 41.2. LOAD WHEEL ACCESS BLOCKING

- 41.3. RAISING REAR OF TRUCK

- 41.4. RAISING ENTIRE TRUCK

- 41.5. RAISING TRUCK WITH A HOIST

- 42. TRUCK DATA, SPECIFICATIONS

Rate this product

You may also like

Clark Service Manual PDF

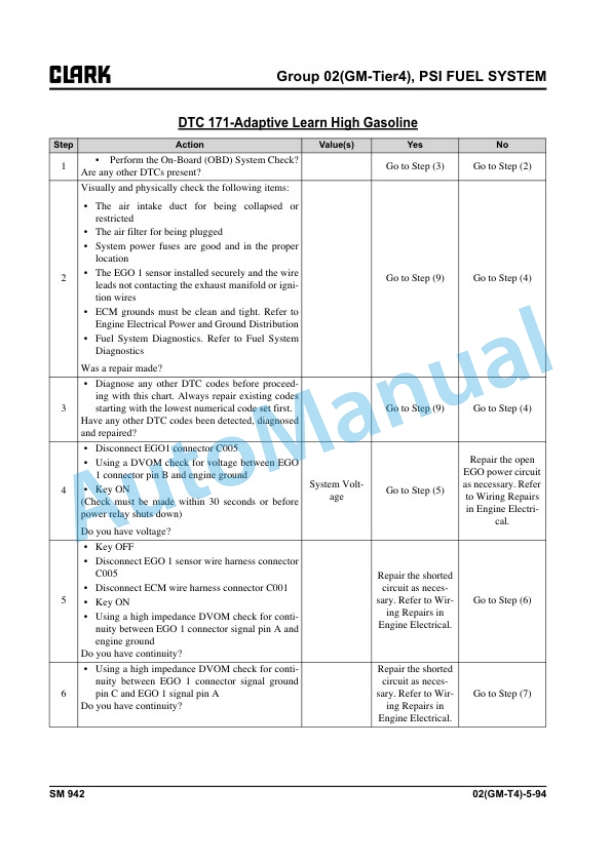

Clark C 40, 45, 50s, 55s D, C 40, 45, 50s, 55s L Service Manual SM-942

$30.00

Clark Service Manual PDF

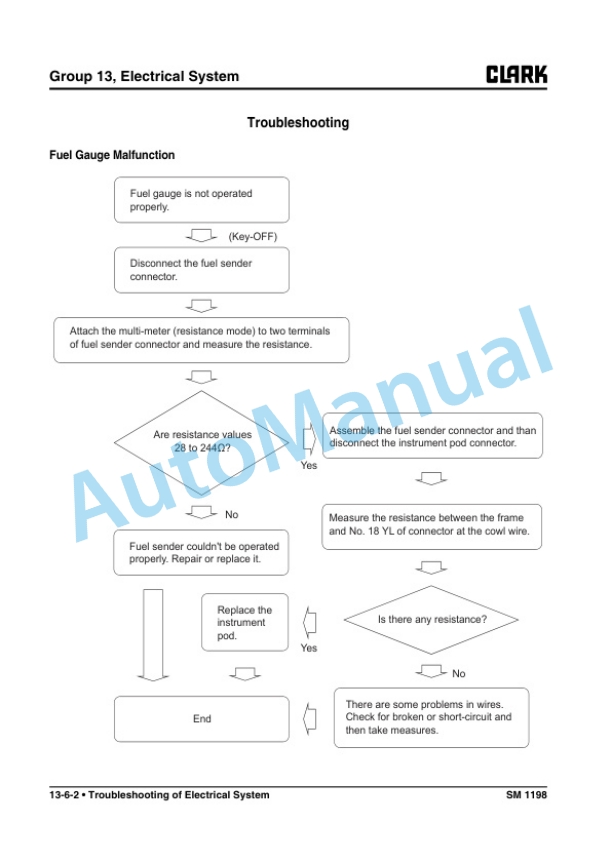

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-1198

$30.00

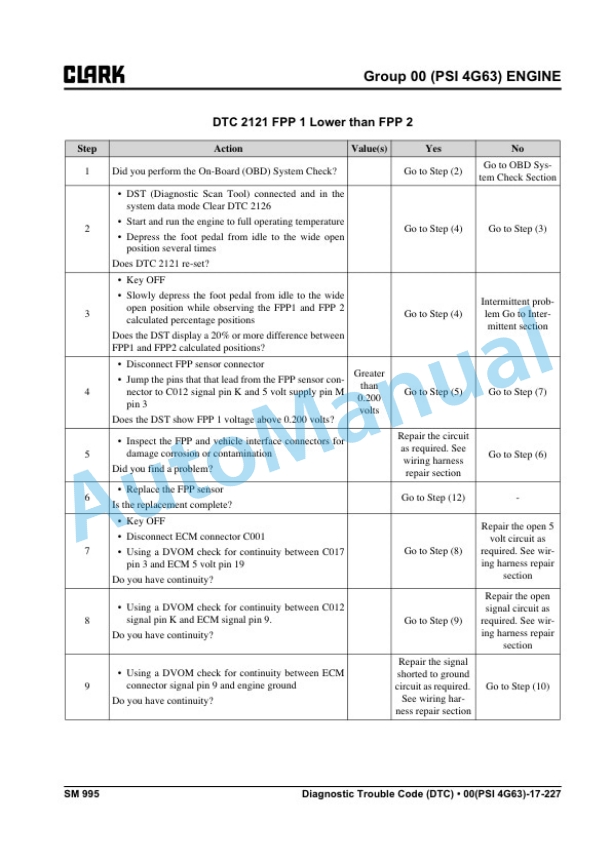

Clark Service Manual PDF

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-995

$30.00

Clark Service Manual PDF

Clark C500 Y 180-200-225S-225L-250S-250L-300S-300L-350 Service Manual SM-575

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00