Clark P-25, HWP-25, PWD-25, HWD-25, P-30, HWP-30, PWP-30, HWD-30, HWD-36, PWD-36 Service Manual SM-568

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-568

- Format: PDF

- Size: 12.1MB

- Number of Pages: 221

Category: Clark Service Manual PDF

-

Model List:

- P-25

- HWP-25

- PWD-25

- HWD-25

- P-30

- HWP-30

- PWP-30

- HWD-30

- HWD-36

- PWD-36

- 1. SERVICE MANUAL SM568

- 2. FOREWORD

- 3. About This Manual

- 4. IMPORTANT SAFETY NOTICE

- 5. PICTORIAL INDEX

- 6. Planned Maintenance Procedures

- 6.1. CHECK SHEET

- 6.2. Visual Inspection

- 6.3. Operational Tests

- 7. LUBRICATION PLANNED MAINTENANCE

- 7.1. LUBRICATION SPECIFICATIONS

- 7.2. HYDRAULIC SYSTEM

- 7.3. LUBRICATION CHART RIDER MODELS

- 7.4. LUBRICATION CHART WALKIES MODELS

- 7.5. Optional Equipment

- 7.6. Miscellaneous Linkage

- 8. BATTERY

- 8.1. BATTERYHANDLING

- 8.2. Battery Removal

- 8.3. Battery Vents

- 8.4. Battery Cleaning

- 8.5. Battery Maintenance

- 8.6. Battery Charging

- 8.7. Battery Electrolyte

- 8.8. Clean Battery Compartment

- 8.9. Install Battery

- 8.10. KEEPING BATTERY RECORDS

- 9. ELECTRIC MOTORS

- 9.1. Electric Motor Maintenance

- 9.1.1. Inspection Procedures

- 9.1.2. Motor Cleanliness

- 9.1.3. Motor Insulation

- 9.2. TEST FOR MOTOR INSULATION RESISTANCE TO GROUND

- 9.3. BRUSH AND COMMUTATOR INSPECTION

- 9.4. Operating Conditions

- 10. ELECTRIC MOTORS

- 10.1. Drive (Traction)

- 10.2. Pump Motor

- 10.3. Disassembly

- 10.4. CLEANING INSPECTION

- 10.5. Visual Insoection

- 10.6. Bearings

- 10.7. Frame and Field Assembly

- 10.8. Armature

- 10.9. Commutator Undercutting

- 10.10. TESTING

- 10.10.1. Frame and Field Assembly

- 10.10.2. Grounded Circuit

- 10.10.3. Open Circuit

- 10.10.4. Ifthearmaturehasbeenturnedand

- 10.10.5. Armature

- 10.10.6. Equalizer Winding Connections

- 10.10.7. Standard Winding Connections

- 10.11. FRAME AND FIELD SERVICE NOTES

- 10.12. FIELD COIL INSTALLATION

- 10.13. ASSEMBLY AND TESTING

- 10.14. Bearing Installation

- 10.15. Brush Inspection Chart

- 10.16. Operating Conditions

- 11. CONTACTORS

- 11.1. Replacement of Contact Tips

- 11.2. Install New Tips

- 11.3. Check Operation

- 11.4. FORWARD REVERSE CONTACTOR ASSEMBLIES

- 11.4.1. Replacement of Contact Tips

- 11.4.2. Install New Tips

- 11.4.3. Check Operation

- 12. CONTACTOR AND EVT5 CONTROL PANELS

- 12.1. CONTROL PANEL REMOVAL

- 12.2. DIsconnect Panels

- 12.3. Control Card Removal Installation

- 12.4. Replacement Control Card Data

- 12.5. Capacitors

- 12.6. CONTROL BOX INTERNAL WIRING

- 13. EVT5 CONTROL

- 13.1. Description

- 13.2. Control Features

- 13.3. Maintenance

- 13.4. TROUBLESHOOTING

- 13.5. Trouble Shooting Notes

- 14. CHECKING COMPONENTS AND CONTROL CARD ADJUSTMENTS

- 14.1. EVT5 CARD ADJUSTMENTS AND INPUT/OUTPUT CONNECTIONS

- 14.2. EVT5 COMPONENT IDENTIFICATION

- 14.3. EVT5 INTERNAL WIRING

- 14.4. CHECKING COMPONENTS

- 14.4.1. Specific Gravity Test

- 14.4.2. Battery Tests

- 14.4.3. 3 and I4 REC Module

- 14.4.4. C Capacitors

- 14.4.5. Thermal Protector

- 14.4.6. Current Sensor Shunt

- 14.4.7. Snubber (1 FIL)

- 15. SEQUENCE OF OPERATION

- 15.1. OPERATIONAL SEQUENCE I

- 15.2. OPERATIONAL SEQUENCE 2

- 15.3. OPERATIONAL SEQUENCE 3

- 15.4. OPERATIONAL SEQUENCE 4

- 15.5. OPERATIONAL SEQUENCE 5

- 15.6. OPERATIONAL SEQUENCE 6

- 15.7. OPERATIONAL SEQUENCE 7

- 15.8. OPERATIONAL SEQUENCE 8

- 15.9. OPERATIONAL SEQUENCE 9

- 15.10. OPERATIONAL SEQUENCE 10

- 15.11. OPERATIONAL SEQUENCE 11

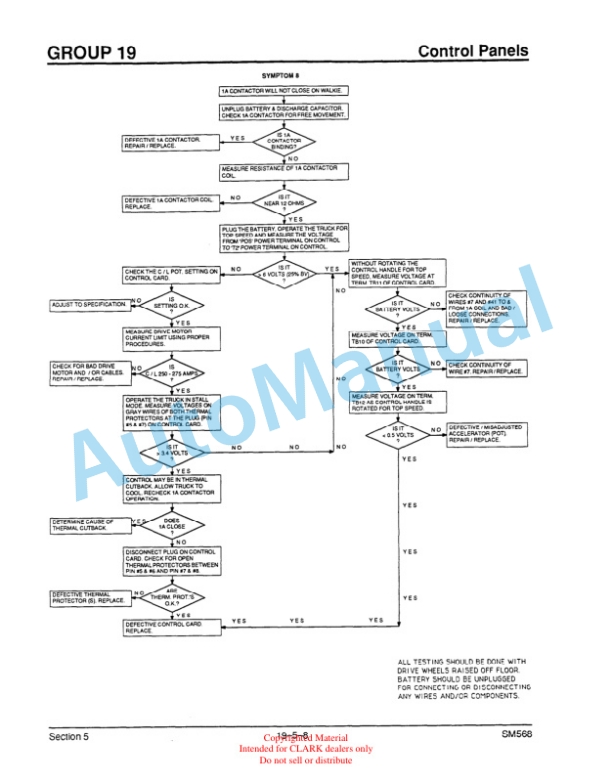

- 16. EVT5 FLOW CHART TROUBLE SHOOTING PROCEDURES

- 16.1. SYMPTOM I

- 16.2. SYMPTOM 2

- 16.3. SYMPTOM 3

- 16.4. SYMPTOM 4

- 16.5. SYMPTOM 5

- 16.6. SYMPTOM 6

- 16.7. SYMPTOM 7

- 16.8. SYMPTOM 8

- 16.9. SYMPTOM 9

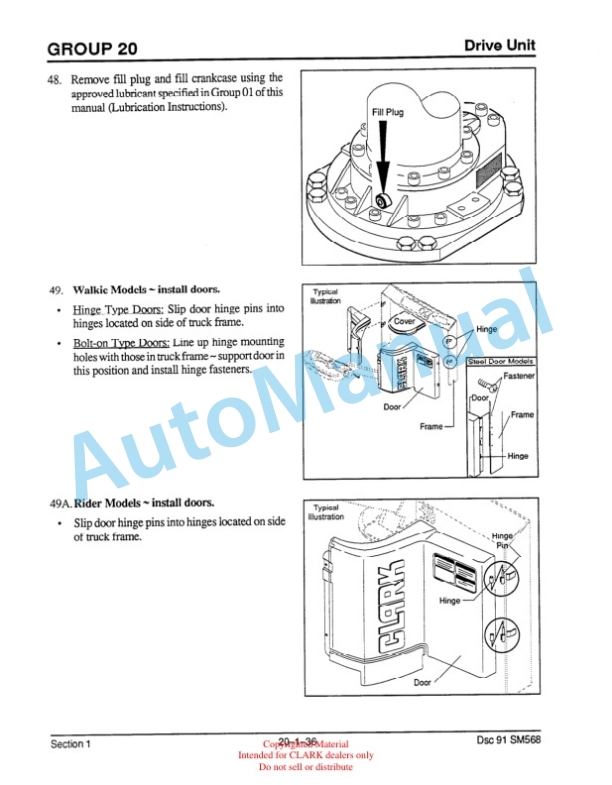

- 17. DRIVE UNIT ASSEMBLY

- 17.1. DESCRIPTION

- 17.2. REMOVAL

- 17.3. DISASSEMBLY

- 17.4. Cleaning Inspection

- 17.5. REASSEMBLY

- 17.6. ADJUSTMENT SPECIFICATIONS

- 17.7. BACKLASH

- 17.8. Installation

- 18. DRIVE MOTOR BRAKES

- 18.1. MOTOR BRAKE ASSEMBLY

- 18.2. MOTOR BRAKE INSPECTION

- 18.3. BRAKE INSTALLATION

- 18.4. Brake Linkage Installation

- 18.5. BRAKE SWITCH

- 18.6. BRAKE SWITCH ADJUSTMENT

- 19. COAST CONTROL

- 19.1. COAST CONTROL DESCRIPTION

- 19.2. Coast Control Preparation

- 19.3. Coast Control Operational Check

- 19.4. Coast Control Operational Adjustment

- 20. CASTER ASSEMBLY

- 20.1. TORQUE SPECIFICATION

- 20.2. Caster Adjustment

- 21. HYDRAULIC SYSTEM

- 21.1. REMOVAL

- 21.2. Installation

- 21.3. Torque Specifications

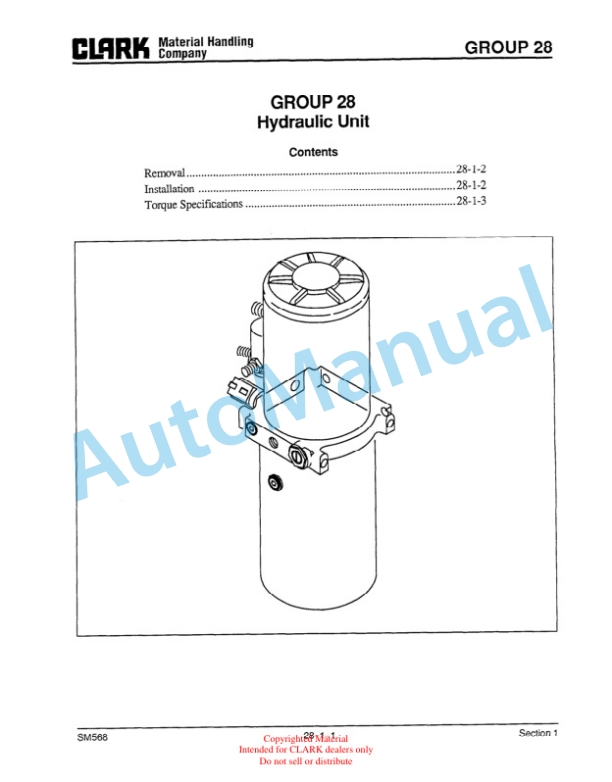

- 22. HYDRAULIC UNIT

- 22.1. ASSEMBLY OF HYDRAULIC UNIT

- 22.2. SPECIFICATIONS

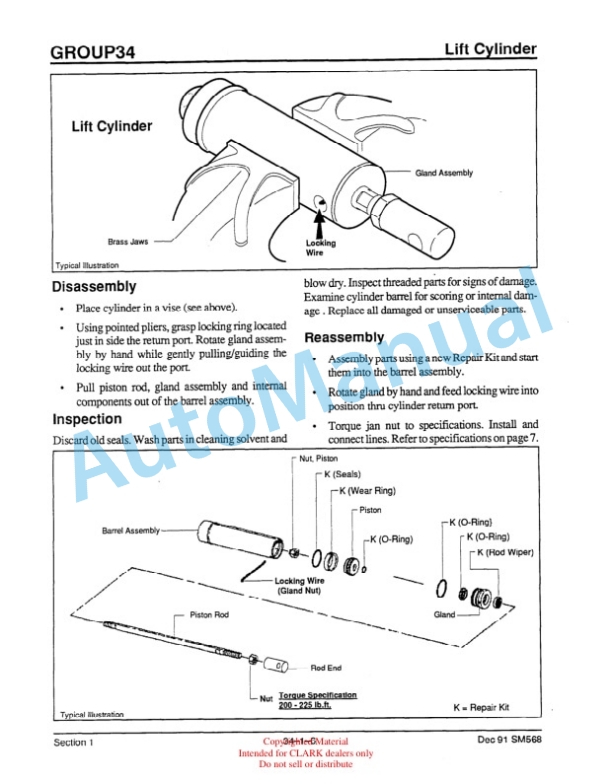

- 23. LIFT CYLINDER

- 23.1. LIFT CYLINDER REMOVAL

- 23.2. Block Lift Frame

- 23.3. Disconnect Hoses

- 23.4. Disconnect Lift Cylinder

- 23.5. Disassembly

- 23.6. Inspection

- 23.7. Reassembly

- 23.8. INSTALLATION SPECIFICATIONS

- 24. LIFT LINKAGE LOAD WHEELS

- 24.1. OPERATIONAL CHECK

- 24.2. Pull Rod Adjustment Check

- 24.3. BUSHING IDENTIFICATION

- 24.4. LIFT LINKAGE REMOVAL

- 24.5. Bushing Removal

- 24.6. Bushing Installation

- 24.7. DUAL LOAD WHEELS

- 24.7.1. Inspection

- 24.7.2. Assembly

- 24.8. SINGLE LOAD WHEELS

- 24.8.1. Inspection

- 24.8.2. Assembly

- 24.9. LIFT LINKAGE INSTALLATION

- 24.10. Pallet Entry Skids

- 25. BODY PARTS

- 25.1. Walkie Model Trucks

- 25.2. Rider Model Trucks

- 26. TRUCK SPECIFICATIONS

- 26.1. BATTERY

- 26.2. BRAKE, MOTOR

- 26.3. CONTROL (EVTS SOLID STATE CONTROL

- 26.4. ELECTRICAL

- 26.5. HYDRAULIC SYSTEM

- 26.6. TRUCK SERVICE WEIGHTS

- 26.7. Torque Specifications

- 27. WIRING SCHEMATICS

- 27.1. IN2222 (Early Model Trucks) Schematic

- 27.2. (Early Model Trucks) Diagram

- 27.3. IN24029 (Late Model Trucks) Schematic

- 27.4. (Late Model Trucks) Diagram

Rate this product

You may also like

Clark Service Manual PDF

Clark 21 D Series Planetary Drive Axle Maintenance and Service Manual SM-21D

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

Clark C 40, 45, 50s, 55s D, C 40, 45, 50s, 55s L Service Manual SM-942

$30.00

Clark Service Manual PDF

Clark C40, 45, 50s, 55s D, C40, 45, 50s, 55s L Service Manual SM-810

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

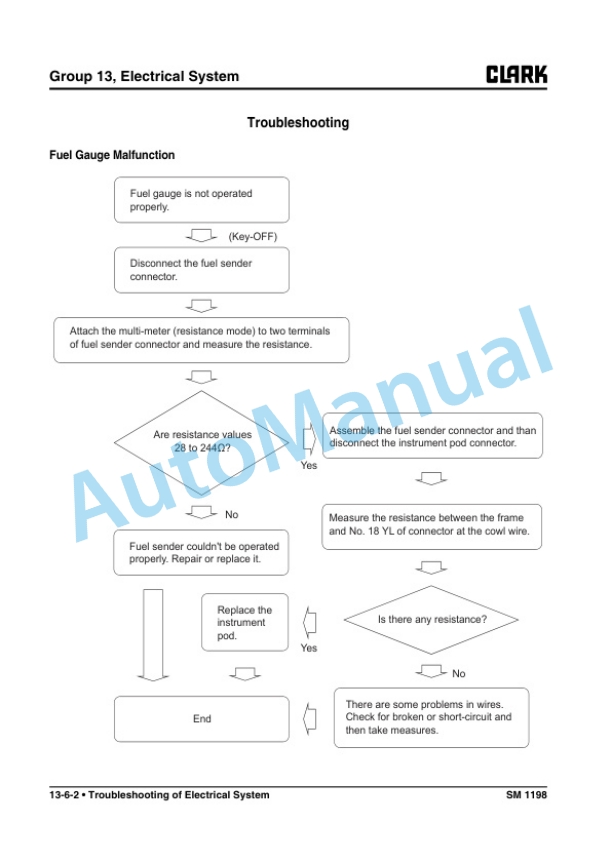

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-1198

$30.00

Clark Service Manual PDF

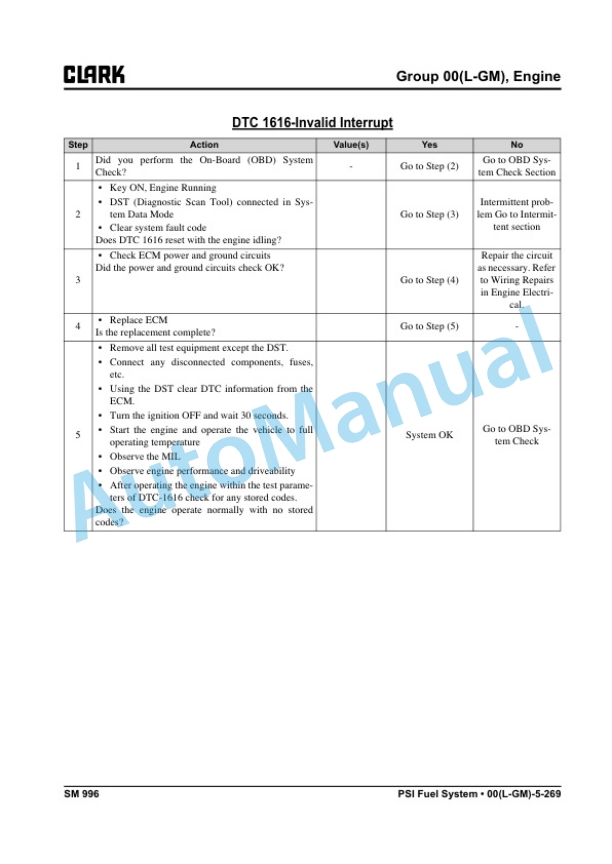

Clark C20, 25, 30, 35 D, L, G, C20, 25, 30, 32C L Service Manual SM-996

$30.00

Clark Service Manual PDF

Clark C15s D-L, C 18s D-L, C 20s D-L, C15s C-L, C 18s C-L, C 20s C-L Service Manual SM-1066

$30.00