Clark PWC 30, PWT 7 Service Manual SM-614

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-614

- Format: PDF

- Size: 14.1MB

- Number of Pages: 333

Category: Clark Service Manual PDF

-

Model List:

- PWC 30

- PWT 7

- 1. Title Page

- 2. TABLE OF CONTENTS

- 3. NOTICE

- 4. GENERAL INFORMATION (GI)

- 4.1. INTRODUCTION

- 4.2. SPECIFICATIONS FOR PWT

- 4.3. SPECIFICATIONS FOR PWC

- 4.4. SERIAL NUMBER LOCATION CURRENT MODELS

- 4.5. RECORD KEEPING

- 4.6. TOOLS REQUIRED TO SERVICE THESE PRODUCTS

- 4.7. TORQUE CHART

- 4.8. CONVERSION FACTORS

- 4.9. STANDARD SPEED AND SCR POTENTIOMETER ADJUSTMENTS

- 4.10. GENERAL SERVICE GUIDE

- 4.11. PWT MAINTENANCE SCHEDULE

- 4.12. PWC FORK LOAD LUBRICATION CHART

- 4.13. PWT LUBRICATION CHART

- 4.14. BATTERY CARE AND SERVICE

- 4.14.1. Specific Gravity

- 4.14.2. The Chemical Reaction

- 4.14.3. Cleaning the Battery

- 4.14.4. Adding Water

- 4.14.5. The Hydrometer

- 4.14.6. Battery Temperature

- 4.14.7. Charging The Battery

- 4.14.8. When To Charge

- 4.15. BATTERY CONTROLLER

- 4.15.1. Operation Adjustment and Maintenance

- 4.15.2. The 933/3 Operation, Troubleshooting and Adjustment

- 4.15.3. What Does It Tell The Driver

- 4.15.4. Reserve Warning Light

- 4.15.5. Lift Lockout

- 4.15.6. What Should The Driver Do

- 4.15.7. Adjustments

- 4.15.8. Table of Pot Settings and Associated Voltages Per Cell

- 4.15.9. What The Gage Measures

- 4.15.10. Troubleshooting

- 4.15.11. Adjustment Procedures

- 4.15.12. Model 1142 Tester and Model 1141 FasTesT Accessory for Curtis 933/3 Battery Controller

- 4.15.13. Features Of The

- 4.15.14. Installation Of The

- 4.15.15. Description Of Operation Of The

- 4.16. PAINT DECAL PWT

- 4.17. PAINT DECAL PWC

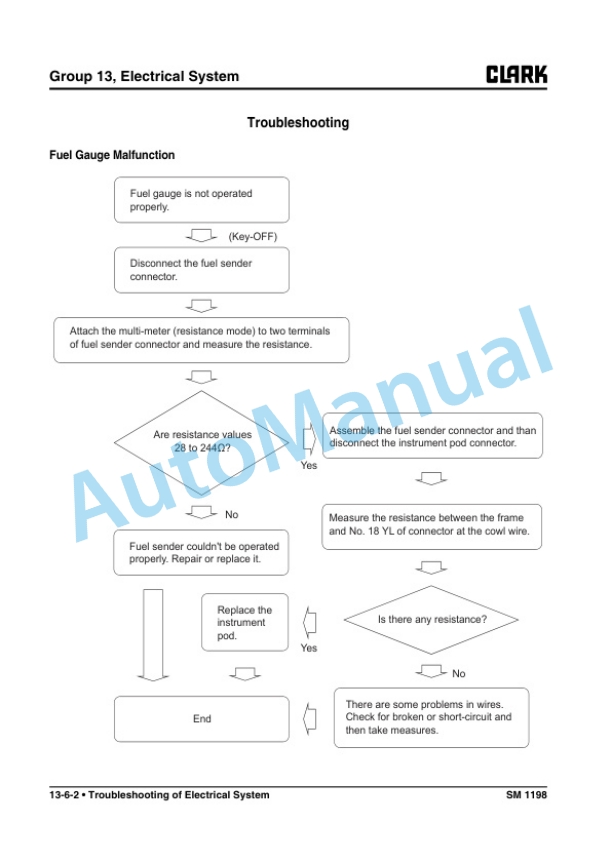

- 5. ELECTRICAL CONTROL (EC)

- 5.1. BASIC ELECTRICAL THEORY

- 5.1.1. Basic Electrical Terms

- 5.1.2. Voltage

- 5.1.3. Ampere

- 5.1.4. Polarity

- 5.1.5. Direct Current (DC)

- 5.1.6. Alternating Current (AC)

- 5.1.7. Commonly Used Terms

- 5.1.8. Fundamental Laws of Electricity

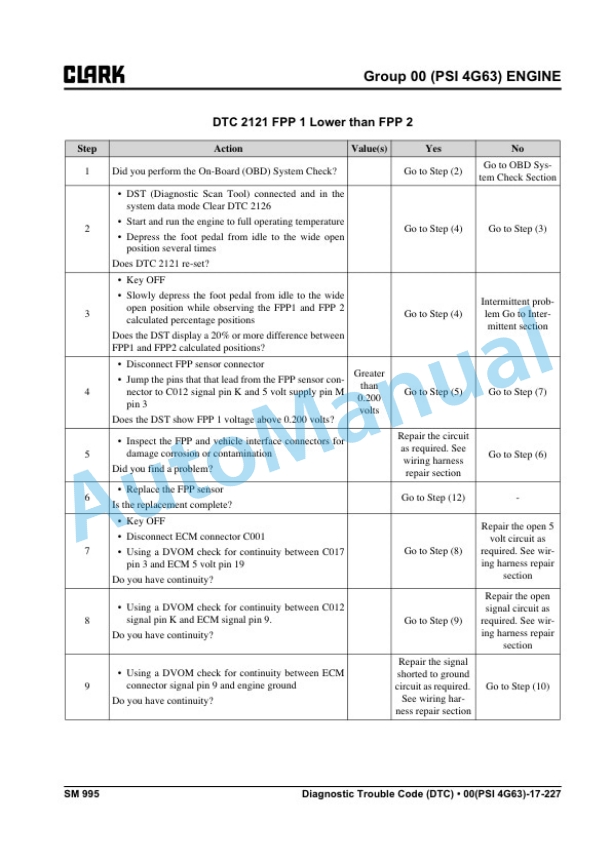

- 5.2. TROUBLESHOOTING ELECTRICAL PROBLEMS

- 5.2.1. The Logic of Electrical Troubleshooting

- 5.2.2. Troubleshooting Procedure

- 5.2.3. Troubleshoot With Your Senses

- 5.2.4. A Troubleshooting Approach

- 5.2.5. BASIC TEST (TOOLS) EQUIPMENT IN TROUBLESHOOTING

- 5.2.6. FRONT PANEL DESCRIPTION

- 5.2.7. DC VOLTAGE MEASUREMENTS 0.25 THROUGH 0250V RANGE

- 5.2.8. DIRECT CURRENT MEASUREMENT

- 5.2.9. RESISTANCE MEASUREMENT OF SEMICONDUCTORS/DIODES/SCRS

- 5.2.10. SERIES II MULTIMETER

- 5.2.11. DIGITAL DISPLAY

- 5.2.12. ROTARY SWITCH

- 5.2.13. MEASURING RESISTANCE

- 5.2.14. TESTING DIODES

- 5.2.15. MEASURING VOLTAGE

- 5.2.16. SYMBOLS

- 5.2.17. HANDYMAN COMPONENT TESTER INSTRUCTIONS

- 5.2.18. TROUBLESHOOTING DOS AND DONTS

- 5.2.19. ELECTRICAL SYMBOLS

- 5.3. BASIC OPERATION FOR PWT RESISTOR CONTROL CONTACTOR

- 5.3.1. Forward Travel

- 5.3.2. Reverse Travel

- 5.3.3. Speed Control Option

- 5.3.4. Class 3 Resistor Units

- 5.3.5. TROUBLESHOOTING PWT RESISTOR CONTROL

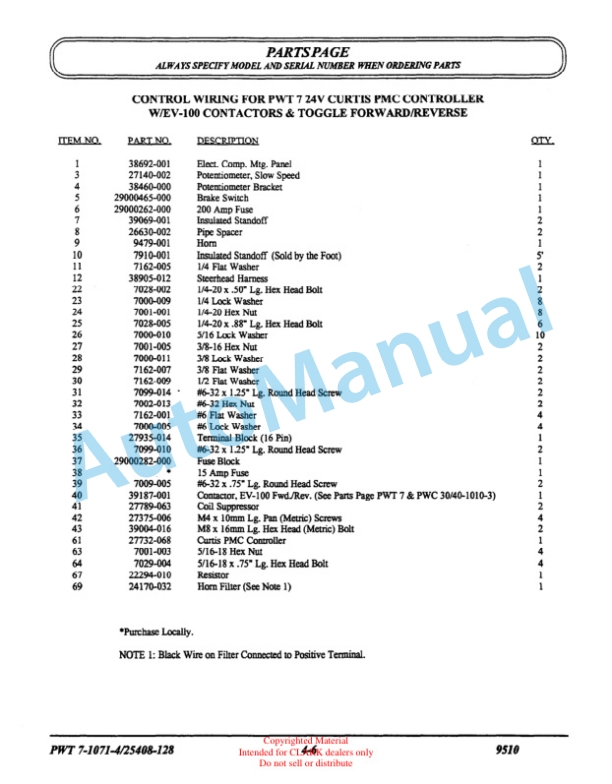

- 5.4. PARTS PAGE

- 5.5. SERVICE GUIDE FOR PMC CONTROL SECOND EDITION 9301

- 5.5.1. FEATURES OF CURTIS PMC SERIES TRANSISTORIZED MOTOR CONTROLLERS

- 5.5.2. FUNCTIONAL OPERATION OF CONTROLLER

- 5.5.3. MAINTENANCE AND ADJUSTMENT

- 5.5.4. TROUBLESHOOTING

- 5.5.5. TROUBLESHOOTING PWT CURTIS PMC CONTROL

- 5.5.6. TROUBLESHOOTING PWT CURTIS PMC CONTROL

- 5.5.7. TROUBLESHOOTING PWT CURTIS PMC CONTROL

- 5.5.8. TROUBLESHOOTING PWT CURTIS PMC CONTROL

- 5.5.9. BASIC OPERATION FOR PWC CURTIS PMC

- 5.5.10. l/98 EC 6l

- 5.5.11. BASIC OPERATION FOR PWC CURTIS PMC

- 5.5.12. BASIC OPERATION FOR PWC CURTIS PMC

- 5.5.13. BASIC OPERATION FOR PWC CURTIS PMC

- 5.5.14. TROUBLESHOOTING PWC CURTIS PMC CONTROL

- 5.5.15. TROUBLESHOOTING PWC CURTIS PMC CONTROL

- 5.5.16. TROUBLESHOOTING PWC CURTIS PMC CONTROL

- 5.5.17. TROUBLESHOOTING PWC CURTIS PMC CONTROL

- 5.5.18. STANDARD SPEED AND SCR POTENTIOMETER ADJUSTMENTS

- 5.5.19. STANDARD SPEED AND SCR POTENTIOMETER ADJUSTMENTS (EV1, EV100 AND CURTIS PMC)

- 5.5.20. STANDARD SPEED AND SCR POTENTIOMETER ADJUSTMENTS

- 5.5.21. EV100 CONTACTOR AND MAINTENANCE

- 5.5.22. EV100 CONTACTOR AND MAINTENANCE

- 5.5.23. EV100 CONTACTOR AND MAINTENANCE

- 5.5.24. EV100 CONTACTOR AND MAINTENANCE

- 5.5.25. EV100 CONTACTOR AND MAINTENANCE

- 5.6. BASIC OPERATION FOR PWT CURTIS PMC

- 5.6.1. Forward Travel

- 5.6.2. Reverse Travel

- 5.6.3. Plugging (Controlled Reverse)

- 5.6.4. Battery Discharge Speed Interrupt

- 5.6.5. TROUBLESHOOTING PWT CURTIS PMC CONTROL

- 5.7. BASIC OPERATION FOR PWC CURTIS PMC

- 5.7.1. Forward Travel

- 5.7.2. Reverse Travel

- 5.7.3. TROUBLESHOOTING PWC CURTIS PMC CONTROL

- 5.8. STANDARD SPEED AND SCR POTENTIOMETER ADJUSTMENTS

- 5.8.1. Main Accelerator Potentiometer Adjustment

- 5.8.2. Adjustment Procedures

- 5.8.3. PWT With Push Button Reverse

- 5.8.4. PWT With Battery Discharge Speed Interrupt

- 5.8.5. EV100 CONTACTOR AND MAINTENANCE

- 5.9. NOTICE

- 5.10. PARTS PAGE

- 6. HYDRAULIC SYSTEM (HD)

- 6.1. BASIC OF HYDRAULIC

- 6.1.1. What is Pressure

- 6.1.2. Pressure On A Confined Fluid

- 6.1.3. How To Determine Pressure

- 6.1.4. One Of Pascals Laws

- 6.1.5. Pascals Hydraulic Lever

- 6.1.6. Multiplying Hydraulic Pressure

- 6.1.7. Force Of An Area

- 6.1.8. NPTF (National Pipe Tapered Fuel)

- 6.1.9. SAE 5514 37 Hydraulic

- 6.1.10. ORS SAE 51453 ORing Face Seal

- 6.1.11. SAE 5514 Straight Thread ORing Boss (ORB)

- 6.2. BASIC HYDRAULIC OPERATION

- 6.2.1. Lift Operation

- 6.2.2. Lower Operation

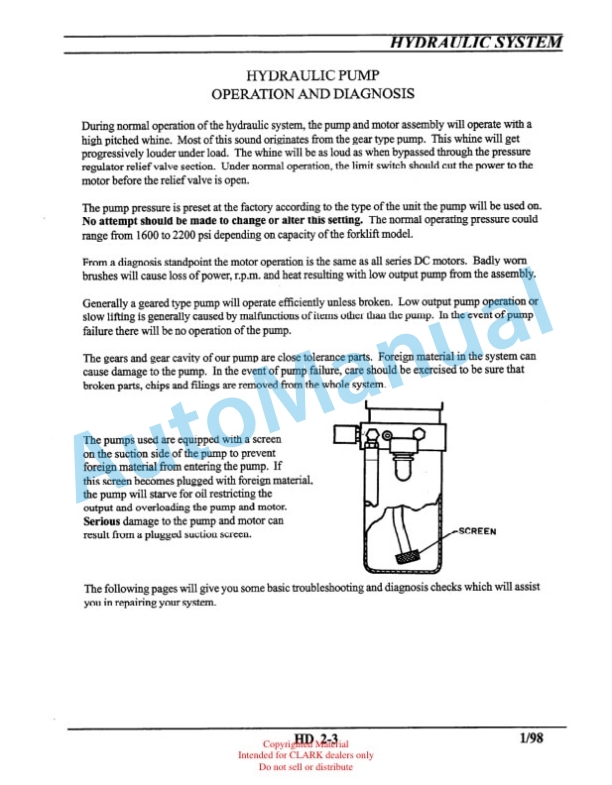

- 6.2.3. HYDRAULIC PUMP OPERATION AND DIAGNOSIS

- 6.2.4. PUMP AND MOTOR DIAGNOSIS

- 6.2.5. PUMP AND SERVICE MAINTENANCE

- 6.2.6. SERVICE AND MAINTENANCE DC PUMP MOTORS

- 7. DRIVE ASSEMBLY (DA)

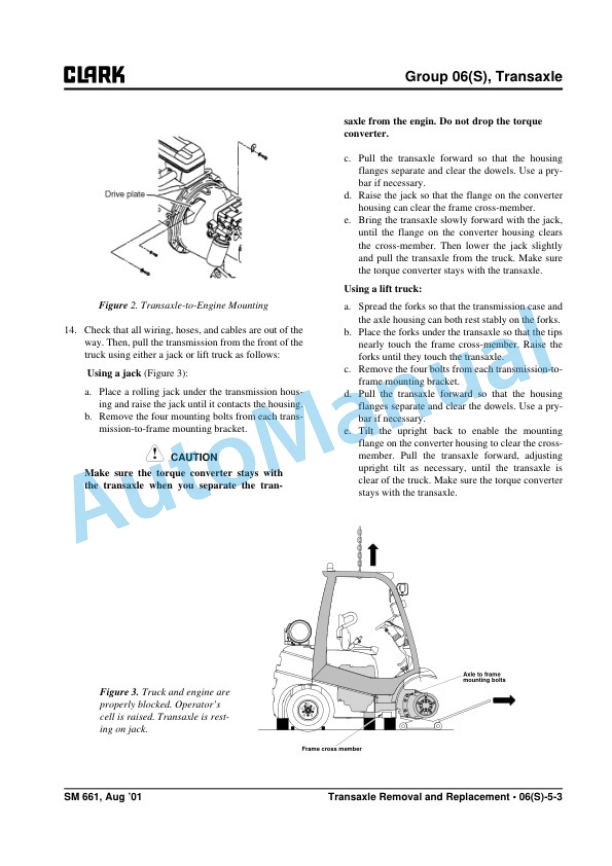

- 7.1. TRANSMISSION DRIVE ASSEMBLY (GENERAL INFORMATION

- 7.1.1. Basic Operation

- 7.1.2. Gears, General Description

- 7.1.3. Gear Ratio and Serial Number Location

- 7.1.4. Steer Bearing

- 7.1.5. Maintenance

- 7.1.6. Planned Maintenance Schedule

- 7.2. TRANSMISSION DRIVE ASSEMBLY (REPAIR AND SERVICE INSTALLATION)

- 7.2.1. Repair and Service

- 7.3. TRANSMISSION DRIVE ASSEMBLY (UNITS BUILT FROM FEB. 1995)

- 7.3.1. Dismantling Lower Transmission Section

- 7.3.2. Assembly Lower Transmission Section

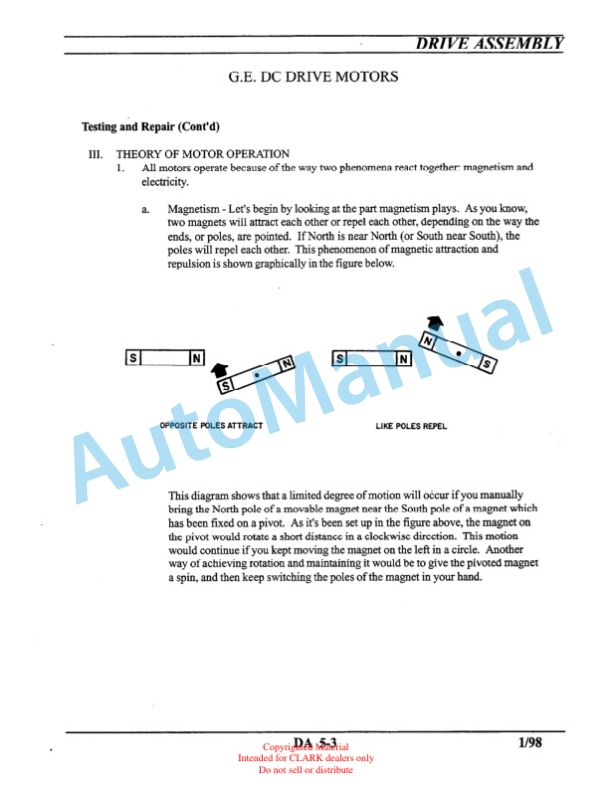

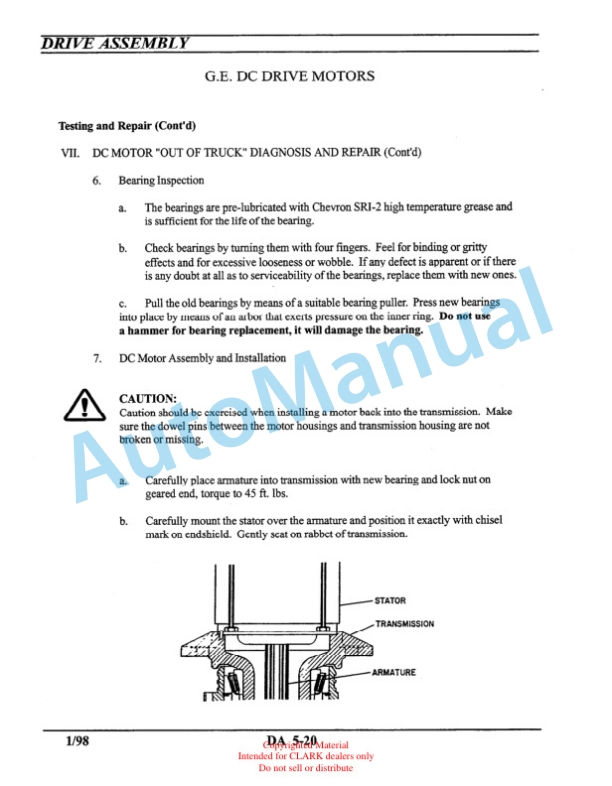

- 7.4. DC DRIVE MOTORS

- 7.4.1. Testing and Repair

- 7.4.2. Planned Maintenance

- 7.4.3. Commutator Check Chart

- 7.5. DRIVE TIRE

- 7.5.1. Tire Assembly Installation

- 7.5.2. Tire Assembly Removal

- 8. BRAKE SYSTEM (BR)

- 8.1. OPERATION SERVICE PROCEDURE

- 8.1.1. Service Procedure

- 8.1.2. General Maintenance

- 8.2. TILT STEERHEAD BRAKE ADJUSTMENT

- 8.3. FIXED STEERHEAD BRAKE ADJUSTMENT

- 9. STEERING SYSTEM (ST)

- 9.1. OPERATION

- 9.1.1. Transmission

- 9.2. PLANNED MAINTENANCE AND SERVICE

- 9.2.1. Transmission

- 9.2.2. Steerhead and Tiller Arm Maintenance

- 10. LOAD CARRIER (LC)

- 10.1. GENERAL INTRODUCTION

- 10.1.1. Load Carrying Device

- 10.1.2. Load Wheel Operation

- 10.2. PLANNED MAINTENANCE

- 10.3. LOAD WHEELS

- 10.3.1. Load Wheel Maintenance

- 10.3.2. LOAD WHEEL REPLACEMENT

- 10.4. FORK HEIGHT SETTING

- 11. BODY AND FRAME (BF)

- 11.1. PARTS PAGE

- 12. OPTIONAL EQUIPMENT (OE)

- 12.1. PARTS PAGE

Rate this product

You may also like

Clark Service Manual PDF

Clark 21 D Series Planetary Drive Axle Maintenance and Service Manual SM-21D

$30.00

Clark Service Manual PDF

Clark C20, 25, 30, 35 D, L, G, C20, 25, 30, 32C L Service Manual SM-996

$30.00

Clark Service Manual PDF

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-995

$30.00

Clark Service Manual PDF

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-1198

$30.00

Clark Service Manual PDF

$30.00