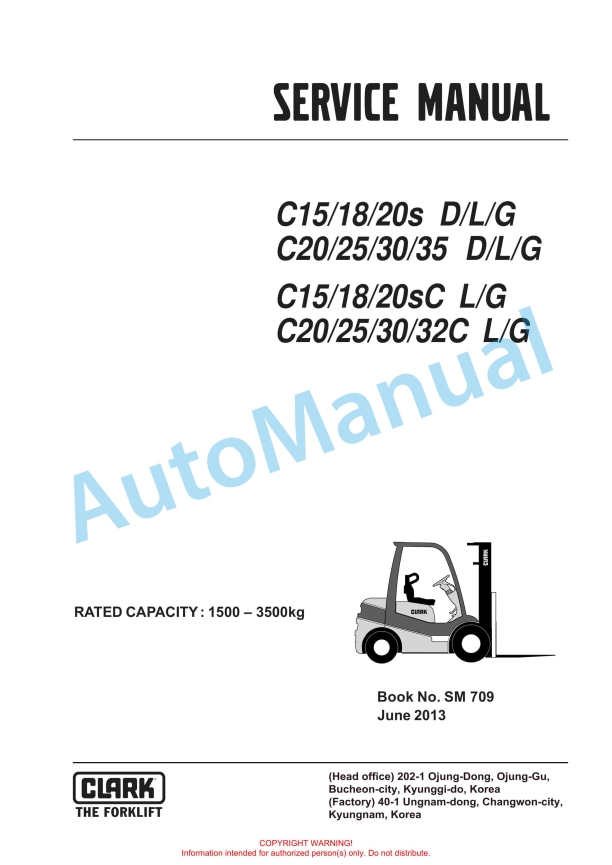

Clark SF20-30D, L, G, CMP20-30D, L, G Service Manual SM-711

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-711

- Format: PDF

- Size: 25.0MB

- Number of Pages: 486

Category: Clark Service Manual PDF

-

Model List:

- SF20-30D

- SF20-30L

- SF20-30G

- CMP20-30D

- CMP20-30L

- CMP20-30G

- 1. GENERAL

- 1.1. REVISION HISTORY

- 1.2. FOREWORD

- 1.2.1. FOREWORD

- 1.2.2. HOW TO READ THIS MANUAL

- 1.3. SAFETY

- 1.3.1. GENERAL PRECAUTIONS

- 1.3.2. PREPARATIONS FOR WORK

- 1.3.3. CAUTIONS DURING OPERATION

- 1.4. STANDARDS

- 1.4.1. STANDARD TIGHTENING TORQUE

- 1.4.2. MEASUREMENT CONVERSIONS

- 2. SPECIFICATIONS

- 2.1. GENERAL

- 2.1.1. LOCATION OF COMPONENTS

- 2.1.2. DIMENSION AND WEIGHT

- 2.2. LOAD CAPACITY

- 2.2.1. CAPACITY CHARTS

- 2.3. COOLANT / FUEL / LUBRICATION

- 2.4. PERIODIC MAINTENANCE

- 2.4.1. PERIODIC MAINTENANCE

- 2.5. TIGHTENING TORQUE

- 2.5.1. TIGHTENING TORQUE

- 3. ENGINE GASOLINE,LPG

- 3.1. GENERAL INFORMATION

- 3.1.1. PERIODIC INSPECTION CHART

- 3.1.2. HOW TO READ THIS CHAPTER

- 3.1.3. ENGINE MODEL AND NUMBERS

- 3.2. SPECIFICATION

- 3.2.1. GENERAL SPECIFICATIONS

- 3.2.2. SERVICE SPECIFICATIONS

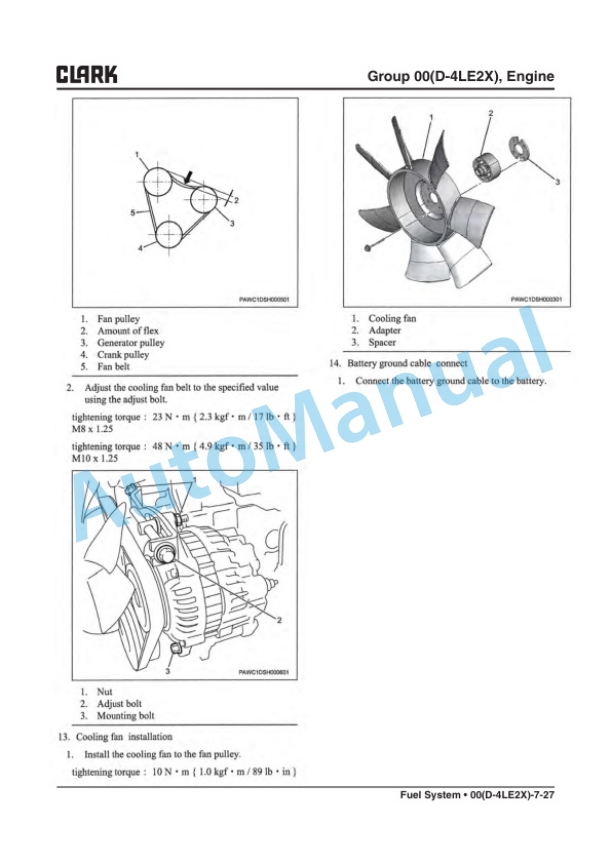

- 3.2.3. TIGHTENING TORQUE

- 3.2.4. SPECIAL TOOLS

- 3.3. ADJUSTMENT

- 3.3.1. VALVE CLEARANCE ADJUSTMENT

- 3.3.2. IGNITION TIMING ADJUSTMENT

- 3.3.3. IDLING SPEED ADJUSTMENT

- 3.3.4. AIR GOVERNOR (HIGH SPEED)

- 3.4. TIMING BELT

- 3.4.1. REMOVAL

- 3.4.2. INSPECTION

- 3.5. ELECTRIC COMPONENT

- 3.5.1. INSPECTION

- 3.5.2. DISTRIBUTOR

- 3.5.3. ALTERNATOR

- 3.5.4. STARTER

- 3.6. COMPONENTS

- 3.6.1. ROCKER ARMS AND CAMSHAFT

- 3.6.2. CYLINDER HEAD AND VALVES

- 3.6.3. FRONT CASE AND OIL PAN

- 3.6.4. PISTON AND CONNECTING ROD

- 3.6.5. CRANKSHAFT AND CYLINDER BLOCK

- 3.7. TROUBLESHOOTING

- 3.7.1. BY SYMPTOM

- 3.7.2. BY COMPONENT

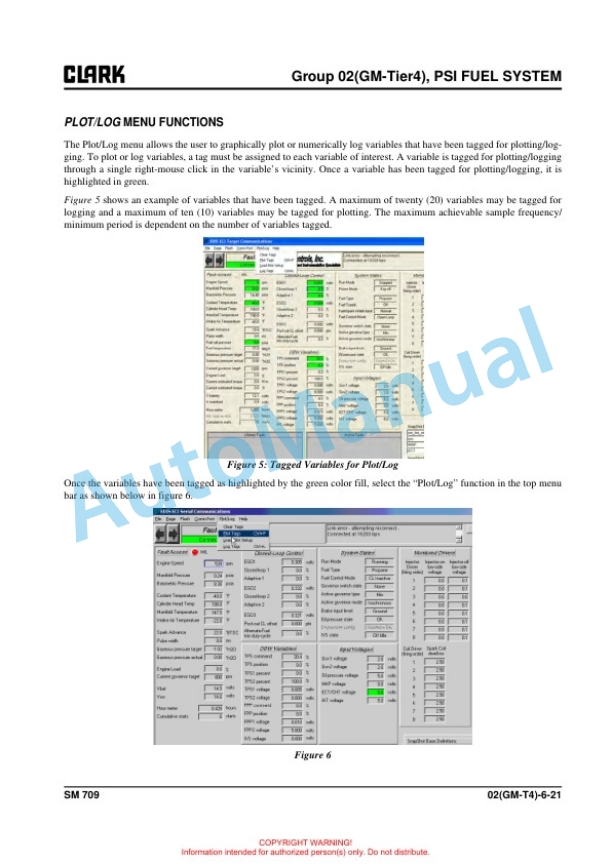

- 3.8. FUEL SYSTEMTIER2(MI4 LP SYSTEM)

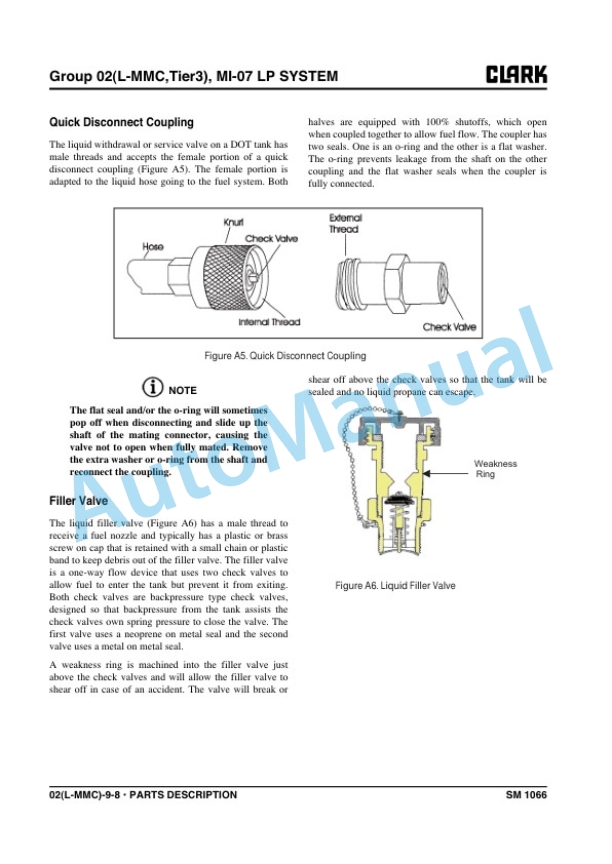

- 3.8.1. CHAPTER 1. LPG AND LPG FUEL TANKS

- 3.8.2. CHAPTER 2. MI04 LPG SYSTEM OPERATIONAL

- 3.8.3. CHAPTER 3. MI 4 MAINTENANCE SCHEDULE

- 3.8.4. CHAPTER 4. MI04 LP BASIC TROUBLESHOOTING

- 3.8.5. CHAPTER 5. MI04 LP ADVANCED DIAGNOSTICS

- 3.8.6. CHAPTER 6. MI04 ELECTRICAL CONNECTIONS

- 3.8.7. CHAPTER 7. N2001 PRESSURE REGULATOR/CONVERTER

- 3.8.8. CHAPTER 8. NCA55500TR AIR/FUEL MIXER

- 3.8.9. CHAPTER 9. TEST AND ADJUSTMENTS

- 4. DIESEL ENGINETIER2 (4TNV88/94L)

- 4.1. SAFETY

- 4.2. GENERAL

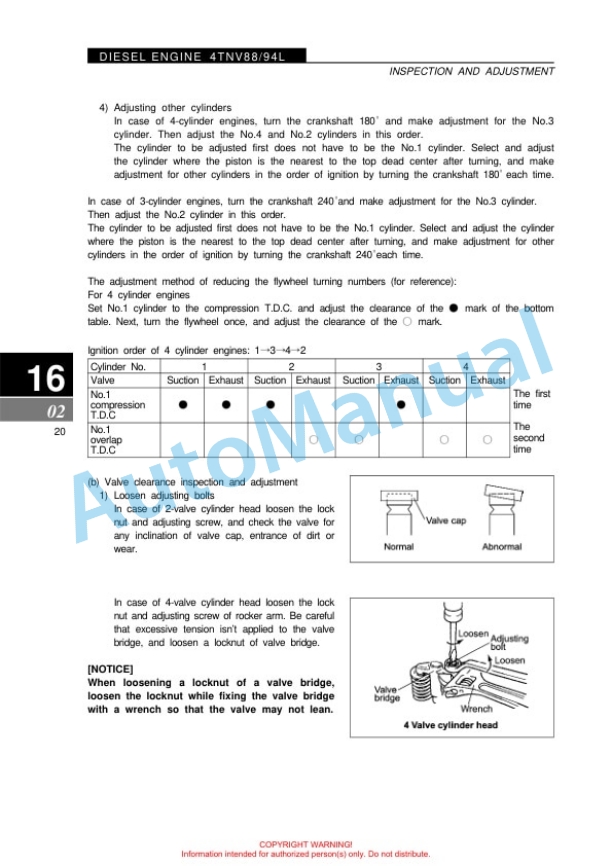

- 4.3. INSPECTION AND ADJUSTMENT

- 4.4. TROUBLESHOOTING

- 4.5. DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

- 4.6. LUBRICATION SYSTEM

- 4.7. COOLING SYSTEM

- 4.8. FUEL INJECTION PUMP/GOVERNOR

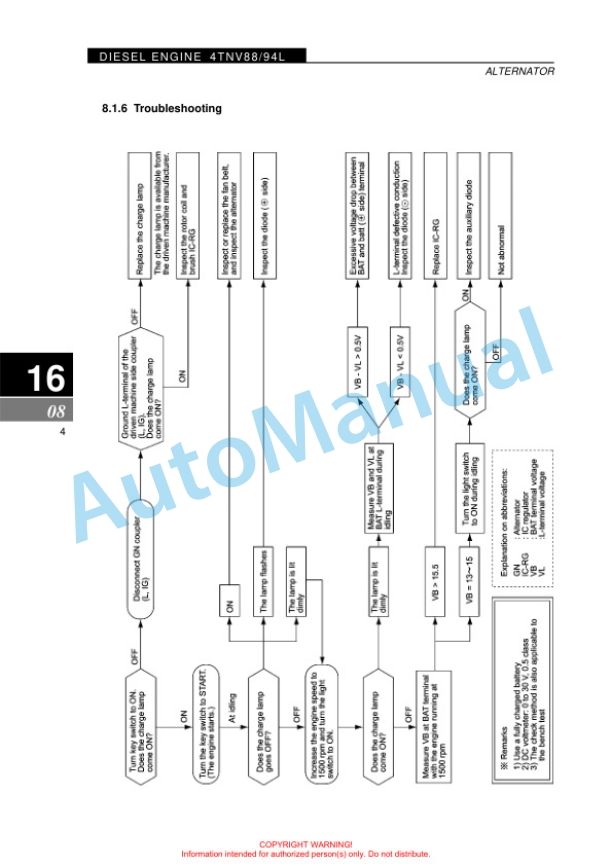

- 4.9. ALTERNATOR

- 4.10. ELECTRIC WIRING

- 4.11. SERVICE STANDARDS

- 4.12. TIGHTENING TORQUE FOR BOLTS AND NUTS

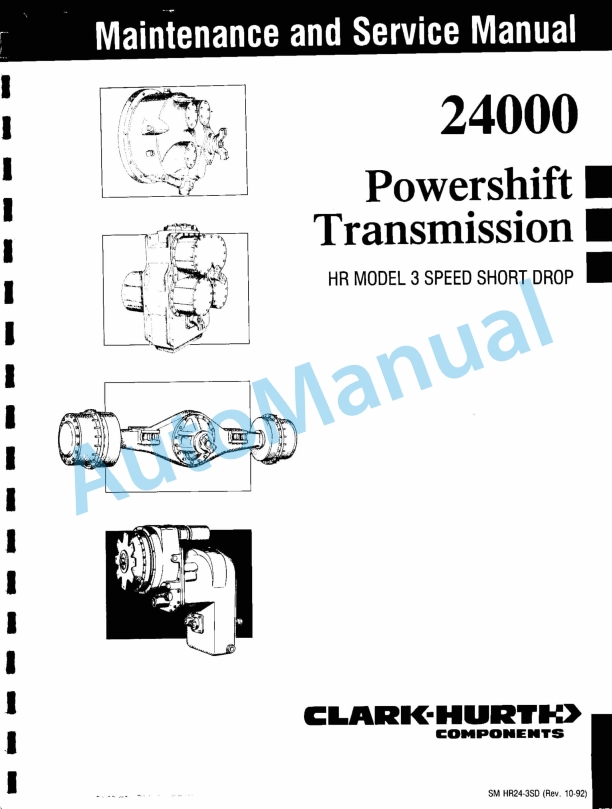

- 5. TRANSAXLE

- 5.1. STRUCTURE AND MAINTENANCE

- 5.1.1. CONSTRUCTION

- 5.1.2. HYDRAULIC CIRCUIT

- 5.1.3. SERVICE MAINTENANCE

- 5.1.4. SPECIFICATION

- 5.1.5. SERVICE BRAKE ADJUSTMENT

- 5.2. SERVICE BRAKE ADJUSTMENT

- 5.2.1. PRECAUTION

- 5.2.2. REMOVE AUXILIARY SUBASSEMBLIES

- 5.2.3. WHEEL END

- 5.2.4. BRAKE ASSEMBLY REMOVAL

- 5.2.5. SEPARATION OF CONVERTER HOUSING AND ADAPTOR PLATE

- 5.2.6. STATOR SUPPORT REMOVAL FROM ADAPTOR PLATE

- 5.2.7. CLUTCH ASSEMBLY, IDLER GEAR PINION SHAFT REMOVAL

- 5.3. ASSEMBLY

- 5.3.1. TRANSAXLE REASSEMBLY

- 5.3.2. DIFFERENTIAL

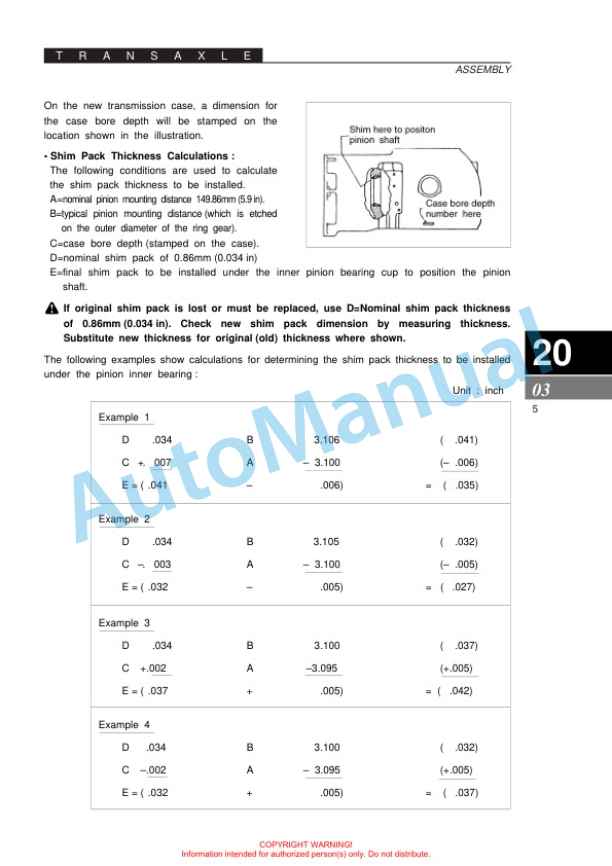

- 5.3.3. PINION GEAR SHIMMING

- 5.3.4. WHEEL END FINAL ASSEMBLY

- 5.3.5. CLUTCH ASSEMBLY

- 5.3.6. STATOR SUPPORT

- 5.3.7. TRANSMISSION ASSEMBLY

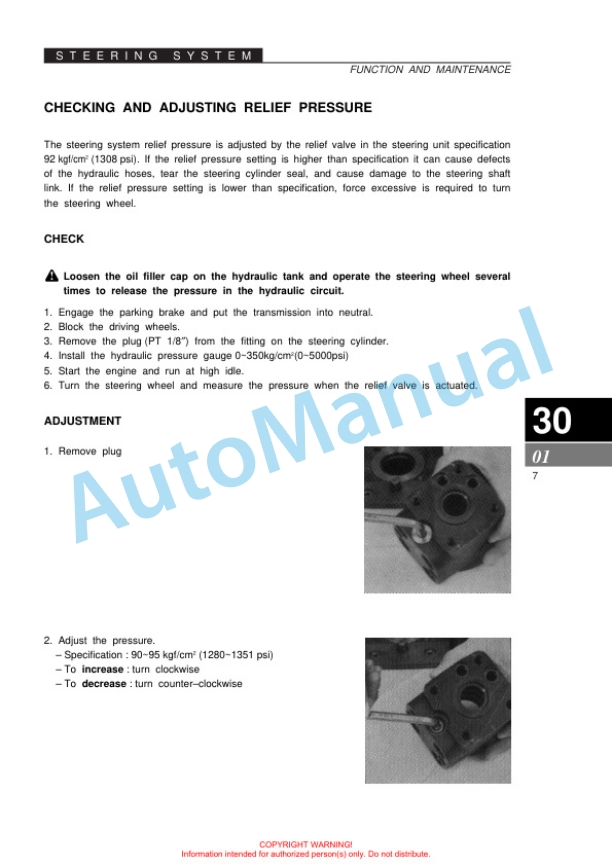

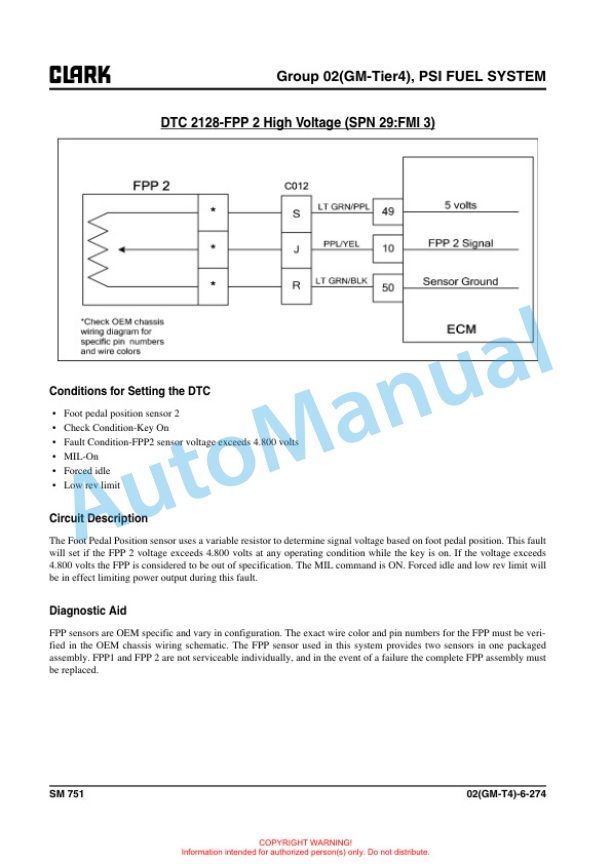

- 6. STEERING SYSTEM

- 6.1. FUNCTION AND MAINTENANCE

- 6.1.1. OUTLINE

- 6.1.2. OPERATING PRINCIPLE DURING LEFT/RIGHT TURN

- 6.1.3. STEERING UNIT

- 6.1.4. OPERATION

- 6.1.5. TROUBLESHOOTING TABLE

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.2.1. STEERING UNIT

- 6.2.2. PRIORITY VALVE

- 7. BRAKE SYSTEM

- 7.1. BRAKE AND INCHING SYSTEM

- 7.1.1. GENERAL

- 7.1.2. BRAKE/INCHING BLEEDING

- 7.1.3. DISASSEMBLY AND ASSEMBLY

- 8. HYDRAULIC STSTEM

- 8.1. MAIN PUMP

- 8.1.1. SPECIFICATION

- 8.1.2. DISASSEMBLY AND ASSEMBLY

- 8.1.3. TROUBLESHOOTING

- 8.1.4. START UP

- 8.2. MAIN HYDRAULIC VALVE

- 8.2.1. VALVE DISASSEMBLY

- 8.2.2. CLEANING, INSPECTION AND REPAIR

- 8.2.3. MAIN HYDRAULIC VALVE ASSEMBLY

- 8.2.4. HYDRAULIC SYSTEM PRESSURE SETTING

- 8.2.5. TROUBLESHOOTING

- 8.3. HYDRAULIC CYLINDERS

- 8.3.1. DISASSEMBLY AND ASSEMBLY

- 9. MAST MAINTENANCE

- 9.1. MAST

- 9.1.1. GENERAL

- 9.1.2. STANDARD MAST

- 9.1.3. FULL FREE LIFT MAST

- 9.1.4. TRIPLE MAST

- 9.2. OTHER COMPONENT

- 9.2.1. CARRIAGE

- 9.2.2. CYLINDER RACKING

- 9.2.3. LIFT CHAINS

- 9.2.4. COUNTERWEIGHT

- 9.2.5. LIFTING, JACKING AND BLOCKING

- 10. CIRCUIT DIAGRAM

- 10.1. HYDRAULIC ELECTRIC CIRCUIT DIAGRAM

- 10.1.1. HYDRAULIC CIRCUIT DIAGRAM

- 10.1.2. ELECTRIC CIRCUIT DIAGRAM (Diesel For EPA tier2)

- 10.1.3. ELECTRIC CIRCUIT DIAGRAM (Gasoline For EPA non tier2)

- 10.1.4. ELECTRIC CIRCUIT DIAGRAM (LPG For EPA tier2)

- 10.1.5. ELECTRIC CIRCUIT DIAGRAM (LPG SECM For EPA tier2)

Rate this product

You may also like

Clark Service Manual PDF

Clark C60 D, C70 D, C80 D, C80D900, C60 L, C70 L, C75 L Service Manual SM -1023

$30.00

Clark Service Manual PDF

Clark C15s D-L, C 18s D-L, C 20s D-L, C15s C-L, C 18s C-L, C 20s C-L Service Manual SM-1066

$30.00

Clark Service Manual PDF

$30.00

Clark Service Manual PDF

$30.00