Clark WP45 Service Manual SM-698

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM-698

- Format: PDF

- Size: 9.4MB

- Number of Pages: 280

Category: Clark Service Manual PDF

-

Model List:

- WP45

- 1. Standard Codes

- 2. Table of Contents

- 3. Warning Symbols

- 4. Prohibitory Symbols

- 5. Battery Safety

- 6. Static Safety

- 7. Welding Safety

- 8. Service Manual Introduction

- 9. Contents, Section M

- 9.1. Machine Information

- 9.1.1. General Product Information

- 9.1.1.1. Truck Presentation.

- 9.1.2. Main Components

- 9.1.3. Inch and Metric (SAE) Fasteners

- 9.1.3.1. Introduction

- 9.1.3.2. Nomenclature, Threads

- 9.1.3.3. Strength Identification

- 9.1.3.4. Conversion of English and Metric Units

- 9.1.4. Technical Service Data

- 9.1.5. Ordering Spare Parts

- 10. Contents, Section P

- 10.1. Planned Maintenance

- 10.1.1. Introduction, Maintenance

- 10.1.1.1. Jacking Truck Off The Floor

- 10.1.1.2. Lubricants

- 10.1.2. Service Schedule

- 10.1.2.1. Planned Maintenance Schedule

- 10.1.2.2. Planned Maintenance Procedures

- 10.1.2.3. Services Performed Every 480 or 960 Operating Hours

- 10.1.2.4. Services Performed Annually or Every 1440 Operating Hours

- 10.1.3. Lubrication Chart

- 10.1.4. Oil and Grease Specifications

- 10.1.4.1. Approved Oils and Grease

- 10.1.4.2. Grease Location Points

- 11. Contents, Section S

- 11.1. Service Instructions

- 11.2. Chassis/Lift Frame

- 11.2.1. Pull rod

- 11.2.1.1. Removal

- 11.2.1.2. Inspection

- 11.2.1.3. Installation

- 11.2.2. Carrier Frame Bushings

- 11.3. Inspection Covers

- 11.3.1. General Information

- 11.4. Driver Controls

- 11.4.1. Decal with Protective Sheet

- 11.4.2. Decal without Protective Sheet

- 11.5. Motor Maintenance Schedule/ Troubleshooting

- 11.5.1. General Information

- 11.5.2. Operating Conditions

- 11.5.3. Troubleshooting

- 11.6. Pump Motor

- 11.6.1. Mounting Points

- 11.6.1.1. Removal

- 11.6.1.2. Installation

- 11.6.2. Pump Motor Repair

- 11.6.2.1. Disassembly

- 11.6.3. Inspection and Troubleshooting

- 11.6.3.1. Drive End Head

- 11.6.3.2. Commutator End Head

- 11.6.3.3. Bearings

- 11.6.4. Brush Inspection

- 11.6.4.1. Brush Replacement Determination

- 11.6.4.2. Replacement Procedures

- 11.7. Drive Motor

- 11.7.1. Mounting Points

- 11.7.1.1. Drive Motor Brush

- 11.7.1.2. Drive Motor Removal

- 11.7.1.3. Drive Motor Installation

- 11.7.2. Component Repair

- 11.7.2.1. Motor Disassembly

- 11.7.3. Motor Inspection

- 11.7.3.1. External Motor

- 11.7.3.2. Brush and Commutator

- 11.7.3.3. Bearings

- 11.7.3.4. Armature Electrical Check

- 11.7.3.5. Frame and Field Service Recommendation

- 11.7.3.6. Assembly/Testing

- 11.8. Transmission

- 11.8.1. System Description

- 11.8.2. Troubleshooting

- 11.8.3. Transmission Mounting

- 11.8.3.1. Wrap Around Bumper

- 11.8.3.2. Removal

- 11.8.3.3. Installation

- 11.8.4. Transmission Repair

- 11.8.4.1. Disassembly

- 11.8.4.2. Reassembly

- 11.8.5. Axle Seal

- 11.8.5.1. Removal

- 11.8.5.2. Installation

- 11.9. Parking Brake System

- 11.9.1. Brake Theory of Operation

- 11.9.2. Brake Adjustment

- 11.9.3. Brake Shoe Removal / Installation

- 11.10. Drive Wheel

- 11.10.1. Removal

- 11.10.2. Installation

- 11.10.3. Tire Pressing Procedure

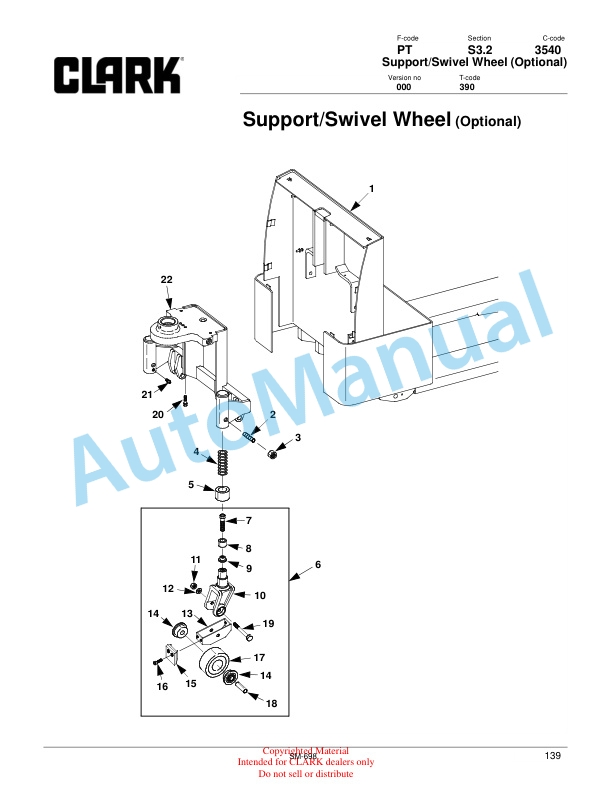

- 11.11. Support/Swivel Wheel (Optional)

- 11.11.1. Maintenance and Adjustments

- 11.11.1.1. Caster Adjustment

- 11.11.2. Troubleshooting

- 11.11.2.1. Stabilizing Caster

- 11.12. Fork Wheels

- 11.12.1. Removal/Installation

- 11.13. Steering

- 11.13.1. Control Handle Head

- 11.13.1.1. Removal

- 11.13.1.2. Installation

- 11.13.2. Driver Protection (Reverser) Assembly Replacement

- 11.13.3. Direction Control Switches

- 11.13.3.1. Removal

- 11.13.3.2. Installation

- 11.13.4. Raise, Lower, and Horn Switches

- 11.13.4.1. Removal

- 11.13.4.2. Installation

- 11.13.5. Potentiometer

- 11.13.5.1. Removal

- 11.13.5.2. Installation

- 11.13.6. Steering Stem

- 11.13.6.1. Removal

- 11.13.6.2. Installation

- 11.14. Electrical Functions

- 11.14.1. General

- 11.14.1.1. Adjustable Settings

- 11.14.1.2. References

- 11.14.1.3. Key Switch S17 in the ON Position

- 11.14.1.4. Operating Arm in Drive Position, S10, Brake Switch Closed

- 11.14.1.5. Travel Request, Fork First

- 11.14.1.6. Travel Request, Forks Trailing

- 11.14.1.7. Reversing/Motor Brake Forks First Direction to Forks Trailing Direction

- 11.14.1.8. Reversing/Motor Brake Forks Trailing Direction to Forks First Direction

- 11.14.1.9. Reverser switch

- 11.14.1.10. Lifting Forks

- 11.14.1.11. Lowering Forks

- 11.14.1.12. Lift Interrupt

- 11.15. Electrical Panel Components

- 11.16. Electrical Symbols

- 11.17. Electrical Schematics

- 11.18. Battery

- 11.18.1. Removal

- 11.18.2. Installation

- 11.18.3. Battery Maintenance

- 11.18.3.1. Battery Inspection and Care

- 11.18.3.2. Battery Exterior Cleaning

- 11.18.3.3. Charging

- 11.18.4. Storage

- 11.18.5. Battery History Record

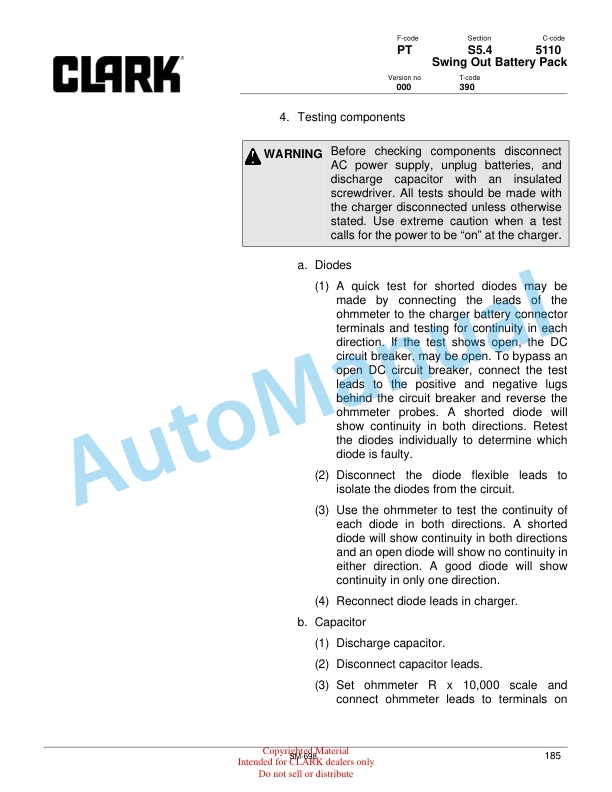

- 11.19. Swing Out Battery Pack

- 11.19.1. Battery Cable Routing Diagram

- 11.19.2. Charger Diagram

- 11.19.3. Troubleshooting

- 11.19.3.1. Electrical Testing

- 11.19.3.2. Equipment required

- 11.19.3.3. Instructions

- 11.20. Battery Connector

- 11.20.1. Location

- 11.20.2. Inspection

- 11.20.3. Installation

- 11.21. Battery Controller/Hourmeter/ Lift Interrupt (Optional)

- 11.21.1. General Information

- 11.21.2. Electrical

- 11.21.2.1. Voltage

- 11.21.3. Battery Controller (BC)

- 11.21.3.1. General Information

- 11.21.3.2. Key Switch

- 11.21.3.3. Hourmeter

- 11.21.4. Troubleshooting

- 11.21.4.1. Battery Discharge Indicator (BDI)

- 11.21.4.2. Hourmeter

- 11.22. Battery Discharge Indicator / Hourmeter

- 11.22.1. General Information

- 11.22.2. Electrical

- 11.22.2.1. Voltage

- 11.22.3. Battery Discharge Indicator (BDI)

- 11.22.3.1. General Information

- 11.22.3.2. Key Switch

- 11.22.3.3. Hourmeter

- 11.22.4. Troubleshooting

- 11.22.4.1. Battery Discharge Indicator (BDI)

- 11.22.4.2. Hourmeter

- 11.23. Start/Stop Switches

- 11.23.1. General

- 11.23.1.1. Test/Inspection

- 11.23.2. Master Control On/Off Switch (S21)

- 11.23.2.1. Inspection

- 11.23.2.2. Removal

- 11.23.2.3. Installation

- 11.24. Transistor Controller

- 11.24.1. Basics Of Circuit Operation

- 11.24.1.1. Control Features

- 11.24.2. Maintenance

- 11.24.2.1. Cleaning

- 11.24.3. Motor Circuit

- 11.24.4. Control Circuit

- 11.24.5. Troubleshooting Guidelines

- 11.24.5.1. General

- 11.24.6. Shorts to Frame Test

- 11.24.7. Definitions

- 11.24.8. Diagnostics and Troubleshooting

- 11.24.8.1. Handset Diagnostics

- 11.24.8.2. Troubleshooting

- 11.24.8.3. Troubleshooting Chart

- 11.24.8.4. Technical Specification

- 11.24.8.5. Troubleshooting Chart Using Handset

- 11.25. Transistor Controller Troubleshooting

- 11.25.1. Troubleshooting Chart Index

- 11.25.2. Troubleshooting Charts

- 11.25.2.1. Special Instructions

- 11.26. Hydraulic System

- 11.26.1. General

- 11.26.2. Troubleshooting

- 11.26.3. Schematic

- 11.26.4. Description

- 11.26.4.1. Relief Pressure

- 11.26.5. Maintenance

- 11.26.6. Lift Limit Switch

- 11.27. Hydraulic Pump

- 11.27.1. Removal

- 11.27.2. Disassembly

- 11.27.3. Inspection

- 11.27.4. Reassembly

- 11.27.5. Installation

- 11.27.6. Adjustments

- 11.27.6.1. Relief valve

- 11.27.6.2. Solenoid Operated Valve

- 11.28. Lift Cylinder

- 11.28.1. Cylinder Repair

- 11.28.1.1. Removal

- 11.28.1.2. Disassembly

- 11.28.1.3. Inspection

- 11.28.1.4. Assembly

- 11.28.1.5. Installation

- 11.29. Battery Charger, Optima Pack

- 11.29.1. Battery Charger Wiring Diagram Optima Pack

- 11.30. Handset Operation

- 11.30.1. Operating Modes

- 11.30.2. Revert to Previous Settings

- 11.30.3. Handset Self Test

Rate this product

You may also like

Clark Service Manual PDF

Clark C 40, 45, 50s, 55s D, C 40, 45, 50s, 55s L Service Manual SM-942

$30.00

Clark Service Manual PDF

Clark C20, 25, 30, 35 D, L, G, C20, 25, 30, 32C L Service Manual SM-996

$30.00

Clark Service Manual PDF

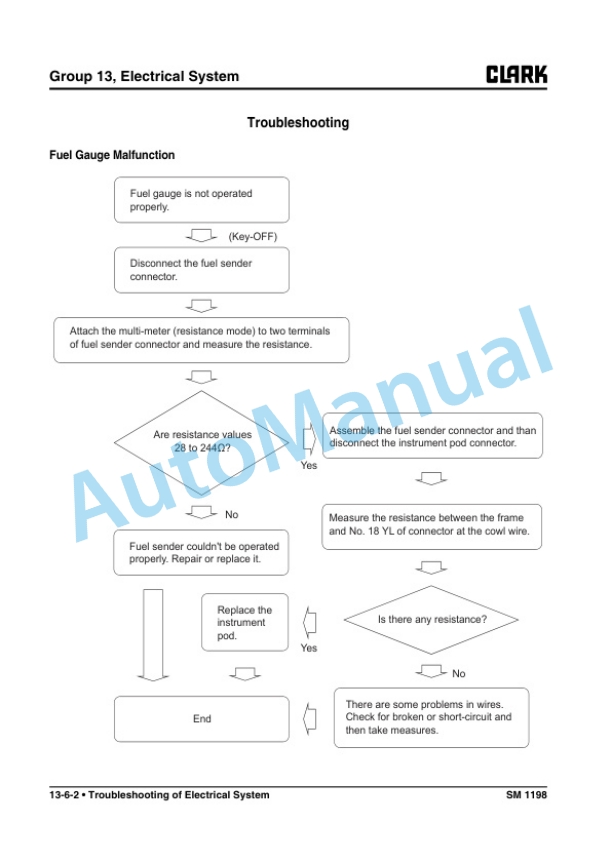

Clark C 15s L, C 18s L, C 20s L, C 15sC L, C 18sC L, C 20sC L Service Manual SM-1198

$30.00

Clark Service Manual PDF

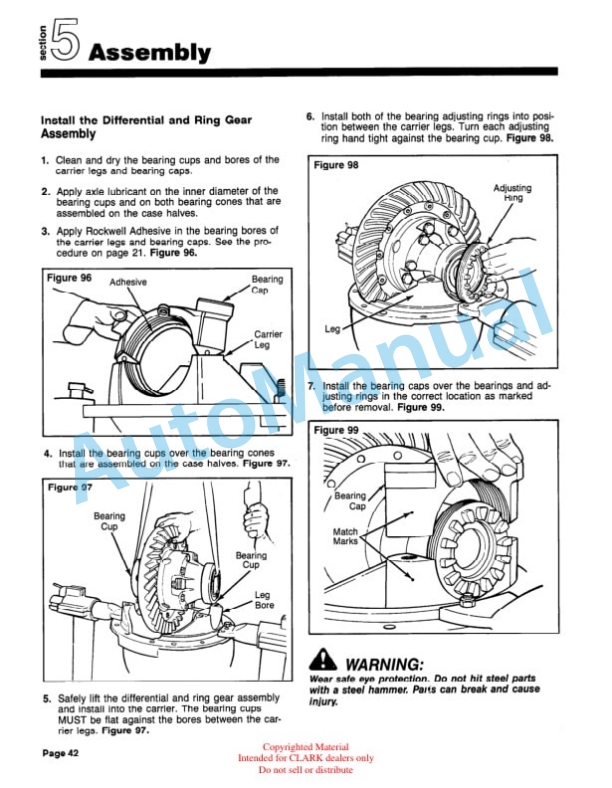

Clark 5000 Series Powershift Transmission Maintenance and Service Manual SM-54

$30.00

Clark Service Manual PDF

Clark C500 Y 180-200-225S-225L-250S-250L-300S-300L-350 Service Manual SM-575

$30.00

Clark Service Manual PDF

$30.00