IMT 14000 Series Crane and Model 19140 (Metric Version) Volume 2 – PARTS AND SPECIFICATIONS 9990043

$20.00

- Model: 14000 Series Crane and Model 19140 (Metric Version)

- Type Of Manual: Volume 2 – PARTS AND SPECIFICATIONS

- Manual ID: 9990043

- Language: English

- Format: PDF

- Size: 2.6MB

- NumPage: 140

Table of Content:

1 ELECTRONIC MANUALS

2 INTRODUCTION

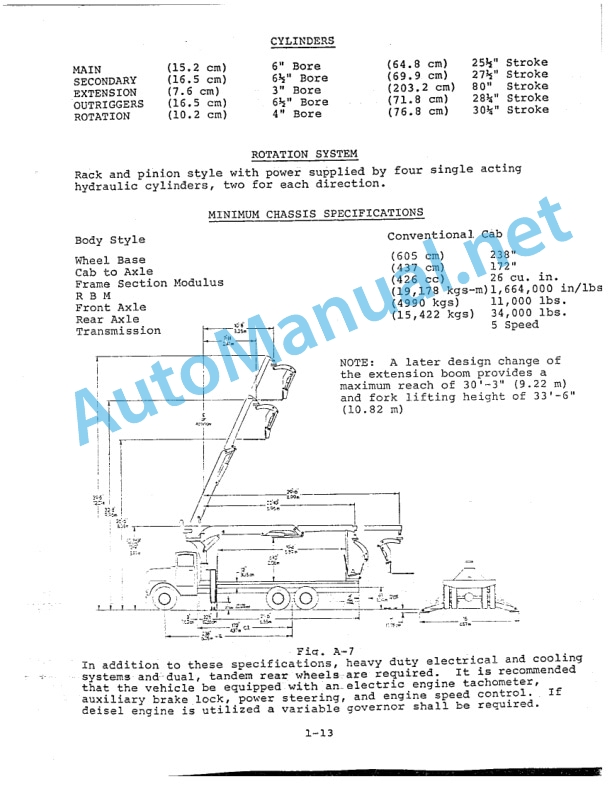

3 14000 SPECIFICATIONS

3.1 GENERAL SPECIFICATIONS

3.2 PERFORMANCE CHARACTERISTICS

3.3 POWER SOURCE

3.4 CYLINDER HOLDING VALVES

3.5 ROTATION SYSTEM

3.6 HYDRAULIC SYSTEM

3.7 CAPACITY ALERT SYSTEM

3.8 CAPACITY CHART-14000 4H1M & 4H2M

3.9 CAPACITY CHART-14000 3H & 4H

3.10 GEOMETRIC CONFIGURATION-14000 4H2M, 4H1M & 4H

3.11 GEOMETRIC CONFIGURATION-14000 3H

3.12 MINIMUM CHASSIS SPECIFICATIONS

4 19140 SPECIFICATIONS

4.1 GENERAL SPECIFICATIONS

4.2 PERFORMANCE CHARACTERISTICS

4.3 POWER SOURCE

4.4 CYLINDER HOLDING VALVES

4.5 ROTATION SYSTEM

4.6 HYDRAULIC SYSTEM

4.7 CAPACITY ALERT SYSTEM

4.8 SELECTED WEIGHTS OF ANCILLARY EQUIPMENT

4.9 CAPACITY CHART-19140 3H & 4H

4.10 GEOMETRIC CONFIGURATION-19140 4H2M, 4H1M & 4H

4.11 GEOMETRIC CONFIGURATION-19140 3H

5 CRANE REFERENCE

5.1 MAJOR CRANE ASSEMBLIES

5.2 WELDMENT PART NUMBER LOCATIONS

5.3 GREASE ZERK LOCATIONS & LUBRICANT REQUIREMENTS

5.4 RECOMMENDED SPARE PARTS LIST

5.5 RECOMMENDED SPARE PARTS LIST (Con’t)

5.6 INSTALLATION

5.7 CRANE MOUNTING

5.8 HYDRAULIC INSTALLATION

5.9 INITIAL CRANE RUN-IN PROCEDURE

5.10 STABILITY CHECK

5.11 HYDRAULIC PUMP

5.12 OUTRIGGERS

5.13 ROTATION

5.14 INNER BOOM

5.15 OUTER BOOM

5.16 EXTENSION BOOMS

5.17 CRANE CONTROLS

5.18 PARKING BRAKE

5.19 CRANE CONTROL STATIONS

5.20 CONTROL DECALS

5.21 VALVEBANK

5.22 OTHER CRANE CONTROLS

5.23 CRANE SET-UP

5.24 REQUIRED CLEARANCES OF CRANES FROM ELECTRICAL TRANSMISSION LINES

5.25 PRECAUTIONS

5.26 OPERATING PROCEDURES

5.27 EQUIPMENT FAMILIARIZATION

5.28 EQUIPMENT CHECKS

5.29 WORK SITE POSITION

5.30 BEFORE LEAVING CAB

5.31 CRANE DEPLOYMENT

5.32 BEFORE MAKING THE LIFT

5.33 READING AND UNDERSTANDING THE CAPACITY CHART

5.34 EXTENSION BOOM SEQUENCE

5.35 IMPROPER EXTENSION BOOM DEPLOYMENT

5.36 LIFTING THE LOAD

5.37 CAPACITY SHUT DOWN/ OVERSTRESS SYSTEM

5.38 OPERATION IN ADVERSE CONDITIONS

5.39 OPERATION IN DUSTY AND SANDY AREAS

5.40 OPERATION IN HIGH HUMIDITY OR SALT AIR CONDITIONS

5.41 OPERATION AT HIGH ALTITUDES

5.42 COLD WEATHER OPERATION

5.43 PREPARATION FOR ROAD TRAVEL

5.44 SAFE VEHICLE TRANSPORT

5.45 INSTALLATION OF VARIABLE DISPLACEMENT PUMP

5.46 INSTALLATION AND HOSE CONNECTIONS

5.47 PRELIMINARY PRESSURE ADJUSTMENT (BEFORE START-UP)

5.48 PUMP STARTUP

5.49 EXISTING INSTALLATION PRESSURE CHECK AND ADJUSTMENT

5.50 FLOW OUTPUT ADJUSTMENT

5.51 MAINTENANCE

5.52 INSPECTION

5.53 DAILY INSPECTIONS

5.54 WEEKLY INSPECTIONS

5.55 MONTHLY INSPECTIONS

5.56 PERIODIC INSPECTIONS

5.57 ADJUSTMENTS AND REPAIRS

5.58 LUBRICATION

5.59 LUBRICANTS

5.60 LUBRICATION POINTS

5.61 HYDRAULIC OIL DETERIORATION

5.62 HYDRAULIC SYSTEM PURGING

5.63 PURGING AIR FROM THE SYSTEM

5.64 HYDRAULIC COMPONENTS

5.65 SYSTEM RELIEF PRESSURE

5.66 CYLINDER HOLDING CAPABILITIES

5.67 FILTER ELEMENT REPLACEMENT

5.68 HYDRAULIC FILTER

5.69 MAINTENANCE AND SERVICE – LONG TERM STORAGE

5.70 HYDRAULIC SYSTEM

5.71 CORROSION CONTROL

5.72 SERVICE

5.73 CLEANLINESS

5.74 HYDRAULIC SYSTEMS

5.75 FASTENERS AND TORQUE VALUES

5.76 LABEL PARTS WHEN DISASSEMBLING

5.77 BOOM WEAR PADS

5.78 PIN AND BEARING INSPECTION AND INSTALLATION

5.79 PIN INSPECTION

5.80 PIN BEARING INSPECTION

5.81 TRUNNION INSPECTION

5.82 INSTALLATION

5.83 TURNTABLE GEAR – REMOVAL AND REPLACEMENT

5.84 PINION AND DRIVE GEAR BUSHINGS – REMOVAL AND REPLACEMENT

5.85 REMOVAL AND REPLACEMENT OF OUTRIGGER ARMS

5.86 VERTICAL OUTRIGGER CYLINDERS – REMOVAL AND REPLACEMENT

5.87 HORIZONTAL OUTRIGGER CYLINDERS – REMOVAL AND REPLACEMENT

5.88 REMOVAL AND REPLACEMENT OF OPERATOR CONTROL VALVE

5.89 EXTENSION CYLINDERS -REMOVAL

5.90 EXTENSION CYLINDERS – REINSTALLATION

5.91 OUTER BOOM – REMOVAL AND REPLACEMENT

5.92 OUTER CYLINDER – REMOVAL AND REPLACEMENT

5.93 INNER CYLINDER-REMOVAL AND REPLACEMENT

5.94 INNER BOOM-REMOVAL AND REPLACEMENT

5.95 MAST-REMOVAL AND REPLACEMENT

5.96 ROTATION MOTOR, C’BAL VALVE & BRAKE-REMOVAL & REPLACEMENT

5.97 CAPACITY SHUT DOWN/OVERSTRESS SYSTEM

5.98 MODE OF OPERATION

5.99 ANTI-TWO BLOCK

5.100 CHECKING CONTROL BOX CIRCUIT

6 PARTS

6.1 PARTS INFORMATION

6.2 BASE & 16′ (4.9m) OUTRIGGER ASM (41710040-1)

6.3 BASE & 16′ (4.9m) OUTRIGGER ASM (41710040-2)

6.4 BASE & 16′ (4.9m) OUTRIGGER ASM (41710040-3)

6.5 BASE & 21′(6.4m) OUTRIGGER ASM (41709801-1)

6.6 BASE & 21′(6.4m) OUTRIGGER ASM (41709801-2)

6.7 BASE & 21′(6.4m) OUTRIGGER ASM (41709801-3)

6.8 MAST ASM (41709874)

6.9 INNER BOOM ASM (41709875)

6.10 OUTER BOOM ASM (41710030)

6.11 SWIVEL HOOK ASM 7-TON (51710187)

6.12 EXTENSION BOOM ASM-3H (41710036)

6.13 EXTENSION BOOM ASM-4H (41710183)

6.14 EXTENSION BOOM ASM-4H/1M (41710184)

6.15 EXTENSION BOOM ASM-4H/2M (41710031)

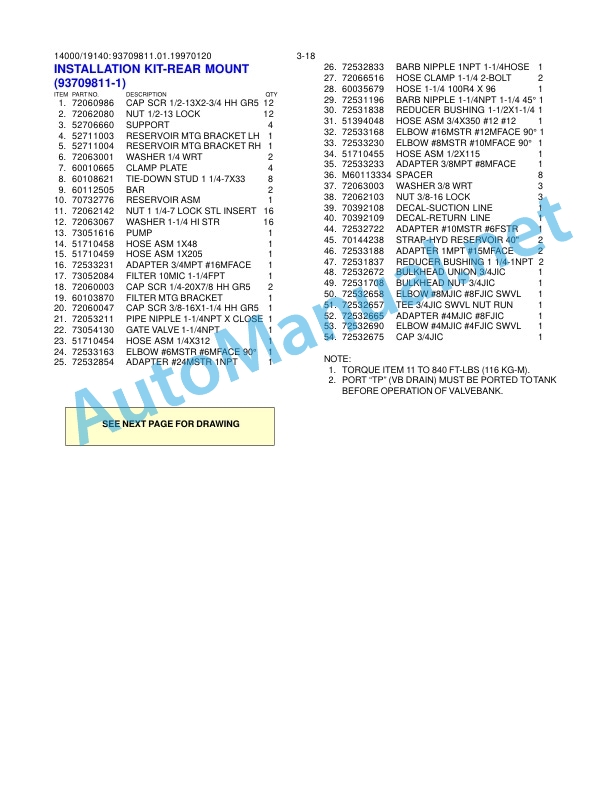

6.16 INSTALLATION KIT-REAR MOUNT (93709811-1)

6.17 INSTALLATION KIT-REAR MOUNT (93709811-2)

6.18 DECAL KIT-14000 SERIES CRANE 3H&4H (95710280-1)

6.19 DECAL KIT-14000 SERIES CRANE 3H&4H (95710280-2)

6.20 DECAL KIT-MODEL 19140 CRANE 3H&4H (95711916-1)

6.21 DECAL KIT-MODEL 19140 CRANE 3h&4h (95711916-2)

6.22 DECAL KIT-14000 SERIES CRANE 4H1M & 4H2M (95711507-1)

6.23 DECAL KIT-14000 SERIES CRANE 4H1M & 4H2M (95711507-2)

6.24 DECAL KIT-MODEL 19140 CRANE 4H1M & 4H2M (95711917-1)

6.25 DECAL KIT-MODEL 19140 CRANE 4H1M & 4H2M (95711917-2)

6.26 RESERVOIR ASM-40 GALLON (70732776)

6.27 1ST STG EXT CYLINDER (73050142)

6.28 2ND STG EXT CYLINDER (73050143)

6.29 4TH STG EXT CYLINDER (73050145)

6.30 INNER BOOM CYLINDER (3C112920)

6.31 OUTER BOOM CYLINDER (3C124920)

6.32 PWR OUT OUTRIGGER CYLINDER (3B055920)

6.33 PWR DN OUTRIGGER CYLINDER (3B070920)

6.34 WEAR PAD & SHIM REPLACEMENT CHART

6.35 AUX OUTRIGGER KIT-REAR MT-PO/PD-LOAD SENSE (31712754-1)

6.36 AUX OUTRIGGER KIT-REAR MT-pO/PD-LOAD SENSE (31712754-2)

6.37 AUX OUTRIGGER KIT-FRONT MT-PO/PD-LOAD SENSE (31712755-1)

6.38 AUX OUTRIGGER KIT-FRONT MT-PO/PD-LOAD SENSE (31712755-2)

6.39 CYLINDER-PWR DN (3B020860)

6.40 CYLINDER-PWR OUT (3B148860)

6.41 CYLINDER-PWR DN (3B208940)

6.42 WINCH KIT (31712879-1)

6.43 WINCH KIT (31712879-2)

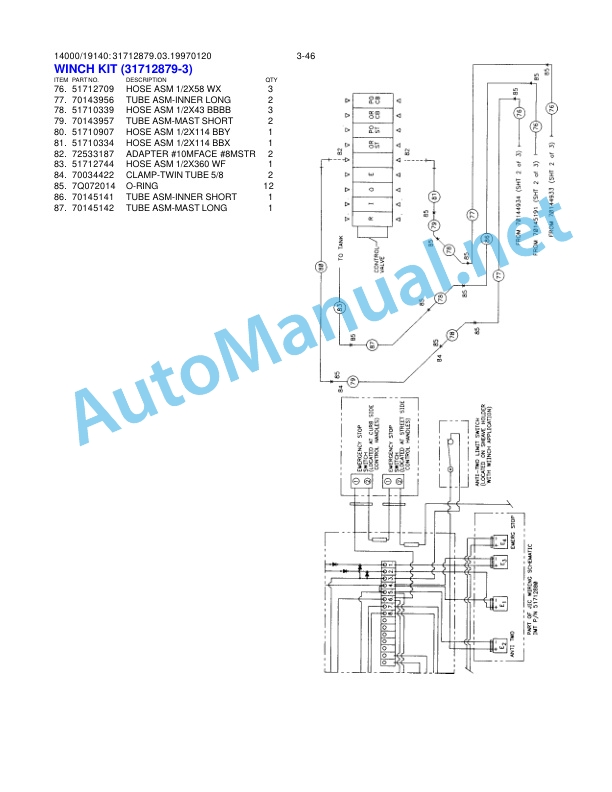

6.44 WINCH KIT (31712879-3)

6.45 ANTI TWO-BLOCKING SYSTEM (70732874)

6.46 HYDRAULIC KIT-VOAC (91712883-1)

6.47 HYDRAULIC KIT-VOAC (91712883-2)

6.48 VALVEBANK ASM-9 SECT VOAC MNL (51712793)

6.49 VALVEBANK-9 SECT MNL (73732967)

6.50 VALVEBANK ASM-9 SECT VOAC RADIO RMT (51712919)

6.51 VALVEBANK-9 SECT RADIO RMT (73733013-1)

6.52 VALVEBANK-9 SECT RADIO RMT (73733013-2)

6.53 CTRL KIT-9F MNL VOAC (90712790-1)

6.54 CTRL KIT-9F MNL VOAC (90712790-2)

6.55 CABLE ASM-JIC BOX (51712855)

6.56 CABLE ASM-JIC BOX RADIO RMT (HETRONICS) (51712880)

6.57 CTRL KIT-9F RMT VOAC (90713043-1)

6.58 CTRL KIT-9F RMT VOAC (90713043-2)

7 GENERAL REFERENCE

7.1 INSPECTION CHECKLIST

7.2 WIRE ROPE INSPECTION

7.3 HOOK INSPECTION

7.4 HOLDING VALVE INSPECTION

7.5 ANTI-TWO BLOCKING DEVICE INSPECTION

7.6 TORQUE DATA CHART-DOMESTIC

7.7 TORQUE DATA CHART-METRIC

7.8 TURNTABLE BEARING FASTENER TIGHTENING SEQUENCE

7.9 TURNTABLE BEARING INSPECTION FOR REPLACEMENT

7.10 LIMITED WARRANTY

8 VOLUME 1

9 CRANE SAFETY