Table of Content:

1 ELECTRONIC MANUALS

2 INTRODUCTION

3 SPECIFICATIONS

3.1 GENERAL SPECIFICATIONS

3.2 LIFTING CAPACITY (from centerline of rotation)

3.3 PERFORMANCE CHARACTERISTICS

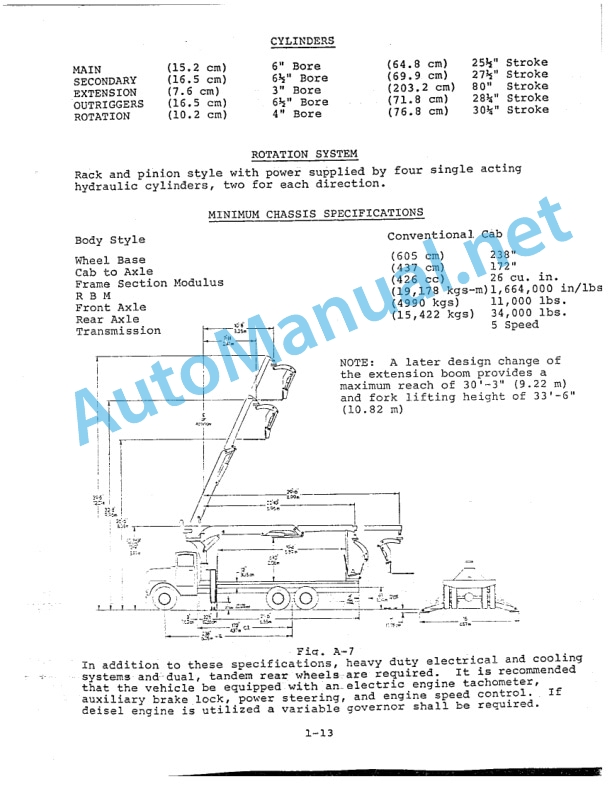

3.4 CYLINDERS

3.5 POWER SOURCE

3.6 CYLINDER HOLDING VALVES

3.7 ROTATION SYSTEM

3.8 ELECTRO-HYDRAULIC SYSTEM

3.9 CONTROLS

3.10 MINIMUM CHASSIS SPECIFICATIONS

3.11 CAPACITY CHART

3.12 GEOMETRIC CONFIGURATION

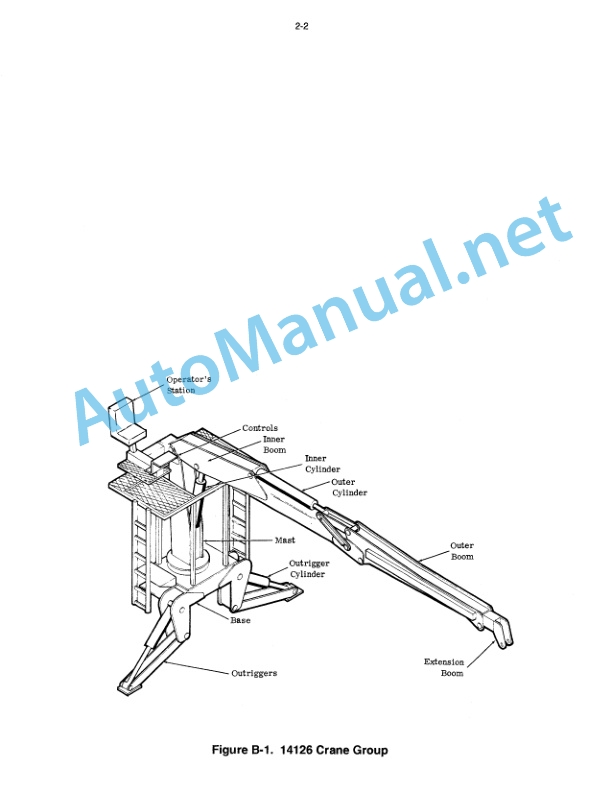

4 CRANE REFERENCE

4.1 MAJOR CRANE ASSEMBLIES

4.2 WELDMENT PART NUMBER LOCATIONS

4.3 GREASE ZERK LOCATIONS & LUBRICANT REQUIREMENTS

4.4 RECOMMENDED SPARE PARTS LIST

4.5 INSTALLATION

4.6 BODY PREPARATION

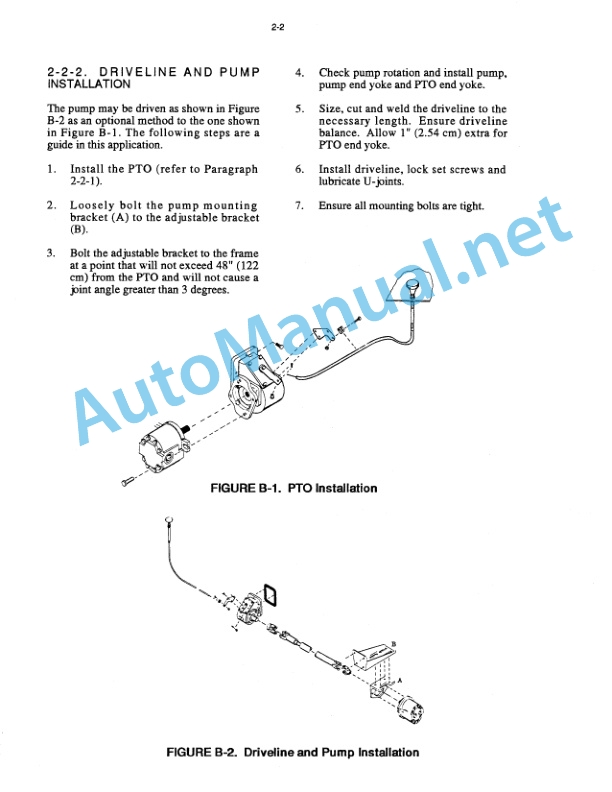

4.7 POWER UNIT INSTALLATION

4.8 HYDRAULIC INSTALLATION

4.9 GROUND WIRE INSTALLATION

5 PARTS

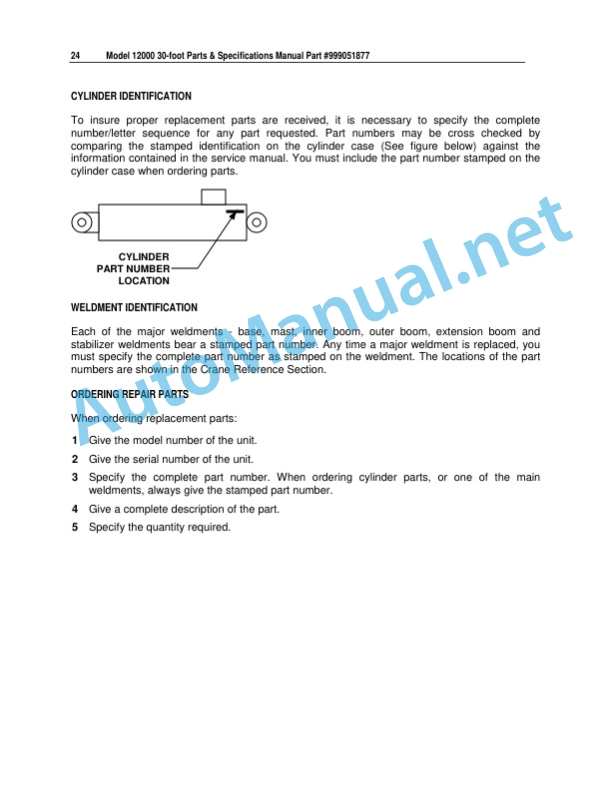

5.1 PARTS INFORMATION

5.2 BASE ASM (41704555)

5.3 MAST ASM (41705323)

5.4 LOWER BOOM ASM (41705324)

5.5 LOWER BOOM CYLINDER (3B202840)

5.6 EXTENSION BOOM ASM (41705325)

5.7 EXTENSION CYLINDER (3B201840)

5.8 HYDRAULIC KIT- 3 SECT-PWR UNIT (91705326)

5.9 VALVEBANK 3-SPOOL (73073039)

5.10 CONTROL KIT-PWR UNIT 3F (90705328)

5.11 REMOTE HANDLE ASM 3F (51705329)

5.12 INSTALLATION KIT (93705327)

5.13 DECAL KIT (95708903)

5.14 OPTION-MNL OUTRIGGER KIT (90701596)

6 GENERAL REFERENCE

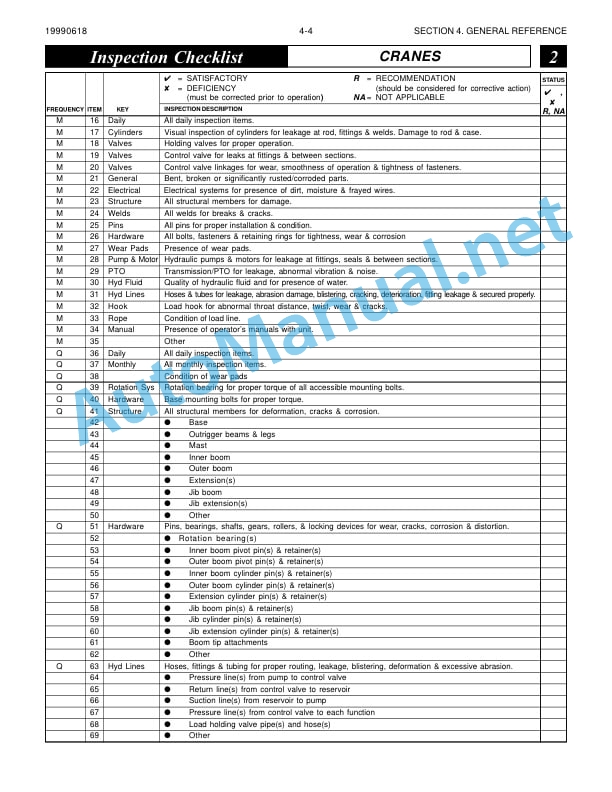

6.1 INSPECTION CHECKLIST

6.2 WIRE ROPE INSPECTION

6.3 HOOK INSPECTION

6.4 HOLDING VALVE INSPECTION

6.5 ANTI-TWO BLOCKING DEVICE INSPECTION

6.6 TORQUE DATA CHART-DOMESTIC

6.7 TORQUE DATA CHART-METRIC

6.8 TURNTABLE BEARING FASTENER TIGHTENING SEQUENCE

6.9 TURNTABLE BEARING INSPECTION FOR REPLACEMENT

6.10 LIMITED WARRANTY