Komatsu 102 Series Diesel Engine Shop Manual YEBM200101

$40.00

- Type Of Manual: Shop Manual

- Manual ID: YEBM200101

- Format: PDF

- Size: 40.2MB

- Number of Pages: 806

Category: Komatsu Shop Manual PDF

-

Model List:

- 102 Series Diesel Engine

- 0.0.1. HOW TO READ THE SHOP MANUAL

- 0.0.2. HOISTING INSTRUCTIONS

- 0.0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.0.4. COATING MATERIALS

- 0.0.5. STANDARD TIGHTENING TORQUE

- 0.0.6. ELECTRIC WIRE CODE

- 0.0.7. UNITS

- 0.0.8. CAPSCREW MARKINGS AND TORQUE VALUES

- 0.0.9. PIPE PLUG TORQUE VALUES

- 0.0.10. SYMBOLS

- 0.0.11. ILLUSTRATIONS

- 0.1. GENERAL

- 0.1.1. APPLICABLE MACHINE

- 0.1.2. GENERAL ASSEMBLY DRAWING

- 0.1.3. ENGINE PERFORMANCE CURVE

- 0.1.4. WEIGHT TABLE

- 0.2. STRUCTURE AND FUNCTION

- 0.2.1. OUTLINE OF AIR INTAKE AND EXHAUST SYSTEMS

- 0.2.2. INTAKE AND EXHAUST DEVICES

- 0.2.3. AIR CLEANER

- 0.2.4. TURBOCHARGER

- 0.2.5. CYLINDER HEAD

- 0.2.6. CYLINDER BLOCK

- 0.2.7. MAIN MOVING PARTS

- 0.2.8. TIMING GEAR PORTION

- 0.2.9. FRONT GEAR COVER

- 0.2.10. CAMSHAFT TIMING PIN

- 0.2.11. VALVE MECHANISM

- 0.2.12. FLYWHEEL, FLYWHEEL HOUSING

- 0.2.13. LUBRICATION SYSTEM DIAGRAM

- 0.2.14. OIL PUMP

- 0.2.15. OIL FILTER, OIL COOLER

- 0.2.16. REGULATOR VALVE, SAFETY VALVE

- 0.2.17. FUEL SYSTEM DIAGRAM

- 0.2.18. FUEL INJECTION PUMP

- 0.2.19. TIMING LOCK PIN FOR FUEL INJECTION PUMP

- 0.2.20. FUEL FILTER

- 0.2.21. FUEL INJECTION NOZZLE

- 0.2.22. FUEL CUT SOLENOID

- 0.2.23. COOLING SYSTEM DIAGRAM

- 0.2.24. WATER PUMP

- 0.2.25. THERMOSTAT

- 0.2.26. FAN DRIVE

- 0.2.27. AIR COMPRESSOR

- 0.2.28. FLOW DIAGRAMSCOMPRESSED AIR SYSTEM

- 0.2.29. ALTERNATOR

- 0.2.30. ALTERNATOR(OPTIONAL)

- 0.2.31. STARTING MOTOR

- 0.2.32. STARTING MOTOR

- 0.2.33. STARTING MOTOR(OPTIONAL)

- 0.2.34. STARTING AID

- 0.3. TEATING AND ADJUSTING

- 0.3.1. SPECIAL TOOL LIST

- 0.3.2. TROUBLESHOOTIN DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM

- 0.3.3. MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION(ENGINE WITH TURBOCHARGER)

- 0.3.4. TESTING TURBOCHARGER WESTGATE VALVE(ENGINE WITH TURBOCHARGER)

- 0.3.5. TESTING TURBOCHARGER WESTGATE CAPSULE (ENGINE WITH TURBOCHARGER)

- 0.3.6. TESTING ACTUATION OF TURBOCHARGER WESTGATE (ENGINE WITH TURBOCHARGER )

- 0.3.7. REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE(ENGINE WITH TURBOCHARGER)

- 0.3.8. ADJUSTING TURBOCHARGER WESTGATE ACTUATOR(ENGINE WITH TURBOCHARGER)

- 0.3.9. MEASURING EXHAUST RESISTANCE

- 0.3.10. REPLACING TURBOCHARGER(ENGINE WITH TURBOCHARGER)

- 0.3.11. TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE

- 0.3.12. ADJUSTING VALVE CLEARANCE

- 0.3.13. TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM

- 0.3.14. FUEL INJECTION PUMP CALIBRATION DATA

- 0.3.15. RUNNING IN STANDARD

- 0.3.16. PERFORMANCE TEST CRITERIA

- 0.3.17. TROUBLESHOOTING DEFECTIVE ACTUATION OF FEED PUMP(DIAPHRAGM TYPE)

- 0.3.18. TROUBLESHOOTING DEFECTIVE ACTUATION OF FEED PUMP(PISTON TYPE)

- 0.3.19. TESING AIR INSIDE FUEL SYSTEM

- 0.3.20. TESING WATER SEPARATOR FUEL FILTER

- 0.3.21. TROUBLESHOOTING FAILURE OF FUEL INJECTION PUMP(BOSCH VE, LUCAS CAV)

- 0.3.22. TESTING HIGHPRESSURE FUEL PIPING

- 0.3.23. TESING FUEL INJECTION NOZZLE

- 0.3.24. TESING FUEL DRAIN PIPING

- 0.3.25. BLEEDING AIR FROM FUEL SYSTEM

- 0.3.26. ADJUSTING FUEL INJECTION TIMING

- 0.3.27. ADJUSTING LOW IDLING SPEED (BOSCH VE, LUCAS CAV)

- 0.3.28. REPLACING FUEL INJECTION NOZZLE

- 0.3.29. TROUBLESHOOTING DEFECTIVE ACTUATION OF COOLING SYSTEM

- 0.3.30. TESTING CARBON DEPOSIT IN AIR COMPRESSOR

- 0.3.31. TESING AIR LEAKAGE FROM AIR COMPRESSOR

- 0.3.32. TESING AIR GOVERNOR, UNLOADER VALVE

- 0.3.33. TESING AIR GOVERNOR

- 0.3.34. TESING BATTERY

- 0.3.35. TESING BATTERY TERMINAL CONNCTIONS

- 0.3.36. TESTING STARTING CIRCUIT

- 0.3.37. TESING ALTERNATOR

- 0.3.38. TESING OIL PRESSURE SWITCH AND WATER TEMPERATURE SENSOR

- 0.3.39. TESING WHITE SMOKE

- 0.3.40. TESING INTAKE HEATER

- 0.3.41. SIDE VIEW OF ENGINE

- 0.3.42. OUTLINE OF ENGINE PERFORMANCE TEST

- 0.3.43. BLOWBY MEASUREMENT AND REPLACEMENT TABLE

- 0.3.44. ENGINE DYNAMOMETER

- 0.3.45. ENGINE PAINWORK

- 0.3.46. TROUBLESHOOTING

- 0.4. DISASSEMBLY AND ASSEMBLY

- 0.4.1. SPECIAL TOOL LIST

- 0.4.2. OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE

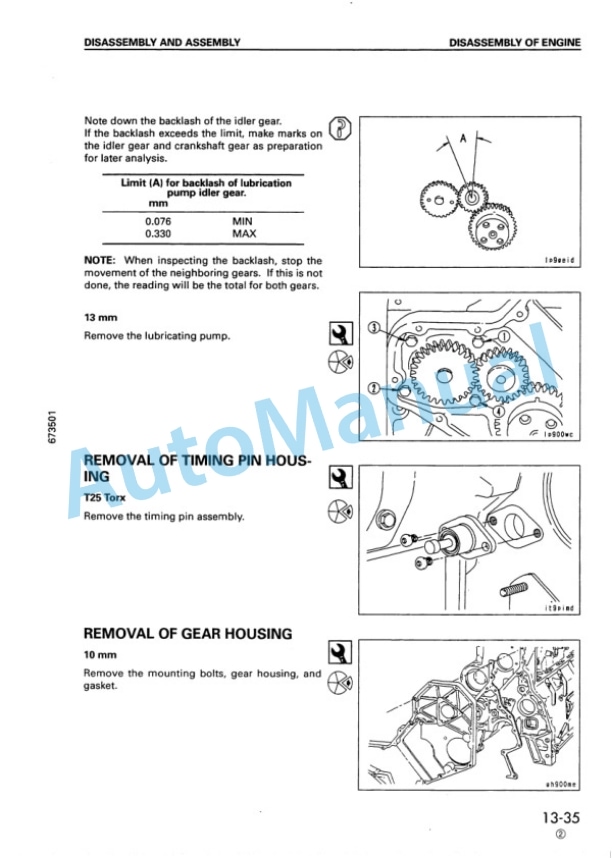

- 0.4.3. DISASSEMBLY OF ENGINE

- 0.4.4. ASSEMBLY OF ENGINE

- 0.4.5. INTAKE GROUP

- 0.4.6. REPLACEMENT OF TURBOCHARGER(ENGINE WITH TURBOCHARGER)

- 0.4.7. REPLACEMENT OF AFTERCOOLER, GASKET(ENGINE WITH AFTERCOOLER)

- 0.4.8. REPLACEMENT OF INTAKE CONNECTOR

- 0.4.9. AIR CONNECTOR

- 0.4.10. REPLACEMENT OF INTAKE MANIFOLD COVER, GASKET

- 0.4.11. AIR CROSSOVER TUBE

- 0.4.12. EXHAUST GROUP

- 0.4.13. REPLACEMENT OF EXHAUST MANIFOLD, GASKET

- 0.4.14. REPLACEMENT OF TURBOCHARGER

- 0.4.15. TURBOCHARGER MOUNTING STUD(ENGINE WITH TURBOCHARGER)

- 0.4.16. CYLINDER BLOCK GROUP

- 0.4.17. CYLINDER BLOCK

- 0.4.18. CRANKSHAFT

- 0.4.19. REPLACEMENT OF TIMEING PIN

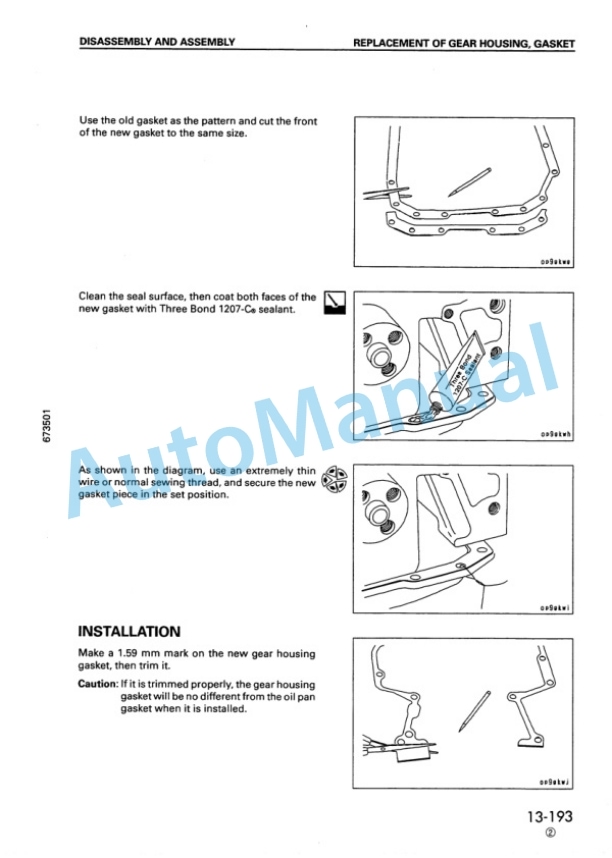

- 0.4.20. REPLACEMENT OF GEAR HOUSING, GASKET

- 0.4.21. REPLACEMENT OF VIBRATION DAMPER, CRANKSHAFT PULLEY

- 0.4.22. PISTON, PIN, CONNECTING ROD

- 0.4.23. BALANCER

- 0.4.24. GEAR COVER

- 0.4.25. CYLINDER HEAD

- 0.4.26. ROCKER LEVER

- 0.4.27. TAPPETS AND PUSH RODS

- 0.4.28. ENGINE MOUNT GROUP

- 0.4.29. FLYWHEEL, RING GEAR

- 0.4.30. FLYWHEEL HOUSING

- 0.4.31. FRONT SUPPORT

- 0.4.32. REMOVAL OF ENGINE

- 0.4.33. INSPECTION OF ENGINE MOUNT

- 0.4.34. INSTALLATION OF ENGINE

- 0.4.35. OIL PAN AND SUCTION TUBE

- 0.4.36. REGULATOR VALVE

- 0.4.37. OIL FILTER BYPASS VALVE

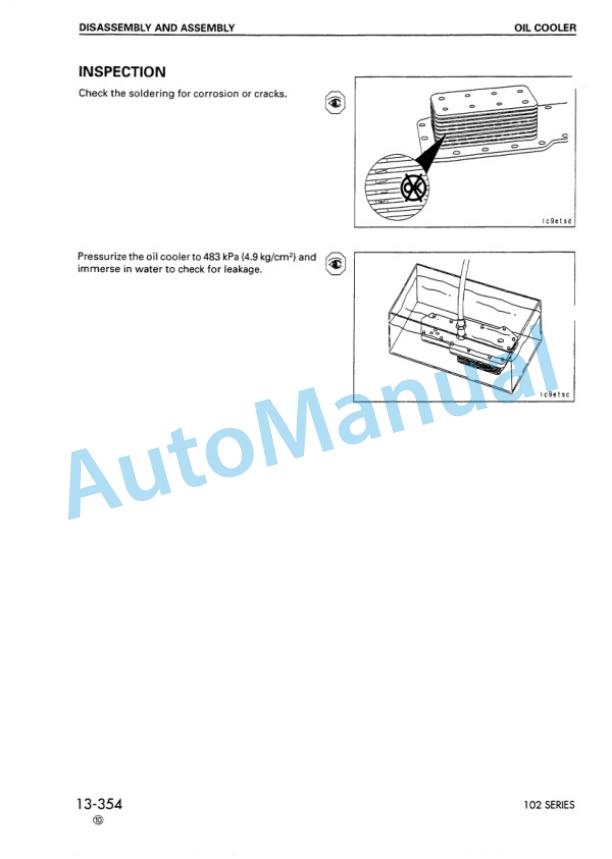

- 0.4.38. OIL COOLER

- 0.4.39. OIL PUMP

- 0.4.40. FUEL INJECTION PUMP GROUP

- 0.4.41. FUEL INJECTION NOZZLE GROUP

- 0.4.42. FEED PUMP(CYLINDER BLOCK MOUNT TYPE)

- 0.4.43. REPLACEMENT OF FUEL FILTER

- 0.4.44. FUEL PIPING

- 0.4.45. WATER PUMP

- 0.4.46. FAN HUB

- 0.4.47. BELT TENSIONER

- 0.4.48. THERMOSTAT

- 0.4.50. COOLANT

- 0.4.51. ACCESSORY DRIVE ADAPTER

- 0.4.52. ALTERNATOR

- 0.4.53. STARTING MOTOR

- 0.5. MAINTENANCE STANDARD

- 0.5.1. TURBOCHARGER

- 0.5.2. EXHAUST MANIFOLD

- 0.5.3. CYLINDER HEAD

- 0.5.4. VALVE, VALVE GUIDE

- 0.5.5. LOCKER ARM SHAFT, PUSH ROD AND TAPPET

- 0.5.6. PISTON, PISTON RING AND PISTON PIN

- 0.5.7. CONNECTING ROD

- 0.5.8. VIBRATION DAMPER

- 0.5.9. FLYWHEEL, FLYWHEEL HOUSING

- 0.5.10. FAN HUB

- 0.5.11. OIL PUMP

- 0.5.12. WATER PUMP, THERMOSTAT

- 0.5.13. FUEL INJECTION PUMP

- 0.5.14. FUEL INJECTION NOZZLE

- 0.6. REPAIR AND REPLACEMENT OF PARTS

- 0.6.1. OUTLINE

- 0.6.2. REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT

- 0.6.3. METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS

- 0.6.4. METHOD FOR REPAIRING TRPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS

- 0.6.5. METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS

- 0.6.6. PROCEDURE AND TOOLS FOR REPAIRING CYLINDER BLOCK

- 0.6.7. INSPECTION AND GRINDING TO REPAIR COMBUSTION DECK

- 0.6.8. INSPECTION AND INSTALLATION OF VALVE GUIDE

- 0.6.9. PROCEDURE 1 FOR BUILDING UP USING SERVICE VALVE GUIDE

- 0.6.10. PROCEDURE 2 FOR BUILDING UP USING SERVICE VALVE GUIDE

- 0.6.11. OUTLINE OF VALVE SEAT REPAIR

- 0.6.12. CALCULATING GRINDING DEPTH OF VALVE SEAT

- 0.6.13. METHOD OF GRINDING VALVE SEAT

- 0.6.14. METHOD OF INSTALLING VALVE SEAT

- 0.6.15. MACHINING EXHAUST VALVE INSERT POCKET

- 0.6.16. METHOD OF GRINDING VALVE

- 0.6.17. ASSEMBLY OF CYLINDER HEAD

- 0.6.18. PROCEDURE FOR REPAIRING CYLINDER BLOCK

- 0.6.19. PROCEDURE FOR REPAIRING CRANKSHAFT

- 0.6.20. PROCEDURE FOR REPAIRING CONNECTING ROD

- 0.6.21. PACKING STYLE OF CYLINDER HEAD AND HOW TO INSTALL PLUGS

- 1. UNDER COVER

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00