Komatsu 108-2 Series Diesel Engine Shop Manual SEBM006906

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM006906

- Format: PDF

- Size: 9.2MB

- Number of Pages: 226

Category: Komatsu Shop Manual PDF

-

Model List:

- 108-2 Series Diesel Engine

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRICAL WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. APPLICABLE MACHINE

- 1.2. SPECIFICATIONS

- 1.3. GENERAL ASSEMBLY DRAWING

- 1.4. ENGINE PERFORMANCE CURVE

- 1.5. WEIGHT TABLE

- 2. STRUCTURE AND FUNCTION

- 2.1. GENERAL STRUCTURE

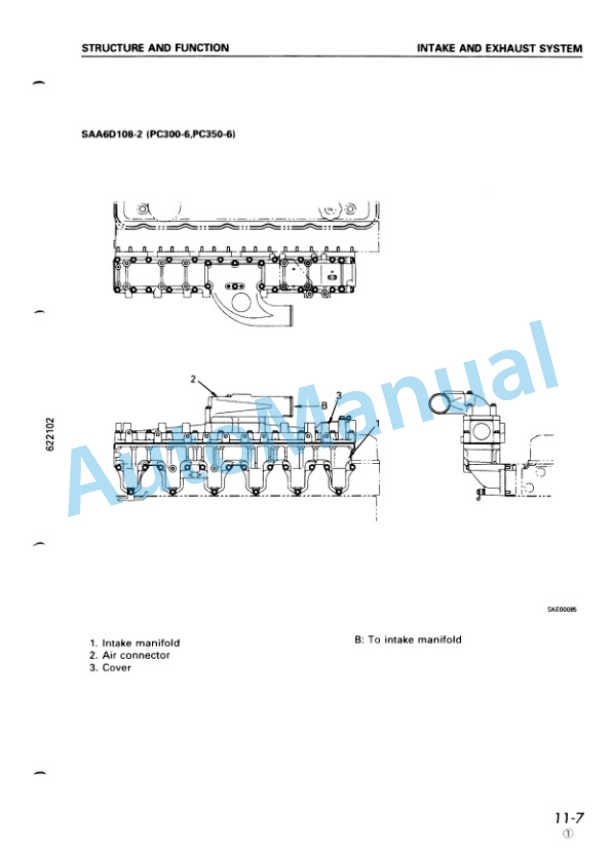

- 2.2. INTAKE AND EXHAUST SYSTEM

- 2.2.1. AFTERCOOLER

- 2.2.2. AIRCOOLED AFTERCOOLER MOUNT

- 2.2.3. AIR CLEANER

- 2.2.4. ELECTRONIC DUST INDICATOR

- 2.2.5. TURBOCHARGER

- 2.3. ENGINE BODY

- 2.3.1. CYLINDER HEAD

- 2.3.2. CYLINDER BLOCK

- 2.3.3. MAIN REVOLVING SYSTEM

- 2.3.4. TIMING GEAR

- 2.3.5. VALVE MECHANISM

- 2.3.6. FLYWHEEL AND FLYWHEEL HOUSING

- 2.4. LUBRICATION SYSTEM

- 2.4.1. LUBRICATION SYSTEM CHART

- 2.4.2. OIL PUMP

- 2.4.3. OIL FILTER

- 2.4.4. OIL COOLER

- 2.5. FUEL SYSTEM

- 2.5.1. FUEL SYSTEM CHART

- 2.5.2. FUEL INJECTION PUMP

- 2.5.3. SPEED CONTROL LEVER ANGLE

- 2.5.4. BOOST COMPENSATOR DEVICE

- 2.5.5. FUEL INJECTION NOZZLE

- 2.5.6. FUEL FILTER

- 2.5.7. FUEL INJECTION PUMP DRIVE CASE

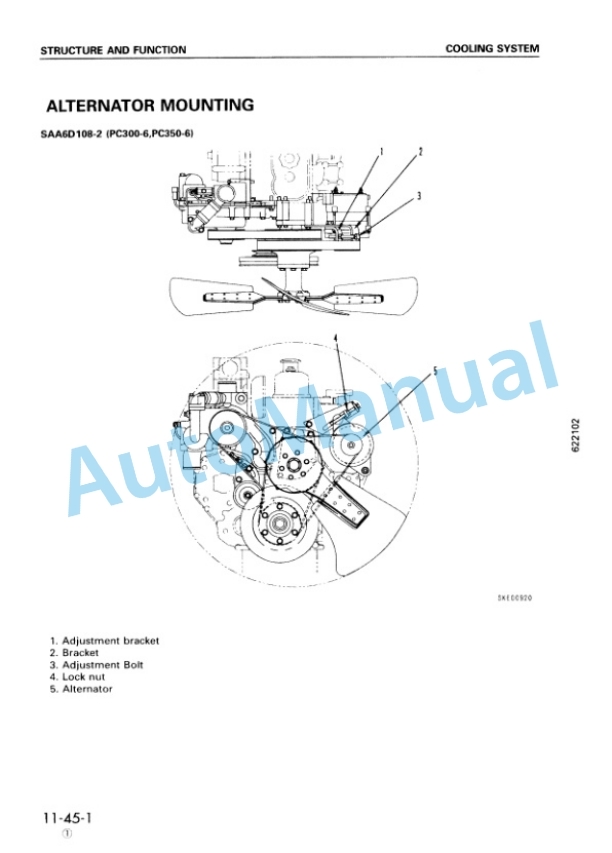

- 2.6. COOLING SYSTEM

- 2.6.1. COOLING SYSTEM, CHART

- 2.6.2. WATER PUMP

- 2.6.3. THERMOSTAT

- 2.7. ELECTRICAL SYSTEM

- 2.7.1. WIRING DIAGRAM

- 2.7.2. ALTERNATOR

- 2.7.3. STARTING MOTOR

- 2.7.4. OIL PRESSURE SWITCH

- 2.7.5. RELAY SWITCH

- 2.7.6. GLOW PLUG

- 3. TESTING AND ADJUSTING

- 3.1. INTAKE AND EXHAUST SYSTEM

- 3.1.1. ADJUSTING VALVE CLEARANCE

- 3.2. ENGINE BODY

- 3.2.1. MEASURING COMPRESSION PRESSURE

- 3.3. FUEL SYSTEM

- 3.3.1. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.3.2. PROCEDURE FOR ADJUSTING FUEL CUT SOLENOID LINKAGE

- 3.3.3. PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 3.4. PERFORMANCE TEST

- 3.4.1. RUNNING IN STANDARD

- 3.4.2. PERFORMANCE TEST CRITERIA

- 3.5. FUEL INJECTION PUMP CALIBRATION DATA

- 3.6. TROUBLESHOOTING

- 3.6.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.6.2. METHOD OF USING TROUBLESHOOTING CHART

- 3.6.3. S1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)

- 3.6.4. S2 ENGINE DOES NOT START

- 3.6.4.1. ENGINE DOES NOT TURN

- 3.6.4.2. ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)

- 3.6.4.3. EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)

- 3.6.5. S3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOWUP IS POOR)

- 3.6.6. S4 ENGINE STOPS DURING OPERATIONS

- 3.6.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)

- 3.6.8. S6 ENGINE LACKS OUTPUT (NO POWER)

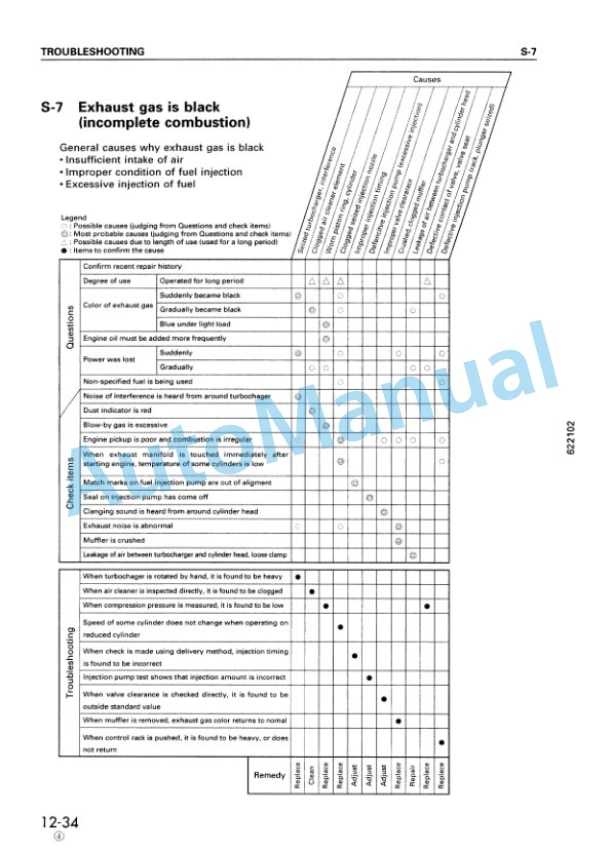

- 3.6.9. S7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)

- 3.6.10. S8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)

- 3.6.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 3.6.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 3.6.13. S11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN

- 3.6.14. S12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)

- 3.6.15. S13 OIL LEVEL RISES

- 3.6.16. S14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)

- 3.6.17. S15 ABNORMAL NOISE IS MADE

- 3.6.18. S16 VIBRATION IS EXCESSIVE

- 3.7. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 3.8. TESTING AND ADJUSTING DATA

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. OVERALL DISASSEMBLY

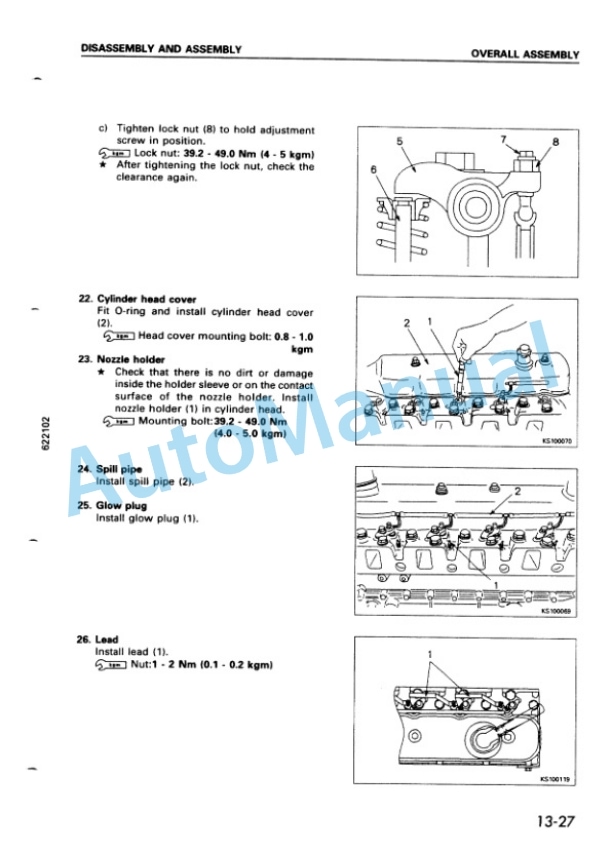

- 4.2. OVERALL ASSEMBLY

- 5. MAINTENANCE STANDARD

- 5.1. INTAKE AND EXHAUST SYSTEM

- 5.1.1. TURBOCHARGER

- 5.2. ENGINE BODY

- 5.2.1. CYLINDER HEAD

- 5.2.2. VALVE AND VALVE GUIDE

- 5.2.3. ROCKER ARM, PUSH ROD AND TAPPET

- 5.2.4. CYLINDER LINER

- 5.2.5. CYLINDER BLOCK

- 5.2.6. CRANKSHAFT

- 5.2.7. CAMSHAFT

- 5.2.8. PISTON, PISTON RING AND PISTON PIN

- 5.2.9. CONNECTING ROD

- 5.2.10. TIMING GEAR

- 5.2.11. FLYWHEEL AND FLYWHEEL HOUSING

- 5.3. LUBRICATION SYSTEM

- 5.3.1. OIL PUMP

- 5.3.2. REGULATOR VALVE

- 5.3.3. SAFETY VALVE

- 5.4. COOLING SYSTEM

- 5.4.1. WATER PUMP AND THERMOSTAT

- 6. REPAIR AND REPLACEMENT OF PARTS

- 6.1. REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

- 6.2. REPLACING VALVE SEAT INSERTS

- 6.3. PRESSURE TEST

- 6.4. REPLACING VALVE GUIDE

- 6.5. GRINDING THE VALVE

- 6.6. REPLACING CAM BUSHING

- 6.7. REPLACING CRANK GEAR

- 6.8. REPLACING CAM GEAR

- 6.9. REPLACING FLYWHEEL RING GEAR

- 6.10. REPLACING MAIN BEARING CAP

- 6.11. GRINDING CRANKSHAFT

- 6.12. REPLACING ENGINE REAR SEAL

- 6.13. REPLACING CONNECTING ROD SMALL END BUSHING

Rate this product

You may also like