Komatsu 114 Series Diesel Engine Shop Manual SEBM024609

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM024609

- Format: PDF

- Size: 16.1MB

- Number of Pages: 444

Category: Komatsu Shop Manual PDF

-

Model List:

- 114 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. SAFETY

- 4.1. SAFETY NOTICE

- 5. FOREWORD

- 5.1. GENERAL

- 5.2. HOW TO READ THE SHOP MANUAL

- 5.3. HOISTING INSTRUCTIONS

- 5.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 5.5. COATING MATERIALS

- 5.6. STANDARD TIGHTENING TORQUE

- 5.7. ELECTRIC WIRE CODE

- 5.8. CONVERSION TABLE

- 5.9. UNITS

- 5.10. CAPSCREW MARKINGS AND TORQUE VALUES

- 5.11. CAPSCREW MARKINGS AND TORQUE VALUES METRIC

- 5.12. CAPSCREW MARKINGS AND TORQUE VALUES U.S. CUSTOMARY

- 5.13. PIPE PLUG TORQUE VALUES

- 5.14. SYMBOLS

- 5.15. ILLUSTRATIONS

- 6. GENERAL

- 6.1. APPLICABLE MACHINE

- 6.2. SPECIFICATION

- 6.3. OVERALL DRAWING

- 6.4. WEIGHT TABLE

- 6.5. ENGINE PERFORMANCE CURVE

- 7. STRACTURE AND FUNCTION

- 7.1. AIR INTAKE DEVICE

- 7.2. EXHAUST MANIFOLD

- 7.3. MAIN CIRCULATION PART

- 7.4. CRANK SHAFT

- 7.5. PISTONPISTON RINGPISTON PIN

- 7.6. CONNECTING ROD

- 7.7. VIBRATION DAMPER

- 7.8. TIMING GEAR PORTION

- 7.9. FRONT GEAR COVER

- 7.10. CAMSHAFT TIMING PIN

- 7.11. TIMING GEAR

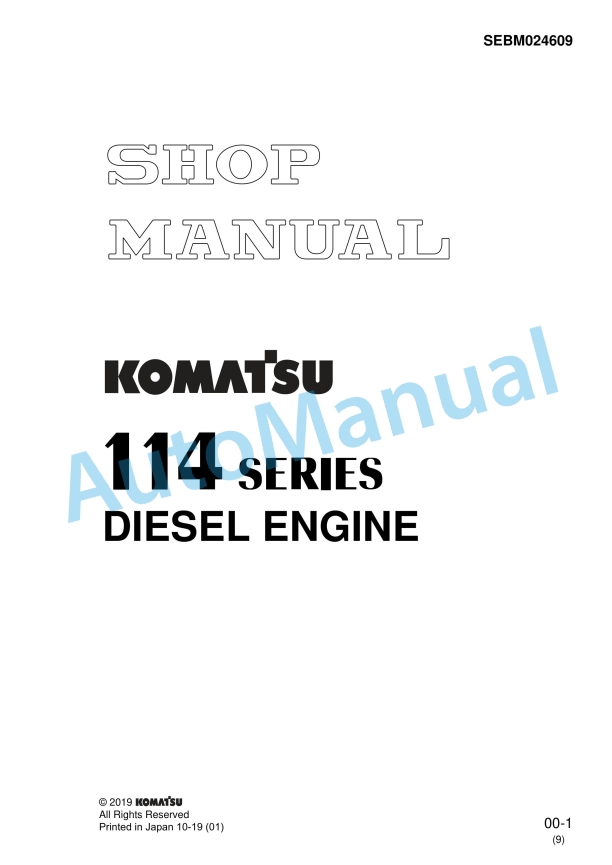

- 7.12. CAM SHAFT

- 7.13. VALVE MECHANISM

- 7.14. VALVE, VALVE GUIDE

- 7.15. ROCKERARM SHAFTPUSH RODTAPPET

- 7.16. OIL PAN

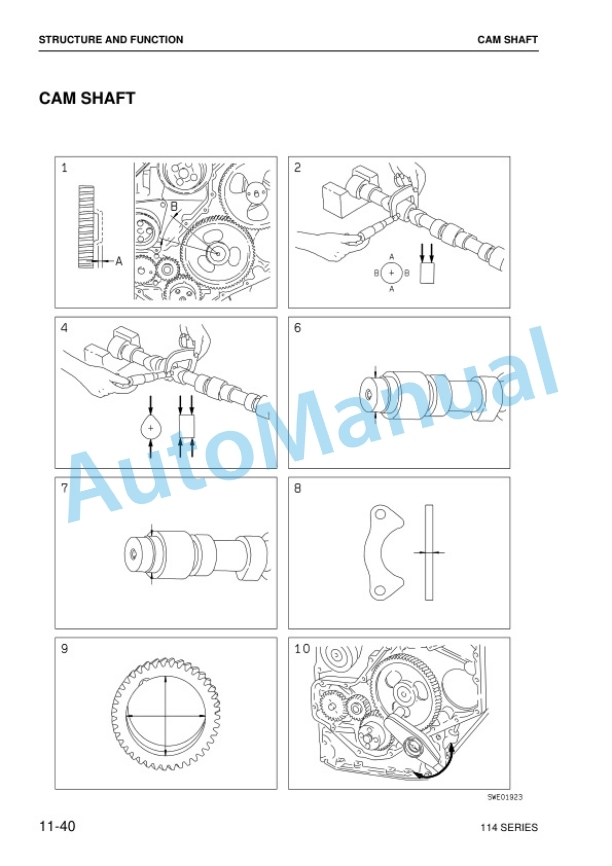

- 7.17. FLYWHEEL, FLYWHEEL HOUSING

- 7.18. LUBRICATION SYSTEM DIAGRAM

- 7.19. OIL PUMP

- 7.20. OIL FILTER, OIL COOLER

- 7.21. REGULATOR VALVE, SAFETY VALVE

- 7.22. FUEL SYSTEM DIAGRAM

- 7.23. FUEL INJECTION PUMP

- 7.24. TIMING LOCK PIN OF FUEL INJECTION PUMP

- 7.25. FUEL FILTER

- 7.26. FUEL INJECTION NOZZLE

- 7.27. FUEL CUT SOLENOID

- 7.28. COOLING SYSTEM DIAGRAM

- 7.29. WATER PUMP DRIVE

- 7.30. WATER PUMP (WITH ONEPIECE BEARING, SHAFT, ONEPIECE WATER SEAL)

- 8. TESTING AND ADJUSTING

- 8.1. SPECIAL TOOL LIST

- 8.2. TROUBLESHOOTING DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM

- 8.3. MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION

- 8.4. TESTING TURBOCHARGER WESTGATE VALVE

- 8.5. TESTING TURBOCHARGER WESTGATE CAPSULE

- 8.6. TESTING ACTUATION OF TURBOCHARGER WESTGATE

- 8.7. REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE

- 8.8. ADJUSTING TURBOCHARGER WESTGATE ACTUATOR

- 8.9. MEASURING EXHAUST RESISTANCE

- 8.10. REPLACING TURBOCHARGER

- 8.11. TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE

- 8.12. ADJUSTING VALVE CLEARANCE

- 8.13. TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM

- 8.14. FUEL INJECTION PUMP CALIBRATION DATA

- 8.15. RUNNING IN STANDARD

- 8.16. PERFORMANCE TEST CRITERIA

- 8.17. TESTING FUEL FEED PUMP

- 8.18. ADJUSTING FUEL CUTOFF SOLENOID

- 8.19. TESTING FOR AIR INSIDE THE FUEL SYSTEM

- 8.20. TESTING WATER SEPARATOR, FUEL FILTER

- 8.21. TESTING HIGHPRESSURE FUEL PIPING

- 8.22. TESTING FUEL INJECTION NOZZLE

- 8.23. TESTING FUEL DRAIN PIPING

- 8.24. BLEEDING AIR FROM FUEL SYSTEM

- 8.25. ADJUSTING TIMING OF FUEL INJECTION PUMP

- 8.26. TROUBLESHOOTING DEFECTIVE OPERATION OF COOLING SYSTEM

- 8.27. STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 8.28. TROUBLESHOOTING OF ENGINE (S MODE)

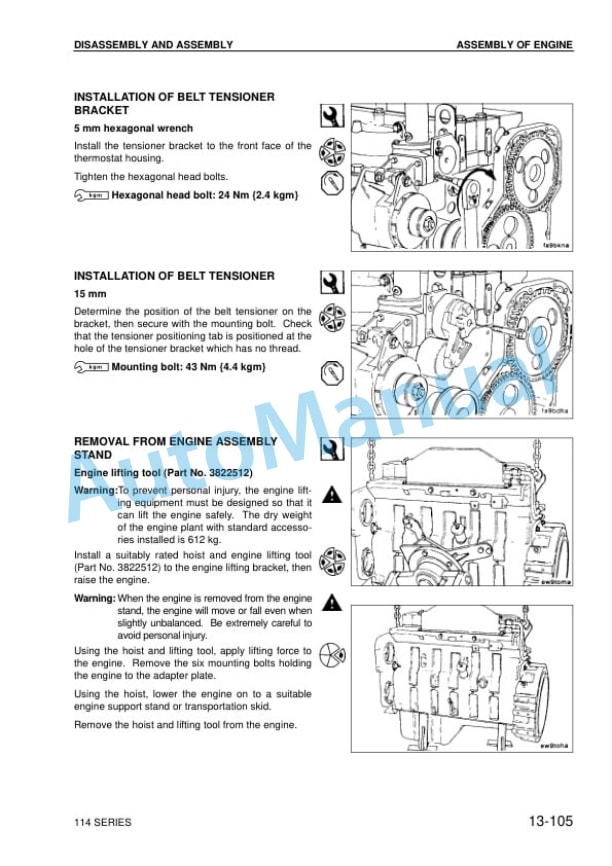

- 9. DISASSEMBLY AND ASSEMBLY

- 9.1. SPECIAL TOOL LIST

- 9.2. OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE

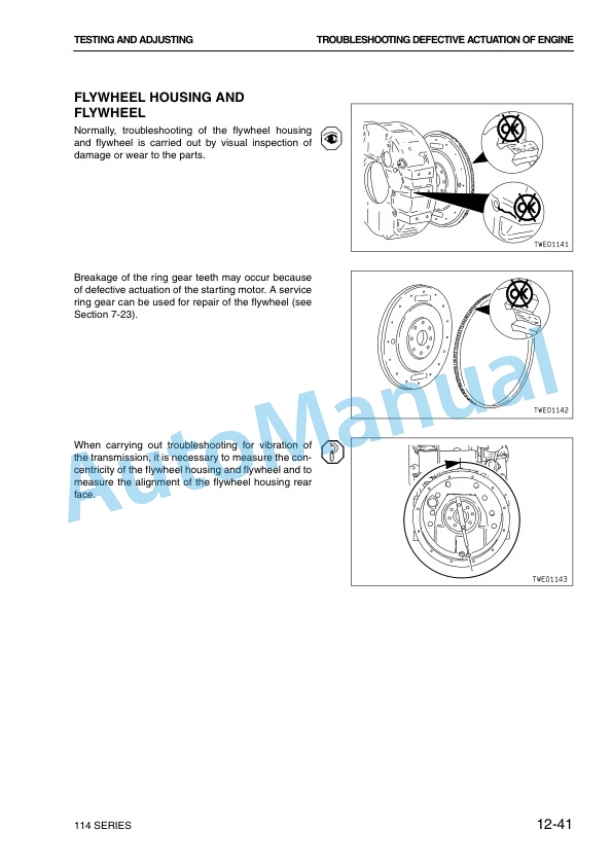

- 9.3. OVERALL DISASSEMBLY OF ENGINE

- 9.4. ASSEMBLY OF ENGINE

- 10. REPAIR AND REPLACEMENT OF PARTS

- 10.1. OUTLINE

- 10.2. REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT

- 10.3. METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS

- 10.4. METHOD FOR REPAIRING TAPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS

- 10.5. METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS

- 10.6. INSPECTION FOR REUSE OF CYLINDER BLOCK

- 10.7. INSTALLATION OF EXPANSION PLUGS

- 10.8. INSTALLATION OF EXPANSION PLUG TO CAMSHAFT HOLE

- 10.9. REMOVAL OF CAMSHAFT BUSHING

- 10.10. INSTALLATION OF CAMSHAFT BUSHING

- 10.11. CLEANING AND INSPECTION OF CYLINDER LINERS BEFORE REUSING THEM

- 10.12. CLEANING AND INSPECTION OF PISTON BEFORE REUSING IT

- 10.13. CLEANING AND INSPECTION OF CRANKSHAFT BEFORE REUSING IT

- 10.14. REPLACEMENT OF CRANKSHAFT GEAR

- 10.15. CLEANING AND INSPECTION OF MAIN BEARINGS BEFORE REUSING THEM

- 10.16. CLEANING AND INSPECTION OF MAIN BEARING CAPS AND MOUNTING BOLTS BEFORE REUSING THEM

- 10.17. CLEANING AND INSPECTION OF CONNECTING ROD BEARINGS BEFORE REUSING THEM

- 10.18. CLEANING AND INSPECTION OF CONNECTING RODS BEFORE REUSING THEM

- 10.19. INSPECTION OF CONNECTING RODS FOR BEND AND TORSION

- 10.20. REPLACEMENT OF CONNECTING ROD BUSHINGS

- 10.21. REPLACEMENT OF VALVE INSERTS OF CYLINDER HEAD

- 10.22. REPLACEMENT OF VALVE GUIDES OF CYLINDER HEAD

- 10.23. CYLINDER HEADPRESSURE TEST

- 10.24. VACUUM TEST ON VALVE SEATS OF CYLINDER HEAD

- 10.25. CLEANING AND INSPECTION OF CYLINDER HEAD BOLTS

Rate this product

You may also like