Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024208

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM024208

- Format: PDF

- Size: 58.8MB

- Number of Pages: 349

Category: Komatsu Shop Manual PDF

-

Model List:

- 125-3 Series Diesel Engine

- 0.1. GENERAL ASSEMBLY DRAWING

- 0.2. WEIGHT TABLE

- 0.3. ENGINE PERFORMANCE CURVE

- 1. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 1.1. GENERAL STRUCTURE

- 1.2. INTAKE, EXHAUST SYSTEM

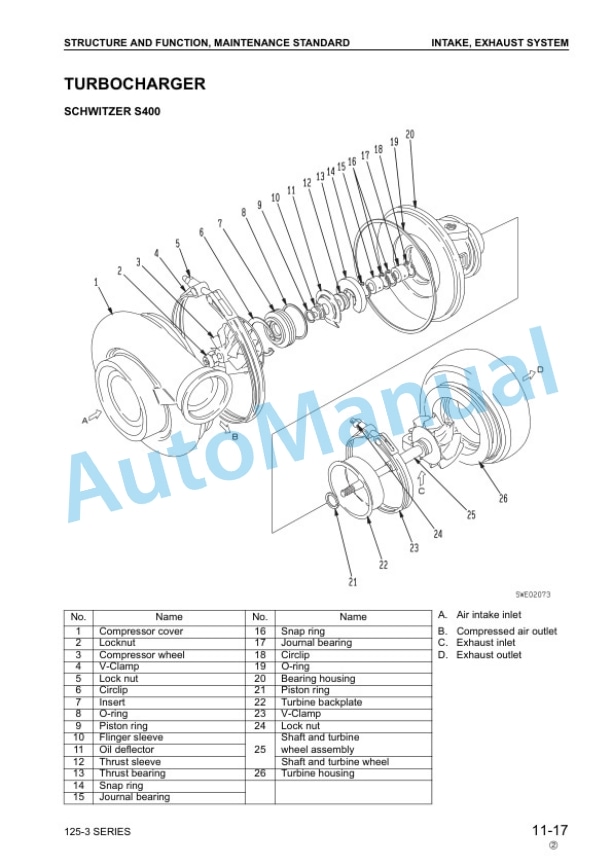

- 1.2.1. INTAKE, EXHAUST SYSTEM

- 1.2.2. MAIN CIRCULATION SYSTEM

- 1.2.3. CRANKSHAFT

- 1.2.4. PISTON

- 1.2.5. CONNECTING ROD

- 1.2.6. FLYWHEEL AND FLYWHEEL HOUSING

- 1.2.7. VIBRATION DAMPER

- 1.2.8. TIMING GEAR

- 1.2.9. VALVE MECHANISM

- 1.2.10. CAMSHAFT

- 1.2.11. CAM FOLLOWER AND PUSH ROD

- 1.2.12. VALVE AND VALVE GUIDE

- 1.2.13. ROCKER ARM SHAFT

- 1.2.14. CROSSHEAD

- 1.3. LUBRICATION SYSTEM

- 1.3.1. LUBRICATION SYSTEM DIAGRAM

- 1.3.2. OIL PUMP

- 1.3.3. OIL FILTER

- 1.3.4. OIL COOLER

- 1.4. FUEL SYSTEM

- 1.4.1. FUEL SYSTEM DIAGRAM

- 1.4.2. OUTLINE OF CRI SYSTEM

- 1.4.3. FUEL PIPING

- 1.4.4. FUEL COOLER

- 1.4.5. FUEL FILTER

- 1.5. COOLING SYSTEM

- 1.5.1. COOLING SYSTEM CHART

- 1.5.2. WATER PUMP

- 1.5.3. THERMOSTAT

- 1.5.4. CORROSION RESISTOR

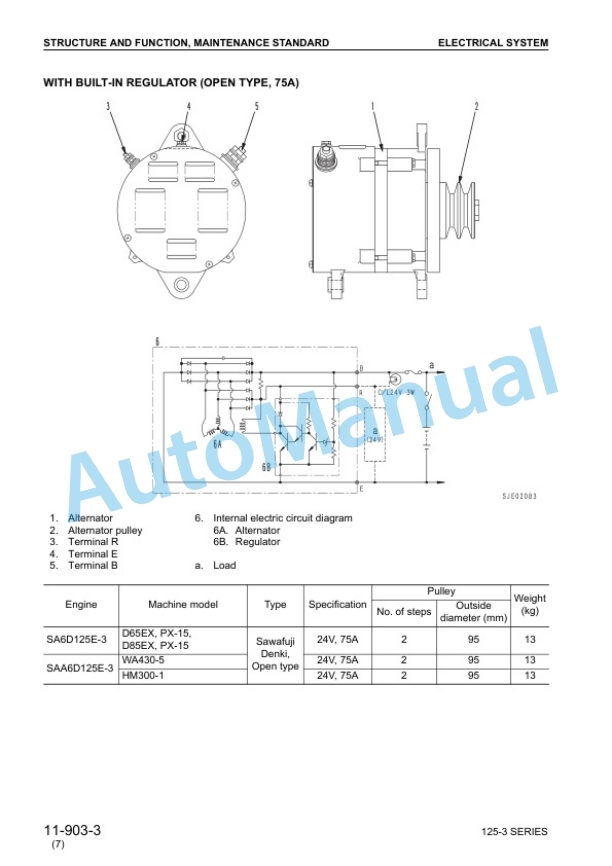

- 1.6. ELECTRICAL SYSTEM

- 1.6.1. ALTERNATOR MOUNTING

- 1.6.2. ALTERNATOR

- 1.6.3. STARTING MOTOR

- 1.6.4. STARTING AID

- 2. TESTING AND ADJUSTING, TROUBLESHOOTING

- 2.1. TESTING AND ADJUSTING DATA

- 2.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 2.3. TESTING AND ADJUSTING TOOL LIST

- 2.4. TESTING AND ADJUSTING

- 2.4.1. MEASURING INTAKE AIR PRESSURE (BOOT PRESSURE)

- 2.4.2. MEASURING EXHAUST TEMPERATURE

- 2.4.3. ADJUSTING VALVE CLEARANCE

- 2.4.4. MEASURING COMPRESSION PRESSURE

- 2.4.5. MEASURING BLOWBY PRESSURE

- 2.4.6. MEASURING ENGINE OIL PRESSURE

- 2.4.7. MEASURING FUEL PRESSURE

- 2.4.8. ADJUSTING ENGINE SPEED SENSOR

- 2.4.9. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.4.10. HANDLING EQUIPMENT IN FUEL SYSTEM

- 2.4.11. RELEASING REMAINING PRESSURE IN FUEL SYSTEM

- 2.4.12. BLEEDING AIR FROM FUEL CIRCUIT

- 2.4.13. REDUCED CYLINDER MODE OPERATION FOR ENGINE

- 2.4.14. CHECKING FOR LEAKAGE IN FUEL SYSTEM

- 2.4.15. ADJUSTING ENGINE STOP MOTOR LEVER

- 2.4.16. CALIBRATION DATA

- 2.4.17. PERFORMANCE TEST

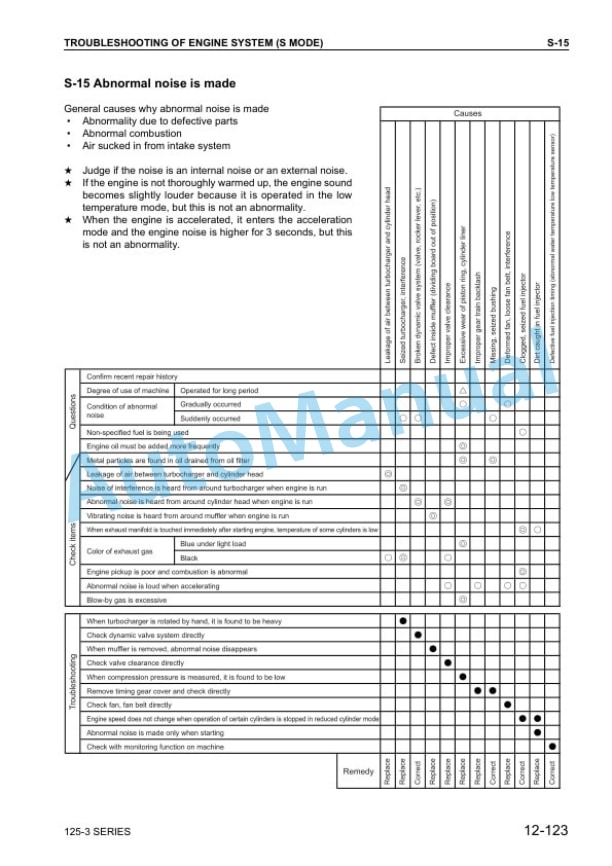

- 2.5. TROUBLESHOOTING

- 2.5.1. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 2.5.2. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. SKETCHES OF SPECIAL TOOLS

- 3.5. GENERAL DISASSEMBLY

- 3.5.1. PREPARATION WORK

- 3.5.2. STARTING MOTOR

- 3.5.3. TURBOCHARGER LUBRICANT RETURN TUBE

- 3.5.4. RADIATOR LOWER HOSE

- 3.5.5. ENGINE OIL COOLER

- 3.5.6. ADAPTER FOR ENGINE OVERHAULING

- 3.5.7. RADIATOR UPPER HOSE

- 3.5.8. EXHAUST MUFFLER

- 3.5.9. FAN SECURING BRACKET

- 3.5.10. TURBOCHARGER LUBRICATION TUBE

- 3.5.11. TURBOCHARGER AND EXHAUST MANIFOLD

- 3.5.12. FUEL FILTER ASSEMBLY

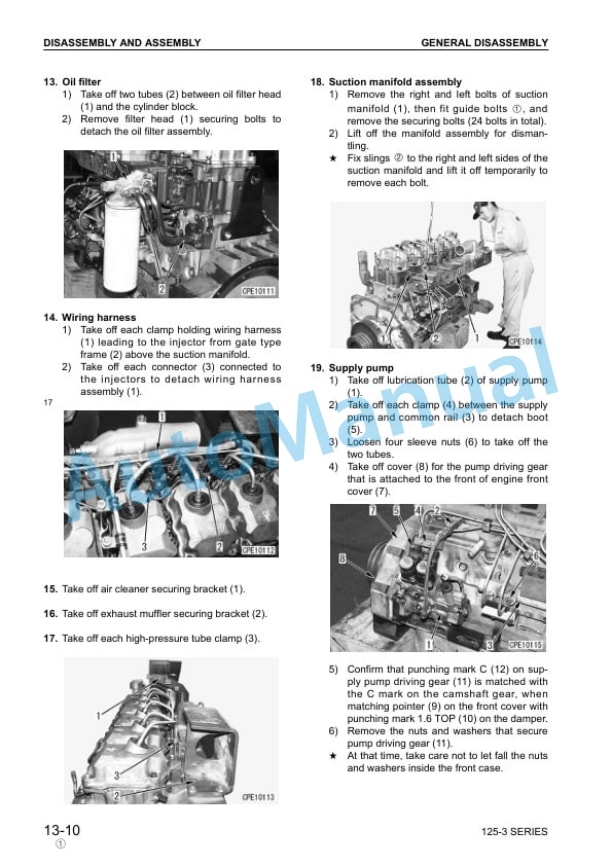

- 3.5.13. OIL FILTER

- 3.5.14. WIRING HARNESS

- 3.5.15. TAKE OFF AIR CLEANER SECURING BRACKET (1)

- 3.5.16. TAKE OFF EXHAUST MUFFLER SECURING BRACKET (2)

- 3.5.17. TAKE OFF EACH HIGHPRESSURE TUBE CLAMP (3)

- 3.5.18. SUCTION MANIFOLD ASSEMBLY

- 3.5.19. SUPPLY PUMP

- 3.5.20. COMMON RAIL

- 3.5.21. SPILL PIPE

- 3.5.22. HEAD COVER

- 3.5.23. INJECTOR HARNESS

- 3.5.24. ROCKER ARM HOUSING

- 3.5.25. INJECTOR HARNESS CONNECTOR

- 3.5.26. THERMOSTAT

- 3.5.27. CAM FOLLOWER COVER

- 3.5.28. CAM FOLLOWER

- 3.5.29. CYLINDER HEAD ASSEMBLY

- 3.5.30. SETTING TO ENGINE OVERHAUL STAND

- 3.5.31. OIL PAN

- 3.5.32. FLYWHEEL

- 3.5.33. FLYWHEEL HOUSING

- 3.5.34. DAMPER

- 3.5.35. FRONT SUPPORT

- 3.5.36. FRONT COVER

- 3.5.37. WATER PUMP

- 3.5.38. CAMSHAFT

- 3.5.39. OIL PUMP

- 3.5.40. IDLER GEAR

- 3.5.41. OIL SUCTION PIPE

- 3.5.42. PISTON COOLING NOZZLE

- 3.5.43. PISTON AND CONNECTING ROD ASSEMBLY

- 3.5.44. CRANKSHAFT

- 3.5.45. CYLINDER LINER

- 3.6. GENERAL ASSEMBLY

- 3.6.1. PREPARATION WORK

- 3.6.2. CYLINDER LINER

- 3.6.3. CRANKSHAFT

- 3.6.4. PISTON AND CONNECTING ROD ASSEMBLY

- 3.6.5. PISTON COOLING NOZZLE

- 3.6.6. OIL SUCTION PIPE

- 3.6.7. IDLER GEAR

- 3.6.8. OIL PUMP

- 3.6.9. CAMSHAFT

- 3.6.10. CAM FOLLOWERS

- 3.6.11. CAM FOLLOWER COVERS

- 3.6.12. WATER PUMP

- 3.6.13. FUEL SUPPLY PUMP DRIVING GEAR

- 3.6.14. FRONT COVER

- 3.6.15. FLYWHEEL HOUSING

- 3.6.16. REAR SEAL

- 3.6.17. FLYWHEEL

- 3.6.18. DAMPER

- 3.6.19. OIL PAN

- 3.6.20. REMOVING ENGINE ASSEMBLY FROM ENGINE OVERHAUL STAND

- 3.6.21. SETTING ENGINE ASSEMBLY ON BLOCKS

- 3.6.22. CYLINDER HEAD

- 3.6.23. CYLINDER HEAD ASSEMBLY

- 3.6.24. ROCKER ARM HOUSING

- 3.6.25. ASSEMBLING INJECTOR HARNESS CONNECTOR TO ROCKER ARM HOUSING

- 3.6.26. CROSSHEAD

- 3.6.27. PUSH ROD

- 3.6.28. ROCKER ARM

- 3.6.29. ADJUSTING VALVE CLEARANCE

- 3.6.30. NOZZLE TIP

- 3.6.31. FUEL INJECTOR

- 3.6.32. HEAD COVER

- 3.6.33. SPILL PIPE

- 3.6.34. THERMOSTAT

- 3.6.35. ENGINE OIL COOLER

- 3.6.36. ENGINE COOLING WATER TEMPERATURE SENSOR

- 3.6.37. ENGINE OIL SUPPLY TUBE

- 3.6.38. HIGHPRESSURE TUBE FOR COMMON RAIL

- 3.6.39. SUCTION MANIFOLD

- 3.6.40. ENGINE OIL FILTER

- 3.6.41. FUEL FILTER

- 3.6.42. TURBOCHARGER AND EXHAUST MANIFOLD ASSEMBLY

- 3.6.43. STARTING MOTOR

- 3.6.44. FAN BRACKET LIFTING HOOK

- 3.6.45. WIRING HARNESS

- 3.6.46. AIR CLEANER

- 3.6.47. EXHAUST MUFFLER

- 4. REPAIR AND REPLACEMENT OF PARTS

- 4.1. CYLINDER HEAD

- 4.1.1. REPLACING VALVE SEAT INSERT

- 4.1.2. REPLACING NOZZLE HOLDER SLEEVE

- 4.1.3. REPLACING VALUE GUIDE

- 4.1.4. REPLACING CROSS HEAD GUIDE

- 4.1.5. GRINDING THE VALVE

- 4.1.6. GRINDING THE FITTING FACE OF CYLINDER HEAD

- 4.1.7. PRESSURE TEST

- 4.2. CYLINDER BLOCK

- 4.2.1. REPLACING CAM BUSHING

- 4.2.2. REPLACING CAM GEAR

- 4.2.3. REPLACING FLYWHEEL RING GEAR

- 4.2.4. REPLACING ENGINE REAR SEAL

- 4.2.5. REPLACING CONNECTING ROD SMALL END BUSHING

- 4.2.6. REPLACING MAIN BEARING CAP

- 4.2.7. GRINDING CRANKSHAFT

- 4.2.8. REPLACING WEAR SLEEVE(WHEN EQUIPPED WITH SLEEVE)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00