Komatsu 125-3 Series Diesel Engine Shop Manual SEBM024209

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM024209

- Format: PDF

- Size: 24.2MB

- Number of Pages: 374

Category: Komatsu Shop Manual PDF

-

Model List:

- 125-3 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. SAFETY

- 5. FOREWORD

- 5.1. GENERAL

- 5.2. HOW TO READ THE SHOP MANUAL

- 5.3. HOISTING INSTRUCTIONS

- 5.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 5.5. COATING MATERIALS

- 5.6. STANDARD TIGHTENING TORQUE

- 5.7. ELECTRIC WIRE CODE

- 5.8. CONVERSION TABLE

- 5.9. UNITS

- 6. GENERAL

- 6.1. OUTLINE

- 6.2. SPECIFICATIONS

- 6.3. GENERAL ASSEMBLY DRAWING

- 6.4. WEIGHT TABLE

- 6.5. ENGINE PERFORMANCE CURVE

- 7. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 7.1. GENERAL STRUCTURE

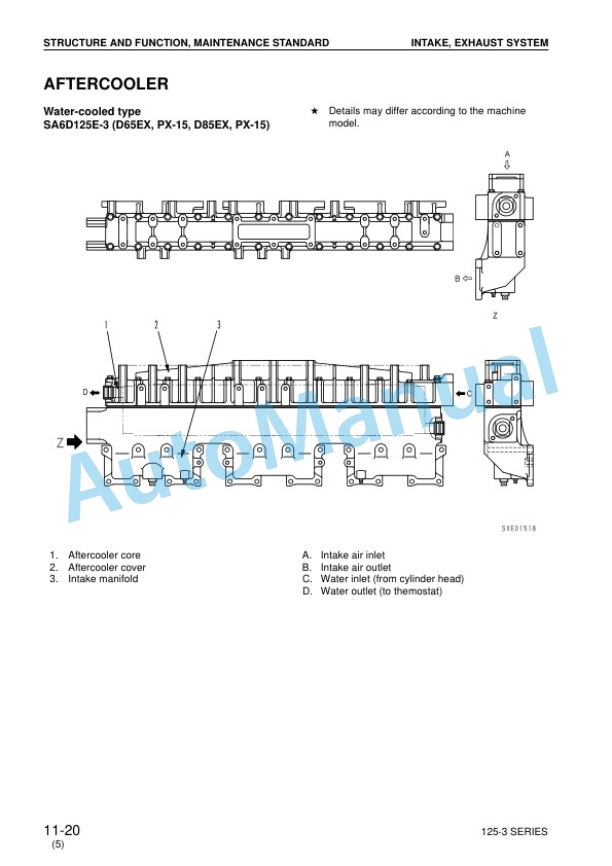

- 7.2. INTAKE, EXHAUST SYSTEM

- 7.2.1. INTAKE, EXHAUST SYSTEM

- 7.2.2. MAIN CIRCULATION SYSTEM

- 7.2.3. CRANKSHAFT

- 7.2.4. PISTON

- 7.2.5. CONNECTING ROD

- 7.2.6. FLYWHEEL AND FLYWHEEL HOUSING

- 7.2.7. VIBRATION DAMPER

- 7.2.8. TIMING GEAR

- 7.2.9. VALVE MECHANISM

- 7.2.10. CAMSHAFT

- 7.2.11. CAM FOLLOWER AND PUSH ROD

- 7.2.12. VALVE AND VALVE GUIDE

- 7.2.13. ROCKER ARM SHAFT

- 7.2.14. CROSSHEAD

- 7.3. LUBRICATION SYSTEM

- 7.3.1. LUBRICATION SYSTEM DIAGRAM

- 7.3.2. OIL PUMP

- 7.3.3. MAIN RELIFE VALVE

- 7.3.4. OIL FILTER

- 7.3.5. SAFETY VALVE

- 7.3.6. OIL COOLER

- 7.4. FUEL SYSTEM

- 7.4.1. FUEL SYSTEM DIAGRAM

- 7.4.2. OUTLINE OF CRI SYSTEM

- 7.4.3. FUEL PIPING

- 7.4.4. FUEL COOLER

- 7.4.5. FUEL FILTER

- 7.5. COOLING SYSTEM

- 7.5.1. COOLING SYSTEM CHART

- 7.5.2. WATER PUMP

- 7.5.3. THERMOSTAT

- 7.5.4. CORROSION RESISTOR

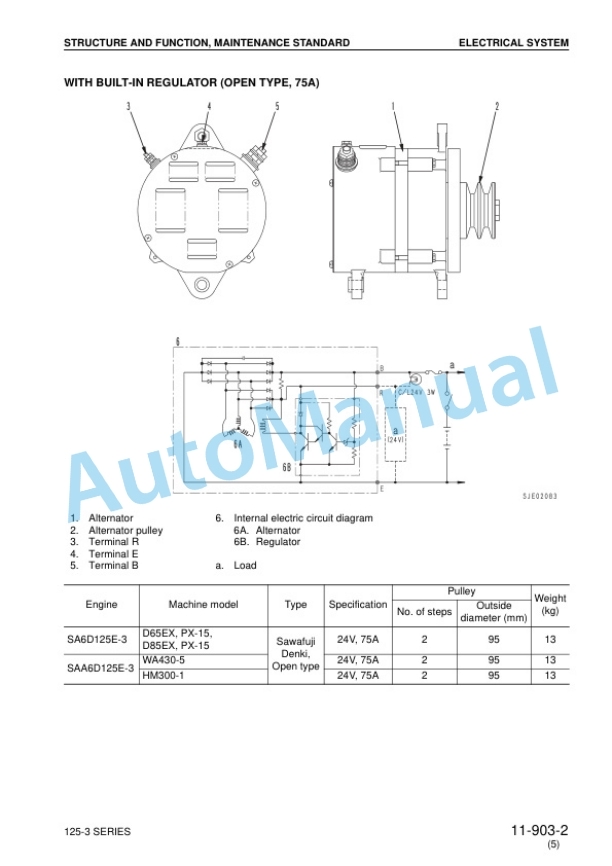

- 7.6. ELECTRICAL SYSTEM

- 7.6.1. ALTERNATOR MOUNTING

- 7.6.2. ALTERNATOR

- 7.6.3. STARTING MOTOR

- 7.6.4. STARTING AID

- 8. TESTING AND ADJUSTING, TROUBLESHOOTING

- 8.1. TESTING AND ADJUSTING DATA

- 8.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 8.3. TESTING AND ADJUSTING TOOL LIST

- 8.4. TESTING AND ADJUSTING

- 8.4.1. MEASURING INTAKE AIR PRESSURE (BOOT PRESSURE)

- 8.4.2. MEASURING EXHAUST TEMPERATURE

- 8.4.3. ADJUSTING VALVE CLEARANCE

- 8.4.4. MEASURING COMPRESSION PRESSURE

- 8.4.5. MEASURING BLOWBY PRESSURE

- 8.4.6. MEASURING ENGINE OIL PRESSURE

- 8.4.7. MEASURING FUEL PRESSURE

- 8.4.8. ADJUSTING ENGINE SPEED SENSOR

- 8.4.9. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 8.4.10. HANDLING EQUIPMENT IN FUEL SYSTEM

- 8.4.11. RELEASING REMAINING PRESSURE IN FUEL SYSTEM

- 8.4.12. BLEEDING AIR FROM FUEL CIRCUIT

- 8.4.13. REDUCED CYLINDER MODE OPERATION FOR ENGINE

- 8.4.14. CHECKING FOR LEAKAGE IN FUEL SYSTEM

- 8.4.15. ADJUSTING ENGINE STOP MOTOR LEVER

- 8.5. CALIBRATION DATA

- 8.6. PERFORMANCE TEST

- 8.6.1. RUNIN STANDARD

- 8.6.2. PERFORMANCE TEST STANDARDS

- 8.7. TROUBLESHOOTING

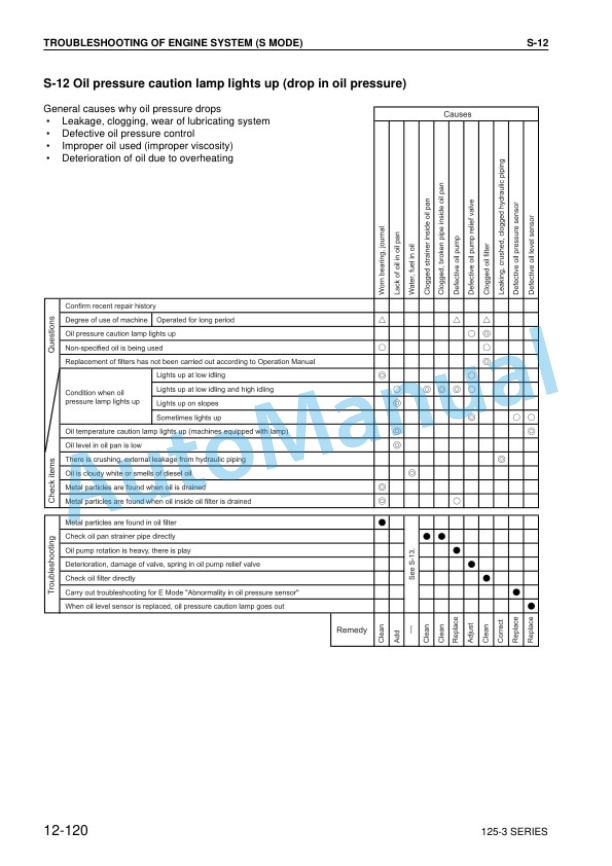

- 8.7.1. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 8.7.2. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 9. DISASSEMBLY AND ASSEMBLY

- 9.1. METHOD OF USING MANUAL

- 9.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 9.3. SPECIAL TOOL LIST

- 9.4. SKETCHES OF SPECIAL TOOLS

- 9.5. GENERAL DISASSEMBLY

- 9.5.1. Preparation work

- 9.5.2. Starting motor

- 9.5.3. Turbocharger lubricant return tube

- 9.5.4. Radiator lower hose

- 9.5.5. Engine oil cooler

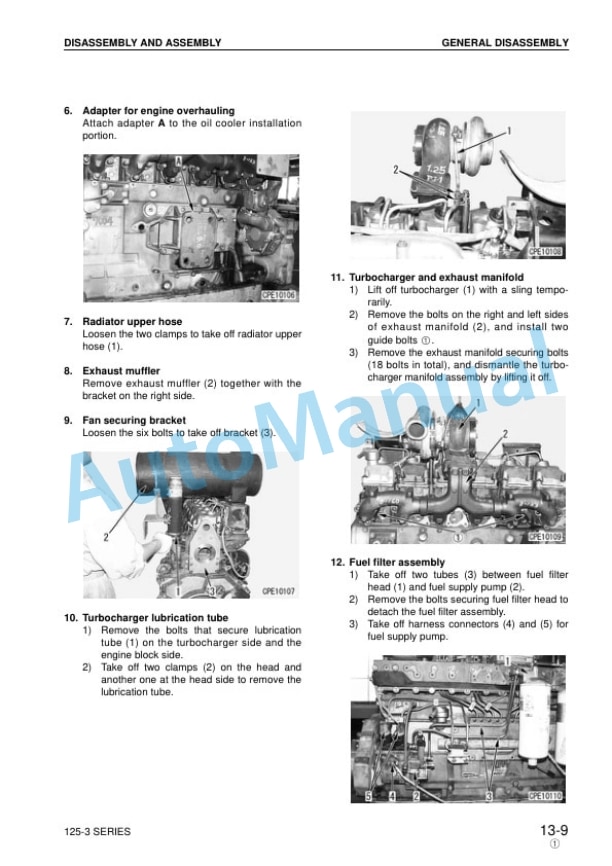

- 9.5.6. Adapter for engine overhauling

- 9.5.7. Radiator upper hose

- 9.5.8. Exhaust muffler

- 9.5.9. Fan securing bracket

- 9.5.10. Turbocharger lubrication tube

- 9.5.11. Turbocharger and exhaust manifold

- 9.5.12. Fuel filter assembly

- 9.5.13. Oil filter

- 9.5.14. Wiring harness

- 9.5.15. Air cleaner securing bracket

- 9.5.16. Exhaust muffler securing bracket

- 9.5.17. High pressure tube clamp

- 9.5.18. Suction manifold assembly

- 9.5.19. Supply pump

- 9.5.20. Common rail

- 9.5.21. Spill pipe

- 9.5.22. Head cover

- 9.5.23. Injector harness

- 9.5.24. Rocker arm housing

- 9.5.25. Injector harness connector

- 9.5.26. Thermostat

- 9.5.27. Cam follower cover

- 9.5.28. Cam follower

- 9.5.29. Cylinder head assembly

- 9.5.30. Setting to engine overhaul stand

- 9.5.31. Oil pan

- 9.5.32. Flywheel

- 9.5.33. Flywheel housing

- 9.5.34. Damper

- 9.5.35. Front support

- 9.5.36. Front cover

- 9.5.37. Water pump

- 9.5.38. Camshaft

- 9.5.39. Oil pump

- 9.5.40. Idler gear

- 9.5.41. Oil suction pipe

- 9.5.42. Piston cooling nozzle

- 9.5.43. Piston and connecting rod assembly

- 9.5.44. Crankshaft

- 9.5.45. Cylinder liner

- 9.6. GENERAL ASSEMBLY

- 9.6.1. Cylinder liner

- 9.6.2. Crankshaft

- 9.6.3. Piston and connecting rod assembly

- 9.6.4. Piston cooling nozzle

- 9.6.5. Oil suction pipe

- 9.6.6. Idler gear

- 9.6.7. Oil pump

- 9.6.8. Camshaft

- 9.6.9. Cam followers

- 9.6.10. Cam follower covers

- 9.6.11. Water pump

- 9.6.12. Fuel supply pump driving gear

- 9.6.13. Front cover

- 9.6.14. Flywheel housing

- 9.6.15. Rear seal

- 9.6.16. Flywheel

- 9.6.17. Damper

- 9.6.18. Oil pan

- 9.6.19. Removing engine assembly from engineoverhaul stand

- 9.6.20. Setting engine assembly on blocks

- 9.6.21. Cylinder head

- 9.6.22. Cylinder head assembly

- 9.6.23. Rocker arm housing

- 9.6.24. Assembling injector harness connector torocker arm housing

- 9.6.25. Crosshead

- 9.6.26. Pushrod

- 9.6.27. Rocker arm

- 9.6.28. Adjusting valve clearance

- 9.6.29. Nozzle tip

- 9.6.30. Fuel injector

- 9.6.31. Head cover

- 9.6.32. Spill pipe

- 9.6.33. Thermostat

- 9.6.34. Engine oil cooler

- 9.6.35. Engine cooling water temperature sensor

- 9.6.36. Engine oil supply tube

- 9.6.37. Highpressure tube for common rail

- 9.6.38. Suction manifold

- 9.6.39. Engine oil filter

- 9.6.40. Fuel filter

- 9.6.41. Turbocharger and exhaust manifold assembly

- 9.6.42. Starting motor

- 9.6.43. Fan bracket lifting hook

- 9.6.44. Wiring harness

- 9.6.45. Air cleaner

- 9.6.46. Exhaust muffler

- 10. REPAIR AND REPLACEMENT OF PARTS

- 10.1. CYLINDER HEAD

- 10.1.1. REPLACING VALVE SEAT INSERT

- 10.1.2. REPLACING NOZZLE HOLDER SLEEVE

- 10.1.3. REPLACING VALUE GUIDE

- 10.1.4. REPLACING CROSS HEAD GUIDE

- 10.1.5. GRINDING THE VALVE

- 10.1.6. GRINDING THE FITTING FACE OF CYLINDER HEAD

- 10.1.7. PRESSURE TEST

- 10.2. CYLINDER BLOCK

- 10.2.1. REPLACING CAM BUSHING

- 10.2.2. REPLACING CAM GEAR

- 10.2.3. REPLACING FLYWHEEL RING GEAR

- 10.2.4. REPLACING ENGINE REAR SEAL

- 10.2.5. REPLACING CONNECTING ROD SMALL END BUSHING

- 10.2.6. REPLACING MAIN BEARING CAP

- 10.2.7. GRINDING CRANKSHAFT

- 10.2.8. REPLACING WEAR SLEEVE (When equipped with sleeve)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00