Komatsu 12V170-2 Series Diesel Engine Shop Manual SEBM036601

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM036601

- Format: PDF

- Size: 11.5MB

- Number of Pages: 333

Category: Komatsu Shop Manual PDF

-

Model List:

- 12V170-2 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. APPLICABLE MACHINE

- 3.2. SPECIFICATIONS

- 3.3. GENERAL ASSEMBLY DRAWING

- 3.4. WEIGHT TABLE

- 3.5. ENGINE PERFORMANCE CURVE

- 4. STRUCTURE AND FUNCTION

- 4.1. GENERAL STRUCTURE

- 4.2. MAIN REVOLVING PART

- 4.3. VALVE SYSTEM

- 4.4. TIMING GEAR

- 4.5. FLYWHEEL AND FLYWHEEL HOUSING

- 4.6. LUBRICATION SYSTEM CHART

- 4.7. OIL PUMP

- 4.8. OIL FILTER, SAFETY VALVE

- 4.9. BYPASS FILTER

- 4.10. OIL COOLER

- 4.11. OIL COOLER BYPASS VALVE

- 4.12. PISTON COOLING VALVE

- 4.13. FUEL SYSTEM CHART

- 4.14. FUEL INJECTION PUMP

- 4.15. FUEL PIPING

- 4.16. FUEL INJECTION PUMP DRIVE

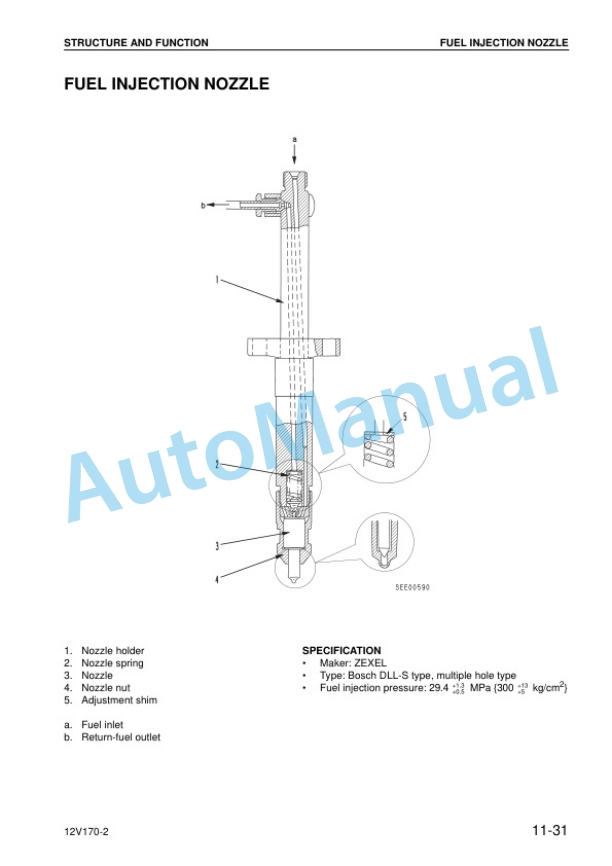

- 4.17. FUEL INJECTION NOZZLE

- 4.18. FUEL FILTER

- 4.19. COOLING SYSTEM CHART

- 4.20. WATER PUMP

- 4.21. WATER PUMP DRIVE

- 4.22. THERMOSTAT

- 4.23. CORROSION RESISTOR

- 4.24. FAN DRIVE AND TENSION PULLEY

- 4.25. ALTERNATOR

- 4.26. STARTING MOTOR

- 4.27. STARTING AID

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR TESTING,ADJUST AND TROUBLESHOOTING

- 5.2. TESTING AND ADJUSTING TOOL LIST

- 5.3. ADJUSTING VALVE CLEARANCE

- 5.4. TESTING AND ADJUSTING OF FUEL INJECTION TIMING(WITH KOMATSU ELECTRONICAL GOVERNOR)

- 5.5. MEASURING COMPRESSION PRESSURE

- 5.6. MEASURING BLOWBY

- 5.7. ADJUSTING FUEL INJECTION PRESSURE (VALVE CRACKING PRESSURE)

- 5.8. INSTALLING ENGINE SPEED SENSOR (WITH ELECTRONIC GOVERNOR)

- 5.9. TESTING AND ADJUSTING ALTERNATOR BELT AND FAN BELT

- 5.10. DATA FOR FUEL INJECTION PRESSURE ADJUSTMENT SHIMS

- 5.11. FUEL INJECTION PUMP CALIBRATION DATA

- 5.12. PERFORMANCE TEST

- 5.13. PERFORMANCE TEST CRITERIA

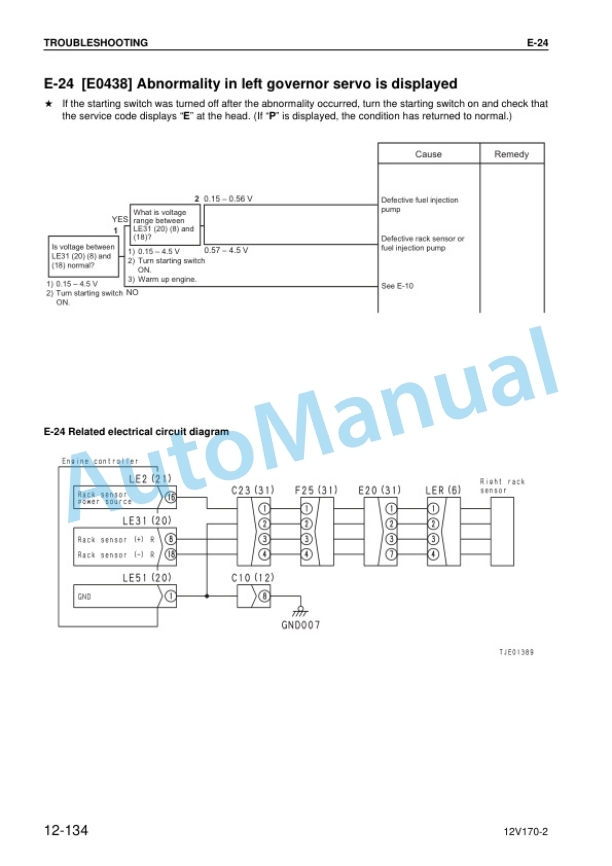

- 5.14. TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM(E MODE)

- 5.15. TROUBLESHOOTING (SMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. GENERAL DISASSEMBLY

- 6.5. CLEANING

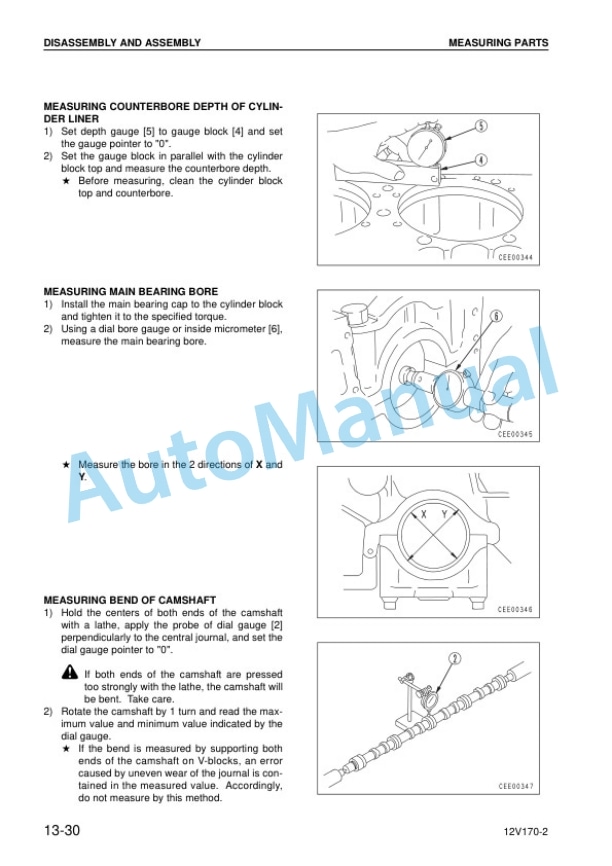

- 6.6. MEASURING PARTS

- 6.7. GENERAL ASSEMBLY

- 7. MAINTENANCE STANDARD

- 7.1. TURBOCHARGER

- 7.2. CYLINDER HEAD

- 7.3. VALVES AND VALVE GUIDE

- 7.4. CROSSHEAD AND CROSSHEAD GUIDE

- 7.5. ROCKER ARM SHAFT

- 7.6. PUSH ROD AND CAM FOLLOWER

- 7.7. FLYWHEEL,FLYWHEEL HOUSING

- 7.8. OIL PUMP

- 7.9. OIL PUMP RELIEF VALVE,PISTON COOLING VALVE,OIL COOLER BYPASS VALVE AND OIL FILTER SAFETY VALVE

- 7.10. WATER PUMP

- 7.11. THERMOSTAT

- 8. REPAIR AND REPLACEMENT OF PARTS

- 8.1. TABLE OF SPECIAL TOOLS

- 8.2. TESTING AND INSPECTING CYLINDER HEAD

- 8.3. REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

- 8.4. REPLACING VALVE SEAT INSERTS

- 8.5. REPLACING NOZZLE HOLDER SLEEVE

- 8.6. CYLINDER HEAD PRESSURE TEST METHOD

- 8.7. REPLACING VALVE GUIDE

- 8.8. REPLACING CROSS HEAD GUIDE

- 8.9. GRINDING VALVE

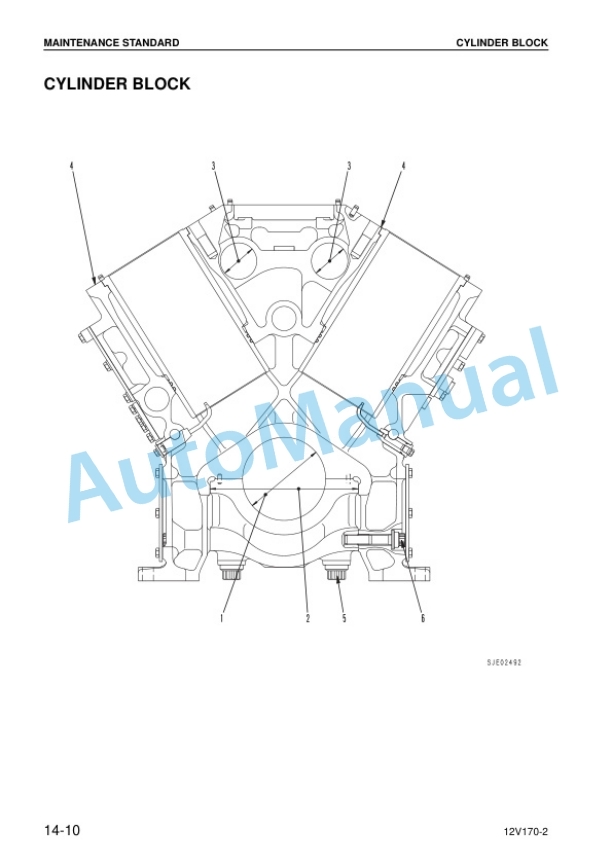

- 8.10. TESTING AND INSPECTING CYLINDER BLOCK

- 8.11. GRINDING TOP SURFACE OF CYLINDING BLOCK

- 8.12. REPLACING MAIN BEARING CAP

- 8.13. REPLACING CAM BUSHING

- 8.14. TESTING CRANKSHAFT

- 8.15. CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

- 8.16. GRINDING CRANKSHAFT

- 8.17. TESTING AND INSPECTING CONNECTING ROD

- 8.18. REPLACING CONNECTING ROD SMALL END BUSHING

- 8.19. REPLACING CAMSHAFT GEAR

- 8.20. REPLACING FLYWHEEL RING GEAR

Rate this product

You may also like