Komatsu 170-3 Series Diesel Engine Shop Manual SEBM023407

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM023407

- Format: PDF

- Size: 51.4MB

- Number of Pages: 433

Category: Komatsu Shop Manual PDF

-

Model List:

- 170-3 Series Diesel Engine

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DIASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. APPLICABLE MACHINE

- 1.2. SPECIFICATIONS

- 1.3. OVERALL DRAWING

- 1.4. WEIGHT TABLE

- 1.5. ENGINE PERFORMANCE CURVE

- 2. STRUCTURE AND FUNCTION

- 2.1. INTAKE AND EXHAUST SYSTEM

- 2.2. ENGINE BODY

- 2.3. LUBRICATION SYSTEM

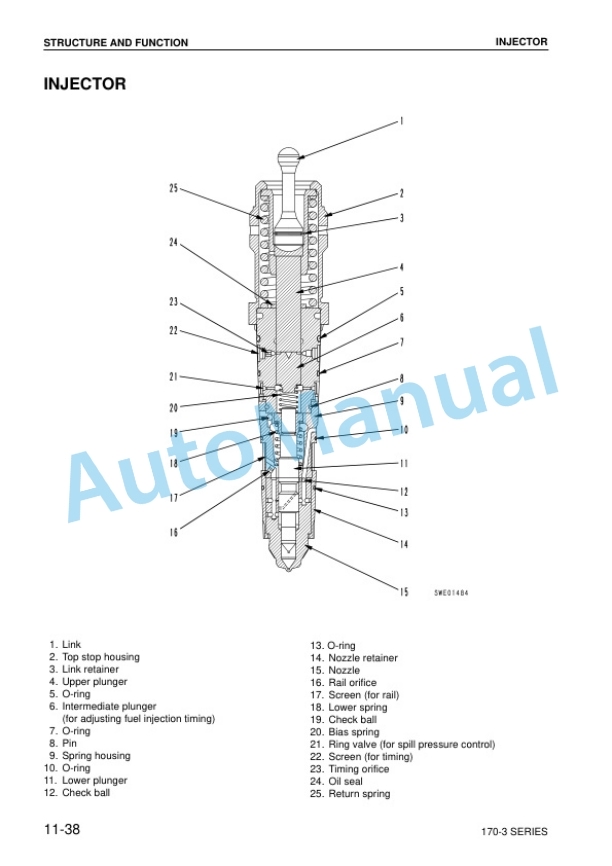

- 2.4. FUEL SYSTEM

- 2.5. COOLING SYSTEM

- 2.6. ELECTRICAL EQUIPMENT

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALVE TABLE FOR TROUBLESHOOTING

- 3.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 3.3. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 3.4. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 3.5. MEASURING EXHAUST TEMPERATURE (OVERALL ENGINE)

- 3.6. TROUBLESHOOTING FOR INJECTOR

- 3.7. ADJUSTING VALVE CLEARANCE

- 3.8. ADJUSTING INJECTOR SET LOAD

- 3.9. MEASURING COMPRESSION PRESSURE

- 3.10. MEASURING BLOWBY PRESSURE

- 3.11. MEASURING OIL PRESSURE

- 3.12. HANDLING EQUIPMENT IN FUEL CIRCUIT

- 3.13. MEASURING FUEL CIRCUIT PRESSURE

- 3.14. VISUAL INSPECTION OF RETURN FUEL

- 3.15. BLEEDING AIR FROM FUEL CIRCUIT

- 3.16. ADJUSTING SPEED SENSOR

- 3.17. REPLACING AND ADJUSTING FAN BELT

- 3.18. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 3.19. PRECAUTIONS WHEN OPERATING ENGINE AS AN INDIVIDUAL PART

- 3.20. ARRANGEMENT OF CONTROL DEVICES AND ELECTRIC CIRCUIT DIAGRAM FOR HPI

- 3.21. RUNIN STANDARD

- 3.22. PERFORMANCE TEST STANDARDS

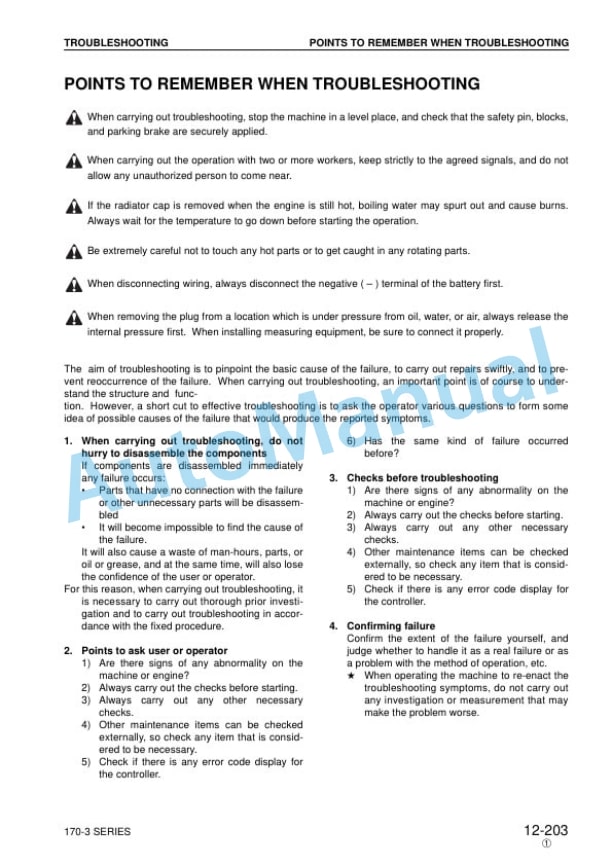

- 3.23. TROUBLESHOOTING

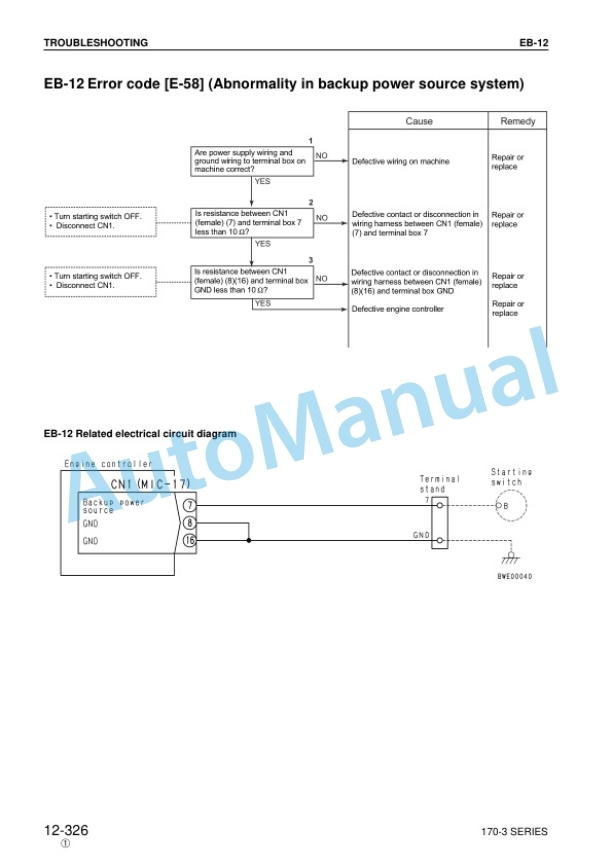

- 3.24. TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGINE FOR CONSTRUCTION EQUIPMENT (EA MODE)

- 3.25. TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGINE FOR GENRATOR EQUIPMENT (EB MODE)

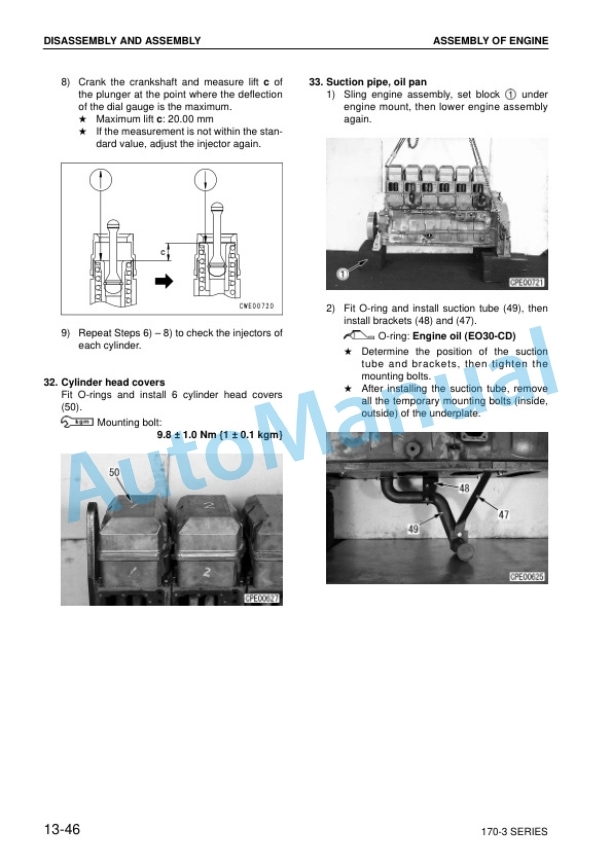

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. DISASSEMBLY OF ENGINE

- 4.5. ASSEMBLY OF ENGINE

- 4.6. WASHING PARTS

- 4.7. MEASURING PARTS

- 5. MAINTENANCE STANDARD

- 5.1. INTAKE AND EXHAUST SYSTEM

- 5.2. ENGINE BODY

- 5.3. LUBRICATION SYSTEM

- 5.4. COOLING SYSTEM

- 6. REPAIR AND REPLACEMENT OF PARTS

- 6.1. TABLE OF SPECIAL TOOLS

- 6.2. TESTING AND INSPECTING CYLINDER HEAD

- 6.3. REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

- 6.4. REPLACING VALVE SEAT INSERTS

- 6.5. PRESSURE TEST METHOD

- 6.6. REPLACING VALVE GUIDE

- 6.7. REPLACING CROSS HEAD GUIDE

- 6.8. GRINDING VALVE

- 6.9. TESTING AND INSPECTING CYLINDER BLOCK

- 6.10. GRINDING THE TOP SURFACE OF CYLINDER BLOCK

- 6.11. REPLACING MAIN BEARING CAP

- 6.12. REPLACING CAM BUSHING

- 6.13. TESTING AND INSPECTING CRANKSHAFT

- 6.14. CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

- 6.15. REPAIRING CRANKSHAFT

- 6.16. TESTING AND INSPECTING OF CONNECTING ROD

- 6.17. REPLACING CRANKSHAFT GEAR

- 6.18. REPLACING CAMSHAFT GEAR

- 6.19. REPLACING FLYWHEEL RING GEAR

Rate this product

You may also like