Komatsu 170-3 Series Diesel Engine Shop Manual SEBM023412

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM023412

- Format: PDF

- Size: 21.2MB

- Number of Pages: 454

Category: Komatsu Shop Manual PDF

-

Model List:

- 170-3 Series Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. APPLICABLE MACHINE

- 3.2. SPECIFICATIONS

- 3.3. OVERALL DRAWING

- 3.4. WEIGHT TABLE

- 3.5. ENGINE PERFORMANCE CURVE

- 4. STRUCTURE AND FUNCTION

- 4.1. INTAKE AND EXHAUST SYSTEM

- 4.2. ENGINE BODY

- 4.3. LUBRICATION SYSTEM

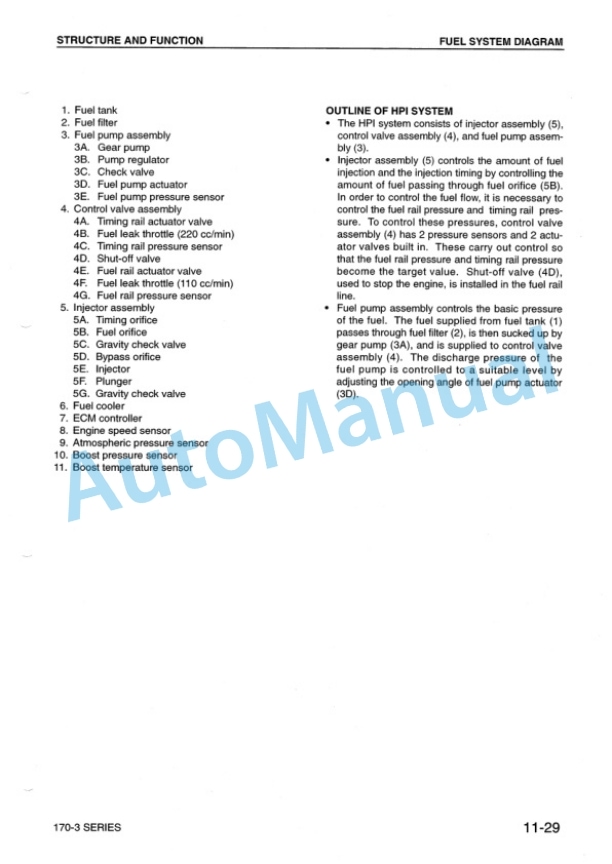

- 4.4. FUEL SYSTEM

- 4.5. COOLING SYSTEM

- 4.6. ELECTRICAL EQUIPMENT

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR TROULESHOOTING

- 5.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.3. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.4. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.5. MEASURING EXHAUSTTEMPERATURE (OVERALL ENGINE)

- 5.6. TROUBLESHOOTING FOR INJECTOR

- 5.7. ADJUSTING VALVE CLEARANCE

- 5.8. ADJUSTING INJECTOR SET LOAD

- 5.9. MEASURING COMPRESSION PRESSURE

- 5.10. MEASURING BLOWBY PRESSURE

- 5.11. MEASURING OIL PRESSURE

- 5.12. HANDLING EQUIPMENT IN FUEL CIRCUIT

- 5.13. MEASRING FUEL CICUIT PRESSURE

- 5.14. VIDUAL INSPECTION OF RETURN FUEL

- 5.15. BLEEDING AIR FROM FUEL CIRCUIT

- 5.16. ADJUSTING SPEED SENSOR

- 5.17. REPLACING AND ADJUSTING FAN BELT

- 5.18. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.19. PRECAUTIONS WHEN OPERATION ENGINE AS AN INDVIDUAL PART

- 5.20. ARRANGEMENT OF CONTROL DEVICES AND ELECTRIC CIRCUIT FOR HPI

- 5.21. RUNIN STANDARD

- 5.22. PERFORMANCE TEST STANDARDS

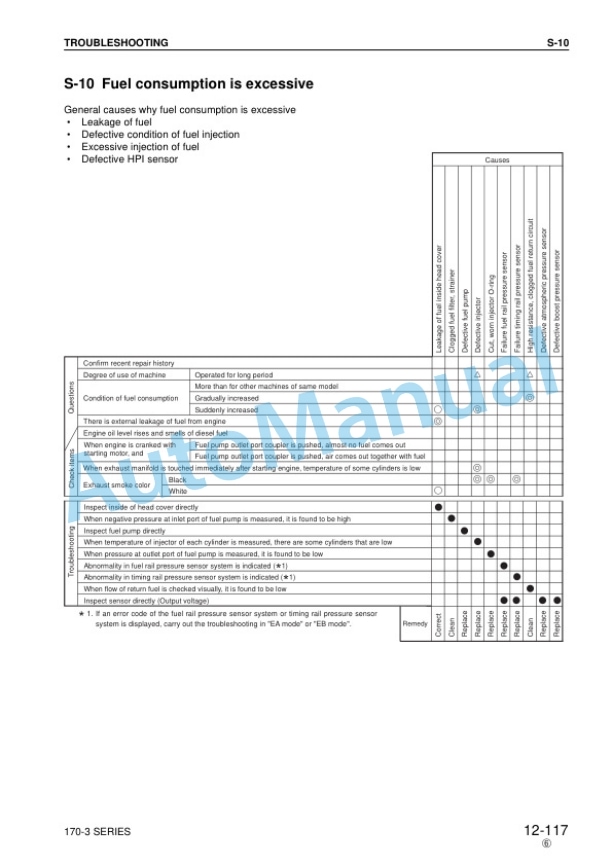

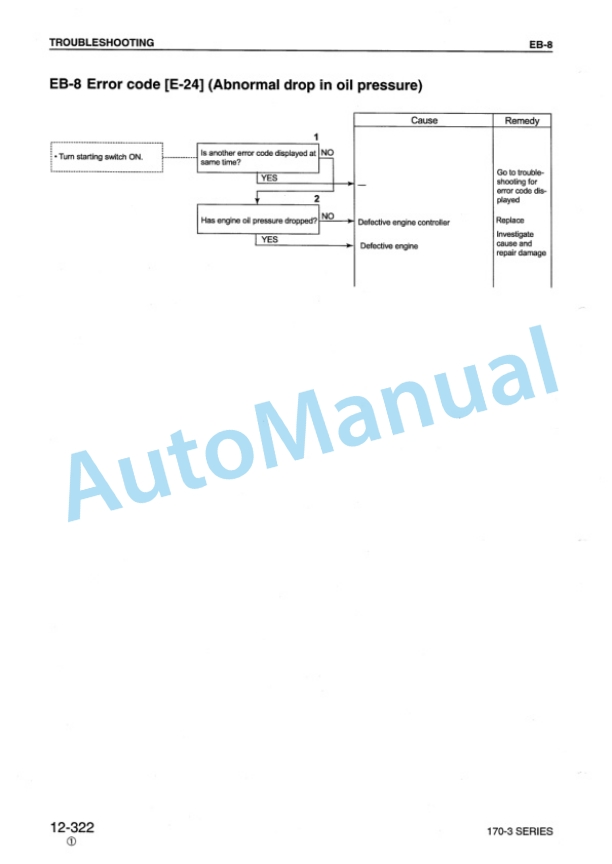

- 5.23. TROUBLESHOOTING OF MECHANICAL SYSTEM (S MODE)

- 5.24. TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM OF ENGINE FOR CONSTRUCTION EQUIPMENT (EA MODE)

- 5.25. TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGING FOR GENERATOR EQUIPMENT

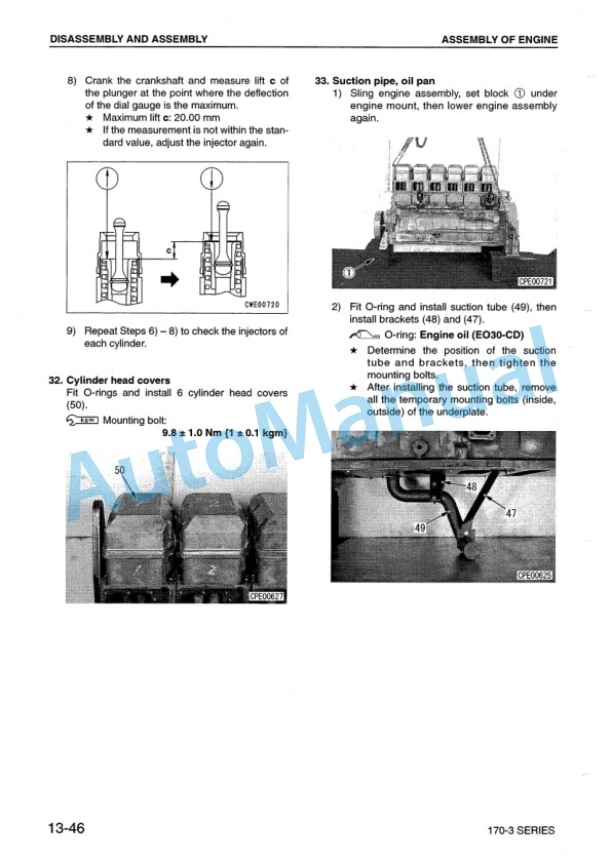

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. DISASSEMBLY OF ENGINE

- 6.5. WASHING PARTS

- 6.6. MEASURING PARTS

- 7. MAINTENANCE STANDARD

- 7.1. NTAKE AND EXHAUST SYSTEM

- 7.2. ENGINE BODY

- 7.3. LUBRICATION SYSTEM

- 7.4. COOLING SYSTEM

- 8. REPAIR AND REPLACEMENT OF PARTS

- 8.1. TABLE OF SPECIAL TOOLS

- 8.2. TESTING AND INSPECTING CYINDER HEAD

- 8.3. REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

- 8.4. REPLACING VALVE SEAT INSERTS

- 8.5. PRESSURE TEST METHOD

- 8.6. REPLACING VALVE GUIDE

- 8.7. REPLACING CROSS HEAD GUIDE

- 8.8. GRINDING VALVE

- 8.9. TESTING AND INSPECTING CYLINDER BLOCK

- 8.10. GRINDING THE TOP SURFACE OF CYLINDER BLOCK

- 8.11. REPLACING MAIN BEARING CAP

- 8.12. REPLACING CAM BUSHING

- 8.13. TESTING AND INSPECTING CRANKSHAFT

- 8.14. CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

- 8.15. REPAIRING CRANKSHAFT

- 8.16. TESTING AND INSPECTING OF CONNECTING ROD

- 8.17. REPLACING CRANKSHAFT GEAR

- 8.18. REPLACING CAMSHAFT GEAR

- 8.19. REPLACING FLYWHEEL RING GEAR

Rate this product

You may also like