Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: DG729

- Format: PDF

- Size: 1.9MB

- Number of Pages: 142

-

Model List:

- 330M Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. FOREWORD

- 3.1.1. ALERTS a description of DANGER, WARNING, CAUTION

- 3.1.2. TABLE OF CONTENTS

- 3.1.3. Truck Model Illustration

- 3.1.4. About This Manual

- 3.1.5. STANDARD TABLES

- 4. SAFETY

- 4.1. GENERAL SAFETY

- 4.2. PRECAUTIONS DURING OPERATION

- 4.2.1. OPERATING THE MACHINE

- 4.2.2. TOWING

- 4.2.3. BATTERY

- 4.3. PRECAUTIONS FOR MAINTENANCE

- 4.3.1. BEFORE CARRYING OUT MAINTENANCE

- 4.3.2. DURING MAINTENANCE

- 4.3.3. TIRES

- 4.4. WARNINGS AND CAUTIONS

- 5. OPERATIONS

- 5.1. OPERATING INSTRUCTIONS

- 5.1.1. PREPARING FOR OPERATION

- 5.1.2. SAFETY IS THINKING AHEAD

- 5.1.3. At The Truck Ground Level Walk Around Inspection

- 5.2. ENGINE STARTUP SAFETY PRACTICES

- 5.3. AFTER ENGINE HAS STARTED

- 5.4. MACHINE OPERATION SAFETY PRECAUTIONS

- 5.5. LOADING

- 5.6. HAULING

- 5.7. PASSING

- 5.8. DUMPING

- 5.9. SAFE PARKING PROCEDURES

- 5.10. SHUTDOWN PROCEDURE

- 5.11. TOWING

- 5.12. BRAKE RELEASE

- 5.13. RELEASE OF PARKING BRAKE

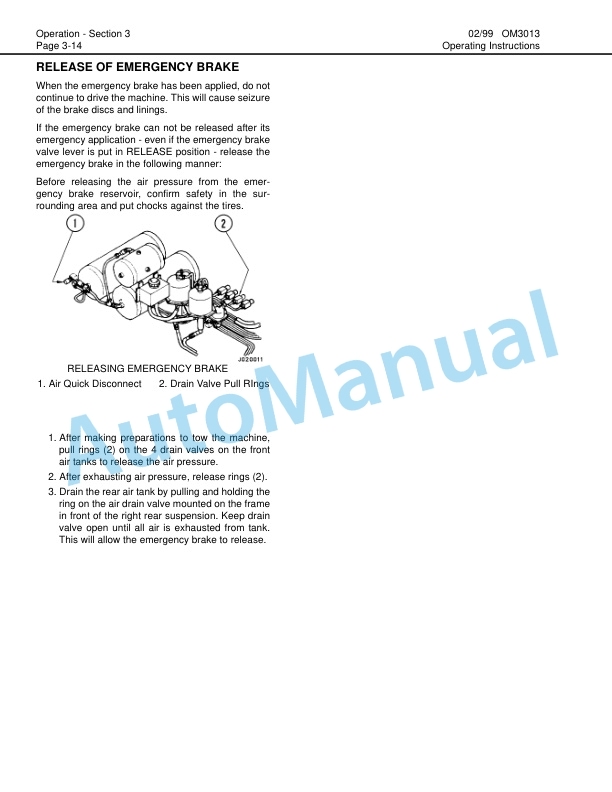

- 5.14. RELEASE OF EMERGENCY BRAKE

- 5.15. OPERATOR CAB AND CONTROLS

- 5.15.1. Steering Wheel And Controls

- 5.15.2. Retarder Control Lever

- 5.15.3. Brake Pedal

- 5.15.4. Throttle Pedal

- 5.15.5. Center Console

- 5.15.6. ENGINE ELECTRONIC CONTROL SYSTEM

- 5.15.6.1. Determining Fault Codes

- 5.15.6.2. EXITING THE DIAGNOSTICS MODE

- 5.15.7. Differential Lock Pedal

- 5.15.8. Hoist Control

- 5.15.9. OPERATOR SEAT

- 5.15.10. OPERATOR SEAT (KAB Model)

- 5.16. INSTRUMENT PANEL AND INDICATORS

- 5.17. GAUGE AND MONITOR PANEL

- 5.18. INDICATORS AND CONTROLS PANEL

- 5.19. INDICATORS AND CONTROL PANEL

- 5.20. INSTRUMENT PANEL RIGHT SIDE

- 5.21. Correction Code Display

- 6. MAINTENANCE

- 6.1. LUBRICATION AND SERVICE

- 6.1.1. LUBRICATION CHART

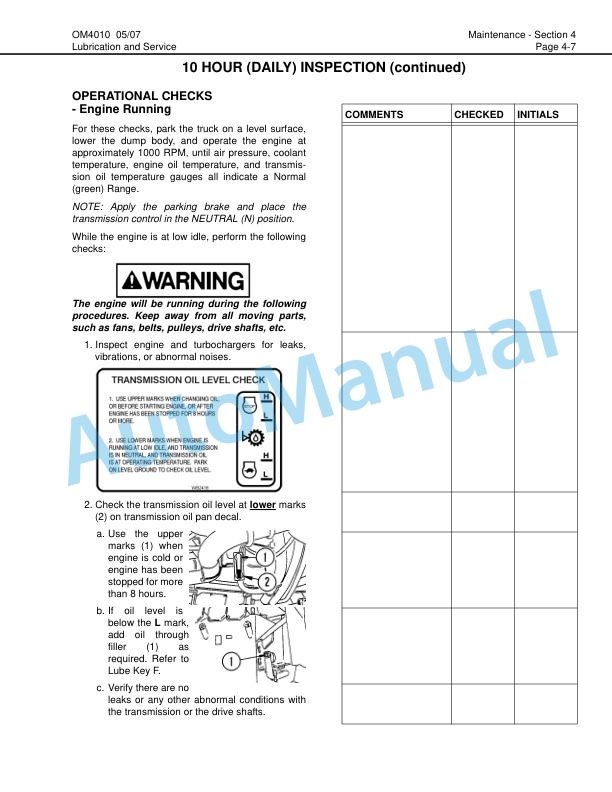

- 6.1.2. HOUR (DAILY) INSPECTION

- 6.1.3. HOUR SERVICE

- 6.1.4. HOUR SERVICE

- 6.1.5. HOUR SERVICE

- 6.1.6. EVERY 2000 HOUR SERVICE

- 6.1.7. EVERY 5000 HOUR SERVICE

- 6.2. HYDRAULIC TANK SERVICE

- 6.3. HIGH PRESSURE HYDRAULIC FILTERS

- 6.4. TRANSMISSION FILTER

- 6.5. PERIODIC REPLACEMENT OF COMPONENT PARTS FOR SAFETY DEVICES

- 6.6. BRAKE CIRCUIT CHECKOUT AND ADJUSTMENT

- 6.6.1. CHECKING FRONT BRAKE PAD WEAR

- 6.6.2. CHECKING REAR BRAKE DISC WEAR

- 6.6.3. BRAKE SYSTEM BLEEDING

- 6.6.4. PARKING BRAKE INSPECTION AND ADJUSTMENT

- 7. SPECIFICATIONS

- 7.1. MAJOR COMPONENTS

- 7.2. SPECIFICATIONS

- 8. OPTIONAL EQUIPMENT

- 8.1. PAYLOAD METER II INDEX

- 8.2. PAYLOAD METER II

- 8.2.1. PAYLOAD METER II ON BOARD WEIGHING SYSTEM (OBWS)

- 8.2.2. GENERAL INFORMATION

- 8.2.2.1. Haul Cycles

- 8.2.3. LIGHTS, SWITCHES, and COMPONENTS

- 8.2.4. TIPS FOR OPERATION

- 8.2.5. EXTERNAL DISPLAY LIGHTS

- 8.2.6. THEORY OF OPERATION

- 8.2.6.1. Basic Description

- 8.2.6.2. Inclinometer

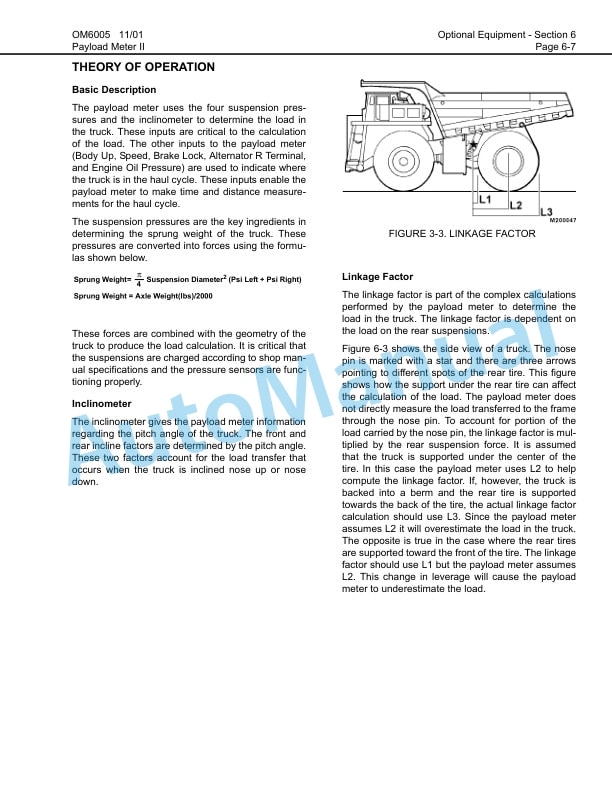

- 8.2.6.3. Linkage Factor

- 8.2.6.4. Gain Factor

- 8.2.6.5. Brake Lock

- 8.2.6.6. Sources of Error

- 8.2.6.7. Typical Data From Service Check Mode

- 8.2.6.8. Example Calculation of Payload

- 8.2.6.9. Viewing Payload Calculation Inputs

- 8.2.6.10. Checking the Gain

- 8.2.6.11. Adjusting the Gain

- 8.2.7. TYPES OF DATA STORED

- 8.2.7.1. Cycle Data

- 8.2.7.2. Engine ON/OFF Data

- 8.2.7.3. Fault Codes and Warning Data

- 8.2.7.4. Engine Operation

- 8.2.7.5. Total Payload and Total Number of Cycles

- 8.2.7.6. Other Data

- 8.2.8. OPERATOR FUNCTIONS

- 8.2.8.1. Using the Operator Load Counter

- 8.2.8.2. Viewing the Operator Load Counter

- 8.2.8.3. Clearing the Operator Load Counter

- 8.2.8.4. Dimming the Lights on the Display

- 8.2.9. INITIAL SETUP OF PAYLOAD METER

- 8.2.9.1. Switch Settings

- 8.2.9.2. Checking the Operator Check Mode

- 8.2.9.3. Checking the Service Check Mode

- 8.2.9.4. Checking the Gt setting

- 8.2.9.5. Checking the Inclinometer Settings

- 8.2.9.6. Calibrating a Truck

- 8.2.10. DISPLAYS AT STARTUP

- 8.2.11. NORMAL OPERATION

- 8.2.12. SETUP AND MAINTENANCE

- 8.2.12.1. Setting The Speed Limit

- 8.2.12.2. Setting the Option Code

- 8.2.12.3. Setting The Machine I.D. Code

- 8.2.12.4. Setting The Operator I.D. Code

- 8.2.12.5. Setting The Time and Date

- 8.2.13. DOWNLOAD OF INFORMATION

- 8.2.14. DISPLAY OF FAULT CODES

- 8.2.15. Monitoring Input Signals

- 8.2.16. Service Check Mode

- 8.2.17. UP Factor Payload Calculation Gain

- 8.2.18. FINAL GEAR RATIO SELECTION

- 8.2.19. BATTERY REPLACEMENT PROCEDURE

- 8.2.19.1. Replacing the Battery

- 8.2.19.2. After Replacing the Battery

- 8.2.20. SUSPENSION PRESSURE SENSOR

- 8.2.21. PAYLOAD METER BACK PANEL

- 8.2.22. CONNECTIONS

- 8.2.23. PAYLOAD METER 2 REINITIALIZATION PROCEDURE

- 8.2.24. PAYLOAD CIRCUIT NUMBERS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001