Komatsu 330M Dump Truck Shop Manual DG744

$40.00

- Type Of Manual: Shop Manual

- Manual ID: DG744

- Format: PDF

- Size: 14.3MB

- Number of Pages: 922

Category: Komatsu Shop Manual PDF

-

Model List:

- 330M Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. FOREWORD

- 4. TABLE OF CONTENTS

- 5. GENERAL INFORMATION

- 5.1. MAJOR COMPONENTS AND SPECIFICATIONS

- 5.2. GENERAL SAFETY AND OPERATING INSTRUCTIONS

- 5.3. WARNINGS AND CAUTIONS

- 5.4. STANDARD CHARTS AND TABLES

- 5.5. STANDARD VALUE TABLES

- 6. STRUCTURES

- 6.1. STRUCTURAL COMPONENTS

- 7. ENGINE, RADIATOR AIR CLEANER

- 7.1. ENGINE

- 7.2. AIR FILTRATION SYSTEM

- 8. ELECTRICAL SYSTEM

- 8.1. DC ELECTRIC SUPPLY SYSTEM

- 8.2. DC ELECTRICAL SYSTEM COMPONENTS

- 8.3. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 8.4. POINTS TO REMEMBER WHEN PERFORMING MAINTENANCE

- 8.5. CHECKS BEFORE TROUBLESHOOTING

- 8.6. CONNECTOR TYPE AND LOCATION

- 8.7. ARSC ( AUTOMATIC RETARDER SPEED CONTROL)

- 8.8. CONNECTOR PIN ALLOCATION CHART

- 8.9. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 8.10. EXPLANATIONS OF FUNCTIONS (CONTROL MECHANISM) OFELECTRICAL SYSTEM

- 8.11. MONITOR PANEL ACTION CODES AND SERVICE MODE

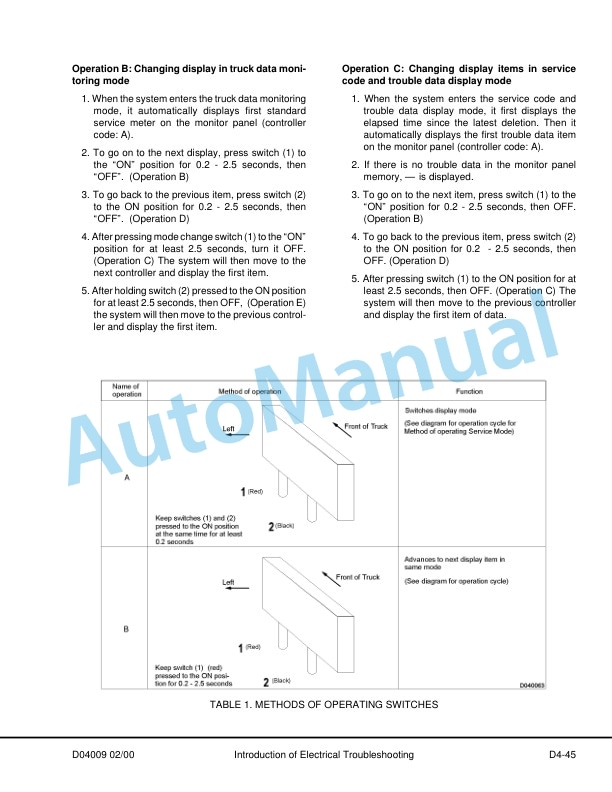

- 8.12. SELFDIAGNOSTIC DISPLAY METHOD FOR MONITOR PANEL ANDCONTROLLERS

- 8.13. TABLE OF SERVICE CODES AND ACTION CODES

- 8.14. METHOD OF USING TABLE

- 8.15. METHOD OF USING TROUBLESHOOTING CHARTS

- 8.16. ADJUSTING ELECTRONIC MONITOR (Speedometer Module)

- 8.17. SETTING ROTARY SWITCH(Model Data, Network Data) WHEN REPLACING TRANSMISSIONCONTROLLER

- 8.18. METHOD OF DELETING DATA FROM TRANSMISSION CONTROLLER MEMORY

- 8.19. TRANSMISSION CONTROLLER SYSTEM TROUBLESHOOTING

- 8.20. MONITOR PANEL TROUBLESHOOTING

- 8.21. ENGINE ELECTRONIC DIAGNOSTIC SYSTEM

- 8.22. ELECTRICAL SPECIFICATIONS

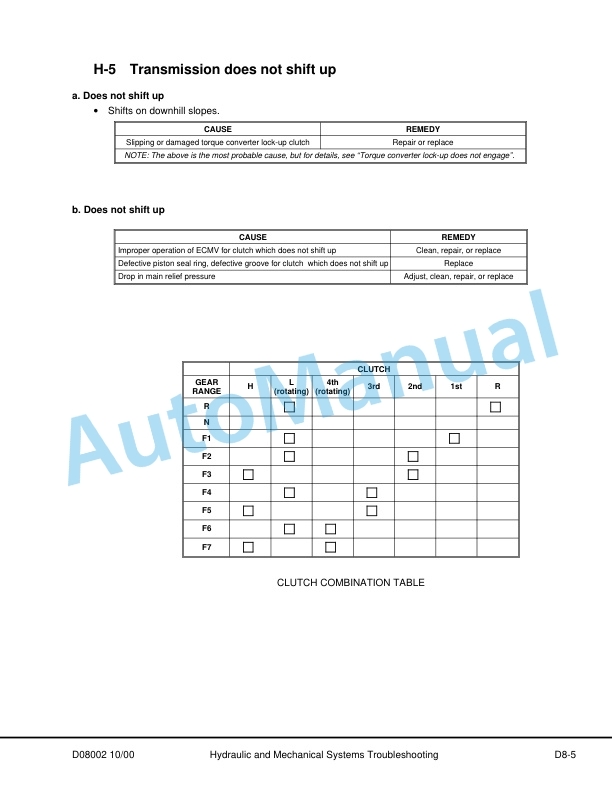

- 8.23. HYDRAULIC AND MECHANICAL SYSTEMS TROUBLESHOOTING

- 8.24. SUSPENSION CONTROLLER SYSTEM TROUBLESHOOTING

- 9. TRANSMISSION

- 9.1. TORQUE CONVERTER VALVE

- 9.2. TRANSMISSION OPERATION

- 9.3. TRANSMISSION

- 9.4. TRANSMISSION FILTER

- 9.5. TRANSMISSION OIL COOLER

- 9.6. DRIVELINES UJOINTS

- 9.7. AUTOMATIC SHIFT CONTROL SYSTEM

- 10. WHEELS, SPINDLES AND FINAL DRIVE

- 10.1. TIRES AND RIMS

- 10.2. FRONT WHEEL HUB AND SPINDLES

- 10.3. FINAL DRIVE ATTACHMENTS

- 10.4. FINAL DRIVE CENTER CASE ASSEMBLY

- 10.5. FINAL DRIVE PLANETARIES AND WHEEL HUBS

- 11. SUSPENSIONS

- 11.1. FRONT SUSPENSION

- 11.2. REAR SUSPENSIONS

- 11.3. OILING AND CHARGING PROCEDURES

- 12. BRAKE SYSTEM

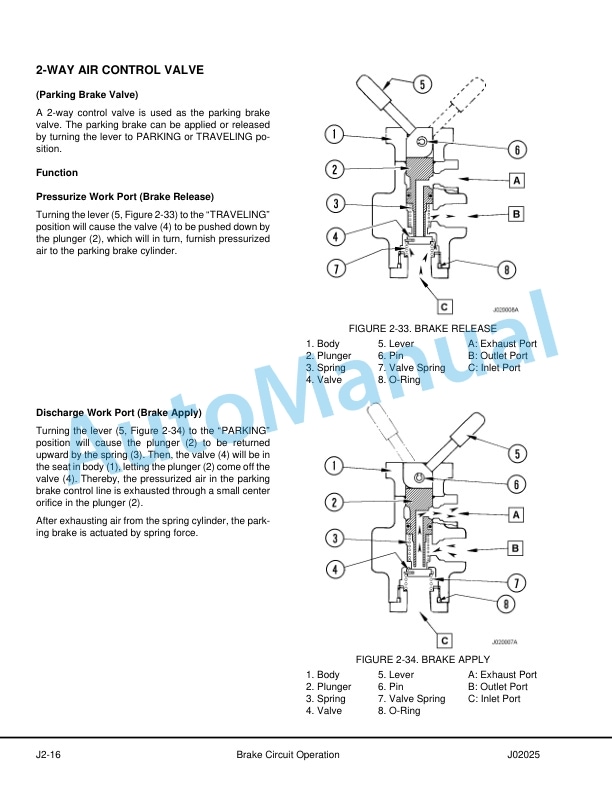

- 12.1. BRAKE CIRCUIT

- 12.2. BRAKE CIRCUIT COMPONENT SERVICE

- 12.3. BRAKE CIRCUIT CHECKOUT AND ADJUSTMENT

- 12.4. FRONT BRAKES

- 12.5. PARKING BRAKE RELEASE AFTER EMERGENCY APPLY

- 13. AIR SYSTEM

- 13.1. AIR SYSTEM COMPONENT REPAIR

- 13.2. AIR SYSTEM OPERATION

- 13.3. COMPONENT DESCRIPTION

- 14. HYDRAULIC SYSTEM

- 14.1. HYDRAULIC SYSTEM

- 14.2. HYDRAULIC SYSTEM COMPONENT REPAIR

- 14.3. STEERING CIRCUIT

- 14.4. STEERING VALVE ASSEMBLY

- 14.5. STEERING CIRCUIT COMPONENT REPAIR

- 14.6. HOIST CIRCUIT

- 14.7. HOIST CIRCUIT COMPONENT REPAIR

- 14.8. HYDRAULIC SYSTEM CHECKOUT

- 15. OPTIONS AND SPECIAL TOOLS

- 15.1. WIGGINS QUICK FILL FUEL SYSTEM

- 15.2. SPECIAL TOOLS

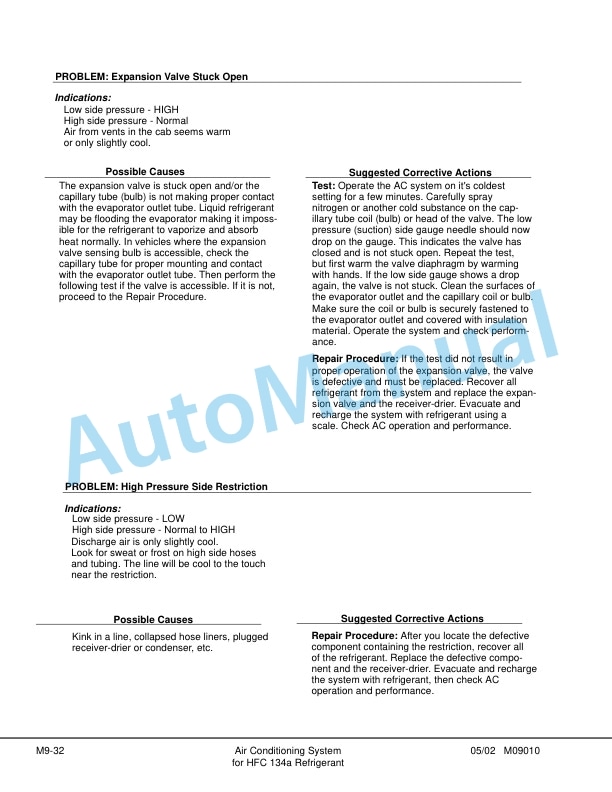

- 15.3. AIR CONDITIONING SYSTEM

- 15.4. PAYLOAD METER II ON BOARD WEIGHING SYSTEM

- 15.5. OPERATOR COMFORT

- 15.6. OPERATOR CAB AND CONTROLS

- 16. LUBRICATION AND SERVICE

- 16.1. LUBRICATION AND SERVICE

- 16.2. LUBRICATION SPECIFICATIONS CHARTS

- 16.3. HOUR (DAILY) INSPECTION

- 16.4. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 16.5. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 16.6. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 16.7. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 16.8. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 16.9. HYDRAULIC TANK SERVICE

- 16.10. HIGH PRESSURE HYDRAULIC FILTERS

- 16.11. TRANSMISSION FILTER

- 16.12. PERIODIC REPLACEMENT OF COMPONENT PARTS FOR SAFETY DEVICES

- 17. ALPHABETICAL INDEX

- 18. SYSTEM SCHEMATICS

- 18.1. AIR SYSTEM PIPING

- 18.2. AIR SYSTEM SCHEMATIC

- 18.3. HYDRAULIC SYSTEM SCHEMATIC

- 18.4. HYDRAULIC SYSTEM PIPING

- 18.5. TRANSMISSION CROSS SECTION VIEW

- 18.6. ELECTRICAL WIRING SCHEMATIC

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00