Komatsu 3D95E-1 Series Engine Shop Manual SEN06834-04

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06834-04

- Format: PDF

- Size: 20.3MB

- Number of Pages: 386

Category: Komatsu Shop Manual PDF

-

Model List:

- 3D95E-1 Series Engine

- 1. Cover

- 2. Index and Foreword

- 2.1. Index

- 2.2. Foreword, Safety, Basic Information

- 2.2.1. How to Read the Engine Shop Manual

- 2.2.2. Safety Notice for Operation

- 2.2.3. Precautions to Prevent Fire

- 2.2.4. Procedures If Fire Occurs

- 2.2.5. Precautions When You Discard Waste Materials

- 2.2.6. Engine Technology to Conform Exhaust Gas Emission

- 2.2.7. Precautions When You Handle Hydraulic Equipment

- 2.2.8. Precautions When You Disconnect and Connect Pipings

- 2.2.9. Precautions When You Handle Electrical Equipment

- 2.2.10. Precautions When You Handle Fuel System Equipment

- 2.2.11. Precautions When You Handle Intake System Equipment

- 2.2.12. Disconnect and Connect PushPull Type Coupler

- 2.2.12.1. How to Disconnect and Connect Type 1 PushPull Type Coupler

- 2.2.12.2. How to Disconnect and Connect Type 2 PushPull Type Coupler

- 2.2.12.3. How to Disconnect and Connect Type 3 PushPull Type Coupler

- 2.2.13. Precautions for Disconnection and Connection of Connectors

- 2.2.14. Disconnect and Connect Deutsch Connector

- 2.2.15. How to Disconnect and Connect Slide Lock Type Connector

- 2.2.16. Disconnect and Connect Connector with Lock to Pull

- 2.2.17. Disconnect and Connect Connector with Lock to Push

- 2.2.18. Disconnect and Connect Connector with Housing to Rotate

- 2.2.19. Standard Tightening Torque Table

- 2.2.20. Conversion Table

- 2.2.21. Abbreviation List

- 3. Specification

- 3.1. Table of Contents

- 3.2. Specifications

- 3.2.1. Outline of Exhaust Gas Regulation

- 3.2.1.1. System Diagram of Engine Conformed to Tier4 Regulation

- 3.2.2. List of Applicable Machines 3D95E1

- 3.2.3. Specifications

- 3.2.3.1. Specifications SAA3D95E1 (PC78US11, PC78US11E0, PC78UU11, PC88MR11, PC88MR11E0)

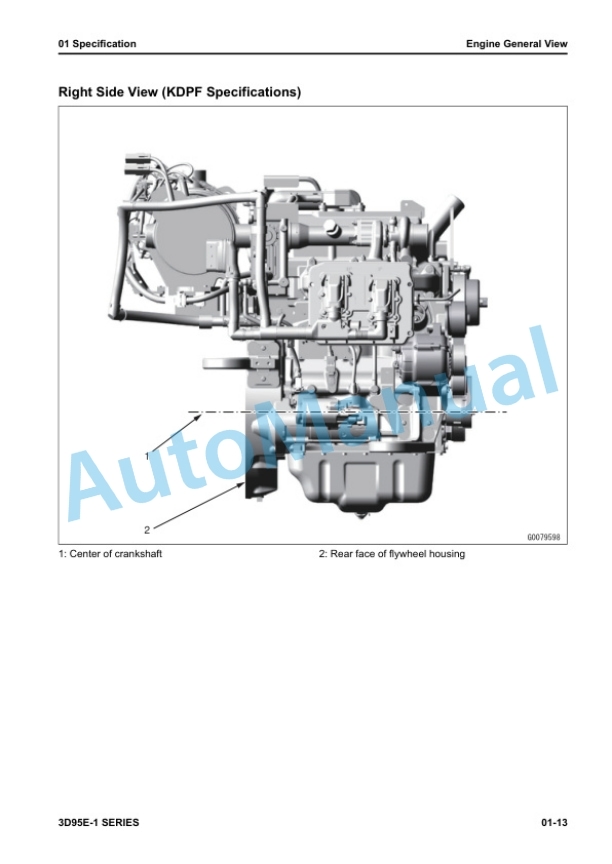

- 3.2.4. Engine General View

- 3.2.4.1. Engine General View SAA3D95E1 (PC78US11, PC78US11E0, PC78UU11, PC88MR11, PC88MR11E0)

- 3.2.5. Weight Table

- 3.2.5.1. Weight Table 3D95E1

- 3.2.6. Engine Performance Curve

- 3.2.6.1. Engine Performance Curve SAA3D95E1 (PC78US11, PC78US11E0, PC78UU11, PC88MR11, PC88MR11E0)

- 4. Structure and Function

- 4.1. Table of Contents

- 4.2. Engine System

- 4.2.1. Layout of Engine Components

- 4.2.1.1. Layout Drawing of Engine Components

- 4.2.2. Intake and Exhaust System Parts

- 4.2.2.1. Layout Drawing of Intake and Exhaust System

- 4.2.2.2. Intake and Exhaust System Circuit Diagram

- 4.2.2.3. Function of Intake and Exhaust System

- 4.2.2.4. Air Cleaner

- 4.2.2.5. Intake Air Heater

- 4.2.3. Engine Main Body Parts

- 4.2.3.1. Cylinder Head

- 4.2.3.2. Cylinder Block

- 4.2.3.3. Main Drive Parts

- 4.2.3.4. Timing Gear

- 4.2.3.5. Front Cover

- 4.2.3.6. Valve System

- 4.2.3.7. Flywheel and Flywheel Housing

- 4.2.4. Turbocharger System

- 4.2.4.1. Turbocharger

- 4.2.4.2. EGR System

- 4.2.4.3. EGR Valve

- 4.2.4.4. EGR Cooler

- 4.2.4.5. High Efficiency Breather System

- 4.2.4.6. High Efficiency Breather

- 4.2.4.7. Exhaust Throttle Valve

- 4.2.4.8. KDOC

- 4.2.4.9. KDPF

- 4.2.5. Lubrication System

- 4.2.5.1. Layout Drawing of Lubrication System Parts

- 4.2.5.2. Lubrication System Circuit Diagram

- 4.2.5.3. Engine Oil Pump

- 4.2.5.4. Engine Oil Filter

- 4.2.5.5. Engine Oil Cooler

- 4.2.5.6. Engine Oil Pan

- 4.2.6. Fuel System

- 4.2.6.1. Layout Drawing of Fuel System Parts

- 4.2.6.2. Fuel System Circuit Diagram

- 4.2.6.3. CRI System

- 4.2.6.4. Supply Pump

- 4.2.6.5. Common Rail

- 4.2.6.6. Injector

- 4.2.6.7. Fuel Prefilter

- 4.2.6.8. Fuel Main Filter

- 4.2.7. Cooling System

- 4.2.7.1. Layout Drawing of Cooling System Parts

- 4.2.7.2. Cooling System Circuit Diagram

- 4.2.7.3. Drive Pulley

- 4.2.7.4. Water Pump

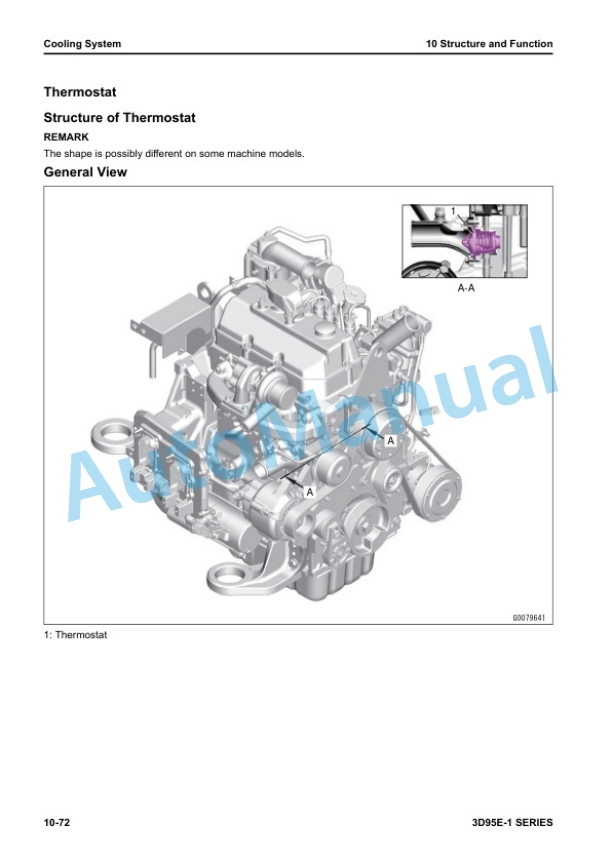

- 4.2.7.5. Thermostat

- 4.3. Electrical System

- 4.3.1. Component Parts of Electrical System

- 4.3.1.1. Alternator

- 4.3.1.2. Starting Motor

- 4.3.1.3. Engine Wiring Harness

- 4.3.1.4. Engine Controller

- 4.3.2. Sensor

- 4.3.2.1. Layout Drawing of Engine Sensor

- 4.3.2.2. Structure of Ambient Pressure Sensor

- 4.3.2.3. Function of Ambient Pressure Sensor

- 4.3.2.4. Structure of Engine Oil Pressure Switch

- 4.3.2.5. Function of Engine Oil Pressure Switch

- 4.3.2.6. Structure of Charge (Boost) Pressure and Temperature Sensor

- 4.3.2.7. Function of Charge (Boost) Pressure and Temperature Sensor

- 4.3.2.8. Structure of Coolant Temperature Sensor

- 4.3.2.9. Function of Coolant Temperature Sensor

- 4.3.2.10. Structure of NE (Crankshaft) Speed Sensor

- 4.3.2.11. Function of NE (Crankshaft) Speed Sensor

- 4.3.2.12. Structure of Bkup (Camshaft) Speed Sensor

- 4.3.2.13. Function of Bkup (Camshaft) Speed Sensor

- 4.3.2.14. Structure of Common Rail Pressure Sensor

- 4.3.2.15. Function of Common Rail Pressure Sensor

- 4.3.2.16. Structure of Mass Air Flow and Temperature Sensor

- 4.3.2.17. Function of Mass Air Flow and Temperature Sensor

- 4.3.2.18. Structure of Air Cleaner Clogging Sensor

- 4.3.2.19. Function of Air Cleaner Clogging Sensor

- 4.3.2.20. Structure of EGR Valve (with Builtin Position Sensor)

- 4.3.2.21. Function of EGR Valve (with Builtin Position Sensor)

- 4.3.2.22. Structure of Exhaust Throttle Valve (with Builtin Position Sensor)

- 4.3.2.23. Function of Exhaust Throttle Valve (with Builtin Position Sensor)

- 5. Standard Value Table

- 5.1. Table of Contents

- 5.2. Standard Value Table for Engine

- 5.2.1. Standard Value Table for Engine SAA3D95E1 (PC78US11, PC78US11E0, PC78UU11, PC88MR11, PC88MR11E0)

- 5.3. Runningin Standard and Performance Test Standard

- 5.3.1. Performance Test Standard and Standard for Operation of Engine for Break in Period SAA3D95E1 (PC78US11, PC78US11E0, PC78UU11, PC88MR11, PC88MR11E0)

- 6. Disassembly and Assembly

- 6.1. Table of Contents

- 6.2. Precautions Before Work

- 6.3. Related Information on Disassembly and Assembly

- 6.3.1. How to Read This Manual

- 6.3.2. Coating Materials List

- 6.3.3. Special Tool List

- 6.3.4. Sketches of Special Tools

- 6.4. Engine System

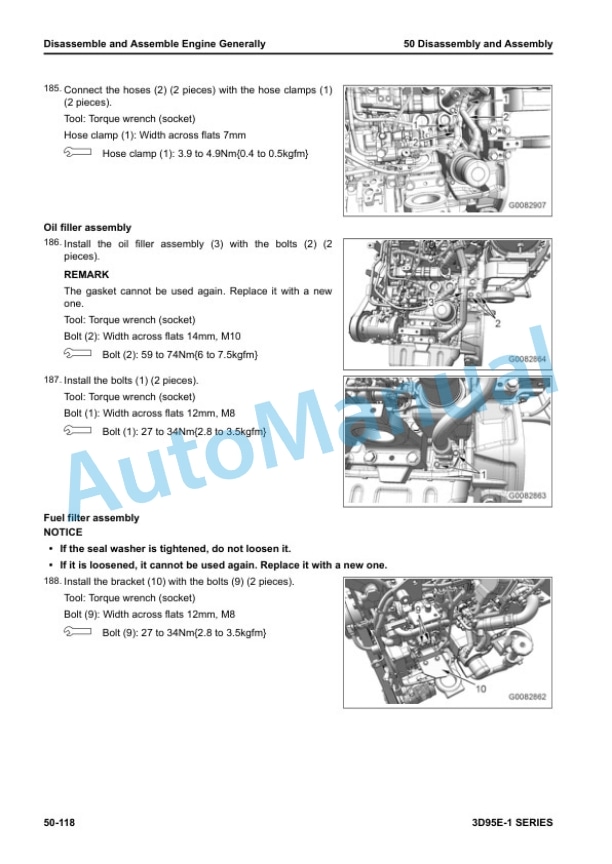

- 6.4.1. Disassemble and Assemble Engine Generally

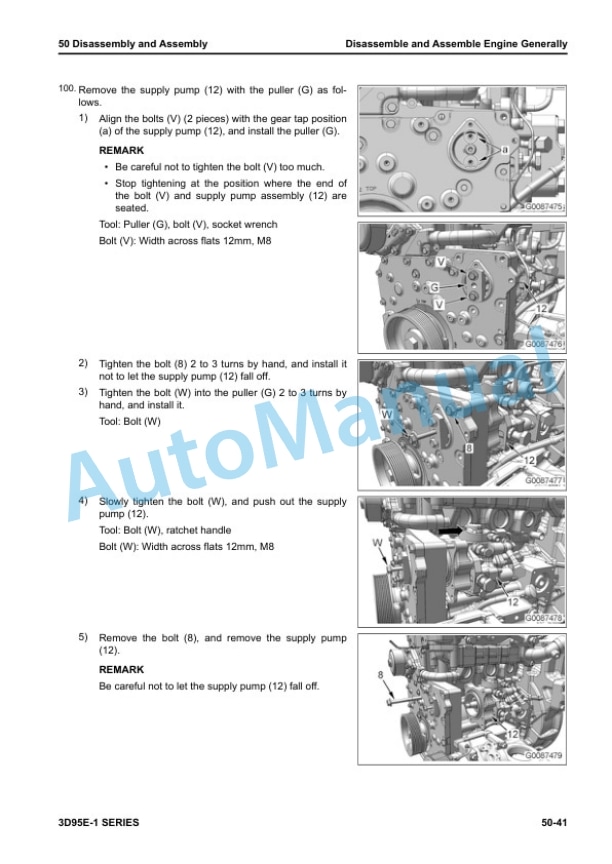

- 6.4.1.1. Disassemble Engine Generally

- 6.4.1.2. How to Assemble Engine Generally

- 6.4.2. Remove and Install Supply Pump Assembly

- 6.4.2.1. How to Remove Supply Pump Assembly

- 6.4.2.2. How to Install Supply Pump Assembly

- 6.4.3. Remove and Install Engine Front Oil Seal

- 6.4.3.1. How to Remove Engine Front Oil Seal

- 6.4.3.2. How to Install Engine Front Oil Seal

- 7. Maintenance Standard

- 7.1. Table of Contents

- 7.2. Explanation of Terms for Maintenance Standard

- 7.3. Engine System

- 7.3.1. Intake and Exhaust System Parts

- 7.3.1.1. Maintenance Standard for Turbocharger

- 7.3.2. Engine Main Body Parts

- 7.3.2.1. Maintenance Standard for Cylinder Head

- 7.3.2.2. Maintenance Standard for Cylinder Block

- 7.3.2.3. Maintenance Standard for Crankshaft

- 7.3.2.4. Maintenance Standard for Piston

- 7.3.2.5. Maintenance Standard for Connecting Rod

- 7.3.2.6. Maintenance Standard for Timing Gear

- 7.3.2.7. Maintenance Standard for Camshaft

- 7.3.2.8. Maintenance Standard for Valve and Valve Guide

- 7.3.2.9. Maintenance Standard for Rocker Arm

- 7.3.2.10. Maintenance Standard for Tappet

- 7.3.2.11. Maintenance Standard for Flywheel

- 7.3.3. Lubrication System

- 7.3.3.1. Maintenance Standard for Engine Oil Pump

- 8. Index

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00