Komatsu 68E-88E Series Diesel Engine Shop Manual SEBM011501

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM011501

- Format: PDF

- Size: 6.1MB

- Number of Pages: 212

Category: Komatsu Shop Manual PDF

-

Model List:

- 68E-88E Series Diesel Engine

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. SPECIFICATIONS AND PERFORMANCE

- 5. CROSS SECTION VIEWS

- 5.1. SPECIAL SWIRL PRECOMBUSTION CHAMBER SYSTEM (INDIRECT INJECTION SYSTEM)

- 5.2. DIRECT INJECTION SYSTEM

- 6. COOLING WATER, LUBRICATING OIL AND FUEL OIL

- 6.1. COOLING WATER

- 6.2. LUBRICATING OIL

- 6.3. FUEL OIL

- 7. TROUBLESHOOTING

- 7.1. TROUBLE CAUSES AND REMEDIES

- 7.2. TROUBLE DIAGNOSIS THROUGH MEASUREMENT OF COMPRESSION PRESSURE

- 8. SPECIAL SERVICE TOOLS AND MEASURING INSTRUMENTS

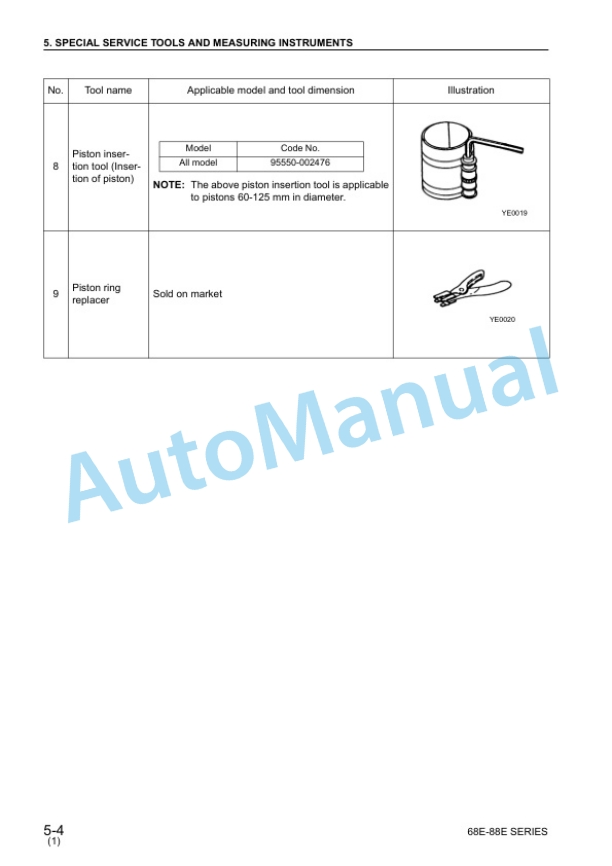

- 8.1. SPECIAL SERVICE TOOLS

- 8.2. MEASURING INSTRUMENTS

- 9. MESUREMENT, INSPECTION AND ADJUSTMENT

- 9.1. MEASURING THE COMPRESSION PRESSURE

- 9.2. ADJUSTING THE VALVE HEAD CLEARANCE

- 9.3. CHECKING THE VBELT TENSION

- 9.4. MEASURING AND CHECKING THE INJECTION PRESSURE AND SPRAY PATTERNS OF THE FUEL INJECTION VALVE

- 9.5. CHECKING AND ADJUSTING THE FUEL INJECTION TIMING

- 9.6. ADJUSTING THE NOLOAD MAXIMUM (OR MINIMUM) REVOLUTIONS

- 9.7. CHECKING THE COOLING WATER SYSTEM AND RADIATOR FOR WATER LEAKAGE

- 9.8. CHECKING THE BATTERY

- 9.9. CHECKING THE SENSORS

- 9.10. CHECKING THE OIL COOLER

- 9.11. CHECKING THE PISTON COOLING NOZZLE

- 10. MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION

- 10.1. CYLINDER HEAD

- 10.2. CYLINDER BLOCK

- 10.3. VALVE ROCKER ARM

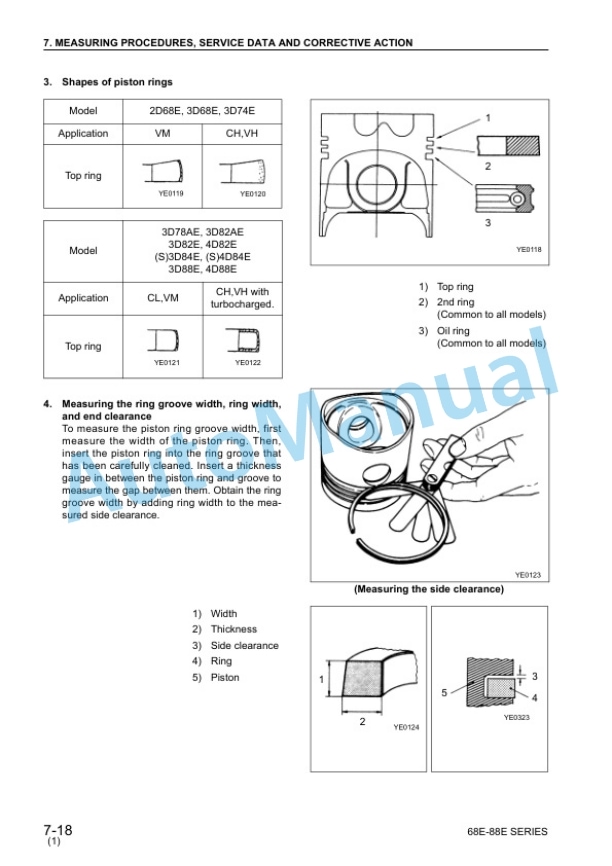

- 10.4. PISTON AND PISTON RING

- 10.5. CONNECTING ROD

- 10.6. CAMSHAFT

- 10.7. CRANKSHAFT

- 10.8. GEARS

- 10.9. TROCHOID PUMP

- 11. DISASSEMBLY AND REASSEMBLY

- 11.1. DISASSEMBLY

- 11.2. PRECAUTIONS BEFORE AND DURING REASSEMBLY

- 12. SERVICE DATA

- 12.1. CYLINDER HEAD

- 12.2. CYLINDER BLOCK

- 12.3. VALVE ROCKER ARM

- 12.4. PISTON

- 12.5. PISTON RING

- 12.6. CONNECTING ROD

- 12.7. CAMSHAFT

- 12.8. CRANKSHAFT

- 12.9. SIDE GAP AND BACKLASH

- 12.10. OTHERS

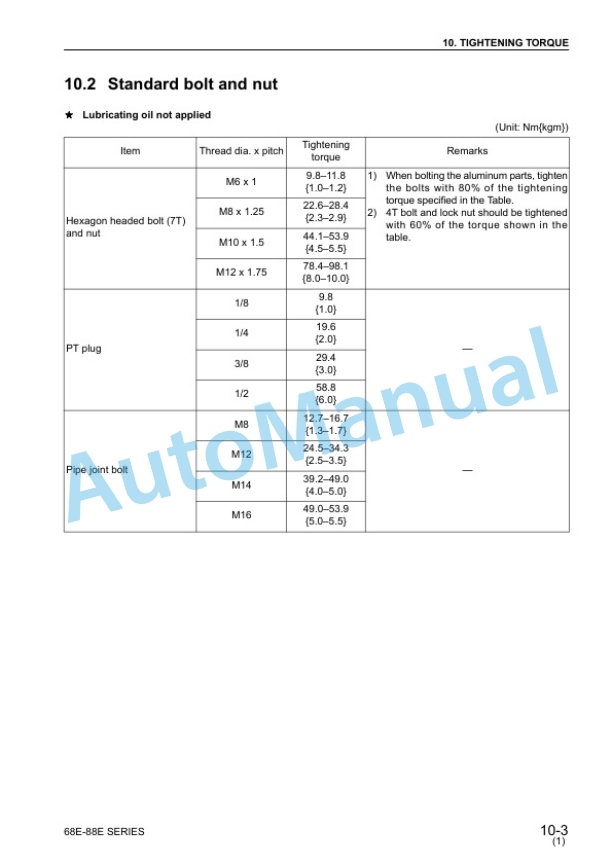

- 13. TIGHTENING TORQUE

- 13.1. MAIN BOLT/NUT

- 13.2. STANDARD BOLT AND NUT

- 14. FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM

- 14.1. EXPLODED VIEW

- 14.2. DISASSEMBLY

- 14.3. INSPECTION

- 14.4. REASSEMBLY

- 15. FUEL INJECTION PUMP FOR DIRECT INJECTION SYSTEM

- 15.1. EXPLODED VIEW (YPES TYPE)

- 15.2. SPECIAL SERVICE TOOLS FOR DISASSEMBLY AND REASSEMBLY

- 15.3. DISASSEMBLY

- 15.4. INSPECTION

- 15.5. REASSEMBLY

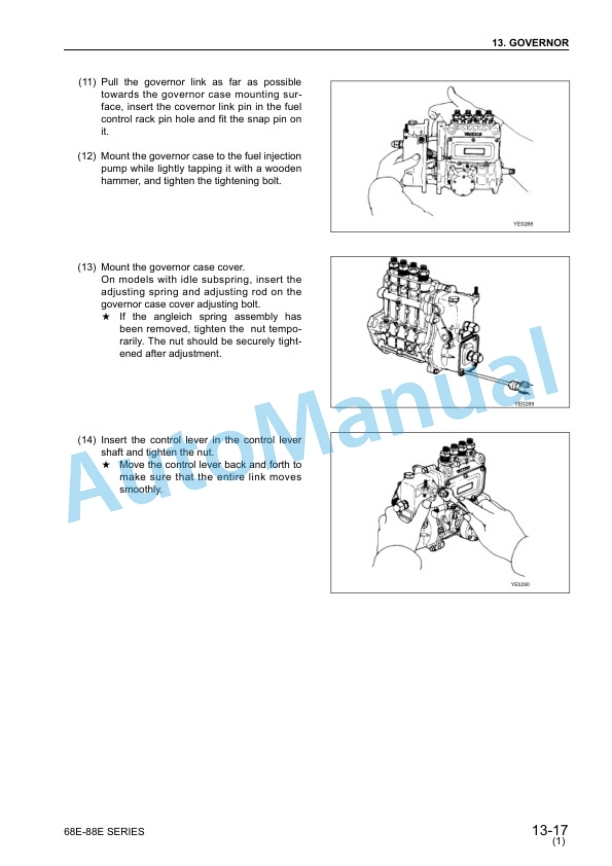

- 16. GOVERNOR

- 16.1. EXPLODED VIEWS OF GOVERNOR FOR INDIRECT INJECTION SYSTEM

- 16.2. EXPLODED VIEWS OF GOVERNOR FOR DIRECT INJECTION SYSTEM

- 16.3. DISASSEMBLY

- 16.4. INSPECTION

- 16.5. REASSEMBLY

- 17. TURBOCHARGER

- 17.1. SPECIFICATIONS

- 17.2. CONSTRUCTION

- 17.3. WASTE GATE VALVE ADJUSTING METHOD

- 17.4. EXPLODED VIEW OF TURBOCHARGER (WITH WASTE GATE)

- 17.5. TIGHTENING TORQUE

- 17.6. SERVICE STANDARDS

- 18. SERVICE INFORMATION FOR CARB ULG REGULATION

- 18.1. LIMITING THE HIGH IDLE AND LOW IDLE ADJUSTMENT SCREW

- 18.2. LIMITING THE FUEL VOLUME LIMITER SCREW

- 19. ATTACHED DRAWING

- 19.1. EXPLODED VIEWS OF ENGINE COMPONENTS

- 19.2. EXPLODED VIEWS OF ENGINE COMPONENTS

- 20. EPA CERTIFIED ENGINE

- 20.1. APPLICABLE MACHINE, SERIAL NUMBER (EPA CERTIFIED ENGINE)

- 20.2. EPA CERTIFICATION PLATE ATTACHING LOCATION

- 20.3. DIFFERENCES WITH THE CURRENT PRODUCTION MODEL

- 20.4. FUEL INJECTION TIMING ADJUSTMENT

- 20.5. SPECIFICATIONS

Rate this product

You may also like