Komatsu 6D105 Series Diesel Engine Shop Manual SEBE61360109

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBE61360109

- Format: PDF

- Size: 21.8MB

- Number of Pages: 350

Category: Komatsu Shop Manual PDF

-

Model List:

- 6D105 Series Diesel Engine

- 0.1. ASSEMBLY DRAWING

- 0.2. WEIGHT TABLE

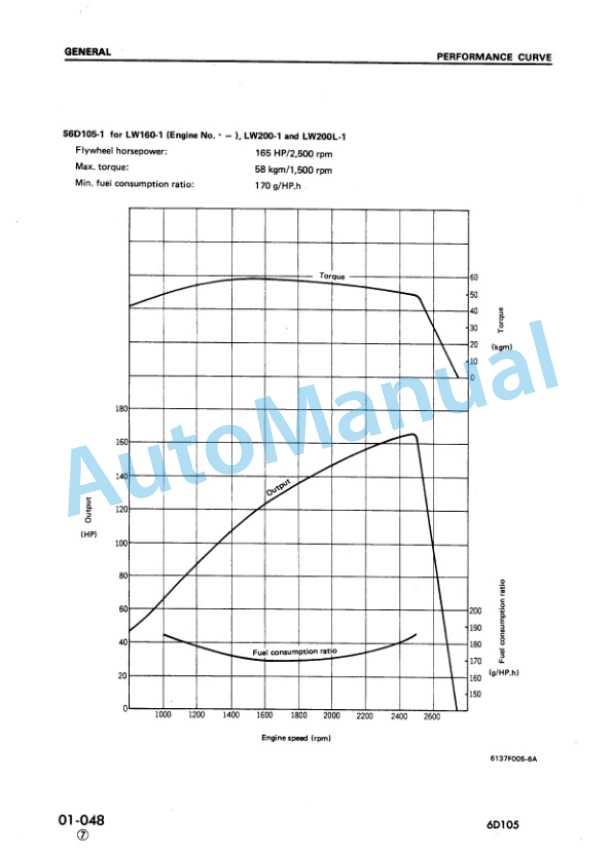

- 0.3. PERFORMANCE CURVE

- 1. STRUCTURE AND FUNCTION

- 1.1. GENERAL STRUCTURE

- 1.2. INTAKE AND EXHAUST SYSTEM

- 1.2.1. INTAKE AND EXHAUST SYSTEM CHART

- 1.2.2. TURBOCHARGER

- 1.3. ENGINE BODY

- 1.3.1. CYLINDER HEAD

- 1.3.2. MAIN CIRCULATION PART (1/3)

- 1.3.3. MAIN CIRCULATION PART (2/3)

- 1.3.4. MAIN CIRCULATION PART (3/3)

- 1.4. LUBRICATING SYSTEM

- 1.4.1. LUBRICATING SYSTEM CHART

- 1.4.2. OIL PUMP

- 1.4.3. REGULATOR VALVE

- 1.4.4. OIL FILTER

- 1.4.5. OIL COOLER

- 1.5. FUEL SYSTEM

- 1.5.1. FUEL SYSTEM CHART

- 1.5.2. FOR CONSTRUCTION EQUIPMENT

- 1.5.3. FOR GENERATOR

- 1.5.4. FUEL INJECTION PUMP

- 1.5.5. GOVERNOR

- 1.5.6. FEED PUMP

- 1.5.7. FUEL INJECTION NOZZLE

- 1.5.8. FUEL FILTER

- 1.5.9. FUEL CUT SOLENOID

- 1.6. COOLING SYSTEM

- 1.6.1. COOLING SYSTEM CHART

- 1.6.2. WATER PUMP

- 1.6.3. THERMOSTAT

- 1.6.4. CORROSION RESISTOR

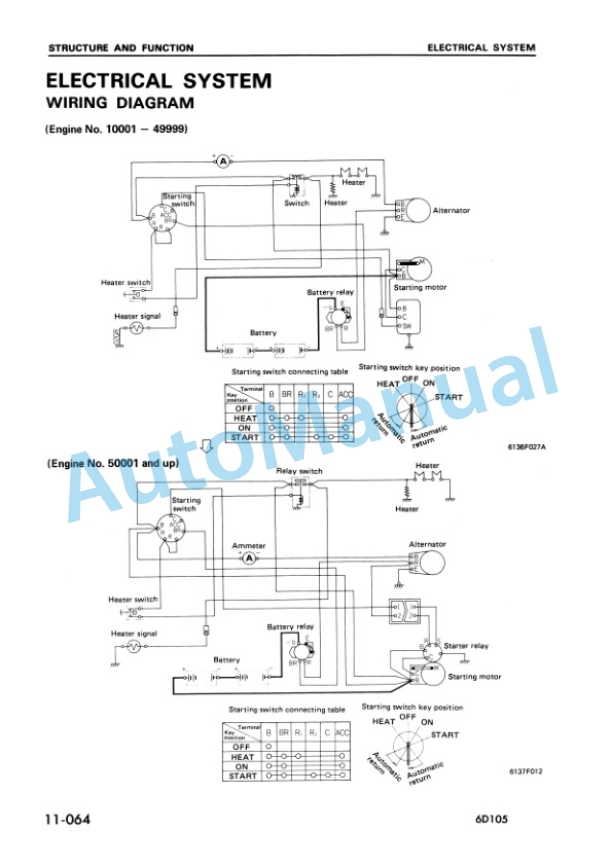

- 1.7. ELECTRICAL SYSTEM

- 2. TESTING AND ADJUSTING

- 2.1. GENERAL OF TESTING AND ADJUSTING

- 2.1.1. MEASURING ENGINE SPEED

- 2.1.2. CRANKING METHOD

- 2.2. INTAKE AND EXHAUST SYSTEM

- 2.2.1. CHECKING INTAKE AND EXHAUST SYSTEM

- 2.2.2. ADJUSTING VALVE CLEARANCE

- 2.2.3. MEASURING EXHAUST COLOR (BOSCH TYPE)

- 2.3. ENGINE BODY

- 2.3.1. MEASURING BLOWBY

- 2.3.2. MEASURING COMPRESSION PRESSURE

- 2.3.3. CLEANING BREATHER ELEMENT

- 2.4. LUBRICATING SYSTEM

- 2.4.1. CHECKING LUBRICATING SYSTEM

- 2.4.2. REPLACEMENT AND CLEANING OF LUBRICATING SYSTEM

- 2.4.3. MEASURING OIL CONSUMPTION

- 2.5. FUEL SYSTEM

- 2.5.1. CHECKING FUEL SYSTEM

- 2.5.2. REPLACEMENT AND CLEANING OF COMPONENTS OF FUEL SYSTEM

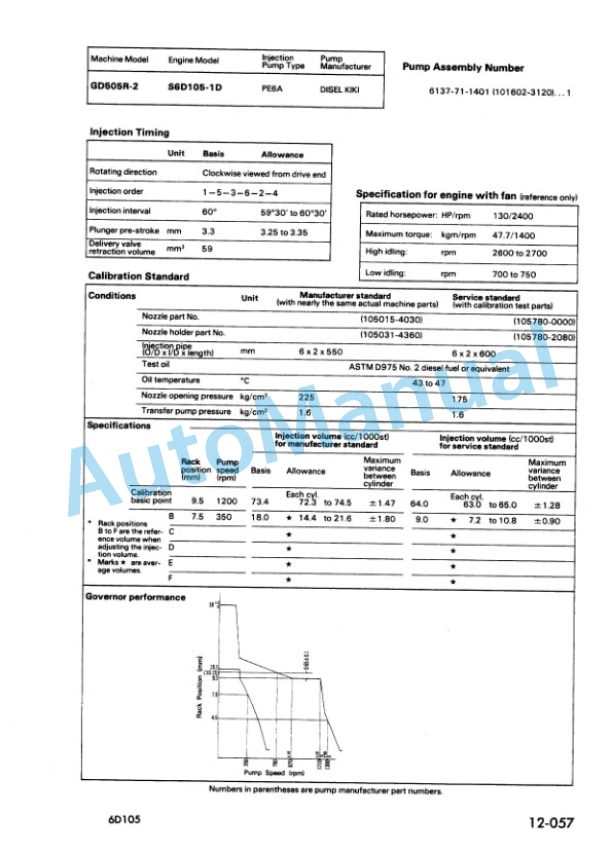

- 2.5.3. CHECKING FUEL INJECTION PUMP

- 2.5.4. CHECKING AND ADJUSTMENT OF FUEL INJECTION NOZZLE

- 2.5.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.5.6. ADJUSTING FUEL CUT SOLENOID (FOR WA3001)

- 2.5.7. CALIBRATION DATA

- 2.6. COOLING SYSTEM

- 2.6.1. CHECKING COOLING SYSTEM

- 2.6.2. REPLACEMENT AND CLEANING OF COMPONENTS OF COOLING SYSTEM

- 2.6.3. CHECKING THERMOSTAT FUNCTION

- 2.6.4. CHECKING AND ADJUSTMENT OF VBELT TENSION AND REPLACEMENT OF VBELT

- 2.7. PERFORMANCE TEST

- 2.7.1. TESTING METHOD OF PERFORMANCE

- 2.7.2. RUNIN CRITERIA

- 2.7.3. PERFORMANCE TEST CRITERIA

- 2.8. TROUBLESHOOTING

- 2.8.1. TESTING AND ADJUSTING DATA

- 2.8.2. TESTING AND ADJUSTING TOOL LIST

- 2.8.3. METHOD OF READING TROUBLESHOOTING TABLE

- 2.8.4. TROUBLESHOOTING TABLE

- 2.8.4.1. STARTING DEFECTIVE OR BADNESS

- 2.8.4.2. ENGINE STOPPED DURING OPERATION

- 2.8.4.3. ENGINE RUNS ABNORMALLY

- 2.8.4.4. FUEL CONSUMPTION TOO HIGH

- 2.8.4.5. LACK OF POWER

- 2.8.4.6. EXHAUST GAS IS BLACK

- 2.8.4.7. EXHAUST GAS IS BLUE

- 2.8.4.8. OIL CONSUMPTION TOO HIGH

- 2.8.4.9. OIL LEVEL RISES

- 2.8.4.10. OL QUICKLY BECOMES DIRTY

- 2.8.4.11. ENGINE OIL PRESSURE GAUGE INDICATOR FLUCTUATES ABNORMALLY

- 2.8.4.12. LACK OF OIL PRESSURE

- 2.8.4.13. OIL IN COOLING SYSTEM

- 2.8.4.14. WATER TEMPERATURE DOES NOT RISE

- 2.8.4.15. WATER TEMPERATURE RISES EXCESSIVELY

- 2.8.4.16. TOO MUCH VIBRATION

- 2.8.4.17. ABNORMAL NOISE EMITTED

- 2.8.4.18. EXCESSIVE WEAR OF ENGINE PARTS

- 2.8.4.19. ENGINE DOES NOT START BECAUSE OF FAULT IN ELECTRICAL SYSTEM

- 2.8.4.20. BATTERY DOES NOT CHARGE

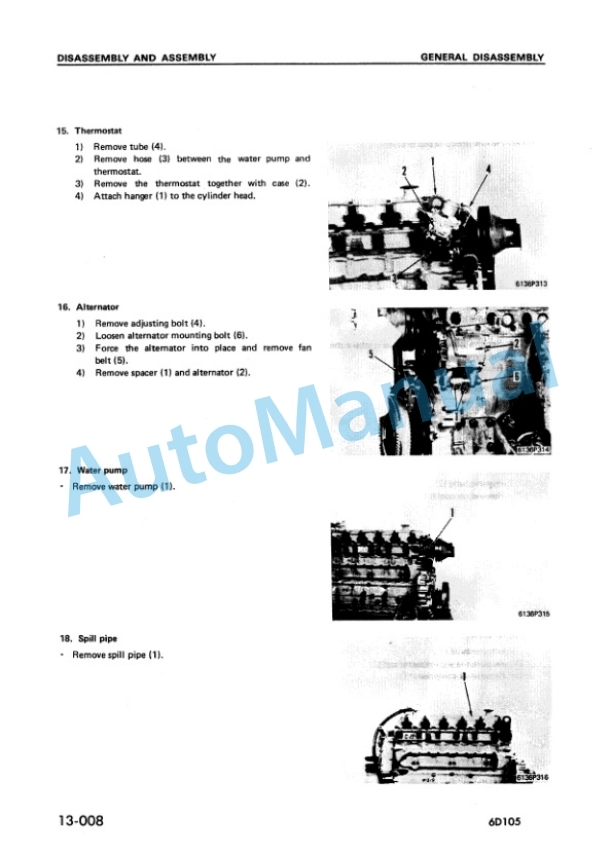

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. GENERAL

- 3.1.1. DISASSEMBLY

- 3.1.2. ASSEMBLY

- 3.2. DISASSEMBLY AND ASSEMBLY OF ACCESSORIES

- 3.2.1. TURBOCHARGER

- 3.2.2. OIL PUMP

- 3.2.3. WATER PUMP

- 4. MAINTENANCE STANDARD

- 4.1. INTAKE AND EXHAUST SYSTEM

- 4.1.1. TURBOCHARGER

- 4.2. ENGINE BODY

- 4.2.1. CYLINDER HEAD

- 4.2.2. VALVES AND VALVE GUIDES

- 4.2.3. ROCKER ARM SHAFT, PUSHROD AND TAPPET

- 4.2.4. PISTON, PISTON RING, PISTON PIN

- 4.2.5. CONNECTING ROD

- 4.2.6. FLYWHEEL AND FLYWHEEL HOUSING

- 4.3. LUBRICATING SYSTEM

- 4.3.1. OIL PUMP

- 4.4. COOLING SYSTEM

- 4.4.1. WATER PUMP, THERMOSTAT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00