Komatsu 6D140-2 Series Diesel Engine Shop Manual SEBM008613

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM008613

- Format: PDF

- Size: 21.3MB

- Number of Pages: 376

Category: Komatsu Shop Manual PDF

-

Model List:

- 6D140-2 Series Diesel Engine

- 1. Cover

- 2. Contents

- 3. General

- 3.1. Applicable machine

- 3.2. Specifications

- 3.3. General assembly drawing

- 3.4. Weight table

- 3.5. Engine performance curve

- 4. Structure and function

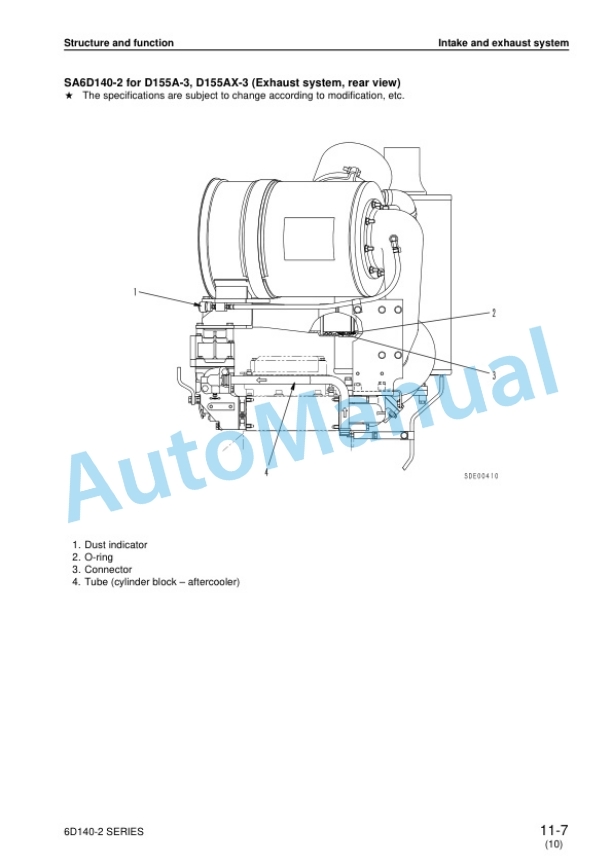

- 4.1. Intake and exhaust system

- 4.1.1. Intake and exhaust system

- 4.1.2. Main circulation system

- 4.1.3. Vibration damper

- 4.1.4. Timing gear

- 4.1.5. Valve system

- 4.1.6. Flywheel and flywheel housing

- 4.2. Lubrication system

- 4.2.1. Lubrication system chart

- 4.2.2. Oil pump

- 4.2.3. Regulator valve and piston cooling valve

- 4.2.4. Oil filter

- 4.2.5. Oil cooler

- 4.3. Fuel system

- 4.3.1. Fuel system chart

- 4.3.2. Fuel injection pump

- 4.3.3. Feed pump

- 4.3.4. Fuel injection nozzle

- 4.3.5. Fuel filter

- 4.3.6. Engine stop motor

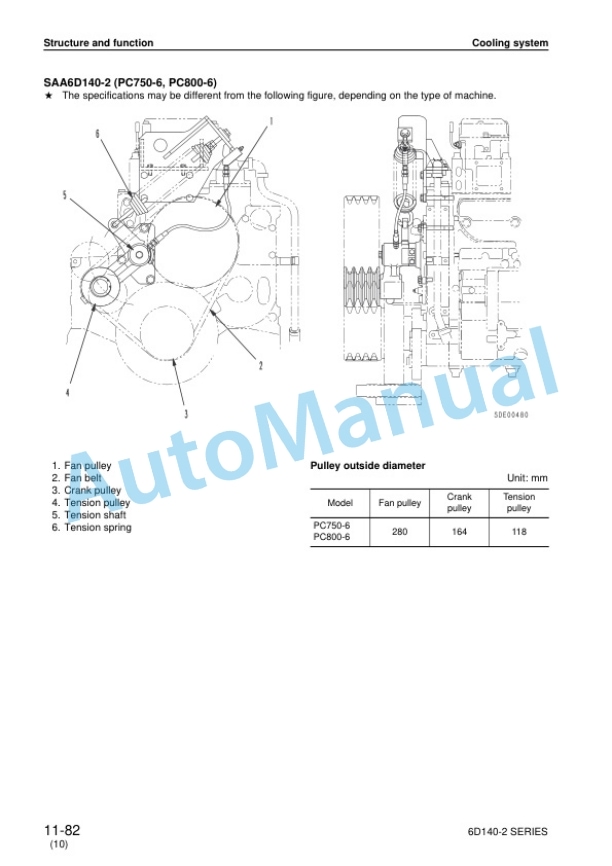

- 4.4. Cooling system

- 4.4.1. Cooling system chart

- 4.4.2. Water pump

- 4.4.3. Thermostat

- 4.4.4. Corrosion resistor

- 4.4.5. Corrosion resistor mounting

- 4.4.6. Cooling fan drive

- 4.5. Accessory

- 4.5.1. Air compressor

- 4.5.2. Exhaust brake

- 4.6. Electrical system

- 4.6.1. Alternator

- 4.6.2. Starting motor

- 4.6.3. Electrical intake air heater

- 4.6.4. Front PTO mounting

- 4.6.5. Front PTO assembly

- 4.6.6. Front PTO drive gear assembly

- 5. Testing and adjusting

- 5.1. Mounting (adjusting) methodof engine speed sensor

- 5.2. Engine body

- 5.2.1. Adjusting valve clearance

- 5.2.2. Measuring compressionpressure

- 5.3. Fuel system

- 5.3.1. Testing and adjusting fuelinjection timing

- 5.3.2. Adjusting fuel injectionpressure

- 5.3.3. Procedure for adjustingengine stop motor cable

- 5.4. Cooling system

- 5.4.1. Checking and adjusting fan belt tension

- 5.5. Fuel injection pump calibration data

- 5.6. Performance test

- 5.6.1. Runin standard

- 5.6.2. Performance test criteria

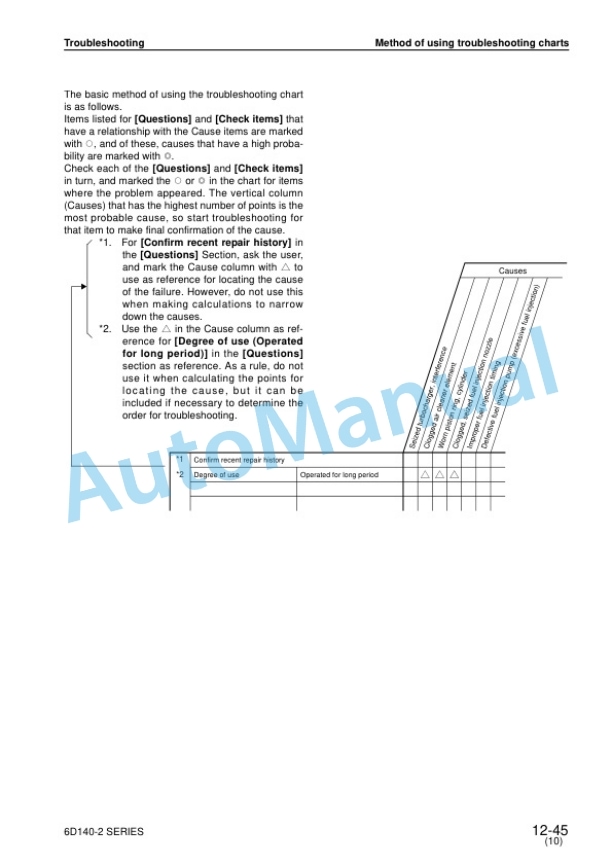

- 5.7. Troubleshooting

- 5.7.1. Points to remember when troubleshooting

- 5.7.2. Method of using troubleshooting charts

- 5.7.3. S1 Starting performance is poor (starting always takes time)

- 5.7.4. S2 Engine does not start

- 5.7.5. S3 Engine does not pick up smoothly (followup is poor)

- 5.7.6. S4 Engine stops during operations

- 5.7.7. S5 Engine does not rotate smoothly (hunting)

- 5.7.8. S6 Engine lacks output (no power)

- 5.7.9. S7 Exhaust smoke is black (incomplete combustion)

- 5.7.10. S8 Oil consumption is excessive (or exhaust smoke is blue)

- 5.7.11. S9 Oil becomes contaminated quickly

- 5.7.12. S10 Fuel consumption is excessive

- 5.7.13. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 5.7.14. S12 Oil pressure caution lamp lights up (drop in oil pressure)

- 5.7.15. S13 Oil level rises (water, fuel in oil)

- 5.7.16. S14 Water temperature becomes too high (overheating)

- 5.7.17. S15 Abnormal noise is made

- 5.7.18. S16 Vibration is excessive

- 5.7.19. Testing and adjusting tool list

- 5.7.20. Testing and adjusting dataa

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. GENERAL DISASSEMBLY

- 6.1.1. Air cleanermuffler

- 6.1.2. Starting motor

- 6.1.3. Turbocharger drain tube

- 6.1.4. Setting engine in engine overhaul stand

- 6.1.5. Corrosion resistor, air compressor suction tube

- 6.1.6. Bracket

- 6.1.7. Connector

- 6.1.8. Tension pulley assembly

- 6.1.9. Fan pulley assembly

- 6.1.10. Alternator assemblypulley

- 6.1.11. Dipstick guide, air compressor

- 6.1.12. Fuel hose

- 6.1.13. Turbocharger

- 6.1.14. Exhaust manifold

- 6.1.15. Aftercooler assembly (Intake manifold assembly)

- 6.1.16. Fuel injection tube

- 6.1.17. Fuel injection pump assembly

- 6.1.18. Tube, bracket, PTO case

- 6.1.19. Fuel filterfuel filter bracket

- 6.1.20. Oil filteroil regulator

- 6.1.21. Oil pan

- 6.1.22. Suction pipe, under frame

- 6.1.23. Flywheel

- 6.1.24. Rear seal

- 6.1.25. Flywheel housing

- 6.1.26. Air vent tube, spill pipe, rocker arm housing cover

- 6.1.27. Nozzle holder, inlet connector

- 6.1.28. Rocker arm

- 6.1.29. Push rod

- 6.1.30. Crosshead

- 6.1.31. Rocker arm housing

- 6.1.32. Cylinder head assembly

- 6.1.33. Vibration dampercrankshaft pulley assembly

- 6.1.34. Front support

- 6.1.35. Thermostat housing

- 6.1.36. Water pump assembly

- 6.1.37. Oil cooler assembly

- 6.1.38. Cam follower

- 6.1.39. Gear case cover

- 6.1.40. Injection pump drive gear

- 6.1.41. Camshaft

- 6.1.42. Oil pump assembly, oil pump idler gear

- 6.1.43. Main idler gear, injection pump drive shaft

- 6.1.44. Piston cooling nozzle

- 6.1.45. Piston and connecting rod assembly

- 6.1.46. Crankshaft

- 6.1.47. Cylinder liner

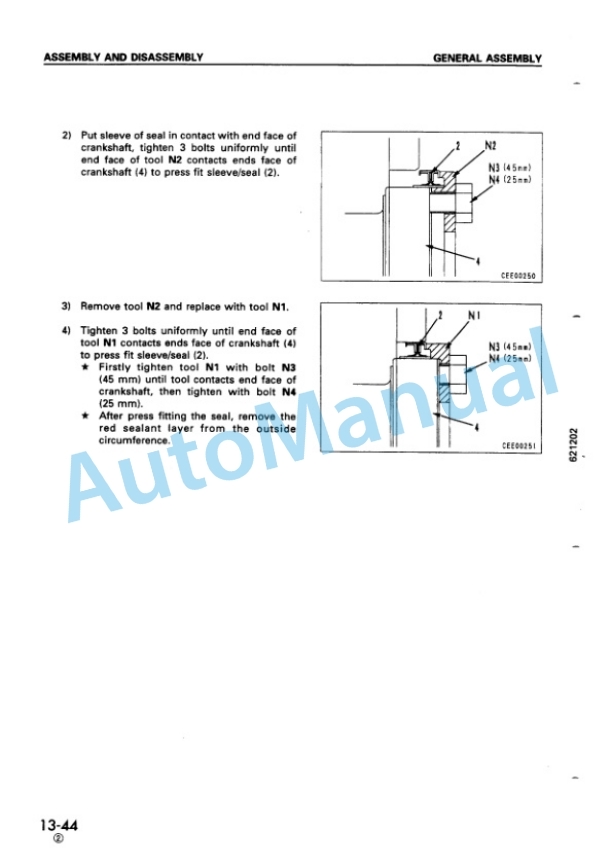

- 6.2. GENERAL ASSEMBLY

- 6.2.1. Tightening bolts by the plastic range turning angle method

- 6.2.2. Drawing of special tool

- 6.2.3. Preparatory work

- 6.2.4. Cylinder liner

- 6.2.5. Crankshaft

- 6.2.6. Piston and connecting rod assembly

- 6.2.7. Piston cooling nozzle

- 6.2.8. Main idler gear, fuel injection pump drive shaft

- 6.2.9. Oil pump idler gear, oil pump assembly

- 6.2.10. Camshaft

- 6.2.11. Fuel injection pump drive gear

- 6.2.12. Fuel injection pump drive shaft oil seal

- 6.2.13. Gear case cover

- 6.2.14. Breather

- 6.2.15. Front seal

- 6.2.16. Cam follower

- 6.2.17. Oil cooler assembly

- 6.2.18. Water pump assembly

- 6.2.19. Thermostat housing

- 6.2.20. Front support

- 6.2.21. Vibration damper, crankshaft pulley assembly

- 6.2.22. Cylinder head assembly

- 6.2.23. Crosshead

- 6.2.24. Rocker arm housing

- 6.2.25. Push rod

- 6.2.26. Rocker arm

- 6.2.27. Adjusting valve clearance

- 6.2.28. Nozzle holder, inlet connector

- 6.2.29. Rocker arm housing cover, spill pipe, air vent tube

- 6.2.30. Flywheel housing

- 6.2.31. Rear seal

- 6.2.32. Flywheel

- 6.2.33. Suction pipe

- 6.2.34. Oil pan

- 6.2.35. Oil filter assembly, oil regulator

- 6.2.36. Fuel filter assemblyfuel filter bracket

- 6.2.37. PTO case tube, bracket

- 6.2.38. Fuel injection pump assembly

- 6.2.39. Adjusting fuel injection pump

- 6.2.40. Fuel injection tube

- 6.2.41. Aftercooler assembly (Intake manifold assembly)

- 6.2.42. Exhaust manifold

- 6.2.43. Turbocharger

- 6.2.44. Fuel hose

- 6.2.45. Dipstick guide, air compressor

- 6.2.46. Alternator assembly, pulley

- 6.2.47. Fan pulley assembly

- 6.2.48. Tension pulley assembly

- 6.2.49. Intake connector

- 6.2.50. Muffler bracket, air cleaner bracket

- 6.2.51. Corrosion resistor

- 6.2.52. Resetting engine in engine stand

- 6.2.53. Turbocharger drain tube

- 6.2.54. Starting motor

- 6.2.55. Air cleaner, muffler

- 6.2.56. Refilling with oil

- 7. Maintenance standard

- 7.1. Intake and exhaust system

- 7.1.1. Turbocharger

- 7.2. Engine body

- 7.2.1. Cylinder head

- 7.2.2. Valve, valve guide

- 7.2.3. Rocker arm and shaft

- 7.2.4. Crosshead and guide

- 7.2.5. Cylinder block

- 7.2.6. Cylinder liner

- 7.2.7. Crankshaft

- 7.2.8. Camshaft

- 7.2.9. Cam follower and push rod

- 7.2.10. Timing gear

- 7.2.11. Piston

- 7.2.12. Connecting rod

- 7.2.13. Flywheel and flywheel housing

- 7.3. Lubrication system

- 7.3.1. Oil pump

- 7.3.2. Regulator valve, piston cooling valve and safety valve

- 7.3.3. Oil cooler

- 7.4. Cooling system

- 7.4.1. Water pump

- 7.4.2. Thermostat

- 8. Repair and replacement of parts

- 8.1. Table of special tools

- 8.2. Cylinder head

- 8.2.1. Grinding of fitting face ofcylinder head

- 8.2.2. Replacing valve seat insert

- 8.2.3. Pressure test

- 8.2.4. Replacing valve guide

- 8.2.5. Replacing crosshead guide

- 8.2.6. Grinding valve

- 8.3. Cylinder block

- 8.3.1. Replacing cam bushing

- 8.3.2. Replacing crankshaft gear

- 8.3.3. Replacing cam gear

- 8.3.4. Replacing flywheel ring gear

- 8.3.5. Replacing connecting rodsmall end bushing

- 8.3.6. Cylinder block parts

- 8.3.7. Testing and inspecting cylinder block

- 8.3.8. Correcting cylinder block top surface, counterbore

- 8.3.9. Replacing main bearing cap

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00