Komatsu 730E-8 Dump Truck Field Assembly Instruction CEAW007810

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: CEAW007810

- Format: PDF

- Size: 7.9MB

- Number of Pages: 281

-

Model List:

- 730E-8 Dump Truck

- 1. INTRODUCTION

- 2. TABLE OF CONTENTS

- 3. SAFETY RULES, TOOLS and EQUIPMENT

- 3.1. SAFETY RULES

- 3.2. TOOLS AND EQUIPMENT FOR ASSEMBLY

- 3.3. HIGH VOLTAGE TOOLS

- 3.4. VDC CUSTOM METER KIT (58B0600800)

- 4. TRUCK COMPONENTS and SPECIFICATIONS

- 4.1. Truck And Engine

- 4.2. Traction Alternator

- 4.3. Main Control Cabinet

- 4.4. AC Induction Traction Motorized Wheels

- 4.5. Suspension

- 4.6. Operators Cab

- 4.7. Power Steering

- 4.8. Dynamic Retarding

- 4.9. Brake System

- 5. SPECIFICATIONS

- 6. MAJOR COMPONENT WEIGHTS

- 7. FIELD WELDING FOR ASSEMBLY OR REPAIR

- 7.1. WELDER QUALIFICATION AND TRAINING

- 7.2. WELD PROCEDURES

- 7.3. APPROVED CONSUMABLES

- 7.4. WELD QUALITY REQUIREMENTS

- 7.5. MATERIALS, CONTROLS, AND PRECAUTIONS

- 7.6. WELD INSPECTION

- 7.7. RECORDS

- 7.8. ANNEX A

- 7.9. ANNEX B

- 7.9.1. TOE HAMMER PEENING

- 7.9.2. TOE GRINDING WITH A ROTARY BURR

- 7.10. BIBLIOGRAPHY

- 7.10.1. SPECIAL PRECAUTIONS WHEN

- 7.10.2. SERVICING AN AC DRIVE SYSTEM TRUCK

- 8. RECEIVING and ASSEMBLY PREPARATION

- 8.1. Preparation

- 8.2. ASSEMBLY LAYOUT

- 9. CHASSIS ASSEMBLY

- 9.1. RECOMMENDED ASSEMBLY DATA

- 9.2. BASIC ASSEMBLY PROCEDURE

- 9.3. ORDER OF ASSEMBLY

- 9.4. SAFETY PRECAUTIONS

- 9.5. HARDWARE TIGHTENING METHOD

- 9.6. GENERAL PRECAUTIONS

- 9.7. ASSEMBLY PROCEDURES

- 9.7.1. Unloading and Preparations

- 9.7.2. Uprights and Front Bumper Installations

- 9.7.3. Wheel Motor Installation

- 9.7.4. Front Suspension Installation

- 9.7.5. Deck Support Installation

- 9.7.6. Center Deck/Control Cabinet Installation

- 9.7.7. Spindle/Hub Installation

- 9.7.8. Steering Cylinder/Tie Rod Installation

- 9.7.9. Fuel Tank Installation

- 9.7.10. Deck Installation

- 9.7.11. Cab Installation

- 9.7.12. Air Intake/Exhaust/Blower Duct Installation

- 9.7.13. Tire Installation

- 9.7.14. Wiring and Hose Installation

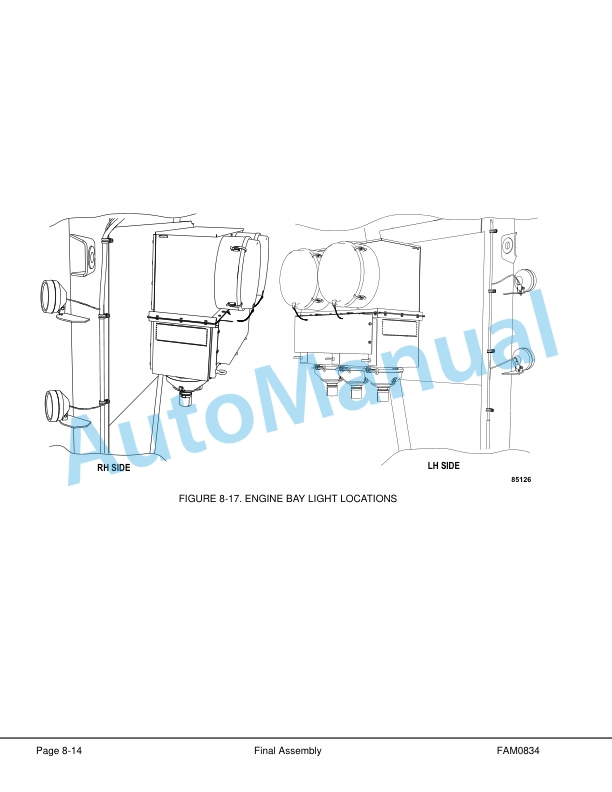

- 9.7.15. Miscellaneous Component Installation

- 10. DUMP BODY ASSEMBLY

- 10.1. GENERAL INFORMATION

- 10.2. LUBRICATION CHART

- 10.3. STANDARD TORQUE CHARTS AND CONVERSION TABLES

- 10.3.1. GENERAL DESCRIPTION

- 10.3.2. EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

- 10.3.3. STANDARD ASSEMBLY TORQUES Grade 9 Capscrews (SAE)

- 10.3.4. STANDARD ASSEMBLY TORQUES For Class 10.9 Capscrews and Class 10 Nuts

- 10.4. SUSPENSION OILING AND CHARGING PROCEDURE

- 10.4.1. GENERAL

- 10.4.2. Front Suspension

- 10.4.3. Rear Suspension

- 10.5. OIL AND NITROGEN SPECIFICATIONS CHART

- 10.6. ACCUMULATOR CHARGING

- 10.6.1. BRAKE ACCUMULATORS

- 10.6.2. STEERING ACCUMULATOR

- 10.6.3. EFFECT OF AMBIENT TEMPERATURE ON CHARGING PRESSURE

- 10.7. TOEIN ADJUSTMENT

- 10.8. SEAT BELTS AND TETHERS CHECKOUT PROCEDURE

- 10.8.1. GENERAL DESCRIPTION

- 10.9. AUTOMATIC LUBRICATION SYSTEM CHECKOUT PROCEDURE

- 10.9.1. Lincoln Flow Master Phase 1 Auto Lube System With Fixed Hydraulic Controls

- 10.9.2. Lube Pump Startup / Purging Procedure

- 10.9.3. Truck Lube System Purging Procedure

- 10.9.4. Adjust Injector Settings

- 10.9.5. Timer

- 10.9.6. Warning System

- 10.10. AIR CONDITIONING SYSTEM CHECKOUT PROCEDURE

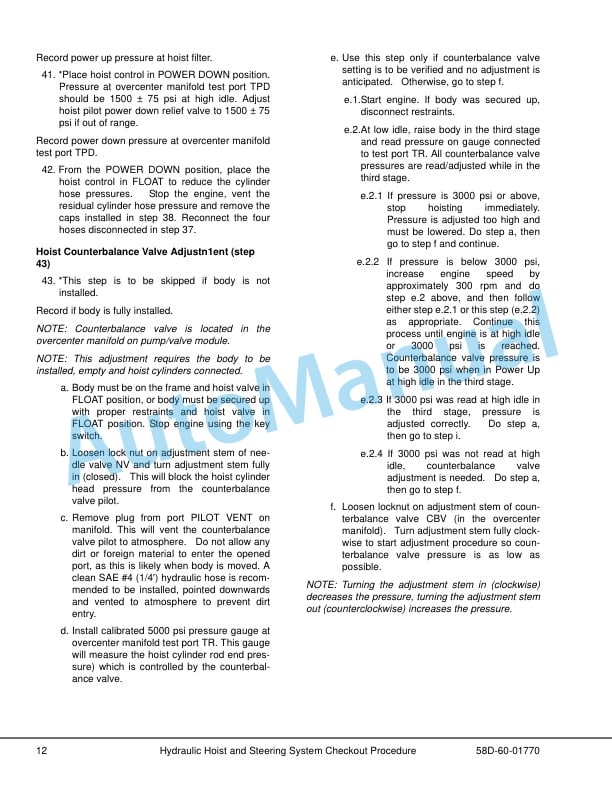

- 10.11. HYDRAULIC HOIST AND STEERING SYSTEM CHECKOUT PROCEDURE

- 10.11.1. Scope

- 10.11.2. Data to Record

- 10.11.3. Required Software

- 10.11.4. Recommended Equipment

- 10.11.5. Precheckout Items

- 10.11.6. Hydraulic System Checkout Data Sheet

- 10.11.6.1. Signature of Inspector or Mechanic performing Checkout

- 10.11.6.2. Name and badge no. (printed)

- 10.12. AUXILIARY HYDRAULIC SYSTEM CHECKOUT PROCEDURE

- 10.12.1. Scope of Checkout Procedure

- 10.12.2. Data to Record

- 10.12.3. Precheckout Items

- 10.12.4. Auxiliary Hydraulic Systems Checkout Data Sheet

- 10.12.4.1. Signature of Inspector or Mechanic performing Checkout

- 10.12.4.2. Name and badge no. (printed)

- 10.13. HYDRAULIC BRAKE SYSTEM CHECKOUT PROCEDURE

- 10.13.1. Scope of Checkout Procedure

- 10.13.2. Purpose of Checkout Procedure

- 10.13.3. Necessary Equipment

- 10.13.4. PreCheckout Items

- 10.13.5. Checkout Procedure Setup

- 10.13.6. Brake System Checkout Procedure

- 10.13.7. Brake System Checkout Data Sheet

- 10.13.7.1. Initial startup and Service Brake Checks

- 10.13.7.2. Brake Lock System

- 10.13.7.3. Park Brake System

- 10.13.7.4. Low Brake Pressure and Auto Apply

- 10.13.7.5. Brake Reapplications

- 10.13.7.6. Park Brake Control Logic Check

- 10.13.7.7. Park Brake Control Logic Check

- 10.14. ELECTRICAL SYSTEM CHECKOUT PROCEDURE

- 10.14.1. General Description

- 10.14.2. Welding and Safety Procedures

- 10.14.3. AC System Description

- 10.14.4. Resistance Checks

- 10.14.5. Megger Preparation and Testing

- 10.14.6. Control System Checkout

- 10.14.7. IM System Checkout

- 10.14.8. Hydraulic System Checkout

- 10.14.9. Drive System Checkout

- 10.15. INTERFACE MODULE (IM) CHECKOUT PROCEDURE

- 10.15.1. Purpose

- 10.15.2. Necessary Equipment

- 10.15.3. Install the Application Code

- 10.15.4. How to Use the IM Realtime Data Monitor Software

- 10.15.5. Check for Fault Codes Associated With the Interface Module

- 10.15.6. Interface Module I/O

- 10.15.7. S/N ___________________ IM Installation Checkout Checklist

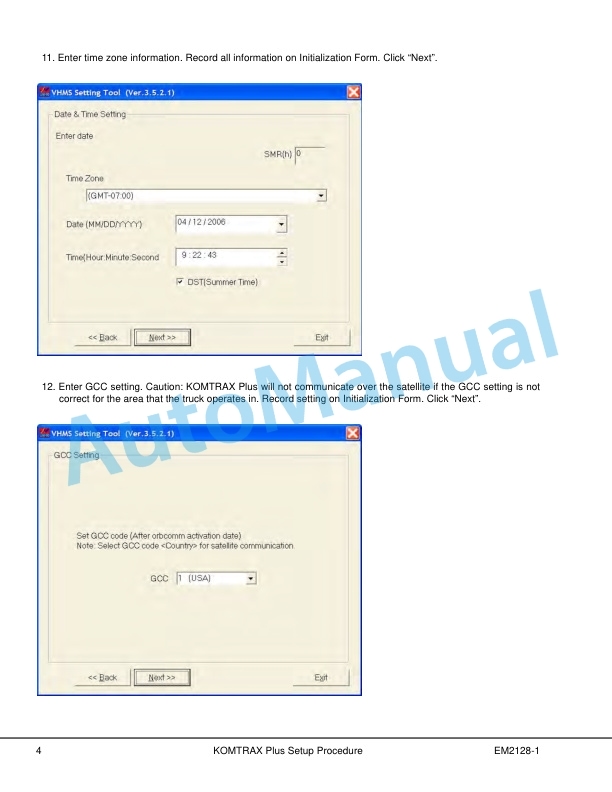

- 10.16. KOMTRAX PLUS SETUP PROCEDURE

- 10.16.1. Purpose

- 10.16.2. Preliminary Procedures

- 10.16.3. Necessary Equipment

- 10.16.4. Check for KOMTRAX Plus System Faults

- 10.16.5. KOMTRAX Plus Setup

- 10.16.6. Begin KOMTRAX Plus Setup

- 10.17. KOMTRAX PLUS CHECKOUT PROCEDURE

- 10.17.1. Purpose

- 10.17.2. Preliminary Procedures

- 10.17.3. Necessary Equipment

- 10.17.4. Check for KOMTRAX Plus System Faults

- 10.17.5. Checkout Procedure

- 10.18. PAYLOAD METER IV CHECKOUT PROCEDURE

- 10.18.1. Appendix A

- 10.18.2. Appendix B

- 10.18.3. Appendix C

- 10.18.4. Payload Meter IV Checkout Procedure Confirmation

- 10.19. WIRELESS BRIDGE CHECKOUT PROCEDURE

- 10.20. RETRACTABLE LADDER SYSTEM CHECKOUT PROCEDURE

- 10.20.1. Scope of Checkout Procedure

- 10.20.2. Precheckout Items

- 10.20.3. Retractable Ladder System (RLS)

- 10.20.4. Retractable Ladder System Checkout Data Sheet

- 10.20.4.1. Ladder System

- 10.21. RESERVE OIL SYSTEM CHECKOUT PROCEDURE

- 10.22. KOMVISION CHECKOUT PROCEDURE

- 10.22.1. STEP 1 Settings

- 10.23. FIELD ASSEMBLY INSPECTION REPORT

- 10.24. HOUR POSTCOMMISSIONING CHECKSHEET

- 11. Blank Page

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100