Komatsu 860E-1KT Dump Truck Operation and Maintenance Manual CEAM039000

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM039000

- Format: PDF

- Size: 16.3MB

- Number of Pages: 212

-

Model List:

- 860E-1KT Dump Truck

- 1. Contents

- 2. INTRODUCTION

- 2.1. FOREWORD

- 2.2. ABOUT THIS MANUAL

- 2.3. WARNINGS

- 2.4. ALERTS

- 2.5. TRUCK MODEL ILLUSTRATION

- 2.6. NONOEM PARTS IN CRITICAL SYSTEMS

- 2.7. SOFTWARE LICENSE INFORMATION

- 3. STANDARD CHARTS AND TABLES

- 3.1. GENERAL INFORMATION

- 3.2. STANDARD TIGHTENING TORQUES

- 3.3. CONVERSION MULTIPLIERS

- 4. GENERAL SAFETY

- 4.1. GENERAL SAFETY

- 4.2. PRECAUTIONS FOR TRUCK OPERATION

- 4.3. OPERATING THE MACHINE

- 4.3.1. EXTERIOR LIGHTING

- 4.4. PRECAUTIONS FOR MAINTENANCE

- 4.4.1. BEFORE PERFORMING MAINTENANCE

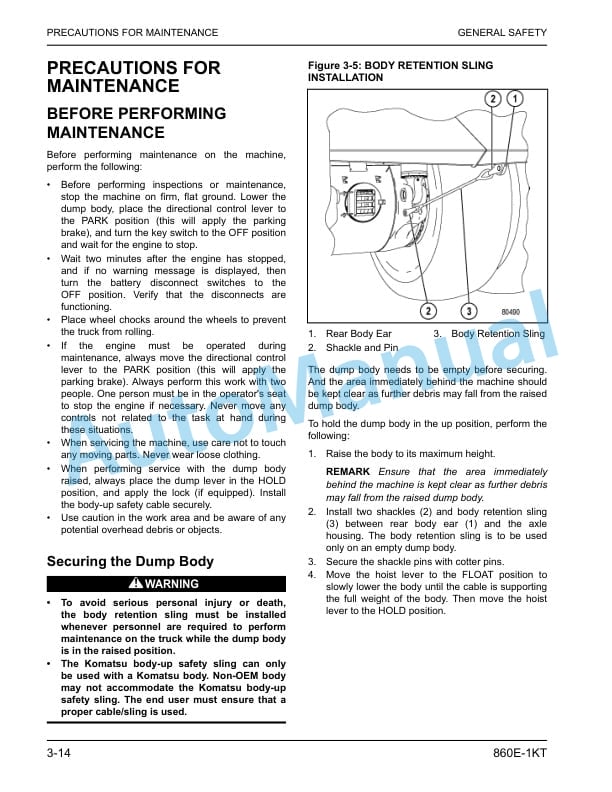

- 4.4.1.1. Securing the Dump Body

- 4.4.2. DURING MAINTENANCE

- 4.4.3. BATTERY HAZARD PREVENTION

- 4.5. WHEN REPAIRS ARE NECESSARY

- 4.6. SPECIAL PRECAUTIONS

- 5. WARNING AND CAUTIONS

- 5.1. GENERAL INFORMATION

- 5.2. PIN PLATE

- 5.3. GRADE SPEED CHART

- 5.4. GREASE POINTS

- 5.5. MACHINE SAFETY

- 5.6. KEY SWITCH

- 5.7. OIL FILL AND CHECK

- 5.8. HIGH PRESSURES

- 5.9. SPRING PRESSURE

- 5.10. BATTERIES

- 5.11. HIGH VOLTAGE

- 5.12. WELDING

- 5.13. EMERGENCY DUMPING

- 5.14. AUTOMATIC LUBRICATION FILL

- 5.15. ROPS/FOPS

- 5.16. COOLANT

- 5.17. TOWING

- 5.18. SEAT WEIGHT CAPACITY

- 5.19. LUBRICATION CHART

- 6. OPERATING INSTRUCTIONS

- 6.1. PREPARING FOR OPERATION

- 6.2. TROLLEY WALK AROUND INSPECTION

- 6.3. PRESHIFT BRAKE TEST

- 6.4. TRUCK OPERATION

- 6.4.1. ENGINE STARTUP SAFETY

- 6.4.2. MACHINE OPERATION SAFETY PRECAUTIONS

- 6.4.3. EMERGENCY STEERING SYSTEM

- 6.4.4. TROLLEY OPERATING INSTRUCTIONS

- 6.4.5. SUDDEN LOSS OF ENGINE POWER OR LOSS OF DRIVE SYSTEM FUNCTION

- 6.4.6. FUEL DEPLETION

- 6.4.7. SAFE PARKING PROCEDURES

- 6.4.8. NORMAL ENGINE SHUTDOWN PROCEDURE

- 6.5. DISABLED TRUCK CONNECTORS

- 6.5.1. GENERAL INFORMATION

- 6.5.2. STEERING AND BRAKE SYSTEM

- 6.5.3. HOIST SYSTEM

- 6.6. TOWING

- 6.6.1. SPECIAL WIRING HARNESS

- 6.6.2. TOWING PROCEDURE

- 6.7. PAYLOAD METER IV SYSTEM

- 6.7.1. GENERAL INFORMATION

- 6.7.2. COMPONENT DESCRIPTION

- 6.7.3. SCOREBOARD

- 6.7.4. OPERATORS DISPLAY AND SWITCH

- 6.7.5. PAYLOAD OPERATION CALCULATION

- 6.7.6. SOURCES FOR PAYLOAD ERROR

- 6.7.7. Clean Truck Tare

- 6.7.8. DOWNLOADING HAUL CYCLE DATA

- 6.7.9. VIEWING ALARM DATA

- 6.7.10. DOWNLOADING ALARM DATA

- 6.8. AUTOMATIC LUBRICATION SYSTEM

- 6.8.1. GENERAL INFORMATION

- 6.8.2. COMPONENT DESCRIPTION

- 6.8.3. SYSTEM OPERATION

- 6.8.4. PREVENTIVE MAINTENANCE PROCEDURES

- 6.8.5. SYSTEM CHECKOUT

- 6.9. RESERVE ENGINE OIL SYSTEM

- 7. OPERATOR CAB AND CONTROLS

- 7.1. CAB INTERIOR

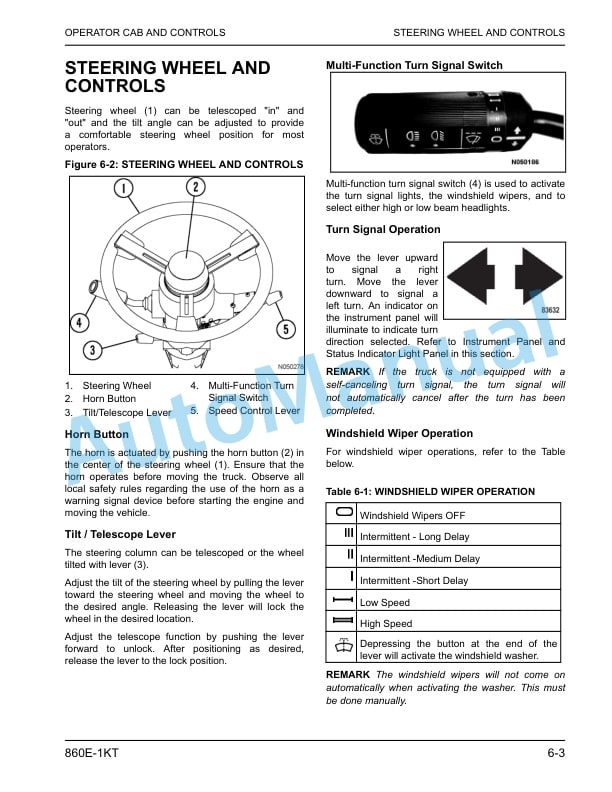

- 7.2. STEERING WHEEL AND CONTROLS

- 7.3. PEDALS

- 7.4. OVERHEAD PANEL AND DISPLAYS

- 7.5. CENTER CONSOLE

- 7.6. DIAGNOSTIC PORTS

- 7.7. OPERATOR SEAT (Standard)

- 7.8. OPERATOR SEAT (Optional)

- 7.9. PASSENGER SEAT (Standard)

- 7.10. PASSENGER SEAT (Optional)

- 7.11. HEATER / AIR CONDITIONER CONTROLS

- 7.12. INSTRUMENT PANEL

- 7.13. STATUS INDICATOR LIGHT PANEL

- 7.13.1. STATUS INDICATOR LIGHT SYMBOLS

- 7.13.1.1. Body Up

- 7.13.1.2. Parking Brake

- 7.13.1.3. Propel System Not Ready

- 7.13.1.4. No Propel

- 7.13.1.5. Engine Warm Up

- 7.13.1.6. Engine Shutdown Delay

- 7.13.1.7. Retarding Grid Dryer

- 7.13.1.8. Wheel Brake Lock

- 7.13.1.9. Traction Control OFF

- 7.13.1.10. Repair Monitor

- 7.13.1.11. Retractable Ladder Down

- 7.13.1.12. Snapshot In Progress

- 7.13.1.13. Pantograph Energized

- 7.13.1.14. Pantograph Up

- 7.13.1.15. Service Brake

- 7.13.1.16. Dynamic Retarding

- 7.13.1.17. No DC Link Voltage

- 7.14. DIGITAL DISPLAY OPERATIONS

- 7.14.1. DIGITAL DISPLAY MENUS

- 7.14.2. ACTIVE WARNINGS MENU

- 7.14.3. PAYLOAD DATA MENU

- 7.14.4. REPAIR ITEMS MENU

- 7.14.5. MAINTENANCE ITEMS MENU

- 7.14.6. CLEARED ITEMS MENU

- 7.14.7. SYSTEM CONTROLS MENU

- 7.14.8. TIRE DATA MENU

- 7.14.9. LANGUAGES MENU

- 7.14.10. CONFIGURE SYSTEM MENU

- 7.15. KOMTRAX Plus

- 7.15.1. KOMTRAX Plus OPERATION

- 7.15.2. DOWNLOADING KOMTRAX Plus DATA

- 7.15.3. UPLOADING KOMTRAX Plus DATA

- 7.16. ORBCOMM

- 7.17. KOMATSU WIRELESS BRIDGE (Optional)

- 7.18. FUSES AND CIRCUIT BREAKERS

- 7.18.1. FUSE BLOCK 1

- 7.18.2. FUSE BLOCK 2

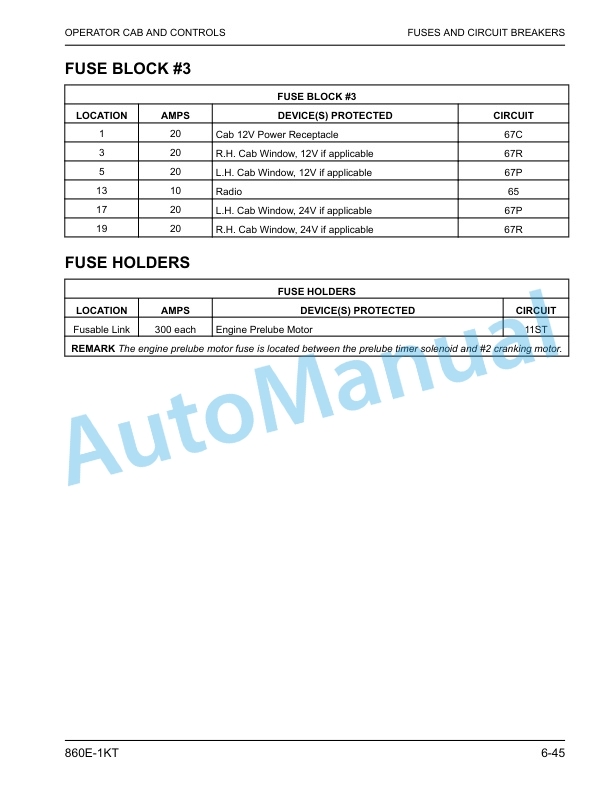

- 7.18.3. FUSE BLOCK 3

- 7.18.4. FUSE HOLDERS

- 7.18.5. CIRCUIT BREAKERS

- 8. LUBRICATION AND SERVICE

- 8.1. GENERAL INFORMATION

- 8.1.1. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 8.1.2. HYDRAULIC SYSTEM SERVICE

- 8.1.3. WHEEL MOTOR SERVICE

- 8.1.4. COOLANT LEVEL SERVICE

- 8.1.5. IGBT COOLANT SERVICE

- 8.1.6. RESERVE ENGINE OIL SERVICE

- 8.1.7. CAB AIR FILTER SERVICE

- 8.1.8. FUEL SYSTEM SERVICE

- 8.1.9. INTAKE AIR CLEANER SERVICE

- 8.1.10. FRONT ENGINE MOUNT TRUNNION SERVICE

- 8.1.11. QUICK FILL SERVICE CENTER

- 8.1.12. TIE ROD INSPECTION AND TORQUE PROCEDURE

- 8.1.13. CHECK AUTOMATIC LUBRICATION (AUTOLUBE) SYSTEM PUMP OIL LEVEL

- 8.1.14. CHANGE AUTOMATIC LUBRICATION (AUTOLUBE) SYSTEM PUMP OIL

- 8.2. PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

- 8.3. INITIAL 50 HOUR LUBRICATION AND MAINTENANCE INSPECTION

- 8.4. INITIAL 100 HOUR LUBRICATION AND MAINTENANCE INSPECTION

- 8.5. EVERY 250 HOUR LUBRICATION AND MAINTENANCE

- 8.6. EVERY 500 HOUR LUBRICATION AND MAINTENANCE

- 8.7. EVERY 1000 HOURS LUBRICATION AND MAINTENANCE

- 8.8. EVERY 1500 HOUR LUBRICATION AND MAINTENANCE INSPECTION

- 8.9. EVERY 2000 HOUR LUBRICATION AND MAINTENANCE INSPECTION

- 8.10. EVERY 3000 HOUR LUBRICATION AND MAINTENANCE INSPECTION

- 8.11. EVERY 4000 HOUR MAINTENANCE

- 8.12. EVERY 5000 HOUR MAINTENANCE

- 8.13. EVERY 6000 HOUR MAINTENANCE

- 8.14. EVERY 12000 HOUR MAINTENANCE

- 8.15. EVERY 18000 HOUR MAINTENANCE

- 8.16. EVERY 24000 HOUR MAINTENANCE

- 8.17. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 9. SPECIFICATIONS

- 9.1. MAJOR COMPONENT DESCRIPTION

- 9.1.1. Truck And Engine

- 9.1.2. Traction Alternator

- 9.1.3. Main Control Cabinet

- 9.1.4. AC Induction Traction Motorized Wheels

- 9.1.5. Suspension

- 9.1.6. Operators Cab

- 9.1.7. Power Steering

- 9.1.8. Dynamic Retarding

- 9.1.9. Brake System

- 9.2. SPECIFICATIONS

- 9.2.1. Engine

- 9.2.2. AC Electric Drive System

- 9.2.3. Dynamic Retarding

- 9.2.4. Battery Electric System

- 9.2.5. Service Capacities

- 9.2.6. Hydraulic Systems

- 9.2.7. Service Brakes

- 9.2.8. Steering

- 9.2.9. Standard Dump Body Capacities And Dimensions

- 9.2.10. Tires

- 9.2.11. Weight Distribution

- 9.2.12. Overall Truck Dimensions

- 10. RADIO

- 10.1. AM/FM RADIO / MP3 / USB / iPOD / AUX PLAYER

- 10.1.1. USB Connection Port

- 10.1.2. Phone/Bluetooth Button

- 10.1.3. Digital Display

- 10.1.4. DISP (Display) Button

- 10.1.5. SRC/PWR/ESC (Source/Power/Escape) Button

- 10.1.6. Volume Knob/OK Button

- 10.1.7. NEXT Button

- 10.1.8. PREV (Previous) Button

- 10.1.9. Preset Buttons

- 10.1.10. RDM (Random) Button

- 10.1.11. RPT (Repeat) Button

- 10.1.12. Mute/Play/Pause Button

- 10.1.13. Browse Button

- 10.1.14. SCAN/ASCN (Scan/Autoscan) Button

- 10.1.15. Auxiliary Jack Port

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001