Komatsu 860E-1KT Electric Dump Truck Operation and Maintenance Manual CEAM019502

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM019502

- Format: PDF

- Size: 7.4MB

- Number of Pages: 182

-

Model List:

- 860E-1KT Electric Dump Truck

- 1. OPERATION AND MAINTENANCE MANUAL 860E1KT DUMP TRUCK

- 2. CONTENTS

- 3. INTRODUCTIONSECTION 10

- 3.1. FOREWORD

- 3.2. TRUCK MODEL ILLUSTRATION

- 3.3. ABOUT THIS MANUAL

- 3.4. ALERTS PAGE

- 3.5. TABLE OF CONTENTS

- 4. STANDARD TORQUE CHARTS AND CONVERSION TABLESSECTION 12

- 4.1. INDEX OF TABLES

- 4.2. EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

- 4.3. STANDARD TIGHTENING TORQUES For Class 10.9 Capscrews Class 10 Nuts

- 4.4. STANDARD TIGHTENING TORQUES

- 4.5. For SAE Grade 5 and Grade 8 Capscrews

- 4.6. STANDARD TIGHTENING TORQUES For SAE Grade 9 Capscrews

- 5. GENERAL SAFETYSECTION 20

- 5.1. Safety Rules

- 5.2. Truck Safety Features

- 5.3. Clothing And Personal Items

- 5.4. Unauthorized Modification

- 5.5. Leaving The Operators Seat

- 5.6. Mounting And Dismounting

- 5.7. Fire Extinguishers And First Aid Kits

- 5.8. Precautions For High Temperature Fluids

- 5.9. Asbestos Dust Hazard Prevention

- 5.10. Fire And Explosion Prevention

- 5.11. Prevent Fire

- 5.12. ROPS Precautions

- 5.13. Preventing Injury From Work Equipment

- 5.14. Precautions For Optional Attachments

- 5.15. Precautions When Starting The Truck

- 5.16. PRECAUTIONS BEFORE OPERATION

- 5.17. OPERATING THE TRUCK

- 5.18. WORKING NEAR BATTERIES

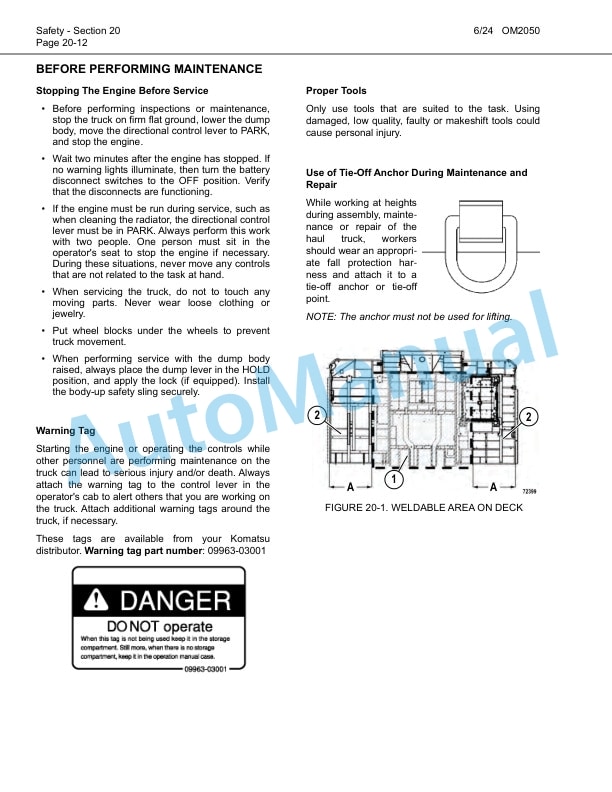

- 5.19. BEFORE PERFORMING MAINTENANCE

- 5.20. WHILE PERFORMING MAINTENANCE

- 5.21. TIRES

- 5.22. WHEN REPAIRS ARE NECESSARY

- 5.23. SPECIAL PRECAUTIONS FOR WORKING ON AC DRIVE TRUCKS

- 5.24. ADDITIONAL JOB SITE RULES

- 6. WARNINGS AND CAUTIONSSECTION 22

- 6.1. GRADE/SPEED CHART

- 6.2. INSTRUMENT PANEL

- 6.3. BATTERIES

- 6.4. HIGH VOLTAGE

- 6.5. RADIATOR

- 6.6. CRUSHING HAZARD

- 6.7. CYLINDER PRESSURE

- 6.8. FILLING THE HYDRAULIC TANK

- 6.9. HYDRAULIC OIL PRESSURE

- 6.10. EMERGENCY TOWING PROCEDURE

- 6.11. EMERGENCY DUMP PROCEDURE

- 6.12. ACCUMULATOR DRAIN VALVES

- 6.13. GREASE POINT

- 6.14. WELDING

- 6.15. EMERGENCY SHUTDOWN

- 6.16. LIFTING POINT

- 6.17. SPRING PRESSURE

- 6.18. ROPS/FOPS

- 6.19. EMERGENCEY EGRESS

- 6.20. PRODUCT IDENTIFICATION PLATE

- 6.21. LUBRICATION CHART

- 7. OPERATING INSTRUCTIONSSECTION 30

- 7.1. PREPARING FOR OPERATION

- 7.2. WALK AROUND INSPECTION

- 7.3. ENGINE STARTUP

- 7.4. AFTER ENGINE HAS STARTED

- 7.5. MACHINE OPERATION SAFETY PRECAUTIONS

- 7.6. OPERATING ON THE HAUL ROAD

- 7.7. STARTING ON A GRADE WITH A LOADED TRUCK

- 7.8. PASSING

- 7.9. LOADING

- 7.10. DUMPING

- 7.11. USING THE SPEED CONTROL FEATURE

- 7.12. SAFE PARKING PROCEDURES

- 7.13. NORMAL ENGINE SHUTDOWN PROCEDURE

- 7.14. SUDDEN LOSS OF ENGINE POWER

- 7.15. EMERGENCY STEERING SYSTEM

- 7.16. FUEL DEPLETION

- 7.17. TOWING

- 7.18. DISABLED TRUCK OPERATION

- 7.19. GENERAL

- 7.20. STEERING AND BRAKE SYSTEM

- 7.21. DISABLED TRUCK DUMPING PROCEDURE

- 7.22. RESERVE ENGINE OIL SYSTEM

- 8. OPERATOR CAB AND CONTROLSSECTION 32

- 8.1. STEERING WHEEL AND CONTROLS

- 8.2. DYNAMIC RETARDING

- 8.3. GRADE/SPEED RETARD CHART

- 8.4. OVERHEAD PANEL COMPONENTS

- 8.5. CENTER CONSOLE

- 8.6. DIAGNOSTIC PORTS

- 8.7. OPERATORS SEAT

- 8.8. HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS

- 8.9. INSTRUMENT PANEL

- 8.10. STATUS INDICATOR LIGHTS

- 8.11. DIGITAL DISPLAY OPERATION

- 8.12. VEHICLE HEALTH MONITORING SYSTEM (VHMS)

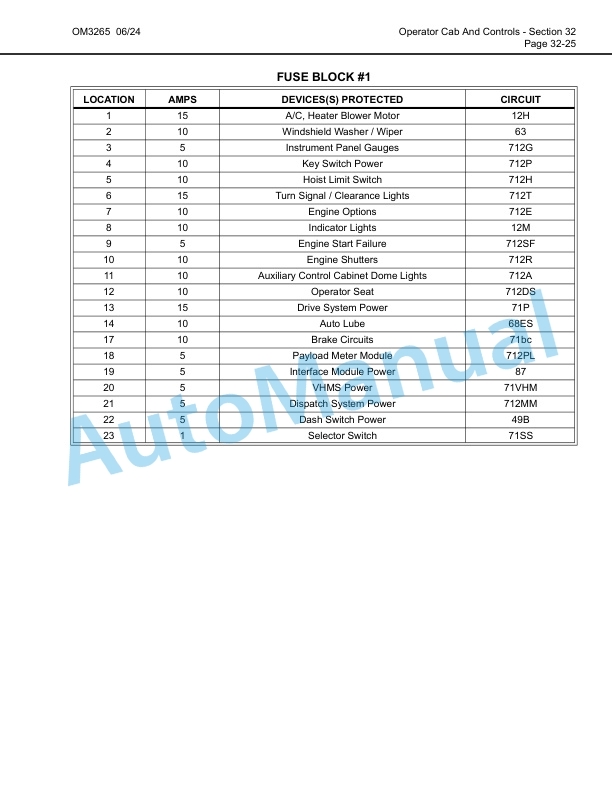

- 8.13. FUSES AND CIRCUIT BREAKERS

- 9. LUBRICATION AND SERVICESECTION 40

- 9.1. GENERAL

- 9.2. SERVICE CAPACITIES

- 9.3. HYDRAULIC TANK SERVICE

- 9.4. WHEEL MOTOR SERVICE

- 9.5. COOLING SYSTEM SERVICE

- 9.6. RESERVE ENGINE OIL SYSTEM

- 9.7. CHECK DUMP BODY PADS

- 9.8. LUBRICATION CHART

- 9.9. HOUR (DAILY) INSPECTIONS

- 9.10. HOUR (DAILY) INSPECTIONS (Cont.)

- 9.11. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 9.12. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 9.13. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 9.14. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 9.15. HOUR LUBRICATION AND MAINTENANCE (Cont.)

- 9.16. ,000 HOURS LUBRICATION AND MAINTENANCE CHECKS

- 9.17. ,000 HOUR MAINTENANCE CHECKS

- 9.18. ,000 HOUR MAINTENANCE CHECKS

- 9.19. ,000 HOUR MAINTENANCE CHECKS

- 10. AUTOMATIC LUBRICATION SYSTEMSECTION 42

- 10.1. GENERAL DESCRIPTION

- 10.2. SYSTEM COMPONENTS

- 10.3. SYSTEM OPERATION

- 10.4. GENERAL INSTRUCTIONS

- 10.5. LUBRICANT PUMP

- 10.6. INJECTORS (SL1 Series H)

- 10.7. PREVENTIVE MAINTENANCE PROCEDURES

- 10.8. SYSTEM CHECKOUT

- 10.9. SYSTEM TROUBLESHOOTING CHART

- 10.10. INJECTOR OPERATION

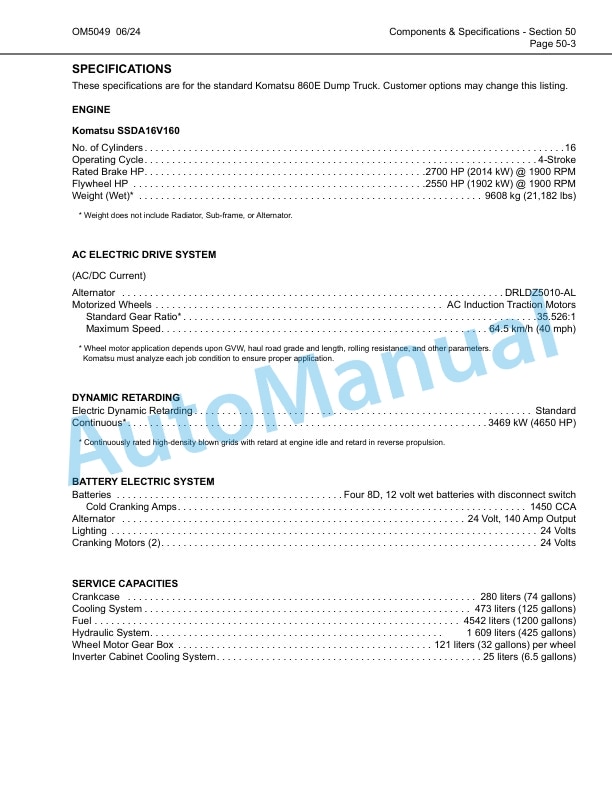

- 11. COMPONENTS SPECIFICATIONSSECTION 50

- 11.1. MAJOR COMPONENT DESCRIPTIONS

- 11.2. SPECIFICATIONS

- 12. PAYLOAD METER IIISECTION 60

- 12.1. Introduction

- 12.2. COMPONENT DESCRIPTION

- 12.3. LOAD DISPLAY AND OPERATOR SWITCHES

- 12.4. PAYLOAD OPERATION CALCULATION

- 12.5. SOURCES FOR PAYLOAD ERROR

- 12.6. HAUL CYCLE DATA

- 12.7. PDM SOFTWARE OVERVIEW

- 12.8. DOWNLOADING DATA

- 12.9. PLM III SYSTEM CONFIGURATION

- 12.10. DATA ANALYSIS

- 13. AM/FM RADIO / CD PLAYERSECTION 70

- 13.1. OPERATING INSTRUCTIONS

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081