Komatsu 930E-4SE Dump Truck Field Assembly Instruction CEAW007011

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: CEAW007011

- Format: PDF

- Size: 9.2MB

- Number of Pages: 308

-

Model List:

- 930E-4SE Dump Truck

- 1. FOREWORD

- 2. TABLE OF CONTENTS

- 3. SAFETY RULES, TOOLS EQUIPMENT

- 3.1. SAFETY RULES

- 3.2. KOMVISION CALIBRATION TOOLS

- 3.3. HIGH VOLTAGE TOOLS

- 3.3.1. VDC CUSTOM METER KIT (58B0600800)

- 3.3.2. BODY PAD SPACER TOOL

- 4. TRUCK COMPONENTS AND SPECIFICATIONS

- 4.1. SPECIFICATIONS

- 4.2. WEIGHT DISTRIBUTION

- 5. MAJOR COMPONENT WEIGHTS

- 5.1. REAR AXLE COMPONENTS

- 6. FIELD WELDING FOR ASSEMBLY OR REPAIR

- 6.1. WELDER QUALIFICATION AND TRAINING

- 6.2. WELD PROCEDURES

- 6.3. APPROVED CONSUMABLES

- 6.4. WELD QUALITY REQUIREMENTS

- 6.5. MATERIALS, CONTROLS, AND PRECAUTIONS

- 6.5.1. WELD INSPECTION

- 6.5.2. RECORDS

- 6.5.3. ANNEX A

- 6.5.4. ANNEX B

- 6.5.5. BIBLIOGRAPHY

- 6.6. SPECIAL PRECAUTIONS WHEN SERVICING AN AC DRIVE SYSTEM TRUCK

- 7. RECEIVING ASSEMBLY PREPARATION

- 7.1. Preparation

- 7.2. ASSEMBLY LAYOUT

- 8. CHASSIS ASSEMBLY

- 8.1. RECOMMENDED ASSEMBLY DATA

- 8.2. BASIC ASSEMBLY PROCEDURE

- 8.3. ORDER OF ASSEMBLY

- 8.4. CHASSIS ASSEMBLY

- 8.4.1. HARDWARE TIGHTENING METHOD

- 8.4.2. GENERAL PRECAUTIONS AND INSTRUCTION

- 8.4.3. HYDRAULIC SYSTEM FLUSHING PROCEDURE

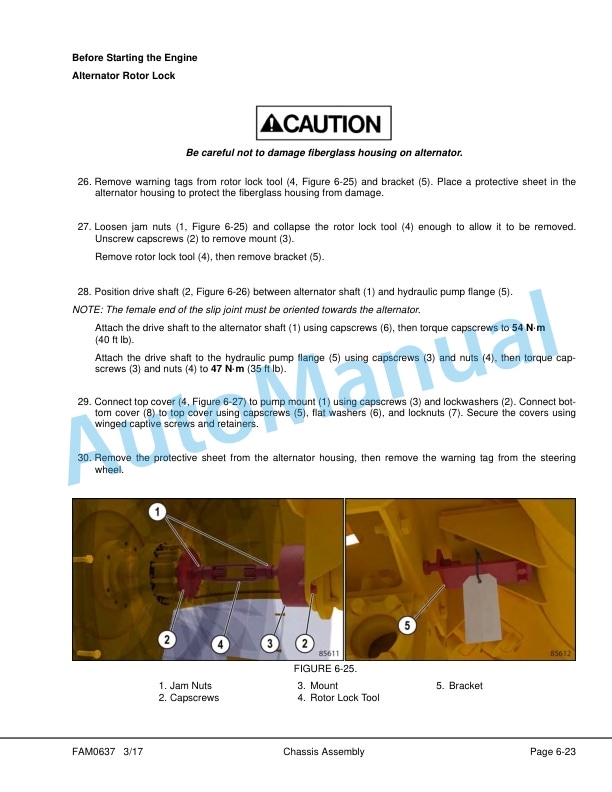

- 8.4.4. Before Starting the Engine

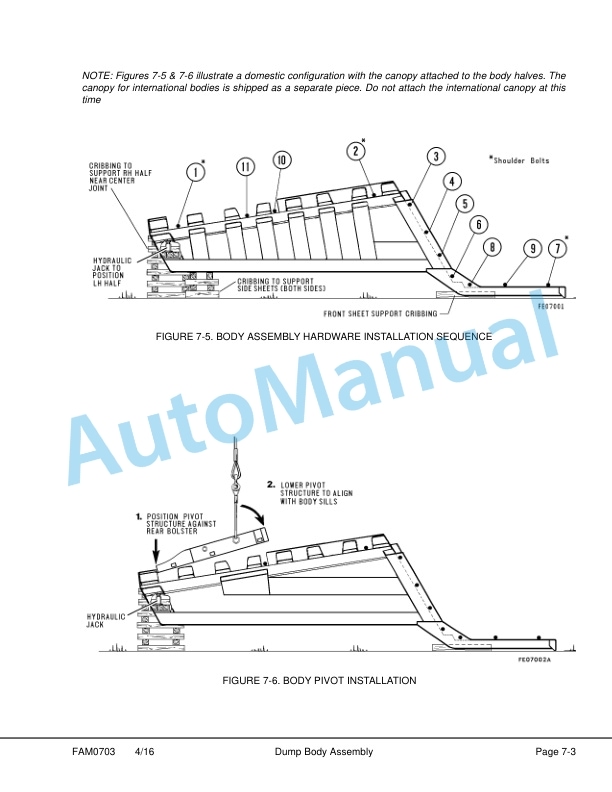

- 9. DUMP BODY ASSEMBLY

- 9.1. GENERAL INFORMATION

- 9.2. LUBRICATION CHART

- 9.3. STANDARD TORQUE CHARTS AND CONVERSION TABLES

- 9.3.1. GENERAL DESCRIPTION

- 9.3.2. EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

- 9.3.3. STANDARD ASSEMBLY TORQUES Grade 9 Capscrews (SAE)

- 9.3.4. STANDARD ASSEMBLY TORQUES For Class 10.9 Capscrews and Class 10 Nuts

- 9.4. TOEIN ADJUSTMENT PROCEDURE

- 9.5. SUSPENSION OILING AND CHARGING PROCEDURE

- 9.5.1. GENERAL

- 9.5.2. Front Suspension

- 9.5.3. Rear Suspension

- 9.6. OIL AND NITROGEN SPECIFICATIONS CHART

- 9.7. AUTOMATIC LUBRICATION SYSTEM CHECKOUT PROCEDURE

- 9.7.1. Lincoln Flow Master Phase 1 Auto Lube System With Fixed Hydraulic Controls

- 9.7.2. Lube Pump Startup / Purging Procedure

- 9.7.3. Truck Lube System Purging Procedure

- 9.7.4. Adjust Injector Settings

- 9.7.5. Timer

- 9.7.6. Warning System

- 9.8. RESERVE OIL SYSTEM CHECKOUT PROCEDURE

- 9.9. AIR CONDITIONING SYSTEM CHECKOUT PROCEDURE

- 9.10. HYDRAULIC SYSTEM CHECKOUT PROCEDURE

- 9.10.1. Scope of Checkout Procedure

- 9.10.2. Data to be Recorded

- 9.10.3. Required Software

- 9.10.4. PreCheckout Items

- 9.10.5. Procedure for Bleeding Down Hydraulic Brake and Steering Accumulators

- 9.10.6. Accumulator Precharge Procedure

- 9.10.7. Pressure Gauge Installation

- 9.10.8. Initial StartUp and Flushing

- 9.10.9. Steering System Checkout and Adjustment

- 9.10.10. Steering Pump with Unloader Valve Adjustment

- 9.10.11. Hoist System Checkout and Adjustment

- 9.10.12. Hoist Counterbalance Valve Adjustment

- 9.10.13. Counterbalance Valve Setting Check

- 9.10.14. Oil Cleanliness Check

- 9.10.15. Hydraulic System Checkout Data Sheet

- 9.10.15.1. Accumulator Precharge procedure

- 9.10.15.2. Initial Startup and Flushing

- 9.10.15.3. Steering System Checkout and Adjustment

- 9.10.15.4. Steering Pump with Unloader Valve Adjustment

- 9.10.15.5. Steering System Diagnostic and Verification

- 9.10.15.6. Hoist System Checkout and Adjustment

- 9.10.15.7. Hoist Counterbalance Valve Adjustment

- 9.10.15.8. Oil Cleanliness Check

- 9.11. HYDRAULIC BRAKE SYSTEM CHECKOUT PROCEDURE

- 9.11.1. Scope of Checkout Procedure

- 9.11.2. Purpose of Checkout Procedure

- 9.11.3. Required Software

- 9.11.4. Necessary Equipment

- 9.11.5. PreCheckout Items

- 9.11.6. Bleed Down Procedure

- 9.11.7. Checkout Procedure Setup

- 9.11.8. Initial Startup and Service Brake Checks

- 9.11.9. Brake Lock System Check

- 9.11.10. Parking Brake System

- 9.11.11. Low Brake Pressure and Auto Apply

- 9.11.12. Brake Reapplications (Stored Energy Check)

- 9.11.13. Park Brake Control Logic Check

- 9.11.14. Brake Lock Control Logic Check

- 9.11.15. The Brake System Checkout Data Sheet follows

- 9.11.16. T Brake System Checkout Data Sheet

- 9.11.16.1. Brake Lock System

- 9.11.16.2. Park Brake System

- 9.11.16.3. Low Brake Pressure and Auto Apply

- 9.11.16.4. Brake Reapplications

- 9.11.16.5. Park Brake Control Logic Check

- 9.11.16.6. Brake Lock Control Logic Check

- 9.12. BRAKE TEST CHECKOUT PROCEDURE

- 9.13. REAR AXLE COOLING AIR PRESSURE SWITCH ADJUSTMENT AND TEST

- 9.14. KOMTRAX PLUS SETUP PROCEDURE

- 9.14.1. Purpose

- 9.14.2. Preliminary Procedures

- 9.14.3. Necessary Equipment

- 9.14.4. Check for KOMTRAX Plus System Faults

- 9.15. KOMTRAX Plus Setup

- 9.15.1. Begin KOMTRAX Plus Setup

- 9.16. KOMTRAX PLUS CHECKOUT PROCEDURE

- 9.16.1. Purpose

- 9.16.2. Preliminary Procedures

- 9.16.3. Necessary Equipment

- 9.16.4. Check for KOMTRAX Plus System Faults

- 9.16.5. Checkout Procedure

- 9.17. PAYLOAD METER IV CHECKOUT PROCEDURE

- 9.17.1. Appendix A

- 9.17.2. Appendix B

- 9.17.3. Appendix C

- 9.17.4. Payload Meter IV Checkout Procedure Confirmation

- 9.18. ELECTRICAL SYSTEM CHECKOUT PROCEDURE

- 9.18.1. General Description

- 9.18.2. Welding and Safety Procedures

- 9.18.3. AC System Description

- 9.18.4. Resistance Checks

- 9.18.5. Megger Preparation and Testing

- 9.18.6. Control System Checkout

- 9.18.7. IM System Checkout

- 9.18.8. Drive System Initial Checkout

- 9.18.9. Hydraulic System Checkout

- 9.18.10. Drive System Checkout

- 9.19. SEAT BELTS AND TETHERS CHECKOUT PROCEDURE

- 9.19.1. GENERAL DESCRIPTION

- 9.20. INTERFACE MODULE CHECKOUT PROCEDURE 930E WITH ACTIA

- 9.20.1. Purpose

- 9.20.2. Necessary Equipment

- 9.20.3. Install the Application Code

- 9.20.4. How to Use the IM Realtime Data Monitor Software

- 9.20.5. Check for Fault Codes Associated With the Interface Module

- 9.20.6. Interface Module I/O

- 9.20.6.1. S/N ___________________ IM Installation Checkout Checklist

- 9.21. KOMVISION CHECKOUT PROCEDURE

- 9.21.1. STEP 1 Settings

- 9.22. WIRELESS BRIDGE CHECKOUT PROCEDURE

- 9.23. FIELD ASSEMBLY INSPECTION REPORT

- 9.24. HOUR POSTCOMMISSIONING CHECKSHEET

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725