Komatsu Air Conditioner Shop Manual SEBM036406

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM036406

- Format: PDF

- Size: 24.9MB

- Number of Pages: 504

Category: Komatsu Shop Manual PDF

-

Model List:

- Air Conditioner

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. BASIC INFORMATION ON AIR CONDITIONERS

- 1.1.1. UNITS RELATED TO REFRIGERATION

- 1.1.2. PRINCIPLE OF COOLING

- 1.1.3. REFRIGERANTS

- 1.1.4. REFRIGERATOR OIL

- 1.2. APPLICABLE MACHINE

- 1.3. SPECIFICATIONS

- 1.3.1. FREON GAS (R12) TYPE

- 1.3.2. NEW REFRIGERANT (R134A) TYPE

- 2. DENSO (FREON GAS TYPE)

- 2.1. STRUCTURE AND FUNCTION

- 2.1.1. PIPING DIAGRAM

- 2.1.2. ELECTRIC WIRING DIAGRAM

- 2.1.3. COMPRESSOR (CRANK TYPE)

- 2.1.4. MAGNETIC CLUTCH

- 2.1.5. CONDENSER

- 2.1.6. RECEIVER (LIQUID TANK) AND SIGHT GAS

- 2.1.7. AIR CONDITIONER UNIT

- 2.1.8. NAMES AND FUNCTIONS

- 2.1.9. OPERATION

- 2.2. TESTING AND ADJUSTING

- 2.2.1. SERVICE TOOL

- 2.2.2. MAINTENANCE PROCEDURE

- 2.2.3. TROUBLESHOOTING

- 2.3. DISASSEMBLY AND ASSEMBLY

- 2.3.1. SPECIAL TOOLS

- 2.3.2. DISASSEMBLY OF MAGNETIC CLUTCH

- 2.3.3. ASSEMBLY OF MAGNETIC CLUTCH

- 2.3.4. DISASSEMBLY OF AIR CONDITIONER UNIT

- 2.3.5. DISASSEMBLY OF BLOWER UNIT

- 2.3.6. DISASSEMBLY OF CONDENSER

- 3. ZEXEL (DIESEL KIKI)

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. LOCATION OF UNIT

- 3.1.2. ELECTRICAL CIRCUIT DIAGRAM

- 3.1.3. PIPING DIAGRAM

- 3.1.4. COMPRESSOR

- 3.1.5. MAGNETIC CLUTCH

- 3.1.6. CONDENSER

- 3.1.7. RECEIVER (LIQUID TANK)

- 3.1.8. EXPANSION VALVE

- 3.1.9. EVAPORATOR

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TIGHTENING TORQUE TABLES

- 3.2.2. SPECIAL TOOLS

- 3.2.3. SERVICE PROCEDURE

- 3.2.4. INSPECTION AND MAINTENANCE

- 3.2.5. TROUBLESHOOTING

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. SPECIAL TOOLS

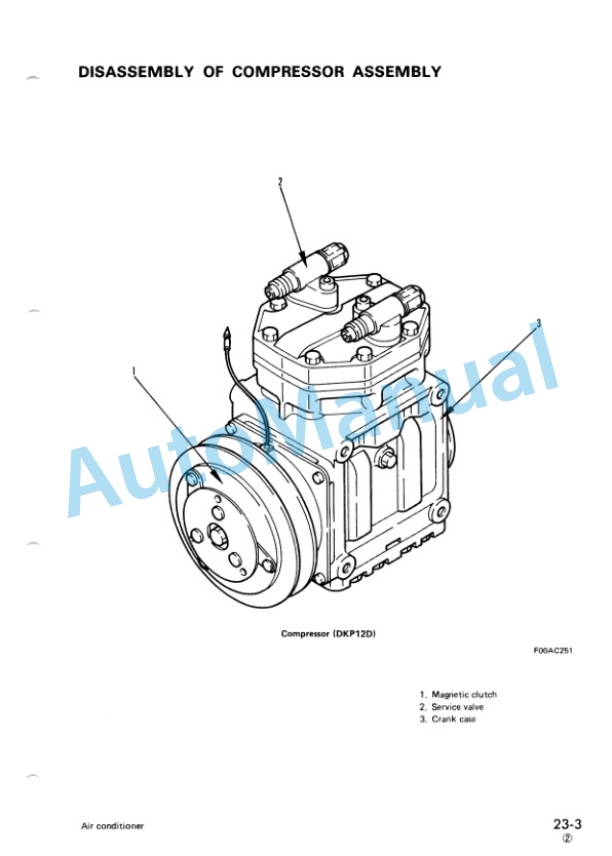

- 3.3.2. DISASSEMBLY OF COMPRESSOR ASSEMBLY

- 3.3.3. JUDGING DEFECTIVE LOCATIONS WHEN DISASSEMBLING

- 3.3.4. DISASSEMBLY

- 3.3.5. ASSEMBLY

- 4. DAIKIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. PIPING DIAGRAM

- 4.1.2. ELECTRICAL CIRCUIT DIAGRAM

- 4.1.3. COMPRESSOR (ROTARY TYPE)

- 4.1.4. CONDENSER

- 4.1.5. RECEIVER DRYER

- 4.1.6. AIR CONDITIONER UNIT

- 4.1.7. OPERATING PROCEDURE

- 4.2. TESTING AND ADJUSTING

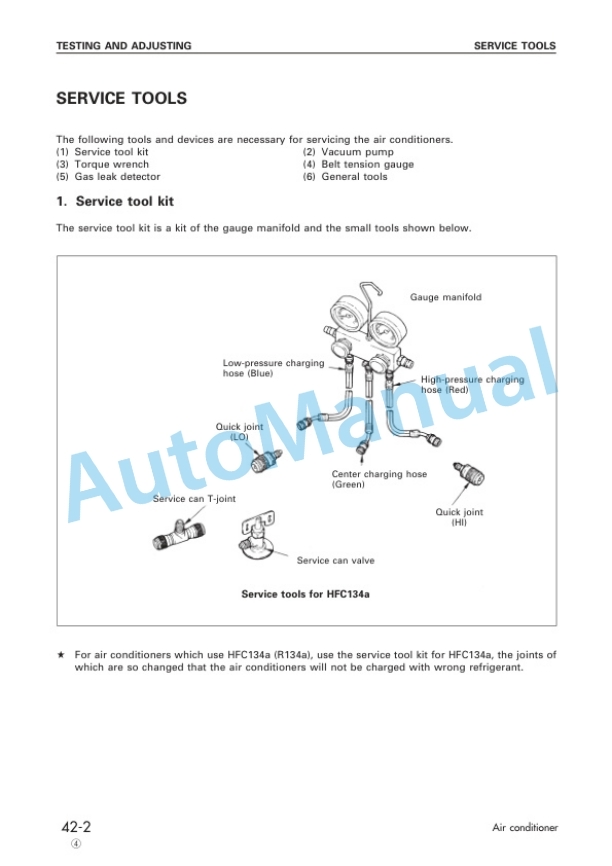

- 4.2.1. SERVICE TOOLS

- 4.2.2. SERVICE PROCEDURE

- 4.2.3. INSEASON CHECKS

- 4.2.4. OFFSEASON CHECKS

- 4.2.5. USING AIR COMPRESSOR DIPSTICK

- 4.2.6. TROUBLESHOOTING

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. TOOLS

- 4.3.2. DISASSEMBLY OF COMPRESSOR ASSEMBLY

- 4.3.3. ASSEMBLY OF COMPRESSOR

- 4.3.4. DISASSEMBLY AND TESTING OF AIR CONDITIONER UNIT

- 4.3.5. CONDENSER UNIT

- 4.3.6. RECEIVER DRYER

- 5. DENSOR (NEW REFRIGERANT TYPE)

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. FUNDAMENTALS OF AIR CONDITIONING

- 5.1.2. CONFIGURATION OF REFRIGERATING CYCLE

- 5.1.3. CONTROL SYSTEM

- 5.2. TESTING AND ADJUSTING

- 5.2.1. SERVICE TOOLS

- 5.2.2. TROUBLESHOOTING

- 5.2.3. CHARGING WITH REFRIGERANT

- 5.2.4. PERIODIC INSPECTION AND MAINTENANCE

- 6. TAKAHASHI WORKS

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. OUTLINE

- 6.1.2. REFRIGERATING CYCLE CIRCUIT DIAGRAM

- 6.1.3. COMPRESSOR

- 6.1.4. CONDENSER

- 6.1.5. RECEIVER DRIER

- 6.1.6. AIR CONDITIONER UNIT

- 6.2. TESTING AND ADJUSTION

- 6.2.1. LIST OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 6.2.2. PRECAUTIONS FOR MEASURING REFRIGERANT PRESSURE, CHARGING WITH REFRIGERANT, AND DISCHARGING REFRIGERANT

- 6.2.3. TESTING QUANTITY OF REFRIGERANT

- 6.2.4. PROCEDURE FOR CHARGING WITH REFRIGERANT

- 6.2.5. PROCEDURE FOR REPLACING SERVICE CAN

- 6.2.6. PROCEDURE FOR DISCHARGING REFRIGERANT

- 6.2.7. CLEANING INTERNAL AND EXTERNAL AIR FILTERS

- 6.2.8. TROUBLESHOOTING

- 7. SANDEN

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. BASIC SYSTEM OF AIR, HEATER, AND COOLER

- 7.1.2. CONTROL PANEL

- 7.1.3. COMPRESSOR, CONDENSER, AND RECEIVER DRIER

- 7.2. TESTING AND ADJUSTING

- 7.2.1. TROUBLESHOOTING

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. DISASSEMBLY, ASSEMBLY OF AIR CONDITONER UNIT

- 7.3.2. DISASSEMBLY, ASSEMBLY OF CONTROL PANEL

- 8. ZEXEL VALEO (NEW REFRIGERANT (R134A) TYPE)

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. COMPARISON OF APPLICABLE MODELS AND AIR CONDITIONER UNITS

- 8.1.2. CONFIGURATION AND FUNCTIONS OF REFRIGERATING CYCLE

- 8.1.3. OUTLINE OF REFRIGERATING CYCLE

- 8.1.4. OUTLINE OF MAIN PARTS

- 8.1.5. OUTLINE OF CONTROL SYSTEM

- 8.2. TESTING AND ADJUSTING

- 8.2.1. LIST OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 8.2.2. INSPECTION AND MAINTENANCE TABLE FOR AIR CONDITIONER

- 8.2.3. INSPECTION AND MAINTENANCE TABLE FOR HEATER

- 8.2.4. INSPECTION WITH SELFDIAGNOSIS FUNCTION

- 8.2.5. INSPECTION TEMPERATURE ADJUSTMENT (AIR MIX DOOR AND MIX ACTUATOR)

- 8.2.6. INSPECTING SELECTION OF AIR OUTLET (MODE DOOR AND MODE ACUTATOR)

- 8.2.7. INSPECTING SELECTION OF INTAKE (INTAKE DOOR AND INTAKE ACTUATOR)

- 8.2.8. INSPECTING RELAYS

- 8.2.9. CHECKING FOR REFRIGERANT LEAKAGE

- 8.2.10. CHARGING WITH REFRIGERANT

- 8.2.11. HANDLING REFRIGERANT CAN AND COMPRESSOR OIL

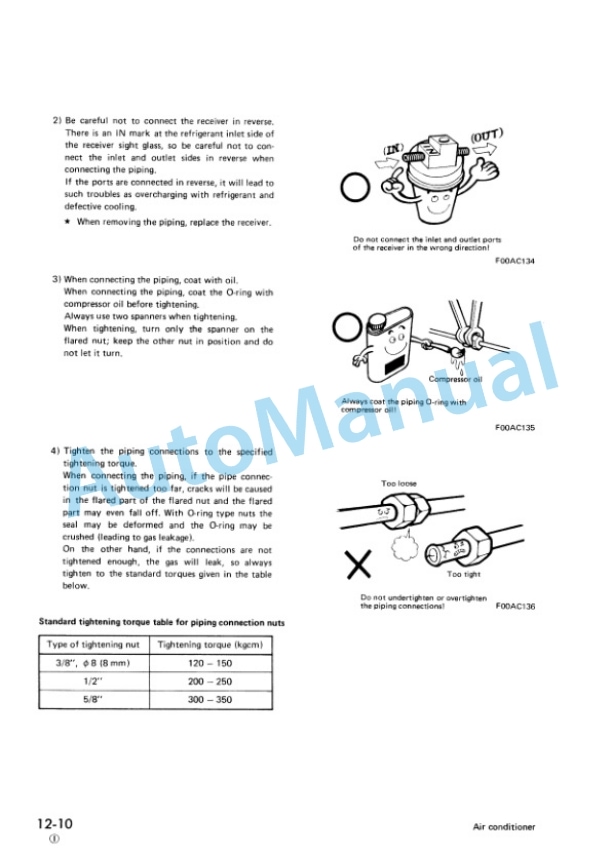

- 8.2.12. PRECAUTIONS FOR CONNECTING AIR CONDITIONER PIPING

- 8.3. TROUBLESHOOTING

- 8.3.1. TROUBLESHOOTING PROCEDURE

- 8.3.2. BLOCK DIAGRAM AND CIRCUIT DIAGRAM OF CONTROL SYSTEM

- 8.3.3. DETAIL OF AIR CONDITIONER UNIT

- 8.3.4. ARRANGEMENT OF CONNECTOR PINS

- 8.3.5. ARRANGEMENT OF CONNECTORS AND HOW TO DISCONNECT CONTROL UNIT CONNECTORS

- 8.3.6. HOW TO INSPECT ELECTRIC PARTS

- 8.3.7. TROUBLESHOOTING CHART

- 8.3.8. TROUBLESHOOTING TABLE

- 8.3.9. TROUBLESHOOTING FOR ELECTRICAL SYSTEM (E MODE)

- 8.3.10. TROUBLESHOOTING WITH GAUGE PRESSURE

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00