Komatsu ASX-HP, BSX-HP High Performance, Electric Stand-up, Counterbalanced Forklift Truck Service Manual SM400

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM400

- Format: PDF

- Size: 7.1MB

- Number of Pages: 225

Category: Komatsu Service Manual PDF

-

Model List:

- ASX-HP High Performance Electric Stand-up Counterbalanced Forklift Truck

- BSX-HP High Performance Electric Stand-up Counterbalanced Forklift Truck

- 1. SM40000

- 1.1. SERVICE MANUAL

- 1.1.1. INTRODUCTION

- 1.1.2. SERIAL NUMBER LOCATION

- 1.1.3. CONTENTS

- 1.1.4. FORKLIFT TRUCKSCOVERED IN THIS PUBLICATION

- 2. SM40001

- 2.1. SAFETY SECTION

- 2.1.1. SAFETY MANAGEMENT

- 2.1.2. SAFE TRAVEL

- 2.1.3. LOADING OPERATIONS

- 2.1.4. STOPPING AND PARKING

- 2.1.5. INSPECTION AND MAINTENANCE

- 2.1.6. STRUCTURE AND STABILITY OF THE LIFT TRUCK

- 2.1.7. SAFETY LABELS

- 2.1.8. OPTIONAL EQUIPMENT

- 2.2. GENERAL INFORMATION

- 2.2.1. INTRODUCTION TO THE EQUIPMENT

- 2.2.2. ABOUT THIS MANUAL

- 2.2.3. SERVICE PRECAUTIONS

- 2.2.4. ELECTRONIC ASSEMBLY PRECAUTIONS

- 3. SM40002

- 3.1. GENERAL MAINTENANCE PROCEDURES

- 3.1.1. GENERAL MAINTENANCE PROCEDURES

- 3.1.1.1. MOVING A DISABLED LIFT TRUCK

- 3.1.1.2. TOWING A DISABLED LIFT TRUCK

- 3.1.1.3. LIFTING A DISABLED LIFT TRUCK

- 3.1.1.4. PUTTING THE LIFT TRUCK ON BLOCKS

- 3.1.1.5. CLEANING INSTRUCTIONS

- 3.1.2. DRIVE WHEEL ASSEMBLY

- 3.1.3. CHANGING DRIVE TIRES

- 3.1.4. DRIVE WHEEL SEAL

- 3.1.5. DRIVE WHEEL SPINDLE

- 3.1.6. ENCODER ASSEMBLY

- 3.1.7. ENCODER BELT ADJUSTMENT

- 3.1.8. DRIVE SHAFT INSERT

- 3.1.9. DRIVE UNIT REBUILD

- 3.1.9.1. DISASSEMBLY

- 3.1.9.2. ASSEMBLY

- 3.1.10. CARRIER REBUILD

- 3.1.11. OVERHEAD GUARD REAR POST

- 3.1.12. BATTERY GATES

- 3.1.13. BATTERY ROLLERS

- 3.1.14. FRONT COVER

- 3.1.15. TOP COVER

- 3.1.16. CONTROL COVER

- 3.1.17. OPERATOR COMPARTMENT PADS

- 3.1.18. FLOOR MAT / BRAKE PEDAL PAD

- 3.1.19. DISC BRAKE UNIT

- 3.1.20. MASTER CYLINDER

- 3.1.21. BRAKE PEDAL

- 3.1.22. BLEEDING THE BRAKE SYSTEM

- 3.1.23. BRAKE ADJUSTMENTS

- 4. SM40006

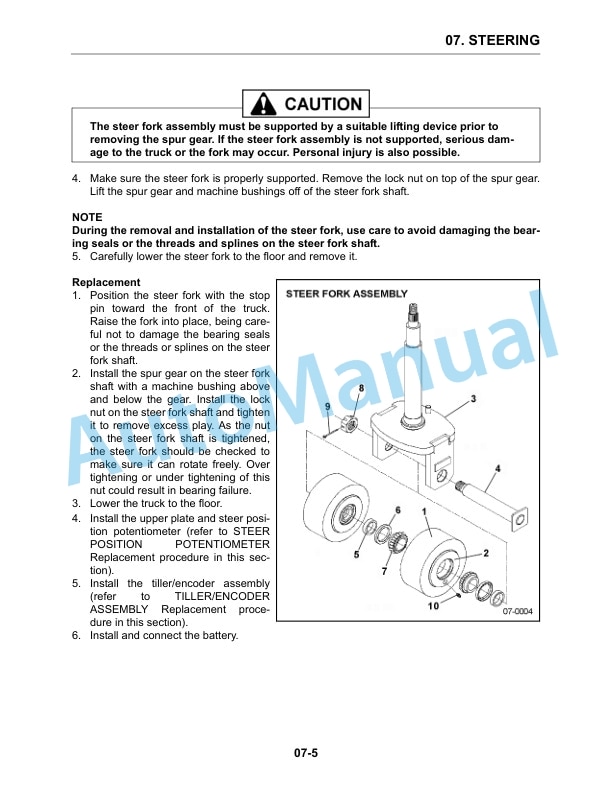

- 4.1. STEERING

- 4.1.1. STEERING SYSTEM ELECTRIC STEER

- 4.1.2. TILLER / ENCODER ASSEMBLY

- 4.1.3. GEARMOTOR

- 4.1.4. SPUR GEAR FORK

- 4.1.5. STEER WHEEL ASSEMBLY

- 4.1.6. CHANGING STEER TIRES

- 4.1.7. STEER POSITION POTENTIOMETER

- 5. SM40007

- 5.1. OPERATOR CONTROLS

- 5.1.1. OPERATOR CONTROLS DIAGRAM

- 5.1.2. CONTROL HANDLE ASSEMBLY

- 5.1.3. CONTROL HANDLEPOTENTIOMETER

- 5.1.4. BATTERY DISCONNECT LEVER

- 5.1.5. HORN BUTTON SPRING

- 5.1.6. LIFT AND TRAVEL SPRINGS

- 6. SM40008

- 6.1. LIFT AND AUXILIARY HYDRAULICS

- 6.1.1. THEORY OF OPERATION

- 6.1.2. LIFT PUMP MOTOR ASSEMBLY

- 6.1.3. LIFT PUMP

- 6.1.4. LIFT PUMP MOTOR BRUSHES

- 6.1.5. SOLENOID VALVE CARTRIDGES

- 6.1.6. MANUAL LOWERING VALVE, RELIEF VALVE, CHECK VALVE,FLOW REGULATORS

- 6.1.7. HYDRAULIC OIL FILTER

- 6.1.8. HYDRAULIC OIL

- 6.1.9. TILT CYLINDERS

- 6.1.10. TILT ANGLE ADJUSTMENT

- 6.1.11. RELIEF PRESSURE ADJUSTMENT

- 6.1.12. HYDRAULIC MANIFOLD DIAGRAM

- 6.1.13. HYDRAULIC MANIFOLD ASSEMBLY (S/N K957001 K02499U)

- 6.1.14. HYDRAULIC MANIFOLD ASSEMBLY (S/N K02500U)

- 7. SM40009

- 7.1. ELEVATING

- 7.1.1. EQUIPMENT DESCRIPTIONS

- 7.1.2. MAST

- 7.1.3. MAST ADJUSTMENT

- 7.1.4. CARRIAGE

- 7.1.5. INNER CHAINS

- 7.1.6. OUTER LIFT CHAINS (TRIPLEX)

- 7.1.7. CHAIN ADJUSTMENT

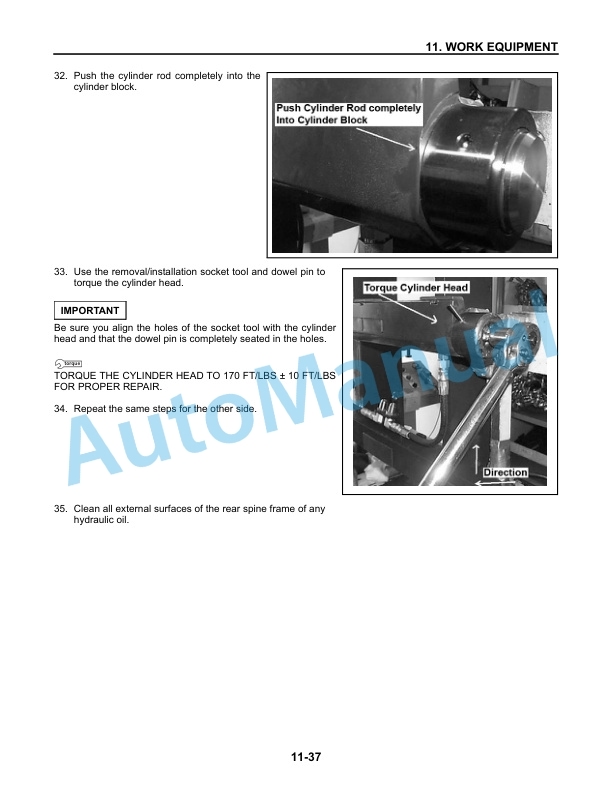

- 7.1.8. CENTER LIFT CYLINDER

- 7.1.9. OUTER LIFT CYLINDERS (TRIPLEX)

- 7.1.10. CENTER CYLINDER SHEAVES

- 7.1.11. MIDDLE RAIL SHEAVES

- 7.1.12. MAIN HYDRAULIC DISTRIBUTOR BLOCK

- 7.1.13. CENTER CYLINDER DISTRIBUTOR BLOCK

- 7.1.14. AUXILIARY INTERNAL REEVING (OPTION)

- 7.1.15. STANDARD HOSE ASSEMBLY

- 7.1.16. BLEEDING AIR FROM THE LIFT CYLINDERS

- 7.1.17. TILT ANGLE ADJUSTMENT

- 8. SM40010

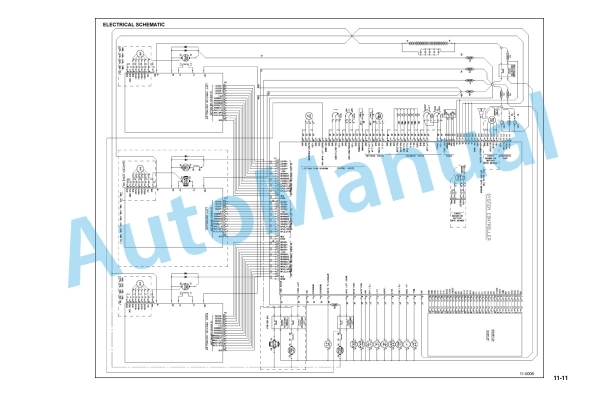

- 8.1. ELECTRICAL

- 8.1.1. CAPACITOR DISCHARGE

- 8.1.2. SYSTEM CONTROLLER / OPERATORDISPLAY BOX

- 8.1.3. OPERATOR DISPLAY BOARD

- 8.1.4. TRACTION AMPLIFIER

- 8.1.5. LIFT AMPLIFIER

- 8.1.6. MAIN POWER CONTACTOR

- 8.1.7. CONTACTOR TIPS

- 8.1.8. FUSES

- 8.1.9. HORN

- 8.1.10. AMPLIFIER DIODES

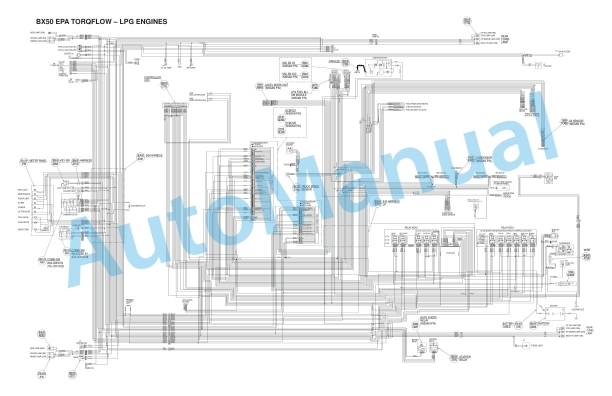

- 8.1.11. ELECTRICAL SCHEMATIC FOLDOUT

- 9. SM40011

- 9.1. PERIODIC MAINTENANCE

- 9.1.1. PERIODIC MAINTENANCE INSPECTION POINTS DIAGRAM

- 9.1.2. SCHEDULED MAINTENANCE TABLE

- 9.1.3. HOUR DAILY INSPECTION

- 9.1.3.1. SRO CIRCUIT

- 9.1.3.2. GENERAL FUNCTIONS

- 9.1.3.3. BATTERY

- 9.1.3.4. CHARGING THE BATTERY

- 9.1.3.5. CHANGING THE BATTERY

- 9.1.3.6. BATTERY CONNECTOR

- 9.1.3.7. BATTERY GATES

- 9.1.3.8. BRAKES

- 9.1.3.9. BRAKE PEDAL / BRAKE LINKAGE

- 9.1.3.10. BRAKE SWITCH

- 9.1.3.11. CARRIAGE / LOAD BACKREST / FORKS

- 9.1.3.12. CONTROL HANDLE

- 9.1.3.13. DECALS

- 9.1.3.14. GEARBOX

- 9.1.3.15. HYDRAULIC SYSTEM

- 9.1.4. HOUR / 5DAY INSPECTION

- 9.1.4.1. BATTERY

- 9.1.4.2. SIDESHIFT CARRIAGE

- 9.1.4.3. HYDRAULIC SYSTEM

- 9.1.4.4. LIFT CHAINS

- 9.1.5. HOUR / 60DAY INSPECTION

- 9.1.5.1. BATTERY

- 9.1.5.2. BRAKES

- 9.1.5.3. CONTACTOR TIPS

- 9.1.5.4. GEARBOX

- 9.1.5.5. HYDRAULIC SYSTEM

- 9.1.5.6. LIFT CHAINS

- 9.1.5.7. MOTOR BRUSHES

- 9.1.6. HOUR / 360 DAY INSPECTION

- 9.1.6.1. BRAKES

- 9.1.6.2. GEARBOX

- 9.1.6.3. HYDRAULIC SYSTEM

- 9.1.6.4. TIRES / WHEELS

- 10. SM40012

- 10.1. PROGRAMMING AND DIAGNOSTICS

- 10.1.1. INTRODUCTION

- 10.1.2. PREOPERATION INFORMATION

- 10.1.3. PERFORMANCE AND DIAGNOSTICS MENU

- 10.1.4. STARTUP SEQUENCE

- 10.1.5. PASSWORD ENTRY

- 10.1.6. PROGRAMMING AND DIAGNOSTICS MENU DIAGRAN

- 10.1.7. CALIBRATION MENU (CALIBRAT)

- 10.1.8. USER PROFILES

- 10.1.9. PROGRAM MENU DIAGRAM

- 10.1.10. DIAGNOSTIC MENU (DIAGNSTC)

- 10.1.11. DIAGNOSTICS INPUT TESTS TABLE

- 10.1.12. DIAGNOSTICS OUTPUT TESTS TABLE

- 10.1.13. ERROR HISTORY

- 10.1.14. OPERATIONAL FEEDBACK DEVICES

- 10.1.15. OPERATIONAL MODES

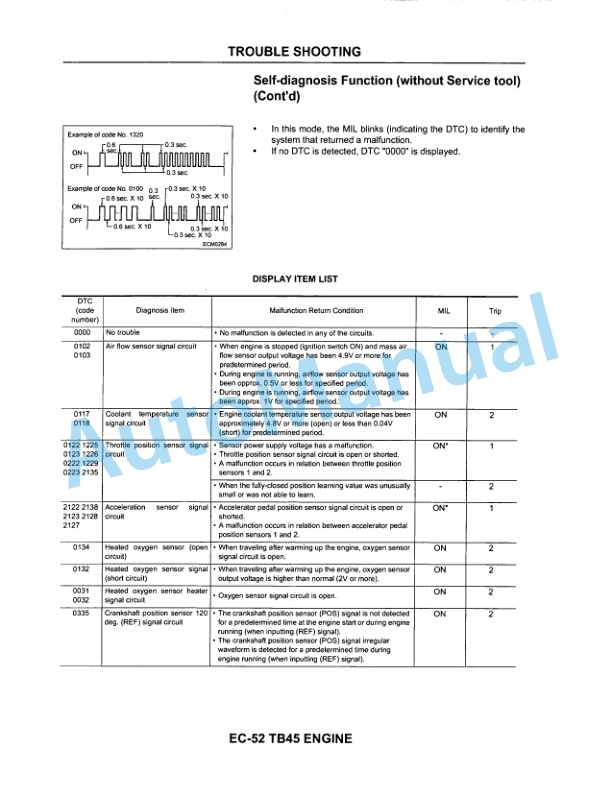

- 10.1.16. ERROR CODE (SYSTEM FAULT CODES) TABLES

- 11. SM40013

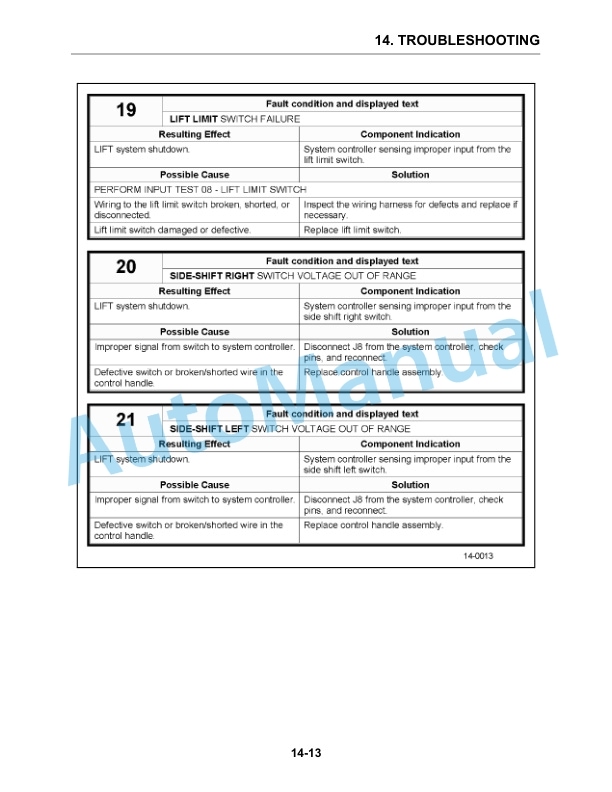

- 11.1. TROUBLESHOOTING

- 11.1.1. TROUBLESHOOTING MECHANICAL

- 11.1.1.1. DRIVE

- 11.1.1.2. BRAKES

- 11.1.1.3. STEERING ELECTRIC

- 11.1.1.4. OPERATOR CONTROLS

- 11.1.1.5. LIFT AND AUXILIARY

- 11.1.1.6. ELEVATING

- 11.1.2. ELECTRONIC FAULT ISOLATION PROCEDURE SOFTWARE VERSION 3.20

- 11.1.2.1. ERRORS FAULT CONDITION CODES

- 11.1.3. ELECTRONIC FAULT ISOLATION PROCEDURE SOFTWARE VERSION 3.20

- 11.1.3.1. WARNINGS

- 12. SM40014

- 12.1. INDUSTRIAL BATTERY

- 12.1.1. INDUSTRIAL BATTERY

- 12.1.2. SAFETY

- 12.1.3. CHANGING THE BATTERY

- 12.1.4. CHARGING THE BATTERY

- 12.1.5. CLEANING THE BATTERY

- 12.1.6. MEASURING SPECIFIC GRAVITY

- 12.1.7. VOLTAGE CHECK

- 12.1.8. ELECTROLYTE LEVEL

- 12.1.9. BATTERY HISTORY RECORD

- 13. SM40015

- 13.1. TORQUE SPECIFICATIONS

- 13.1.1. SAE BOLTS 1/4 TO 1 1/2

- 13.1.2. METRIC BOLTS M3 TO M12

- 13.1.3. CAP / MACHINE SCREWS

Rate this product

You may also like

Komatsu Service Manual PDF

Komatsu CX50 Forklift Truck EPA Tier 2 Compliant Service Manual SM206

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

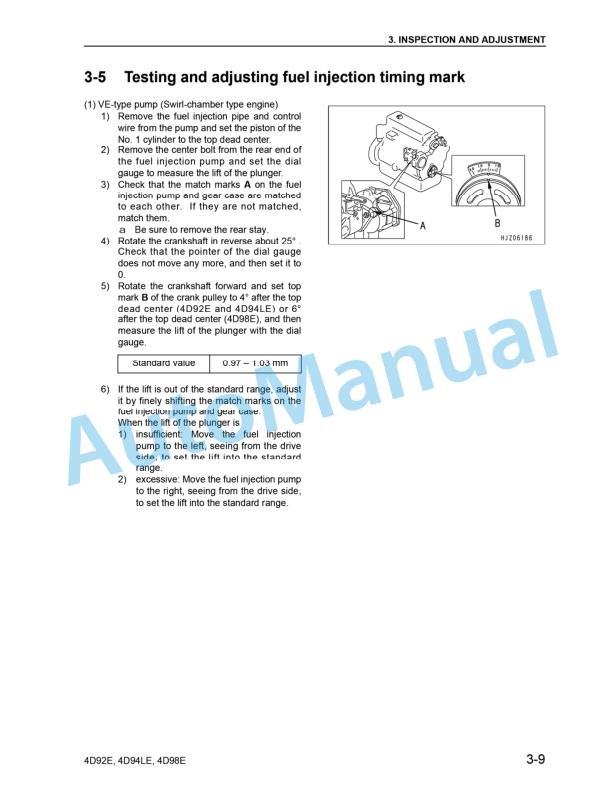

Komatsu 4D94E, 4D94L, 4D98E Diesel Engine Forklift Truck Service Manual 4D94E-BE4

$30.00

Komatsu Service Manual PDF

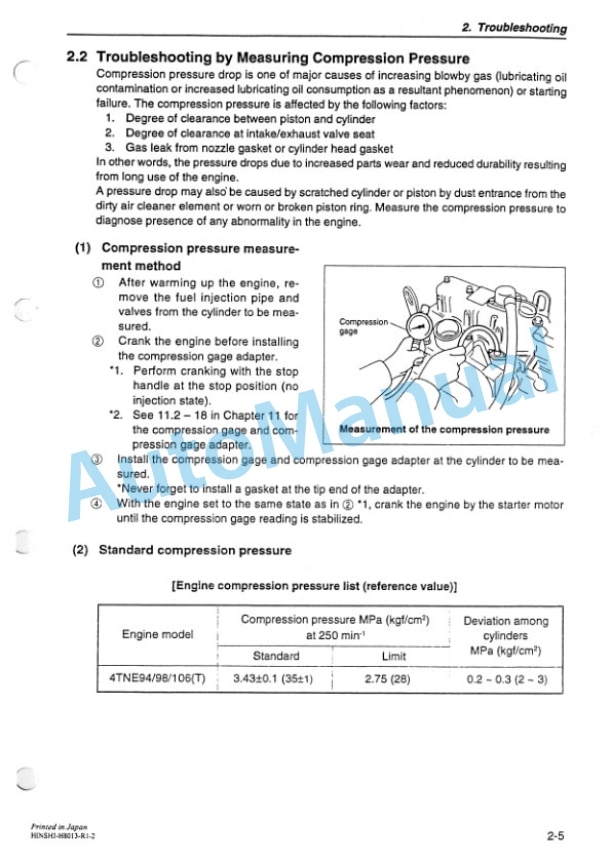

Komatsu 4TNE94.98.106T Diesel Engine Service Manual HINSHI-H8013-R1

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00