Komatsu BBX50 Series Electric Forklift Truck Service Manual SM150

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM150

- Format: PDF

- Size: 12.8MB

- Number of Pages: 371

Category: Komatsu Service Manual PDF

-

Model List:

- BBX50 Series Electric Forklift Truck

- 1. GENERAL DATA SAFETY

- 1.1. SM150 COVER PAGE

- 1.1.1. TABLE OF CONTENTS

- 1.1.2. FORKLIFT TABLE

- 1.1.3. CH. 1 SAFETY SECTION

- 1.1.3.1. SAFETY MANAGEMENT

- 1.1.3.2. SAFE TRAVEL

- 1.1.3.3. LOADING OPERATIONS

- 1.1.3.4. STOPPING AND PARKING

- 1.1.3.5. INSPECTION MAINT.

- 1.1.3.6. STRUCTURE STABILITY

- 2. SPECIFICATIONS

- 2.1. SM150 COVER PAGE

- 2.1.1. CH. 10 GENERAL SPECIFICATIONS

- 2.1.1.1. PERIODIC REPLACEMENT OF PARTS

- 2.1.1.2. STANDARD TORQUE TABLES

- 2.1.1.3. LOCTITE USAGE

- 2.1.1.4. CONVERSION TABLES

- 3. TESTING ADJUSTING

- 3.1. SM150 COVER PAGE

- 3.1.1. CH. 20 TESTING / ADJUSTING

- 3.1.1.1. SERVICE DATA TABLES

- 3.1.1.2. CONTROLLER

- 3.1.1.2.1. SELECTING FUNCTIONS

- 3.1.1.2.2. OPTIONAL DEVICES

- 3.1.1.3. DISPLAY OPERATION

- 3.1.1.4. BATTERY

- 3.1.1.5. FUSES

- 3.1.1.6. TRACTION AC MOTOR

- 3.1.1.7. PUMP AC MOTOR

- 3.1.1.8. TRANSFER CASE

- 3.1.1.9. ACCELERATOR PEDAL

- 3.1.1.10. BRAKE PEDAL

- 3.1.1.11. WHEEL BRAKE

- 3.1.1.12. PARKING BRAKE LEVER

- 3.1.1.13. HYDRAULIC TANK

- 3.1.1.14. BLEEDING AIR

- 4. REMOVAL INSTALLATION

- 4.1. SM150 COVER PAGE

- 4.1.1. CH. 30 REMOVAL INSTALLATION

- 4.1.1.1. HYDRAULIC PUMP MOTOR

- 4.1.1.2. CONTROLLER

- 5. DISASSEMBLY ASSEMBLY

- 5.1. SM150 COVER PAGE

- 5.1.1. CH. 40 DISASSEMBLY / ASSEMBLY

- 5.1.1.1. TRANSFER

- 5.1.1.2. DIFFERENTIAL

- 5.1.1.3. FRONT AXLE

- 5.1.1.4. BRAKE MASTER CYL.

- 5.1.1.5. HYD. CONTROL VALVE

- 5.1.1.6. TRACTION MOTOR

- 5.1.1.7. PUMP MOTOR

- 6. MAINTENANCE STANDARD

- 6.1. SM150 COVER PAGE

- 6.1.1. CH. 50 MAINTENANCE STANDARD

- 6.1.1.1. TRANSFER

- 6.1.1.2. DIFFERENTIAL

- 6.1.1.3. FRONT AXLE

- 6.1.1.4. BRAKE MASTER CYLINDER

- 6.1.1.5. WHEEL BRAKE

- 6.1.1.6. REAR AXLE

- 6.1.1.7. CONTROL VALVE

- 6.1.1.8. MAST, CARRIAGE, FORK

- 6.1.1.9. TRACTION MOTOR

- 6.1.1.10. PUMP MOTOR

- 7. STRUCTURE FUNCTION

- 7.1. SM150 COVER PAGE

- 7.1.1. CH. 60 STRUCTURE FUNCTION

- 7.1.1.1. CONTROLLER

- 7.1.1.2. DISPLAY

- 7.1.1.3. CHARACTER DISPLAY LIST

- 8. TROUBLESHOOTING

- 8.1. SM150 COVER PAGE

- 8.1.1. CH. 70 TROUBLESHOOTING

- 8.1.1.1. PREPARATION

- 8.1.1.2. FAILURE ANALYSIS

- 8.1.1.3. CPU PCB PRECAUTIONS

- 8.1.1.4. WIRE HARNESS PINS

- 8.1.1.5. ELECTRICAL CIRCUIT DIAGRAM

- 8.1.1.6. WIRING DIAGRAM

- 8.1.1.7. CONTROLLER

- 8.1.1.7.1. CHECK MAIN CONTACTOR

- 8.1.1.7.2. CHECK CURRENT SENSORS

- 8.1.1.7.3. CHECK COOLING FANS

- 8.1.1.7.4. CONNECTOR VOLTAGE

- 8.1.1.7.5. BLOCK DIAGRAM

- 8.1.1.8. ERROR CODE LIST

- 8.1.1.9. TRACTION/PUMP MOTORS

- 8.1.1.10. CONTROL VALVE

- 9. ANNUAL INSPECTION TABLES

- 9.1. SM150 COVER PAGE

- 9.1.1. CH. 80 ANNUAL INSPECTION TABLE

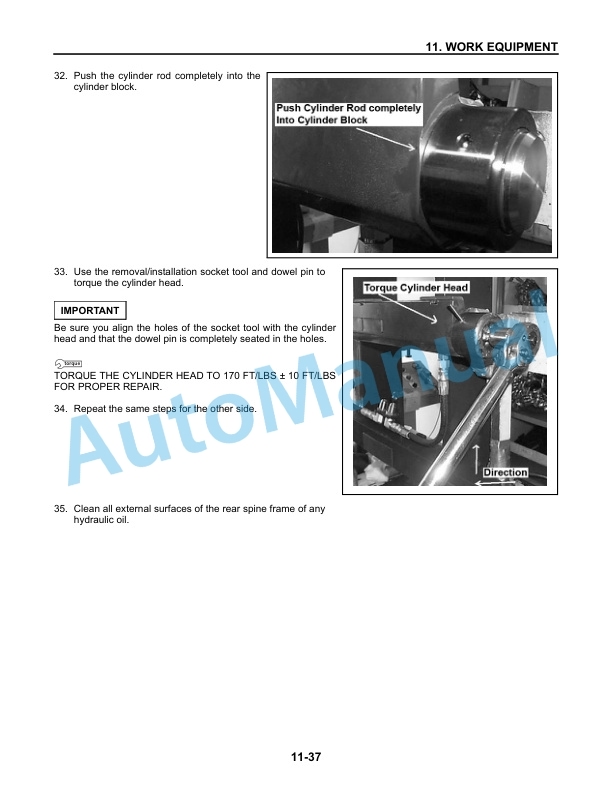

- 10. SERIES MS MAST

- 10.1. Contents

- 10.1.1. Introduction

- 10.1.2. Special Definitions

- 10.1.3. Truck System Requirements

- 10.1.4. Mounting Bracket Installation

- 10.1.5. Mast Installation

- 10.1.6. Chain Inspection and Tension

- 10.1.7. Internal Reeving Installation

- 10.1.8. Periodic Maintenance

- 10.1.9. Daily Inspection

- 10.1.10. Hour Inspection

- 10.1.11. Hour Inspection

- 10.1.12. Mast Removal

- 10.1.13. Main Lift Cylinder Description

- 10.1.14. Cylinder Operation

- 10.1.15. Main Lift Cylinder Removal

- 10.1.16. Main Lift Cylinder Service

- 10.1.17. Cylinder Bleeding

- 10.1.18. Valve Cartridge Service

- 10.1.19. Piston Removal

- 10.1.20. Carriage Description

- 10.1.21. Carriage RemovalMast on Truck

- 10.1.22. Carriage Removal Mast on Floor

- 10.1.23. Carriage Inspection

- 10.1.24. Upright Description

- 10.1.25. Upright Operation

- 10.1.26. Upright Disassembly

- 10.1.27. Upright Inspection

- 10.1.28. Uprights Reassembly

- 10.1.29. Mast Skewing

- 10.1.30. Chain Inspection and Tension

- 10.1.31. Measuring Chain Stretch

- 10.1.32. Main Lift Chain Adjustment

- 10.1.33. Main Lift Chain Service

- 11. SERIES MT 20MAST A

- 11.1. Contents

- 11.1.1. Special Definitions

- 11.1.2. Introduction

- 11.1.3. Truck System

- 11.1.4. Requirements

- 11.1.5. Mounting Bracket

- 11.1.6. Installation

- 11.1.7. Mast Installation

- 11.1.8. Chain Inspection and Tension

- 11.1.9. Free lift Cylinder Supply

- 11.1.10. Upright Rail Lubrication

- 11.1.11. Cylinder Bleeding

- 11.1.12. Mast Skewing

- 11.1.13. Single Function Internal Reeving

- 12. SERIES MT MAST B

- 12.1. Contents

- 12.1.1. Double Function Internal Reeving

- 12.1.2. Periodic Maintenance

- 12.1.3. Daily Inspection

- 12.1.4. Hour Inspection

- 12.1.5. Hour Inspection

- 12.1.6. Section 4 Troubleshooting

- 13. SERIES MT MAST C

- 13.1. Contents

- 13.1.1. Mast Removal

- 13.1.2. Main Lift Cylinder Description

- 13.1.3. Free Lift Cylinder Description

- 13.1.4. Cylinder Operation

- 13.1.5. Main Lift Cylinder Removal

- 13.1.6. Free Lift Cylinder Removal

- 13.1.7. Main Lift Cylinder Service

- 13.1.8. Free Lift Cylinder Service

- 13.1.9. Cylinder Bleeding

- 13.1.10. Valve Cartridge Service

- 13.1.11. Piston Removal

- 13.1.12. Carriage

- 13.1.13. Carriage RemovalMast on Truck

- 13.1.14. Carriage RemovalMast on Floor

- 13.1.15. Carriage Inspection

- 13.1.16. Upright Description

- 13.1.17. Upright Operation

- 13.1.18. Upright Disassembly

- 13.1.19. Upright Inspection

- 13.1.20. Upright Reassembly

- 13.1.21. Mast Skewing

- 13.1.22. Chains

- 13.1.23. Inspection and Tension

- 13.1.24. Measuring Chain Stretch

- 13.1.25. Main Lift Chain Adjustment

- 13.1.26. Free Lift Chain Adjustment

- 13.1.27. Free Lift Chain Service

- 13.1.28. Main Lift Chain Service

- 14. SERIES MD MAST

- 14.1. Contents

- 14.1.1. Special Definitions

- 14.1.2. Introduction

- 14.1.3. Truck System

- 14.1.4. Requirements

- 14.1.5. Mounting Bracket

- 14.1.6. Installation

- 14.1.7. Mast Installation

- 14.1.8. Chain Inspection and Tension

- 14.1.9. Upright Rail Lubrication

- 14.1.10. Cylinder Bleeding

- 14.1.11. Mast Skewing

- 14.1.12. Single Function Internal Reeving

- 14.1.13. Double Function Internal Reeving

- 14.1.14. Periodic Maintenance

- 14.1.15. Daily Inspection

- 14.1.16. Hour Inspection

- 14.1.17. Hour Inspection

- 14.1.18. Section 4 Troubleshooting

- 14.1.19. Mast Removal

- 14.1.20. Main Lift Cylinder Description

- 14.1.21. Free Lift Cylinder Description

- 14.1.22. Cylinder Operation

- 14.1.23. Main Lift Cylinder Removal

- 14.1.24. Free Lift Cylinder Removal

- 14.1.25. Main Lift Cylinder Service

- 14.1.26. Free Lift Cylinder Service

- 14.1.27. Cylinder Bleeding

- 14.1.28. Valve Cartridge Service

- 14.1.29. Piston Removal

- 14.1.30. Carriage

- 14.1.31. Carriage RemovalMast on Truck

- 14.1.32. Carriage RemovalMast on Floor

- 14.1.33. Carriage Inspection

- 14.1.34. Upright Description

- 14.1.35. Upright Disassembly

- 14.1.36. Upright Inspection

- 14.1.37. Upright Reassembly

- 14.1.38. Mast Skewing

- 14.1.39. Chains

- 14.1.40. Inspection and Tension

- 14.1.41. Measuring Chain Stretch

- 14.1.42. Free Lift Chain Adjustment

- 14.1.43. Free Lift Chain Service

Rate this product

You may also like

Komatsu Service Manual PDF

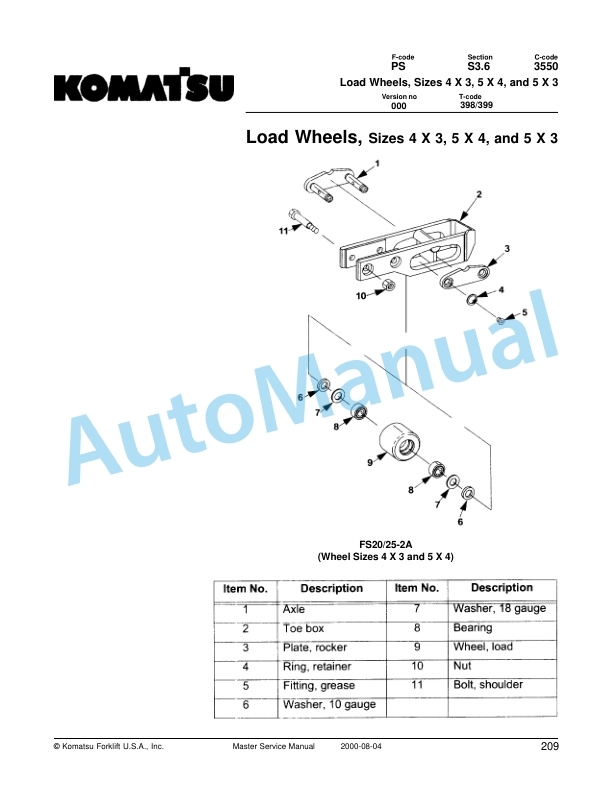

Komatsu FR18S-2A, FR23S-2A, FR15DR-2A Forklift Truck Service Manual

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

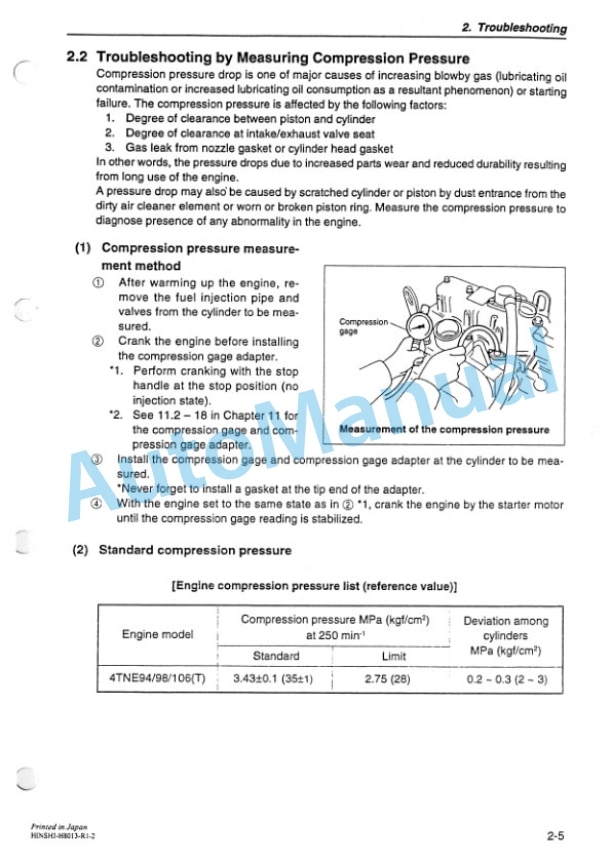

Komatsu 4TNE94.98.106T Diesel Engine Service Manual HINSHI-H8013-R1

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

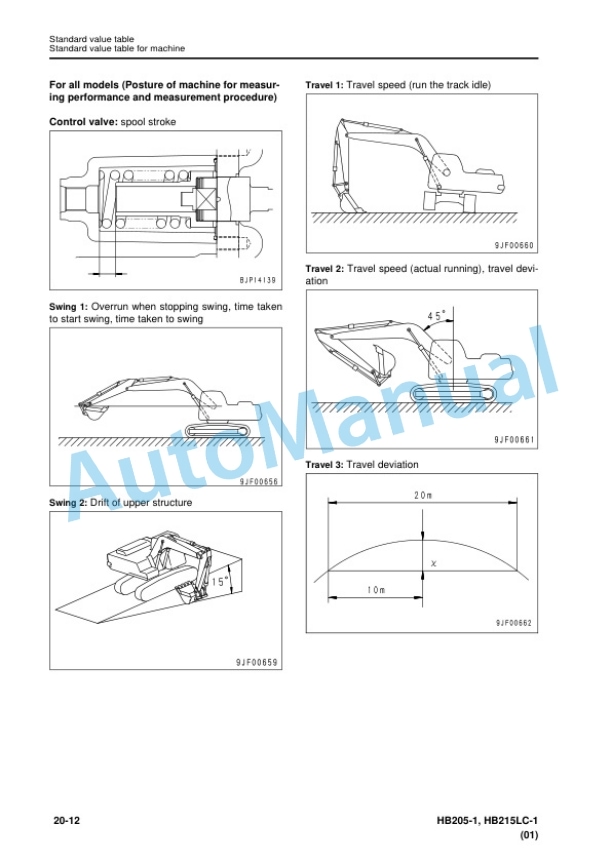

Komatsu HB205-1, HB215LC-1 Hydraulic Excavator Service Manual SEN05393-10

$30.00

Komatsu Service Manual PDF

Komatsu FB10M-2, FB13M-2, FB15M-2, FB18M-2 Forklift Truck Service Manual SM018

$30.00

Komatsu Service Manual PDF

$30.00