Komatsu BR200-1 Series Shop Manual SEBM003602

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM003602

- Format: PDF

- Size: 15.2MB

- Number of Pages: 504

Category: Komatsu Shop Manual PDF

-

Model List:

- BR200-1 Series

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL LOCATIONS

- 3.2. GENERAL ASSEMBLY DRAWING

- 3.3. SPECIFICATIONS

- 3.4. WEIGHT TABLE

- 3.5. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. POWER TRAIN

- 4.2. TRACK FRAME AND RECOIL SPRING

- 4.3. FINAL DRIVE

- 4.4. HYDRAULIC CIRCUIT DIAGRAM

- 4.5. HYDRAULIC TANK

- 4.6. OLSS

- 4.7. HYDRAULIC PUMP

- 4.7.1. FRONT MAIN PUMP AND REAR MAIN PUMP(HPV090090)

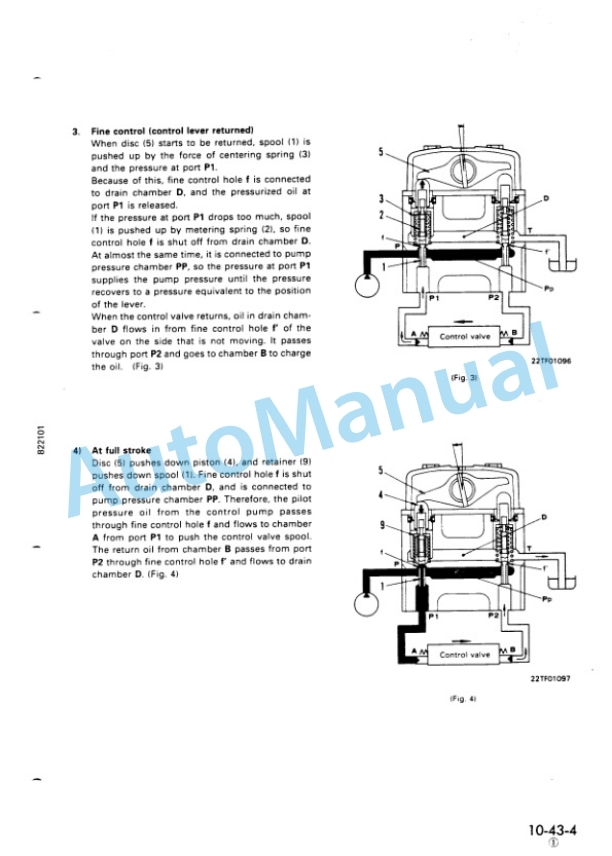

- 4.7.2. SERVO VALVE

- 4.7.3. TVC VALVE

- 4.7.4. CONC VALVE

- 4.7.5. CHARGING PUMP

- 4.8. SOLENOID VALVE (FOR CRUSHER,BELT CONVEYOR,TRAVEL)

- 4.9. TANDEM PUMP (FOR BELT CONVEYOR,PLATE FEEDER)

- 4.10. HYDRAULIC PUMP

- 4.11. HYDRAULIC 3TANDEM PUMP

- 4.12. PLATE FEEDER MOTOR

- 4.13. FIRST BELT CONVEYOR MOTOR

- 4.14. SOLENOID VALVE (FOR PLATE FEEDER,CRUSHER MOTOR,CONVEYOR MOTOR)

- 4.15. RELIEF VALVE (FOR PLATE FEEDER,FIRST BELT CONVEYOR)

- 4.16. FLOW CONTROL VALVE (FOR PLATE FEEDER)

- 4.17. CRUSHER

- 4.18. PLATE FEEDER

- 4.19. FIRST BELT CONVEYOR

- 4.20. ELECTRICAL CIRCUIT DIAGRAM

- 4.21. SYSTEM STRUCTURE DRAWING

- 4.22. MONITOR SYSTEM

- 4.22.1. MONITOR PANEL

- 4.22.2. SENSOR

- 4.23. PLATE FEEDER RETURN SYSTEM

- 4.23.1. PLATE FEEDER PRESSURE SENSOR

- 4.23.2. TIMER

- 4.24. AUTOMATIC STOP SYSTEM FOR CONVEYOR OVERLOAD

- 4.25. AUTOMATIC REVERSE SYSTEM FOR CRUSHER OVERLOAD

- 4.26. AUTOMATIC SPEED SHIFT SYSTEM FOR CRUSHER

- 4.27. AUTOMATIC OPERATION SYSTEM FOR FEEDER

- 5. TESTING AND ADJUSTING

- 5.1. TABLE OF JUDGEMENT STANDARD VALUE

- 5.2. TOOLS OF TESTING,ADJUSTING,AND TROUBLESHOOTING

- 5.3. ADJUSTING VALVE CLEARANCE

- 5.4. MEASURING COMPRESSION PRESSURE

- 5.5. TESTNG AND ADJUSTING FUEL INJECTION TIMING

- 5.6. ADJUSTING FUEL CONTROL LEVER

- 5.7. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN CRUSHER,PLATE FEEDER,BELT CONVEYOR,TRAVEL CIRCUIT

- 5.8. TESTING AND ADJUSTING CHARGING PUMP PRESSURE

- 5.9. TESTING AND ADJUSTING MAIN PUMP CONTROL PRESSURE

- 5.10. MEASURING STROKE OF SERVO PISTON

- 5.11. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.12. MEASURING OUTPUT PRESSURE OF PPC VALVE

- 5.13. TESTING AND ADJUSTING CRUSHER

- 5.14. CRUSHER RELATED PARTS

- 5.15. AIR BLEEDING

- 5.16. TROUBLESHOOTING

- 5.16.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

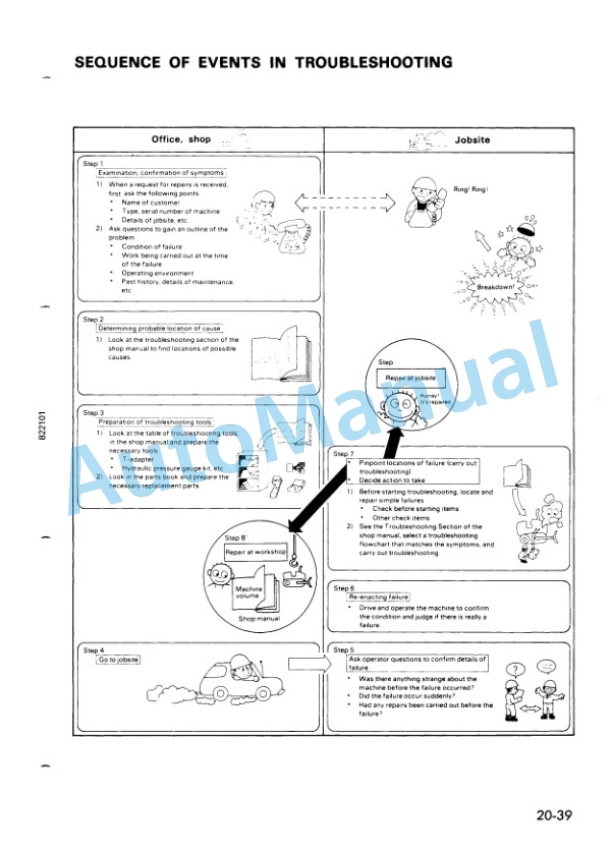

- 5.16.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.16.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 5.16.4. CHECKS BEFORE TROUBLESHOOTING

- 5.16.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.16.6. CONNECTOR TABLE FOR CONNECTOR

- 5.16.7. METHOD OF PROCEEDING WITH TROUBLESHOOTING

- 5.16.8. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.16.9. JUDGEMENT TABLE FOR ELECTRICAL SYSTEM OR HYDRAULIC,MECHANICAL SYSTEM (BR2001,BR200J1)

- 5.16.10. JUDGEMENT TABLE FOR ELECTRICAL SYSTEM OR HYDRAULIC,MECHANICAL SYSTEM (BR200S1)

- 5.16.11. JUDGEMENT TABLE FOR ELECTRICAL SYSTEM OR HYDRAULIC,MECHANICAL SYSTEM (BR200R1)

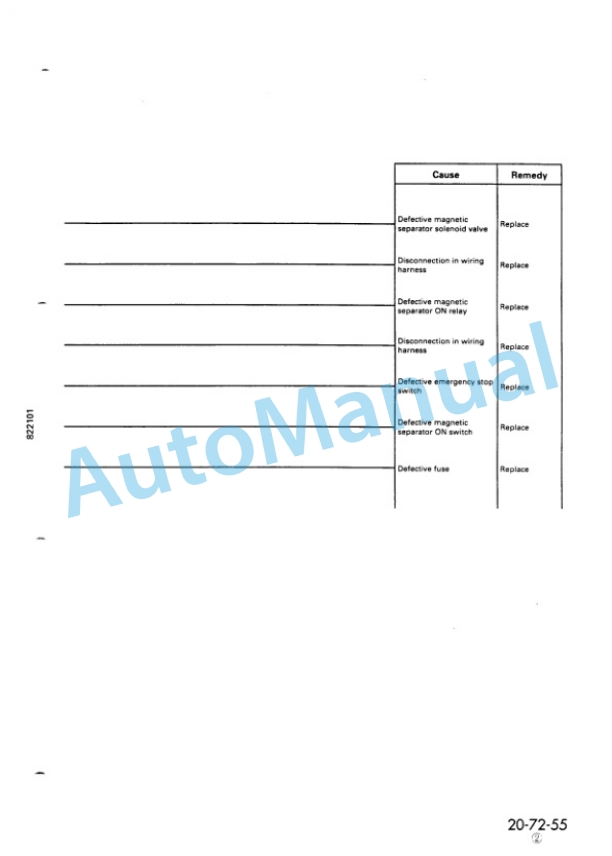

- 5.16.12. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) (BR2001,BR200J1,BR200J1A)

- 5.16.13. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) (BR200S1)

- 5.16.14. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) (BR200R1)

- 5.16.15. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 5.16.16. TROUBLESHOOTING OF MONITOR SYSTEM (M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. STARTING MOTOR

- 6.4.1. REMOVAL AND INSTALLATION

- 6.5. ALTERNATOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. ENGINE OIL COOLER

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. FUEL INJECTION PUMP

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. WATER PUMP

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. NOZZLE HOLDER

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. TURBOCHARGER

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. THERMOSTAT

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. ENGINE FRONT SEAL

- 6.12.1. REMOVAL AND INSTALLATION

- 6.13. ENGINE REAR SEAL

- 6.13.1. REMOVAL AND INSTALLATION

- 6.14. CYLINER HEAD

- 6.14.1. REMOVAL AND INSTALLATION

- 6.15. HYDRAULIC COOLER

- 6.15.1. REMOVAL AND INSTALLATION

- 6.16. REDIATOR,HYDRAULIC COOLER

- 6.16.1. REMOVAL AND INSTALLATION

- 6.17. ENGINE,HYDRAULIC PUMP

- 6.17.1. REMOVAL AND INSTALLATION

- 6.18. DAMPER

- 6.18.1. REMOVAL AND INSTALLATION

- 6.19. TRAVEL MOTOR

- 6.19.1. REMOVAL AND INSTALLATION

- 6.20. TRAVEL MOTOR,FINAL DRIVE

- 6.20.1. REMOVAL AND INSTALLATION

- 6.20.2. REMOVAL AND INSTALLATION

- 6.21. IDLER,RECOIL SPRING

- 6.21.1. REMOVAL AND INSTALLATION

- 6.21.2. DISASSEMBLY AND ASSEMBLY

- 6.22. TRACK ROLLER

- 6.22.1. REMOVAL AND INSTALLATION

- 6.23. CARRIER ROLLER

- 6.23.1. REMOVAL AND INSTALLATION

- 6.24. TRACK SHOE

- 6.24.1. REMOVAL AND INSTALLATION

- 6.25. CHARGING PUMP

- 6.25.1. REMOVAL AND INSTALLATION

- 6.26. HYDRAULIC PUMP

- 6.26.1. REMOVAL AND INSTALLATION

- 6.26.2. DISASSEMBLY

- 6.26.3. ASSEMBLY

- 6.27. MAIN PUMP INPUT SHAFT OIL SEAL

- 6.27.1. REMOVAL AND INSTALLATION

- 6.28. CONTROL VALVE

- 6.28.1. REMOVAL AND INSTALLATION

- 6.28.2. DISASSEMBLY

- 6.28.3. ASSEMBLY

- 6.29. MAIN RELIEF VALVE

- 6.29.1. REMOVAL AND INSTALLATION

- 6.29.2. DISASSEMBLY AND ASSEMBLY

- 6.30. TVC VALVE

- 6.30.1. REMOVAL AND INSTALLATION

- 6.31. CONC VALVE

- 6.31.1. REMOVAL AND INSTALLATION

- 6.32. SERVO VALVE

- 6.32.1. REMOVAL AND INSTALLATION

- 6.33. PPC SHUTTLE VALVE

- 6.33.1. REMOVAL AND INSTALLATION

- 6.34. TRAVEL PPC VALVE

- 6.34.1. DISASSEMBLY AND ASSEMBLY

- 6.35. CHEEK PLATE

- 6.35.1. REMOVAL AND INSTALLATION

- 6.36. DRIVEN GEAR

- 6.36.1. REMOVAL AND INSTALLATION

- 6.37. TOGGLE PLATE

- 6.37.1. REMOVAL AND INSTALLATION

- 6.38. TOGGLE SEAT

- 6.38.1. REMOVAL AND INSTALLATION

- 6.39. FLYWHEEL AND VSHEAVE

- 6.39.1. REMOVAL AND INSTALLATION

- 6.40. SWING JAW

- 6.40.1. REPLACEMENT

- 6.41. BEARING ON FRAME SIDE

- 6.41.1. REPLACEMENT

- 6.42. THRUST RETAINER

- 6.42.1. REPLACEMENT

- 6.43. DRIVE GEAR

- 6.43.1. REMOVAL AND INSTALLATION

- 6.44. CRUSHER MOTOR

- 6.44.1. REMOVAL AND INSTALLATION

- 6.45. COUPLING(BR200S1)

- 6.45.1. REMOVAL

- 6.45.2. INSTALLATION

- 6.46. PLATE FEEDER MOTOR

- 6.46.1. REMOVAL AND INSTALLATION

- 6.47. CUTTER PIECE

- 6.47.1. REPLACEMENT

- 6.48. PROCEDURE FOR CHANGING GREASE

- 6.49. PROCEDURE FOR REPLACING CUTTER HOLDER

- 6.50. PROCEDURE FOR TURNING OR REPLACING IMPACT PLATES

- 6.51. ROTOR LINER

- 6.51.1. CHECK AND REPLACEMENT

- 6.52. PROTECTOR

- 6.52.1. REMOVAL AND INSTALLATION

- 6.53. CONTACT PLATE

- 6.53.1. REMOVAL AND INSTALLATION

- 6.54. SHEAR PIN OF CONTACT PLATE DAMPER

- 6.54.1. REPLACEMENT

- 6.55. ROTO BEARING UNIT

- 6.55.1. REMOVAL AND INSTALLATION

- 6.56. ROTOR

- 6.56.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. FINAL DRIVE

- 7.2. TRACK FRAME AND RECOIL SPRING

- 7.3. CHARGING PUMP AND RELIEF VALVE

- 7.4. CONTROL VALVE

- 7.5. TRAVEL SHUTTLE VALVE

- 7.6. TRAVEL MOTOR

- 7.7. PLATE FEEDER MOTOR

Rate this product

You may also like