Komatsu BR380JG-1 Shop Manual SEBM034104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM034104

- Format: PDF

- Size: 40.9MB

- Number of Pages: 557

Category: Komatsu Shop Manual PDF

-

Model List:

- BR380JG-1

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. ENGINE RELATED PARTS

- 4.2. RADIATOR,OIL COOLER,AFTERCOOLER

- 4.3. POWER TRAIN

- 4.4. DRIVE SYSTEMS FOR COMPONENTS

- 4.5. FINAL DRIVE

- 4.6. TRACK FRAME AND RECOIL SPRING

- 4.7. IDLER

- 4.8. CARRIER ROLLER

- 4.9. TRACK ROLLER

- 4.10. TRACK SHOE

- 4.11. ARRANGEMENT OF HYDRAULIC EQUIPMENT

- 4.12. HYDRAULIC TANK AND HYDRAULIC OIL FILTER

- 4.13. HYDRAULIC PUMP

- 4.14. CONTROL VALVE

- 4.15. SELFREDUCING PRESSURE VALVE

- 4.16. CLSS

- 4.17. CRUSHER MOTOR

- 4.18. GRIZZLY FEEDER MOTOR

- 4.19. CONVEYOR MOTOR

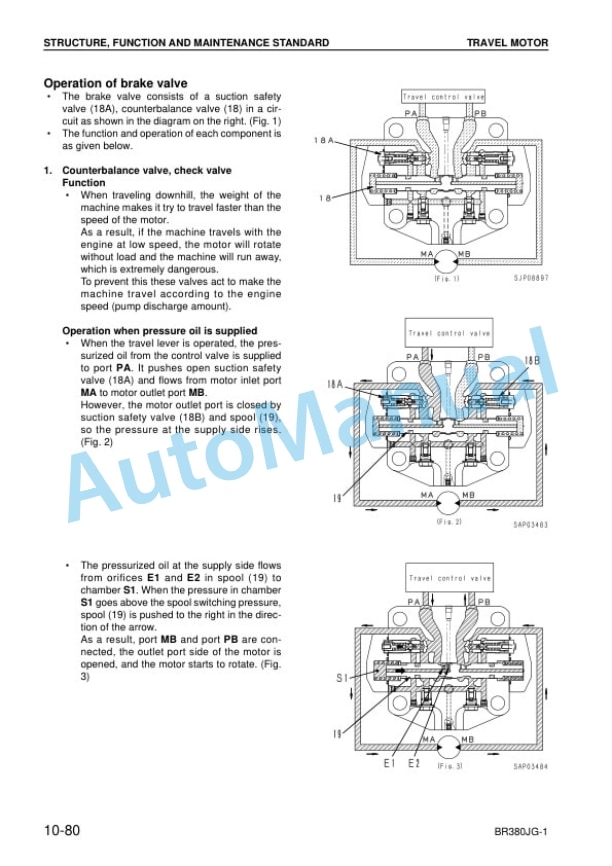

- 4.20. TRAVEL MOTOR

- 4.21. TRAVEL JUNCTION VALVE

- 4.22. VALVE CONTROL

- 4.23. TRAVEL PPC VALVE

- 4.24. SOLENOID VALVE

- 4.25. EPC VALVE

- 4.26. ELECTROMAGNETIC SELECTOR VALVE

- 4.27. GRIZZLY FEEDER SEMIAUTOMATIC SYSTEM

- 4.28. ABNORMAL LOAD STOP SYSTEM

- 4.29. PRIMARY BELT CONVEYOR

- 4.30. GRIZZLY FEEDER

- 4.31. CRUSHER

- 4.32. CRUSHER TOOTH TIP ADJUSTMENT SYSTEM

- 4.33. VIBRATOR

- 4.34. ENGINE CONTROL

- 4.35. ELECTRONIC CONTROL SYSTEM DEVICES

- 4.36. MULTI MONITOR SYSTEM

- 4.37. SENSOR

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TOOLS FOR TESTING,ADJUSTING AND TROUBLESHOOTING

- 5.3.2. INSPECTION AND ADJUSTMENT OF ENGINE RPM

- 5.3.3. MEASURING EXHAUST GAS COLOR

- 5.3.4. ADJUSTING VALVE CLEARANCE

- 5.3.5. MEASURING COMPRESSION PRESSURE

- 5.3.6. MEASURING BLOWBY PRESSURE

- 5.3.7. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 5.3.8. MEASUREMENT OF ENGINE OIL PRESSURE

- 5.3.9. ADJUSTMENT OF ENGINE SPEED SENSOR

- 5.3.10. DIODE INSPECTION PROCEDURE

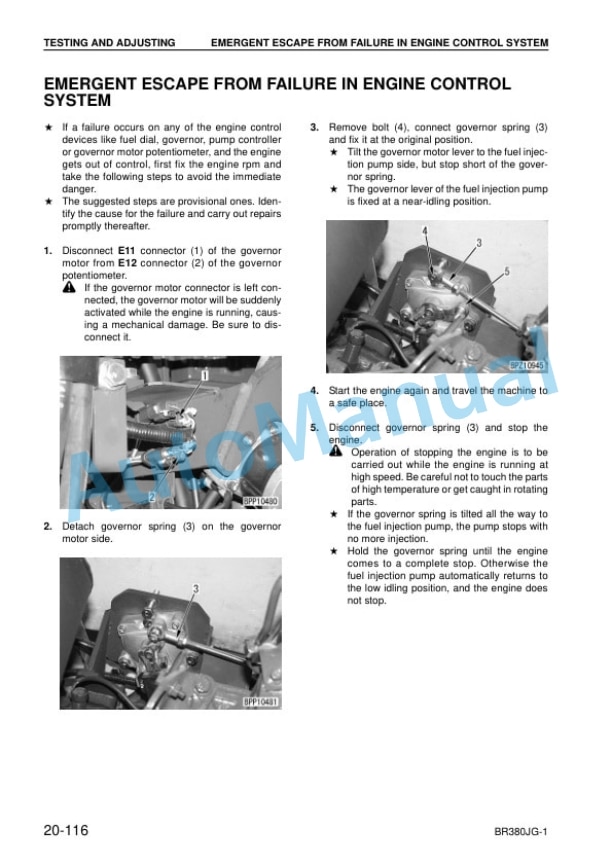

- 5.3.11. EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

- 5.3.12. TESTING AND ADJUSTING OIL PRESSURES IN WORK EQUIPMENT AND TRAVEL CIRCUITS

- 5.3.13. TESTING CONTROL CIRCUIT OIL PRESSURE (OIL PRESSURE REDUCED BY SELFPRESSURE)

- 5.3.14. TESTING AND ADJUSTING PUMP PC CONTROL CIRCUIT OIL PRESSURE

- 5.3.15. TESTING AND SDJUSTING PUMP LS CONTROL CIRCUIT OIL PRESSURE

- 5.3.16. MEASURING SOLENOID VALVE OUTPUT PRESSURE

- 5.3.17. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.3.18. MEASURING OIL LEAKAGE

- 5.3.19. BLEEDING AIR FROM EACH PART

- 5.3.20. TESTING TRAVEL DEVIATION

- 5.3.21. INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

- 5.3.22. SPECIAL FUNCTIONS OF MONITOR PANEL

- 5.3.23. TESTING AND ADJUSTING JAW CRUSHER

- 5.3.24. TESTING AND ADJUSTING CRUSHER DRIVE BELT TENSION

- 5.3.25. TESTING AND ADJUSTING PRIMARY BELT CONVEYOR

- 5.3.26. TESTING AND ADJUSTING MAGNETIC SEPARATOR

- 5.3.27. LIST OF COMPANIES WHICH HANDLES RADIO CONTROLLERS

- 5.3.28. PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL SYSTEM

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

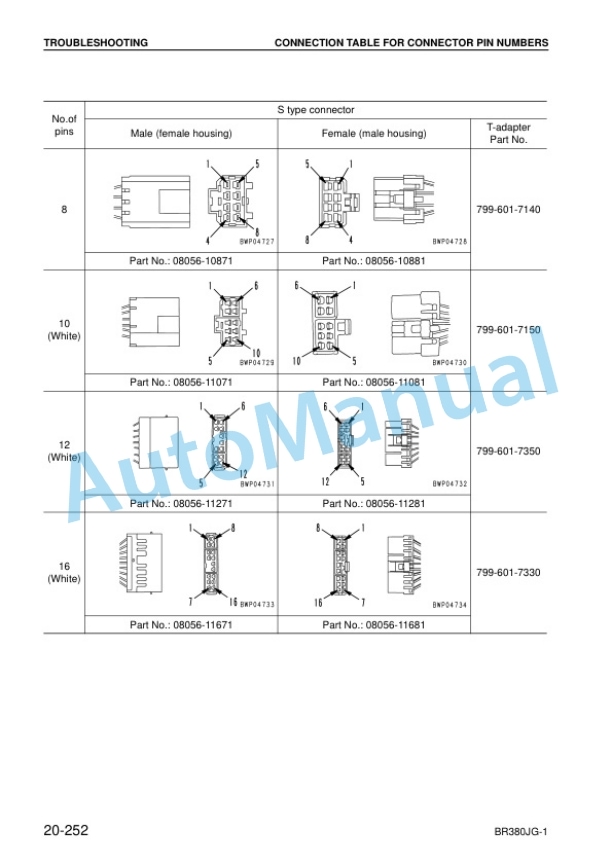

- 5.4.6. TYPES AND LOCATIONS OF CONNECTORS

- 5.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.8. TBRANCH BOX AND TBRANCH TABLE

- 5.4.9. TROUBLESHOOTING WHEN ERROR CODE ELECTRICAL SYSTEM AND FAILURE CODE MECHANICAL SYSTEM ARE INDICATED

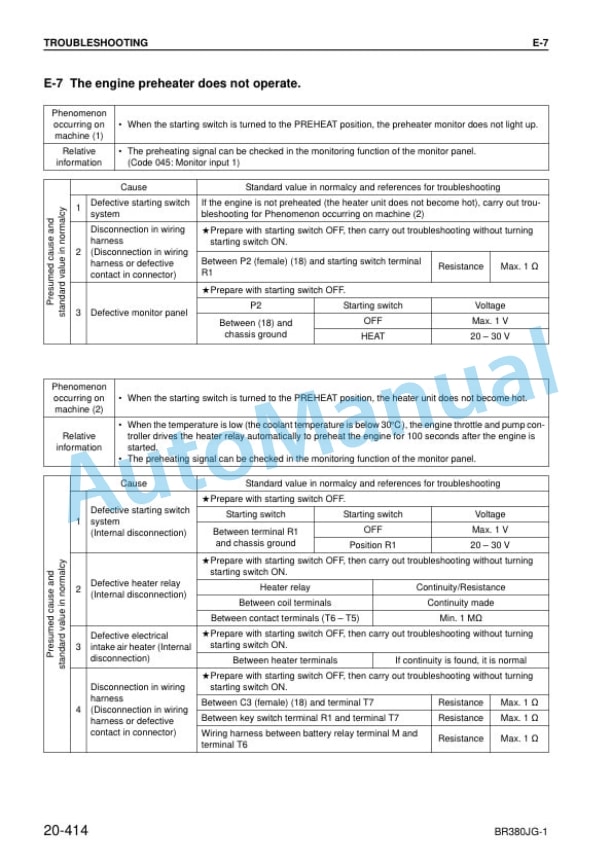

- 5.4.10. TROUBLESHOOTING FOR ELECTRICAL SYSTEM (EMODE)

- 5.4.11. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (HMODE)

- 5.4.12. TROUBLESHOOTING OF ENGINE (SMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. DISASSEMBLY AND ASSEMBLY OF CRUSHER

- 6.4. DISASSEMBLY AND ASSEMBLY OF LOCK CYLINDER

- 6.5. REMOVAL AND INSTALLATION OF PRIMARY CONVEYOR ASSEMBLY

- 6.6. REPLACEMENT OF BELT

- 6.7. REPLACEMENT PROCEDURE FOR PRIMARY BELT CONVEYOR MOTOR

- 6.8. REPLACEMENT PROCEDURE FOR PRIMARY BELT CONVEYOR HEAD PULLEY FRAME

- 6.9. PROCEDURE FOR FOLDING ENGINE FRONT COVER

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM (1/2)

- 7.2. HYDRAULIC CIRCUIT DIAGRAM (2/2)

- 7.3. ELECTRICAL CIRCUIT DIAGRAM (1/3)

- 7.4. ELECTRICAL CIRCUIT DIAGRAM (2/3)

- 7.5. ELECTRICAL CIRCUIT DIAGRAM (3/3)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00