Komatsu CD110R-2 Crawler Carrier Shop Manual SEBM030004

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM030004

- Format: PDF

- Size: 18.7MB

- Number of Pages: 416

Category: Komatsu Shop Manual PDF

-

Model List:

- CD110R-2 Crawler Carrier

- 1. COVER

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. SAFETY

- 4.1. SAFETY NOTICE

- 5. FOREWORD

- 5.1. GENERAL

- 5.2. HOW TO READ THE SHOP MANUAL

- 5.3. HOISTING INSTRUCTIONS

- 5.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 5.5. COATING MATERIALS

- 5.6. STANDARD TIGHTENING TORQUE

- 5.7. ELECTRIC WIRE CODE

- 5.8. CONVERSION TABLE

- 5.9. UNITS

- 6. GENERAL

- 6.1. SPECIFICATION DRAWING

- 6.2. SPECIFICATIONS

- 6.3. WEIGHT TABLE

- 6.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 7. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 7.1. DAMPER

- 7.2. COOLING SYSTEM

- 7.3. POWER TRAIN

- 7.4. SWING CIRCLE

- 7.5. SWING MACHINERY

- 7.6. TRACK FRAME

- 7.7. IDLER CUSHION

- 7.8. IDLER

- 7.9. TRACK ROLLER BOGIE

- 7.10. TRACK ROLLER

- 7.11. CARRIER ROLLER

- 7.12. SPROCKET

- 7.13. TRACK SHOE

- 7.14. HYDRAULIC COMPONENT LAYOUT

- 7.15. FLOW COMPENSATION VALVE

- 7.16. SOLENOID VALVE

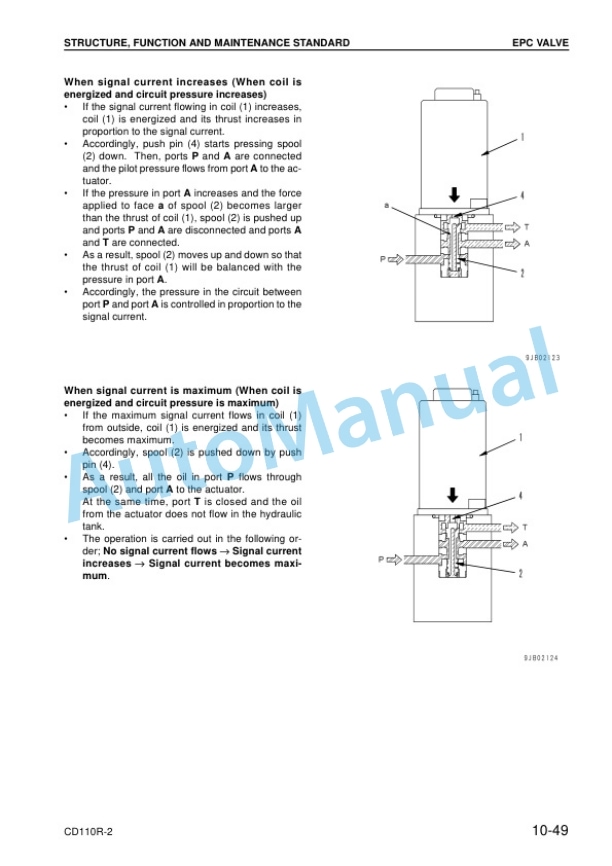

- 7.17. EPC VALVE

- 7.18. ACCUMULATOR

- 7.19. CENTER SWIVEL JOINT

- 7.20. DUMP CYLINDER

- 7.21. CONTROL VALVE

- 7.22. SWING MOTOR

- 7.23. SWING PPC VALVE

- 7.24. TRAVEL PPC VALVE

- 7.25. BODY PPC VALVE

- 7.26. WORK EQUIPMENT

- 7.27. AIR CONDITIONER PIPING

- 7.28. ELECTRIC CONTROL SYSTEM

- 7.29. SYSTEM COMPONENTS

- 7.30. MONITOR SYSTEM

- 7.31. SENSORS

- 8. TESTING AND ADJUSTING

- 8.1. STANDARD VALUE TABLE FOR ENGINE

- 8.2. STANDARD VALUE TABLE FOR CHASSIS

- 8.3. TESTING AND ADJUSTING

- 8.3.1. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 8.3.2. TESTING ENGINE SPEED

- 8.3.3. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 8.3.4. MEASURING EXHAUST GAS COLOR

- 8.3.5. ADJUSTING VALVE CLEARANCE

- 8.3.6. MEASURING COMPRESSION PRESSURE

- 8.3.7. MEASURING BLOWBY PRESSURE

- 8.3.8. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 8.3.9. MEASURING ENGINE OIL PRESSURE

- 8.3.10. ADJUSTING ENGINE STOP SOLENOID

- 8.3.11. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 8.3.12. ADJUSTMENT OF ENGINE SPEED SENSOR

- 8.3.13. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 8.3.14. EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

- 8.3.15. BLEEDING AIR FROM FUEL CIRCUIT

- 8.3.16. MEASURING CLEARANCE OF SWING CIRCLE BEARING

- 8.3.17. TESTING AND ADJUSTING TRACK SHOE TENSION

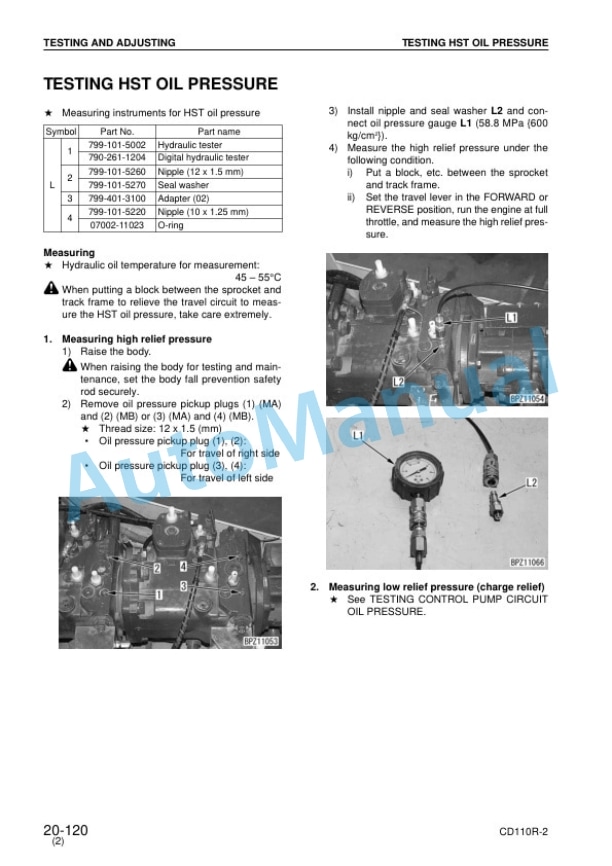

- 8.3.18. TESTING HST OIL PRESSURE

- 8.3.19. TESTING AND ADJUSTING WORK EQUIPMENT AND SWING CIRCUIT PRESSURE

- 8.3.20. TESTING CONTROL PUMP CIRCUIT PRESSURE

- 8.3.21. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 8.3.22. ADJUSTING SWING PPC VALVE

- 8.3.23. TESTING TRAVEL DEVIATION

- 8.3.24. MEASURING OIL LEAKAGE

- 8.3.25. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 8.3.26. BLEEDING AIR FROM EACH PART

- 8.4. TROUBLESHOOTING

- 8.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 8.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 8.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 8.4.4. CHECKS BEFORE TROUBLESHOOTING

- 8.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

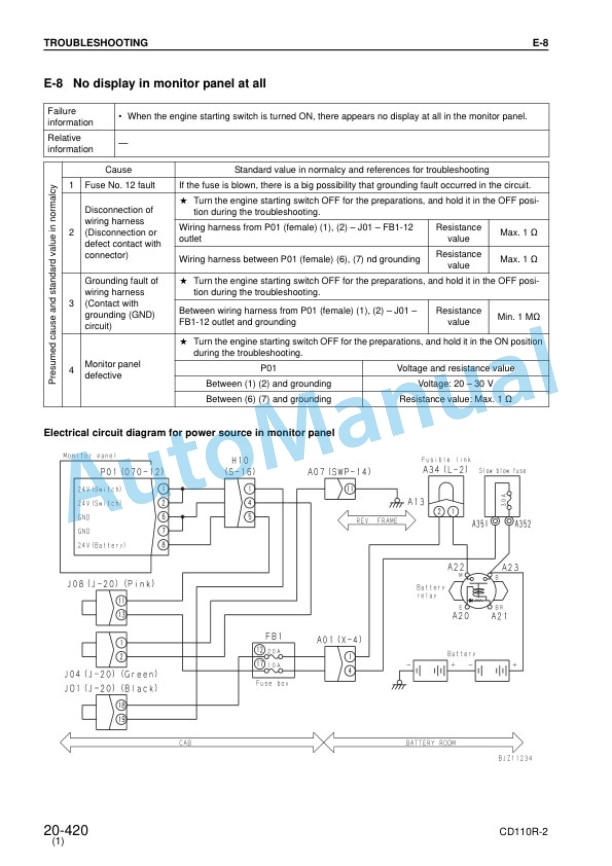

- 8.4.6. CONNECTOR ARRANGEMENT AND ELECTRIC CIRCUIT DIAGRAM OF EACH SYSTEM

- 8.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 8.4.8. TADAPTERBOXES AND TADAPTER TABLE

- 8.4.9. EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

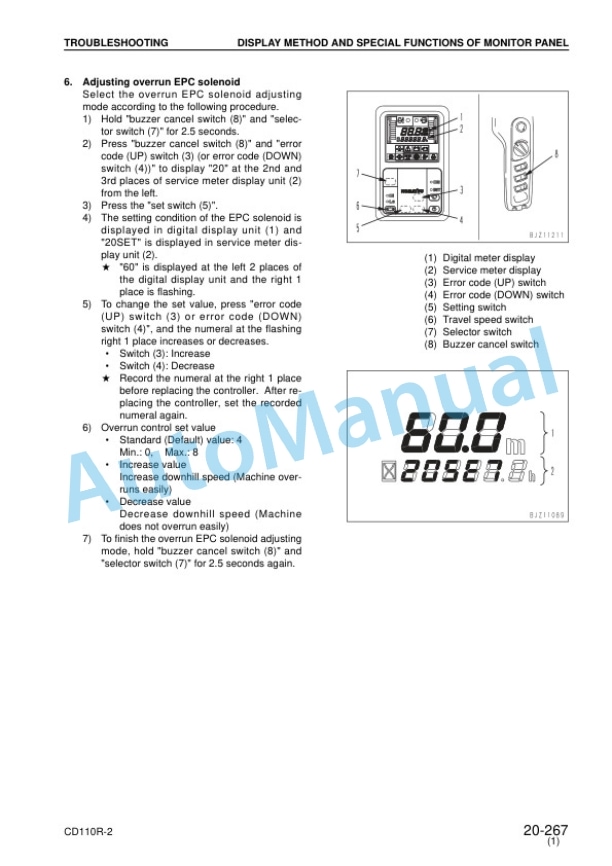

- 8.4.10. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 8.4.11. TROUBLESHOOTING WHEN ERROR CODE ELECTRICAL SYSTEM IS INDICATED

- 8.4.12. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 8.4.13. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (HMODE)

- 8.4.14. TROUBLESHOOTING OF ENGINE (S MODE)

- 9. OTHERS

- 9.1. HYDRAULIC CIRCUIT DIAGRAM

- 9.2. ELECTRICAL CIRCUIT DIAGRAM (1/4)

- 9.3. ELECTRICAL CIRCUIT DIAGRAM (2/4)

- 9.4. ELECTRICAL CIRCUIT DIAGRAM (3/4)

- 9.5. ELECTRICAL CIRCUIT DIAGRAM (4/4)

Rate this product

You may also like