Komatsu CK30-1 Compact Track Loader Shop Manual CEBM017100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM017100

- Format: PDF

- Size: 13.3MB

- Number of Pages: 302

Category: Komatsu Shop Manual PDF

-

Model List:

- CK30-1 Compact Track Loader

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. STANDARD TIGHTENING TORQUE

- 0.4. COATING MATERIALS

- 0.5. ELECTRIC

- 0.6. WEIGHT TABLE

- 0.7. TABLE OF OIL AND COOLANT QUANTITIES

- 0.8. METHOD OF USING THE CONVERSION TABLE

- 1. STRUCTURE AND FUNCTION

- 1.2. POWER TRAIN

- 1.3. FRAME

- 1.4. TRACK TENSIONER IDLER WHEEL

- 1.5. TRACK TENSIONER CYLINDER AND BUMPER SPRING

- 1.6. LOWER IDLER ROLLER

- 1.7. REAR IDLER ROLLER

- 1.8. HYDRAULIC CIRCUIT (STANDARD)

- 1.9. HYDRAULIC CIRCUIT (FLOAT)

- 1.10. HYDRAULIC CIRCUIT (FLOAT PATTERN CHANGE)

- 1.11. HYDRAULIC CIRCUIT (HIGHFLOW)

- 1.12. HYDRAULIC CIRCUIT (SUPER HIGHFLOW)

- 1.13. HYDRAULIC CIRCUIT (SUPER HIGHFLOW / PATTERN CHANGE)

- 1.14. HYDRAULIC PUMP

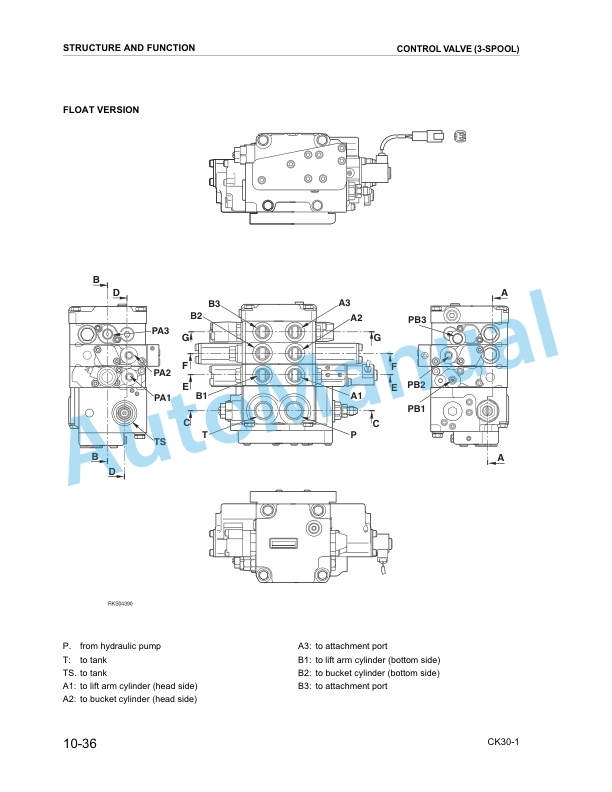

- 1.15. CONTROL VALVE (3SPOOL)

- 1.16. CONTROL VALVE (4SPOOL)

- 1.17. CLSS

- 1.18. SOLENOID VALVE

- 1.19. ACCUMULATOR

- 1.20. PATTERN CHANGE VALVE (OPTIONAL)

- 1.21. OPERATION

- 1.22. PPC VALVE (STANDARD)

- 1.23. PPC VALVE (PATTERN CHANGE) (OPTIONAL)

- 1.24. PPC VALVE (STANDARD)

- 1.25. PPC VALVE PATTERN CHANGE (OPTIONAL)

- 1.26. EQUIPMENT CONTROL PPC VALVE

- 1.27. CYLINDERS

- 1.28. ELECTRICAL DIAGRAM (ENGINE LINE) (1/3)

- 1.29. ELECTRICAL DIAGRAM (ENGINE LINE) (2/3)

- 1.30. ELECTRICAL DIAGRAM (ENGINE LINE) (3/3)

- 1.31. ELECTRICAL DIAGRAM (FRAME LINE STANDARD) (1/3)

- 1.32. ELECTRICAL DIAGRAM (FRAME LINE STANDARD) (2/3)

- 1.33. ELECTRICAL DIAGRAM (FRAME LINE STANDARD) (3/3)

- 1.34. ELECTRICAL DIAGRAM (FRAME LINE OPTIONAL) (1/3)

- 1.35. ELECTRICAL DIAGRAM (FRAME LINE OPTIONAL) (2/3)

- 1.36. ELECTRICAL DIAGRAM (FRAME LINE OPTIONAL) (3/3)

- 1.37. ELECTRICAL DIAGRAM (CABIN LINE STANDARD) (1/5)

- 1.38. ELECTRICAL DIAGRAM (CABIN LINE STANDARD) (2/5)

- 1.39. ELECTRICAL DIAGRAM (CABIN LINE STANDARD) (3/5)

- 1.40. ELECTRICAL DIAGRAM (CABIN LINE STANDARD) (4/5)

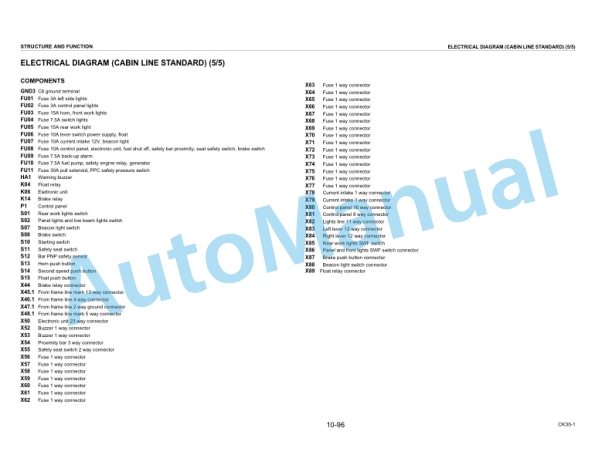

- 1.41. ELECTRICAL DIAGRAM (CABIN LINE STANDARD) (5/5)

- 1.42. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (1/7)

- 1.43. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (2/7)

- 1.44. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (3/7)

- 1.45. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (4/7)

- 1.46. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (5/7)

- 1.47. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (6/7)

- 1.48. ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL) (7/7)

- 1.49. ELECTRICAL DIAGRAM (TOPCABIN LIGHT LINE STANDARD) (1/2)

- 1.50. ELECTRICAL DIAGRAM (TOPCABIN LIGHT LINE STANDARD) (2/2)

- 1.51. ELECTRICAL DIAGRAM (TOPCABIN LIGHT LINE HOMOLOGATION) (1/2)

- 1.52. ELECTRICAL DIAGRAM (TOPCABIN LIGHT LINE HOMOLOGATION) (2/2)

- 2. TESTING AND ADJUSTMENTS

- 2.1. NORMAL OR STANDARD TECHNICAL DATA

- 2.2. SPECIAL TOOLS

- 2.3. CHECKING THE ENGINE SPEED

- 2.4. ADJUSTMENT OF VALVE CLEARANCE

- 2.5. MEASUREMENT OF THE COMPRESSION PRESSURE

- 2.6. CONTROL AND ADJUSTMENT OF THE FAN BELT TENSION

- 2.7. CONTROL AND ADJUSTMENT OF THE INJECTION TIMING

- 2.8. CHECKING ENGINE OIL PRESSURE

- 2.9. ADJUSTING THE STROKE OF THE ACCELERATOR CABLES

- 2.10. REGULATION OF PPC VALVES DRIVE PRESSURE

- 2.11. ADJUSTMENT OF THE PPC VALVE CLEARANCES

- 2.12. ADJUSTING THE POSITION OF THE SERVOCONTROL ENGAGEMENT SAFETY SENSOR

- 2.13. CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS

- 2.14. TESTING THE HYDRAULIC PUMP

- 2.15. VALVE CALIBRATION

- 2.16. CONTROL VALVE

- 2.17. CONTROL AND REGULATION OF THE SERVOCONTROLPOWER SUPPLY

- 2.18. ELIMINATION OF RESIDUAL PRESSURES PRESSURISATION OF THE TANK

- 2.19. BLEEDING AIR FROM THE HYDRAULIC CIRCUITS

- 2.20. TRACK TENSION TEST AND ADJUSTMENT

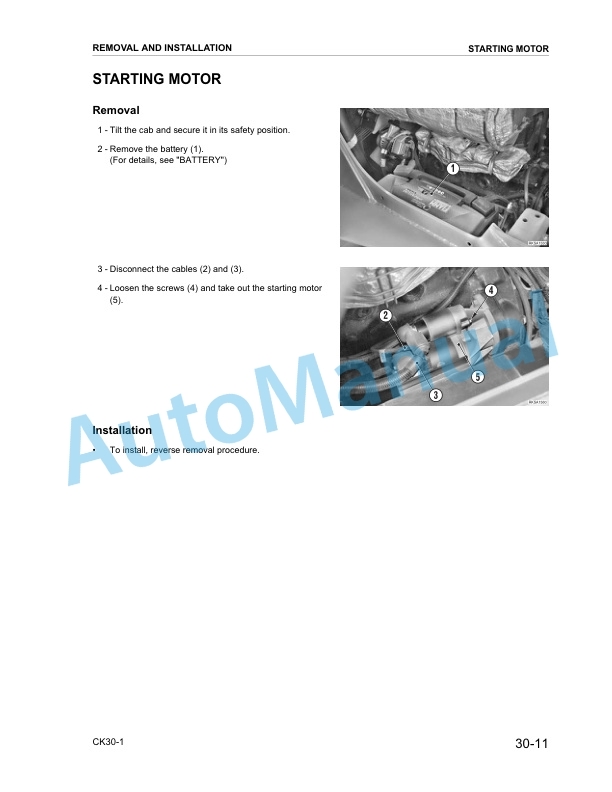

- 3. REMOVAL AND INSTALLATION

- 3.1. HOW TO READ THE MANUAL

- 3.2. PRECAUTIONS TO BE TAKEN WHILE WORKING

- 3.3. AIR INTAKE FILTER

- 3.4. COOLANT LIQUID PUMP

- 3.5. ENGINEPUMP GROUP

- 3.5.1. Removal

- 3.5.2. Installation

- 3.6. COMPLETE HYDRAULIC PUMP

- 3.7. ENGINEPUMP COUPLING

- 3.8. HEATING SYSTEM BLOWER FAN

- 3.9. BUCKET CYLINDER

- 3.9.1. Removal

- 3.9.2. Installation

- 3.10. WORK EQUIPMENT CYLINDERS

- 3.10.1. Disassembly

- 3.10.2. Assembly

- 3.11. COMPLETE WORKING EQUIPMENT

- 3.11.1. Removal

- 3.11.2. Installation

- 3.12. WORKING EQUIPMENT SUPPORT FRAME

- 3.13. LOWER IDLER ROLLER

- 3.14. TRACK TENSIONER CYLINDER

- 4. STANDARD MAINTENANCE

- 4.2. FRAME AND BUMPER SPRING

- 4.3. TRACK TENSIONER IDLER WHEEL

- 4.4. DRIVE WHEEL

- 4.5. LOWER IDLER ROLLERS

- 4.6. REAR IDLER WHEEL

- 4.7. HYDRAULIC PUMP

- 4.8. CONTROL VALVE

- 4.9. PPC VALVE

- 4.10. PPC VALVE

- 4.11. PATTERN CHANGE VALVE (OPTIONAL)

- 4.12. CYLINDERS

- 4.13. WORKING EQUIPMENT

- 5. OTHER

- 5.1. ELECTRICAL DIAGRAM (STANDARD)

- 5.2. ELECTRICAL DIAGRAM (OPTIONAL)

Rate this product

You may also like