Komatsu CX50 Forklift Truck Service Manual SM203

$30.00

- Type Of Manual: Service Manual

- Manual ID: SM203

- Format: PDF

- Size: 39.9MB

- Number of Pages: 680

Category: Komatsu Service Manual PDF

-

Model List:

- CX50 Forklift Truck

- 1. Foreword and general information

- 1.1. Safety notice

- 1.2. How to read the shop manual

- 1.3. Explanation of terms for maintenance standard

- 1.4. Handling of electric equipment and hydraulic components

- 1.5. Handling of new types of connectors used on engines

- 1.6. How to read electric wire code

- 1.7. Precautions when carrying out operation

- 1.8. Standard tightening torque tables

- 1.9. Conversion tables

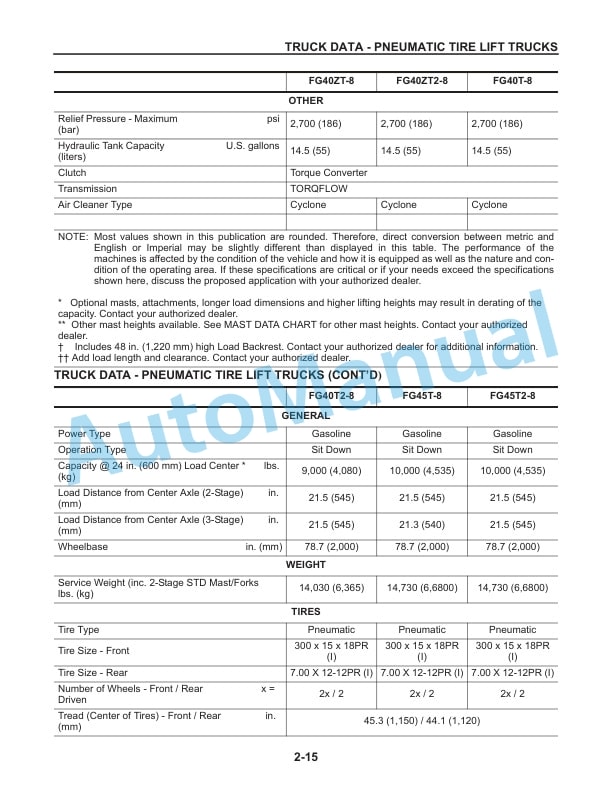

- 2. Specifications

- 2.1. Dimensional diagram

- 2.2. Diesel engine lift truck with SAA4D95LE5A engine (UL spec)

- 2.3. Gasoline engine lift truck with EBTTB452A/3A (UL spec)

- 2.4. Weight table

- 2.5. Lubricants

- 3. Structure, function and maintenance standard

- 3.1. Engine and cooling system

- 3.2. Power train

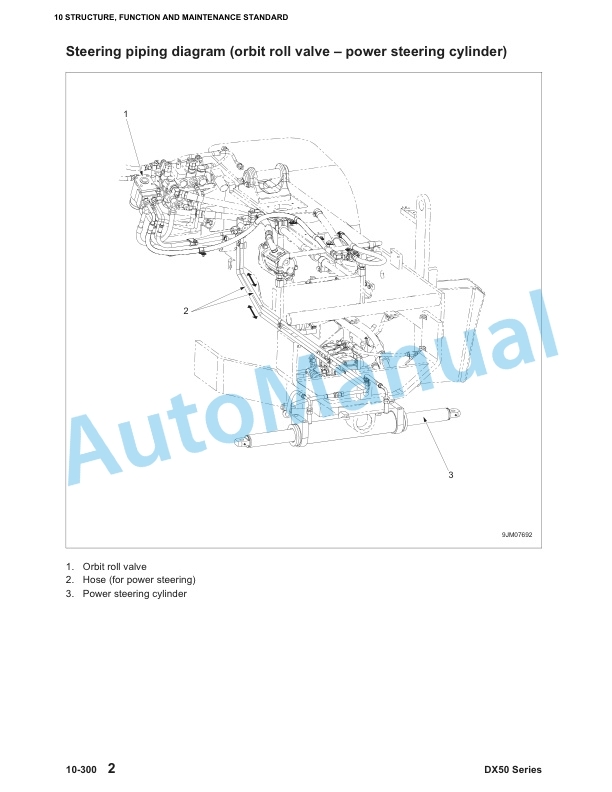

- 3.3. Steering system

- 3.4. Brake system

- 3.5. Undercarriage and frame

- 3.6. Hydraulic system

- 3.7. Work equipment

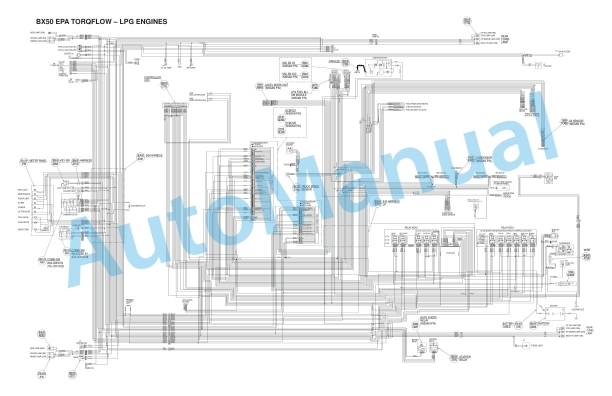

- 3.8. Electric devices Part 1

- 3.9. Electric devices Part 2

- 4. Standard value table

- 4.1. Lift truck with SAA4D95LE5A engine (UL spec)

- 4.2. Lift truck with EBTTB452A/3A engine (UL spec)

- 5. Testing and adjusting

- 5.1. Check of troubleshooting software functions and failure codes

- 5.2. Hydraulic piping pressure release procedure

- 5.3. Replacement of engine oil and engine oil filter

- 5.4. Replacement of fuel filter

- 5.5. Cleaning of radiator

- 5.6. Check of air cleaner and replacement of cleaner element

- 5.7. Oil level check and oil replacement of differential case

- 5.8. Oil replacement and strainer cleaning of Torqflow transmission

- 5.9. Testing power train oil pressure

- 5.10. Check of hydraulic tank

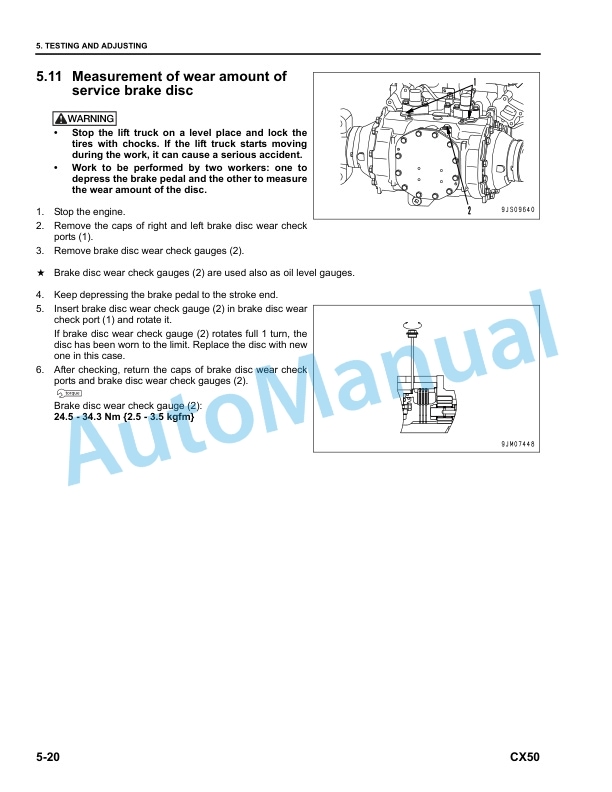

- 5.11. Measurement of wear amount of service brake disc

- 5.12. Check of parking brake

- 5.13. Air bleeding procedure

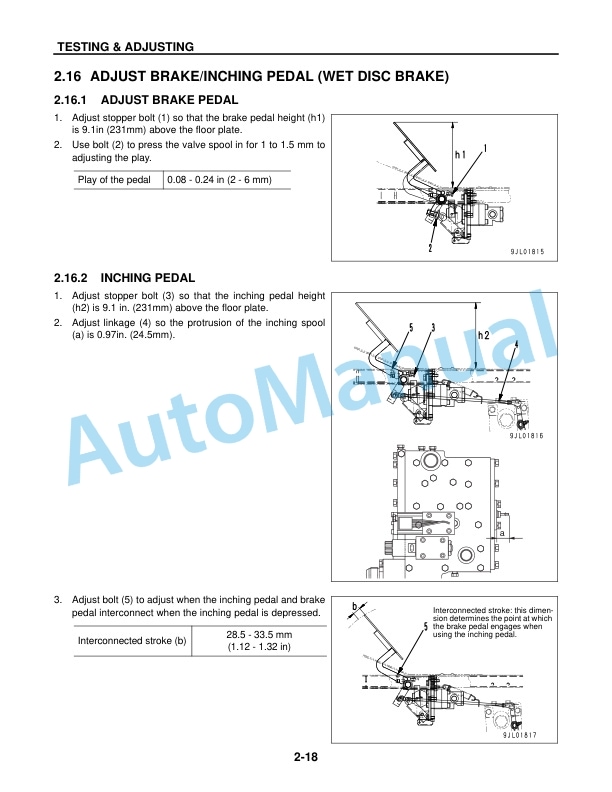

- 5.14. Adjustment of brake pedal

- 5.15. Adjustment of inching pedal

- 5.16. Measurement of cylinder hydraulic drift and hydraulic forward drift

- 5.17. Adjustment of mast Japan manufacture

- 5.18. Adjustment of fork carriage Japan manufacture

- 5.19. Check of drive shaft for looseness, play and damage

- 5.20. Check of diode

- 6. Troubleshooting

- 6.1. General information on troubleshooting

- 6.2. Failure codes ISO controller (UL spec)

- 6.3. Electrical system (Emode) SAA4D95LE5A engine (UL spec)

- 6.4. Electrical system (Emode) EBTTB452A/3A engine (UL spec)

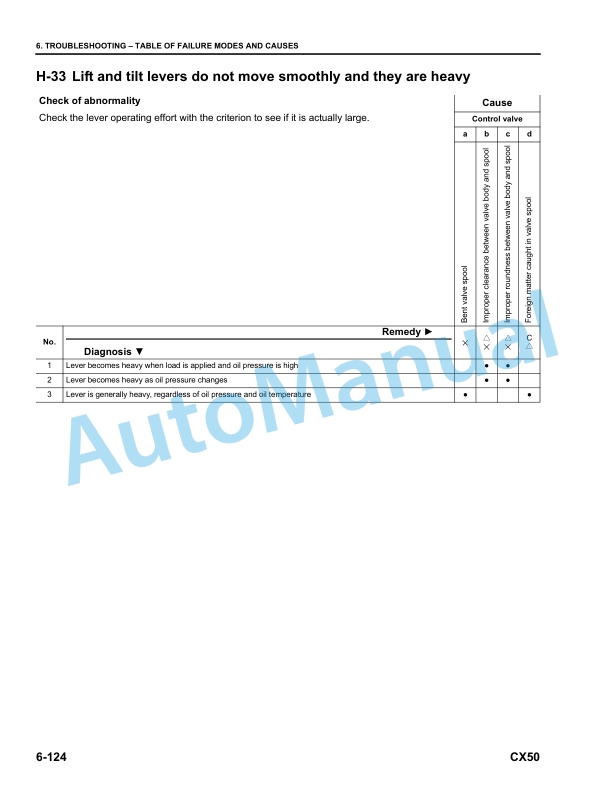

- 6.5. Hydraulic and mechanical system (Hmode)

- 7. Disassembly and assembly

- 7.1. General information

- 7.2. Engine and cooling system

- 7.3. Power train components

- 7.4. Hydraulic equipment

- 7.5. Work equipment

- 7.6. Electric devices

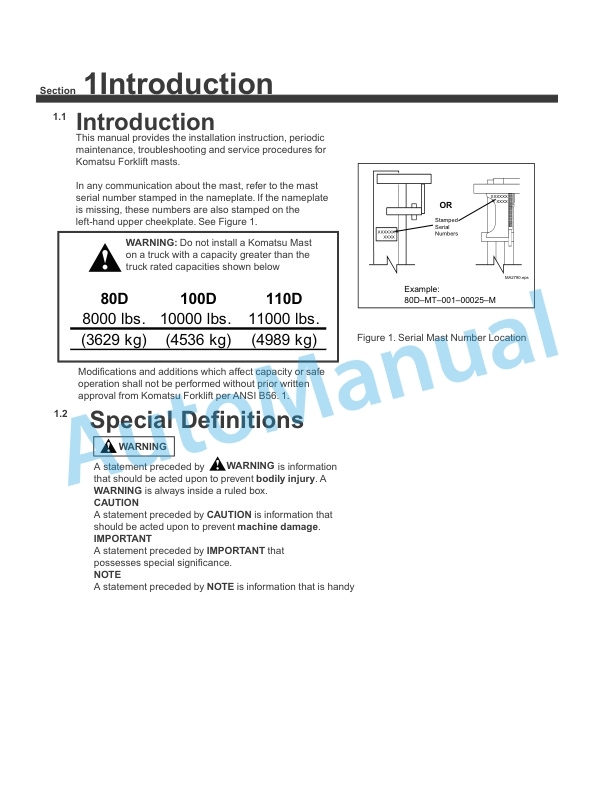

- 8. manufactured masts

- 8.1. MS 2Stage Masts

- 8.2. MT 3Stage Masts

- 8.3. DSeries Sideshifter

- 8.4. ESeries Sideshifter

- 9. Yearly inspection criteria

- 10. Diagrams and drawings

- 10.1. Hydraulic circuit

- 10.2. Electrical circuit UL spec

Rate this product

You may also like

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu FB10M-2, FB13M-2, FB15M-2, FB18M-2 Forklift Truck Service Manual SM018

$30.00

Komatsu Service Manual PDF

Komatsu ASX Stand-up Counterbalanced Electric Forklift Truck Service Manual SM401

$30.00

Komatsu Service Manual PDF

Komatsu FR18S-2A, FR23S-2A, FR15DR-2A Forklift Truck Service Manual

$30.00