Komatsu D150A-1, D155A-1 Shop Manual SEBM0170A07R

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM0170A07R

- Format: PDF

- Size: 165.8MB

- Number of Pages: 1110

Category: Komatsu Shop Manual PDF

-

Model List:

- D150A-1

- D155A-1

- 2. Contents

- 3. Safety

- 3.1. How to read the shop manual

- 3.2. Hoisting instructions

- 3.3. Standard tightening torque

- 4. General

- 4.1. Specifications

- 4.2. General assembly drawing

- 4.3. Engine specifications

- 4.4. Weight table

- 4.5. Position of serial numbers (Engine)

- 4.6. Position of serial numbers (body)

- 4.7. Table of oil and coolant

- 5. Engine structure and function

- 6. Engine Testing and adjusting

- 6.1. Tool list

- 6.2. Trouble shooting criteria

- 6.3. General instructions

- 6.4. Intake ans exhaust system

- 6.5. Engine body

- 6.6. Lubrication system

- 6.7. Fuel system

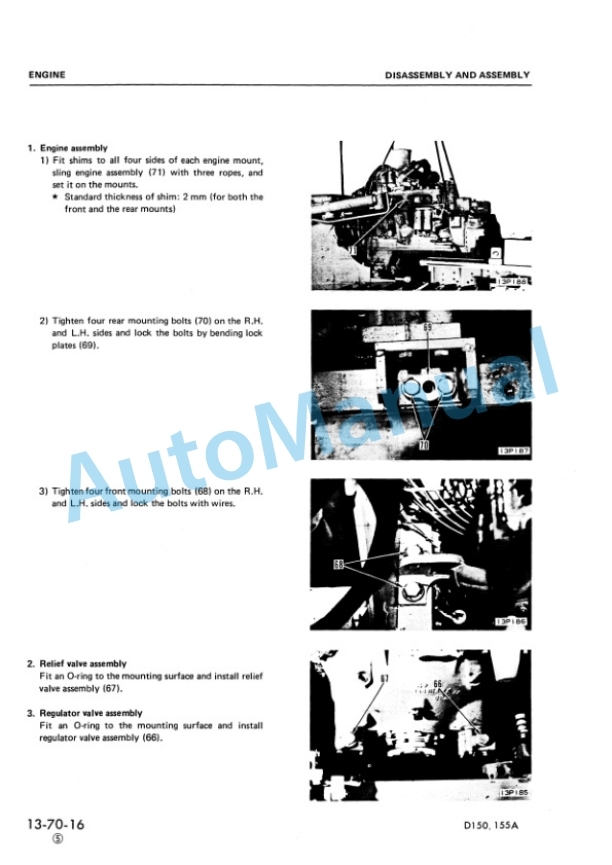

- 7. Engine disassembly and assembly

- 7.1. Dismounting turbocharger

- 7.2. mounting turbocharger

- 7.3. Dismounting engine oil cooler

- 7.4. Mounting engine oil cooler

- 7.5. torque convertor oil cooler

- 7.6. Nozzle holder

- 7.7. Fuel injection pump

- 8. Power traing Structure and functions

- 8.1. General

- 8.2. Main clutch

- 8.3. Inertia brake

- 8.4. Transmisssion D150A

- 8.5. Double mesh preventive device

- 8.6. Torque convertor

- 8.7. Transmission D155A

- 8.8. Torqflow

- 8.9. Transmission lubrication relief vanlve

- 8.10. Transmission control valve

- 8.11. Transmission pump

- 8.12. Bevel gear shaft and steering clutch

- 8.13. Steering and brake piping

- 8.14. steering hydraulic system

- 8.15. Brake hydraulic system

- 8.16. Steering brake and booster D150A AND D155A

- 8.16.1. Steering control valve

- 8.16.2. Steering and brake piping

- 8.16.3. Steering and brake hydraulic circuit

- 8.17. Steering brake and booster D155A 25001

- 8.18. Steering control valve d155a 25001

- 8.19. Steering pump

- 8.20. Final drive

- 9. power train testing and adjusting

- 9.1. Main clutch hydraulic control

- 9.2. Torqflow hydraulic control

- 9.3. Steering hydraulic control

- 9.4. Brake hydraulic control

- 9.5. Table of oil pressure measuring points

- 9.6. Procedure for measuring oil pressure and temperature

- 9.7. Procedure for measurment of lever and pedal travel

- 9.8. Adjustment procedure for strokes

- 9.9. Adjusting main clutch

- 9.10. Table of maintenance standerds

- 10. Power train disassembly and assembly

- 10.1. pto and flywheel

- 10.2. Main clutch

- 10.3. Transmission assembly

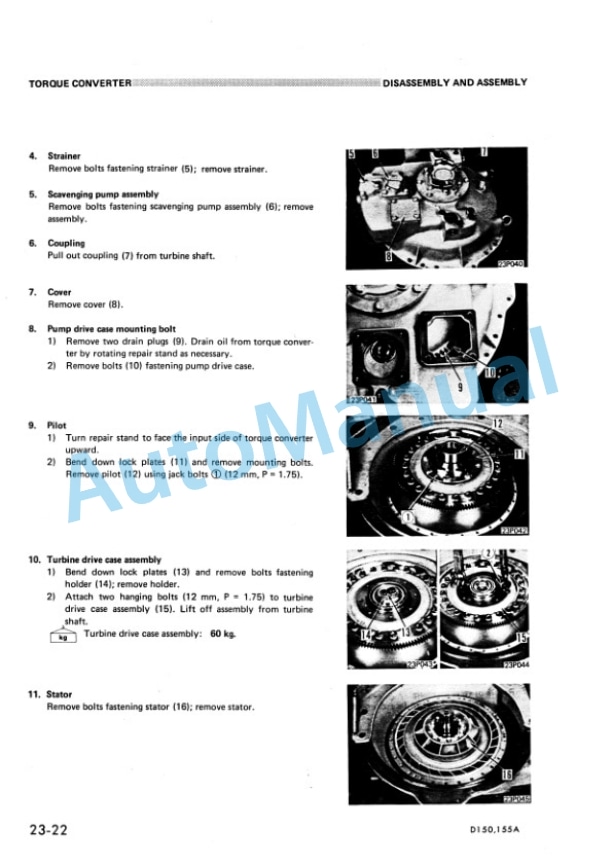

- 10.4. Torque convertor

- 10.5. Torque convertor relief valve

- 10.6. Torque converter regulator valve

- 10.7. Torqflow transmission D155 15001 25000

- 10.8. Torqflow transmission D155A Sn 25001

- 10.8.1. Mounting Torqflow transmission

- 10.8.2. Dismounting Transmission control valve

- 10.8.3. Mounting transmission control valve

- 10.8.4. Transmission lubrication valve

- 10.8.5. Steering clutch

- 10.9. Bevel gear and bevel gear shaft

- 10.10. Final drive

- 10.11. Steering control valve

- 10.12. Steering brake interlocking valve

- 10.13. Brake safety valve

- 10.14. Brake booster

- 10.15. Final drive

- 10.16. Torqflow pump

- 10.17. Steering pump

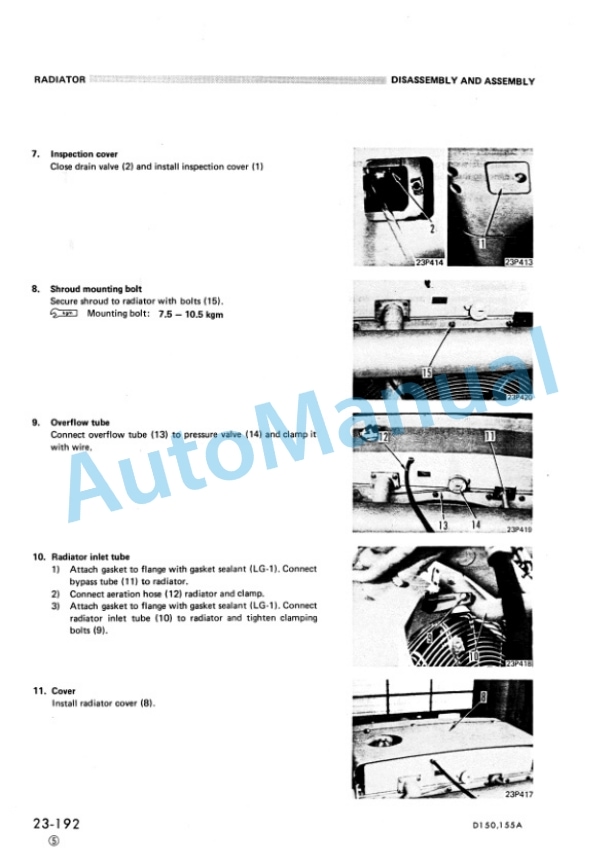

- 10.18. Torque converter oil cooler

- 11. Power Train Maintenance standard

- 11.1. Transmission

- 11.2. Bevel gear shaft and steering system

- 11.3. Final drive

- 12. Undercarriage Structure and function

- 12.1. Track

- 12.2. Track group

- 12.3. Recail spring

- 12.4. Idler

- 12.5. Track roller, carrier roller

- 12.6. Suspension

- 13. undercarriage Testing and adjusting

- 14. indercarriage Disassembly and assembly

- 15. Undercarriage maintenance standard

- 15.1. Undercarriage

- 16. Hydraulic system structure and function

- 16.1. Hydraulic control

- 16.2. Hydraulic tank

- 16.3. Hydraulic control valve

- 16.4. Ripper selector valve and pilot check valve

- 16.5. Pin puller valve

- 16.6. Pilot valve

- 16.7. Rotary servo valve

- 16.8. Servo valve hydralic control/valve

- 16.9. Safety valve

- 16.10. Cylinders

- 16.11. Piston valve

- 16.12. Hydraulic control

- 17. Hydraulic system testing and adjusting

- 17.1. General description

- 17.2. Hydraulic control

- 17.3. Pin puller control

- 17.4. Measurment of oil pressure and temperature

- 17.5. Measurment of operating force

- 17.6. Table of maintance standard

- 18. Hydraulic control sysyem Disassembly and assembly

- 18.1. Disassembly and assembly

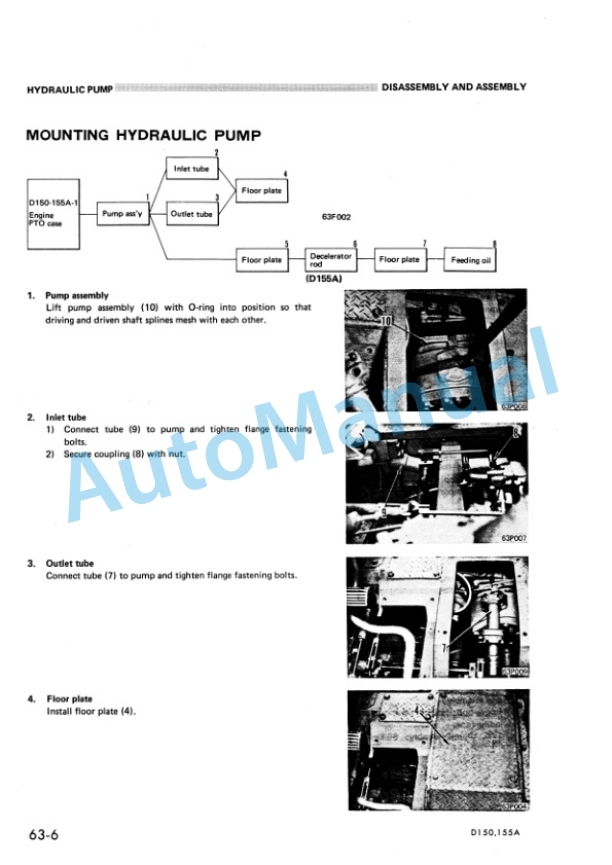

- 18.2. Hydraulic pump

- 18.3. Hydraulic tank

- 18.4. Ripper blade control valve

- 18.5. Blade tilt control valve

- 18.6. Blade tilt servo valve

- 18.7. Ripper servo valve

- 18.8. Ripper pin puller valve

- 18.9. Ripper selector valve

- 18.10. Blade lift cylinder

- 18.11. Blade tilt cylinder

- 18.12. Ripper lift Tilt cylinder

- 18.13. Ripper pin puller cylinder

- 19. Hydraulic system Maintance standard

- 19.1. Torque specifications for nuts and bolts

- 19.2. Hydraulic control valve

- 19.3. Cylinders

- 20. Work equipment structure and function

- 20.1. Multi ripper

- 20.2. Giant ripper

- 21. Work equipment testing and adjustment

- 21.1. Straight tilt dozer

- 22. work equipment disassembly assembly

- 22.1. Blade

- 22.2. Ripper

- 23. Work equipment Maintenance standard

- 23.1. Torque specifications

- 23.2. Straight tilt dozer

- 23.3. Multi ripper

- 23.4. Giant ripper

- 24. Others Electrical system

- 24.1. Electical circuit diagram

- 24.2. Electical wiring diagram

- 24.3. Warning module

- 24.4. Automatic priming system

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00