Komatsu D155A-2 Bull Dozer Shop Manual SEBM01750209

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM01750209

- Format: PDF

- Size: 28.6MB

- Number of Pages: 520

Category: Komatsu Shop Manual PDF

-

Model List:

- D155A-2 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. STRUCTURE AND FUNCTION

- 3.1. GENERAL

- 3.2. POWER TRAIN HYDRAULIC SYSTEM

- 3.3. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 3.4. TORQUE CONVERTER

- 3.5. TORQFLOW TRANSMISSION

- 3.6. TRANSMISSION CONTROL

- 3.7. TORQFLOW HYDRAULIC CIRCUIT DIAGRAM

- 3.8. TRANSMISSION CONTROL VALVE

- 3.9. TRANSMISSION LUBRICATION RELIEF VALVE

- 3.10. TRANSMISSION PUMP

- 3.11. TRANSMISSION AND STEERING OIL STRAINER

- 3.12. TRANSMISSION OIL FILTER

- 3.13. STEERING OIL FILTER

- 3.14. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 3.15. STEERING CONTROL

- 3.16. STEERING CONTROL (FOR ASSIST BRAKE)

- 3.17. STEERING AND BRAKE PIPING

- 3.18. STEERING AND BRAKE HYDRAULIC SYSTEM

- 3.19. STEERING AND BRAKE HYDRAULIC CIRCUIT DIAGRAM

- 3.20. STEERING PUMP

- 3.21. STEERING MAIN RELIEF VALVE

- 3.22. STEERING AND BRAKE CONTROL VALVE

- 3.23. STEERING BRAKE

- 3.24. SPRING ASSIST BRAKE SYSTEM

- 3.25. FINAL DRIVE

- 3.26. PTO (POWER TAKE OFF)

- 3.27. TRACK GROUP

- 3.28. IDLER CUSHION

- 3.29. IDLER

- 3.30. TRACK ROLLER AND CARRIER ROLLER

- 3.31. TRACK (LUBRICATED TRACK LINK)

- 3.32. TRACK (DRY TYPE TRACK LINK)

- 3.33. SUSPENSION

- 3.34. HYDRAULIC PIPING

- 3.35. HYDRAULIC CONTROL

- 3.36. HYDRAULIC SYSTEM

- 3.37. HYDRAULIC CIRCUIT DIAGRAM

- 3.38. HYDRAULIC TANK

- 3.39. HYDRAULIC PUMP

- 3.40. BLADE LIFT AND RIPPER CONTROL VALVE

- 3.41. BLADE TILT CONTROL VALVE

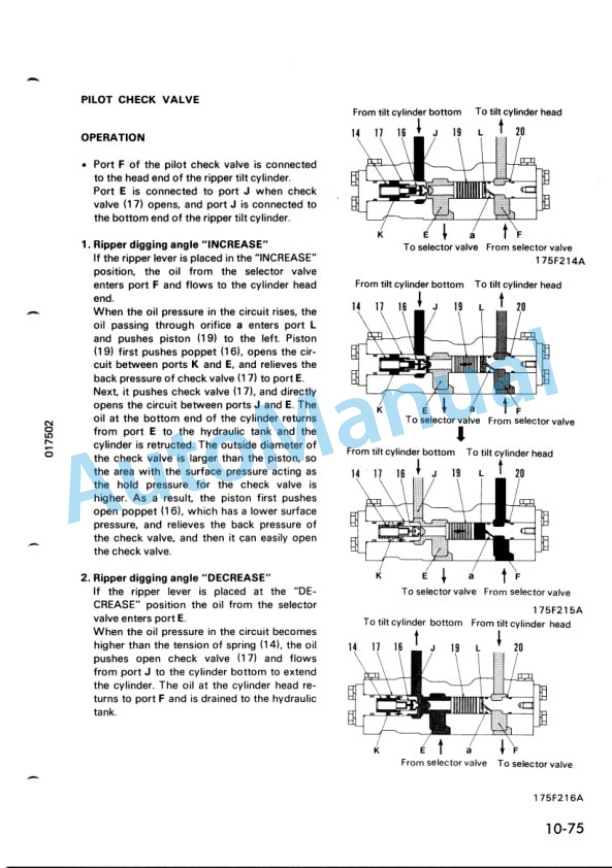

- 3.42. RIPPER SELECTOR VALVE AND PILOT CHECK VALVE

- 3.43. HYDRAULIC LEVER OPERATION

- 3.44. CYLINDER

- 3.45. CYLINDER STAY

- 3.46. WORK EQUIPMENT CONTROL HYDRAULIC SYSTEM

- 3.47. WORK EQUIPMENT CONTROL HYDRAULIC CIRCUIT DIAGRAM

- 3.48. PILOT SOLENOID VALVE

- 3.49. PINPULLER SOLENOID VALVE (FOR GIANT RIPPER)

- 3.50. PINPULLER CYLINDER (FOR GIANT RIPPER)

- 3.51. ROTARY SERVO VALVE

- 3.52. STRAIGHT TILT DOZER

- 3.53. VARIABLE MULTIPLE SHANK RIPPER

- 3.54. VARIABLE GIANT RIPPER

- 3.55. ELECTRICAL CIRCUIT DIAGRAM

- 3.56. EVMS (ELECTRONIC VEHICLE MONITORING SYSTEM)

- 3.57. APS (AUTO PRIMING SYSTEM)

- 3.58. AIR CONDITIONER

- 4. TESTING AND ADJUSTING

- 4.1. TABLE OF STANDARD VALUES FOR ENGINE

- 4.2. TABLE OF STANDARD VALUES FOR CHASSIS

- 4.3. TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE

- 4.4. TESTING AND ADJUSTING

- 4.4.1. TESTING AND ADJUSTING TOOL LIST

- 4.4.2. ADJUSTING VALVE CLEARANCE

- 4.4.3. MEASURING COMPRESSION PRESSURE

- 4.4.4. ADJUSTING FUEL INJECTION TIMING

- 4.4.5. MEASURING TORQUE CONVERTER STALL SPEED

- 4.4.6. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 4.4.7. MEASURING OIL PRESSURE

- 4.4.8. ADJUSTING FUEL CONTROL LINKAGE

- 4.4.9. ADJUSTING GEAR SHIFT LEVER LINKAGE

- 4.4.10. ADJUSTING STEERING CLUTCH LINKAGE

- 4.4.11. ADJUSTING TRAVEL OF BRAKE PEDAL

- 4.4.12. ADJUSTING BRAKE PEDAL LINKAGE

- 4.4.13. ADJUSTING SPRING ASSIST BRAKE

- 4.4.14. ADJUSTING BLADE CONTROL LINKAGE

- 4.4.15. ADJUSTING RIPPER CONTROL LINKAGE

- 4.5. HMODE TROUBLESHOOTING

- 4.5.1. PREPARATION FOR TROUBLESHOOTING

- 4.5.2. METHOD OF READING TROUBLESHOOTING TABLE

- 4.5.3. PREVENTING RECURRENCE OF THE SAME TROUBLE

- 4.5.4. TROUBLESHOOTING

- 4.6. MMODE TROUBLESHOOTING

- 4.6.1. CONNECTOR TYPE AND MOUNTING POSITION

- 4.6.2. POSITION OF CONNECTORS FOR TROUBLESHOOTING

- 4.6.3. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 4.6.4. PROCEDURE FOR TROUBLESHOOTING

- 4.6.5. CHECKS BEFORE TROUBLESHOOTING

- 4.6.6. METHOD OF USING TROUBLESHOOTING CHART

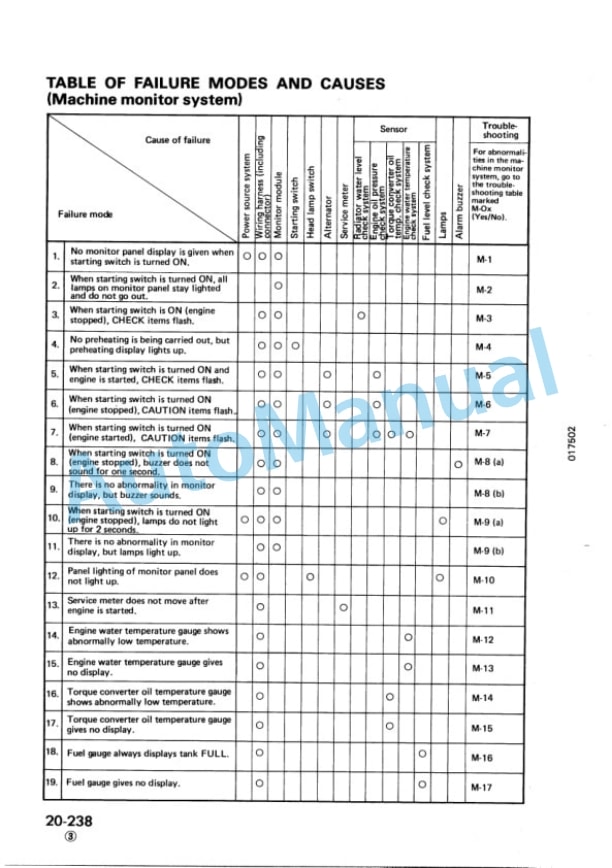

- 4.6.7. TABLE OF FAILURE MODES AND CAUSES (MACHINE MONITOR SYSTEM)

- 4.7. EMODE TROUBLESHOOTING FOR ELECTRICAL SYSTEM

- 4.7.1. TABLE OF FAILURE MODES AND CAUSES

- 4.7.2. APS SYSTEM

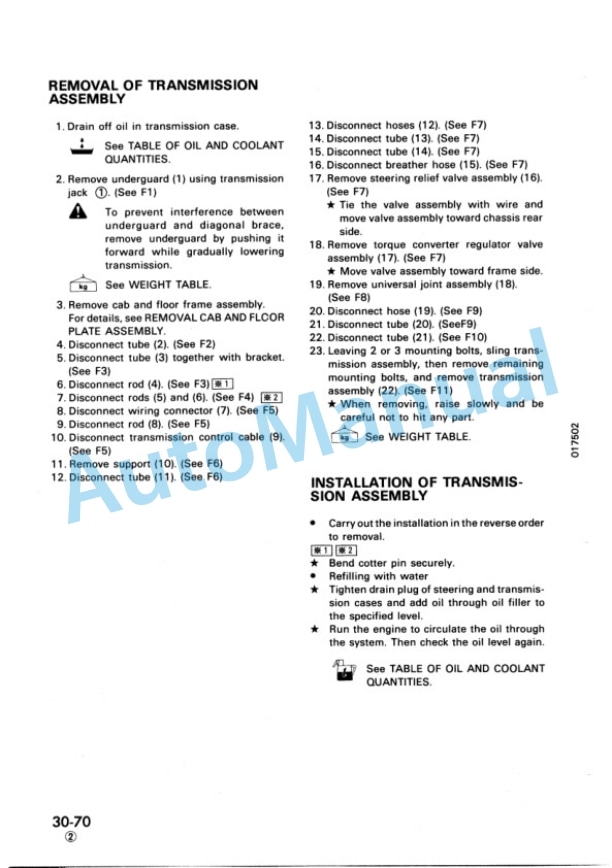

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. METHOD OF USING MANUAL

- 5.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 5.3. SPECIAL TOOL LIST

- 5.4. WEIGHT TABLE

- 5.5. TABLE OF TIGHTENING TORQUE AND STANDARD VALUE

- 5.6. TABLE OF OIL AND COOLANT QUANTITIES

- 5.7. FUEL INJECTION PUMP

- 5.8. ENGINE OIL COOLER

- 5.9. TORQUE CONVERTER OIL COOLER

- 5.10. TORQUE CONVERTER

- 5.10.1. REMOVAL

- 5.10.2. INSTALLATION

- 5.10.3. DISASSEMBLY

- 5.10.4. ASSEMBLY

- 5.11. TORQUE CONVERTER RELIEF VALVE

- 5.11.1. REMOVAL

- 5.11.2. INSTALLATION

- 5.11.3. DISASSEMBLY

- 5.11.4. ASSEMBLY

- 5.12. TORQUE CONVERTER REGULATOR VALVE

- 5.12.1. REMOVAL

- 5.12.2. INSTALLATION

- 5.12.3. DISASSEMBLY

- 5.12.4. ASSEMBLY

- 5.13. TRANSMISSION CONTROL VALVE

- 5.13.1. REMOVAL

- 5.13.2. INSTALLATION

- 5.13.3. DISASSEMBL

- 5.13.4. ASSEMBLY

- 5.14. TRANSMISSION LUBRICATION VALVE

- 5.14.1. REMOVAL

- 5.14.2. INSTALLATION

- 5.14.3. DISASSEMBLY

- 5.14.4. ASSEMBLY

- 5.15. BEVEL GEAR AND SHAFT

- 5.15.1. REMOVAL

- 5.15.2. INSTALLATION

- 5.16. STEERING CLUTCH

- 5.16.1. REMOVAL

- 5.16.2. INSTALLATION

- 5.16.3. DISASSEMBLY

- 5.16.4. ASSEMBLY

- 5.17. STEERING RELIEF VALVE

- 5.18. STEERING AND BRAKE VALVE

- 5.18.1. REMOVAL

- 5.18.2. INSTALLATION

- 5.18.3. DISASSEMBLY

- 5.18.4. ASSEMBLY

- 5.19. TRANSMISSION PUMP

- 5.20. ASSIST BRAKE CYLINDER

- 5.20.1. OVERALL DISASSEMBLY

- 5.20.2. OVERALL ASSEMBLY

- 5.20.3. PRESSFITTING JIG DIMENSION TABLE FOR LINK PRESS

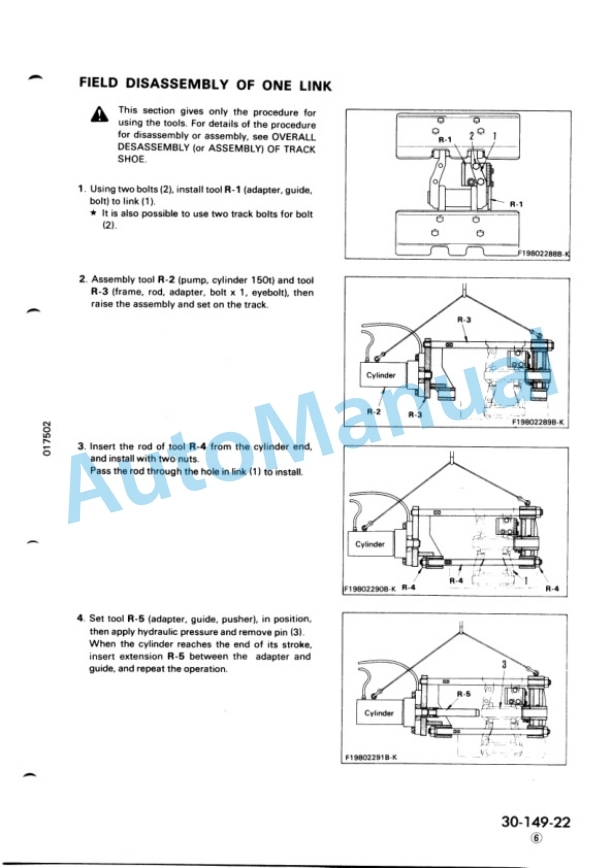

- 5.20.4. FIELD DISASSEMBLY OF ONE LINK

- 5.20.5. FIELD ASSEMBLY OF ONE LINK

- 5.20.6. DISASSEMBLY OF MASTER LINK

- 5.20.7. ASSEMBLY OF MASTER LINK

- 5.21. HYDRAULIC PUMP

- 5.21.1. REMOVAL

- 5.21.2. INSTALLATION

- 5.22. BLADE AND RIPPER CONTROL VALVE

- 5.22.1. REMOVAL

- 5.22.2. INSTALLATION

- 5.22.3. DISASSEMBLY

- 5.22.4. ASSEMBLY

- 5.23. BLADE TILT CONTROL VALVE

- 5.23.1. DISASSEMBLY

- 5.23.2. ASSEMBLY

- 5.24. SERVO VALVE ASSEMBLY FOR BLADE LIFT

- 5.24.1. REMOVAL

- 5.24.2. INSTALLATION

- 5.25. SERVO VALVE ASSEMBLY FOR BLADE TILT

- 5.25.1. REMOVAL

- 5.25.2. INSTALLATION

- 5.26. SERVO VALVE ASSEMBLY FOR RIPPER

- 5.26.1. REMOVAL

- 5.26.2. INSTALLATION

- 5.27. RIPPER SELECTOR VALVE

- 5.27.1. REMOVAL

- 5.27.2. INSTALLATION

- 5.27.3. DISASSEMBLY

- 5.27.4. ASSEMBLY

- 5.28. BLADE LIFT CYLINDER

- 5.28.1. REMOVAL

- 5.28.2. INSTALLATION

- 5.29. BLADE TILT CYLINDER

- 5.29.1. REMOVAL

- 5.29.2. INSTALLATION

- 5.30. RIPPER LIFT CYLINDER

- 5.30.1. REMOVAL

- 5.30.2. INSTALLATION

- 5.31. RIPPER TILT CYLINDER

- 5.31.1. REMOVAL

- 5.31.2. INSTALLATION

- 5.32. HYDRAULIC CYLINDER

- 5.32.1. DISASSEMBLY

- 5.32.2. ASSEMBLY

- 5.33. PINPULLER CYLINDER

- 5.34. CAB AND FLOOR FRAME

- 6. MAINTENANCE STANDARD

- 6.1. TORQUE CONVERTER

- 6.2. TORQFLOW TRANSMISSION

- 6.3. TRANSMISSION CONTROL VALVE

- 6.4. TRANSMISSION LUBRICATION VALVE

- 6.5. TRANSMISSION PUMP

- 6.6. BEVEL GEAR SHAFT

- 6.7. STEERING CLUTCH

- 6.8. STEERING PUMP

- 6.9. STEERING MAIN RELIEF VALVE

- 6.10. STEERING AND BRAKE CONTROL VALVE

- 6.11. STEERING BRAKE

- 6.12. ASSIST BRAKE CYLINDER

- 6.13. ASSIST BRAKE AUTOMATIC DRAIN VALVE

- 6.14. TRACK (LUBRICATED TRACK LINK)

- 6.15. TRACK (DRY TYPE TRACK LINK)

- 6.16. SUSPENSION

- 6.17. HYDRAULIC PUMP

- 6.18. BLADE LIFT AND RIPPER CONTROL VALVE

- 6.19. BLADE TILT CONTROL VALVE

- 6.20. RIPPER SELECTOR VALVE AND PILOT CHECK VALVE

- 6.21. HYDRAULIC CYLINDER

- 6.22. CYLINDER STAY

- 6.23. PINPULLER CYLINDER (FOR GIANT RIPPER)

- 6.24. ROTARY SERVO VALVE (FOR BLADE LIFT)

- 6.25. STRAIGHT TILTDOZER

- 6.26. VARIABLE MULTISHANK RIPPER

- 6.27. VARIABLE GIANT RIPPER

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00