Komatsu D155A-2 Bull Dozer Shop Manual SEBM018602

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM018602

- Format: PDF

- Size: 27.4MB

- Number of Pages: 462

Category: Komatsu Shop Manual PDF

-

Model List:

- D155A-2 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL,COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. ENGINE CONTROL

- 4.2. RADIATOR,OIL COOLER

- 4.4. POWER TRAIN

- 4.5. POWER TRAIN SYSTEM

- 4.6. POWER TRAIN HYDRAULIC PIPING DIAGRAM

- 4.7. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.8. TORQUE CONVERTER

- 4.9. TRANSMISSION CONTROL

- 4.10. TRANSMISSION

- 4.11. TRANSMISSION CONTROL VALVE

- 4.12. TRANSMISSION LUBRICATION RELIEF VALVE

- 4.13. STEERING CONTROL

- 4.14. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 4.15. STEERING MAIN RELIEF VALVE

- 4.16. STEERING BRAKE

- 4.17. STEERING AND BRAKE CONTROL VALVE

- 4.18. SPRING ASSIST BRAKE SYSTEM

- 4.19. FINAL DRIVE

- 4.20. TRACK FRAME

- 4.21. RECOIL SPRING

- 4.22. SUSPENSION

- 4.23. WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM

- 4.24. WORK EQUIPMENT CONTROL

- 4.25. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.26. HYDRAULIC TANK

- 4.27. ROTARY SERVO VALVE

- 4.28. PISTON VALVE

- 4.29. PIN PULLER SWITCH

- 4.30. PINPULLER SOLENOID VALVE

- 4.31. MAIN CONTROL VALVE

- 4.32. RIPPER SELECTOR VALVE AND PILOT CHECK VALVE

- 4.33. PILOT SOLENOID VALVE

- 4.34. CYLINDER STAY

- 4.35. WORK EQUIPMENT

- 4.37. AIR CONDITIONER

- 4.38. ACTUAL ELECTRIC WIRING DIAGRAM

- 4.39. MONITOR SYSTEM

- 4.40. SENSOR

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR FUNCTIONS RELEVANT TO THE ENGINE

- 5.2. STANDARD VALUE TABLE FOR FUNCTIONS RELEVANT TO THE MACHINE BODY

- 5.3. STANDARD VALUE TABLE FOR ELECTRIC EQUIPMENT AND PARTS

- 5.4. TESTING AND ADJUSTING

- 5.4.1. LIST OF EQUIPMENT,PARTS AND TOOLS NECESSARY FOR INSPECTIONS,ADJUSTMENTS AND FOR TROUBLESHOOTING

- 5.4.2. MEASURING THE ENGINE REVOLUTION

- 5.4.3. MEASURING THE INTAKE MANIFOLD PRESSURE (BOOST PRESSURE)

- 5.4.4. MEASURING THE EXHAUST TEMPERATURE

- 5.4.5. MEASURING THE EXHAUST GAS COLOR

- 5.4.6. ADJUSTING THE VALVE CLEARANCE

- 5.4.7. MEASURING THE COMPRESSION PRESSURE

- 5.4.8. MEASURING THE BLOWBY PRESSURE

- 5.4.9. MEASURING THE ENGINE OIL PRESSURE

- 5.4.10. INSPECTING AND ADJUSTING THE FUEL INJECTION TIMING

- 5.4.11. INSPECTING AND ADJUSTING THE ALTERNATOR BELT TENSION

- 5.4.12. INSPECTING AND ADJUSTING THE AIR COMPRESSOR BELT TENSION

- 5.4.13. MEASURING THE TORQUE CONVERTER STALLING REVOLUTION RATE

- 5.4.14. MEASURING THE TORQUE CONVERTER STALLING WORK EQUIPMENT PUMP RELIEVING REVOLUTION RATE (FULL STALL REVOLUTION RATE)

- 5.4.15. MEASURING THE OIL PRESSURE

- 5.4.16. ADJUSTING THE STROKES AND LINKAGES

- 5.5. TROUBLESHOOTING

- 5.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

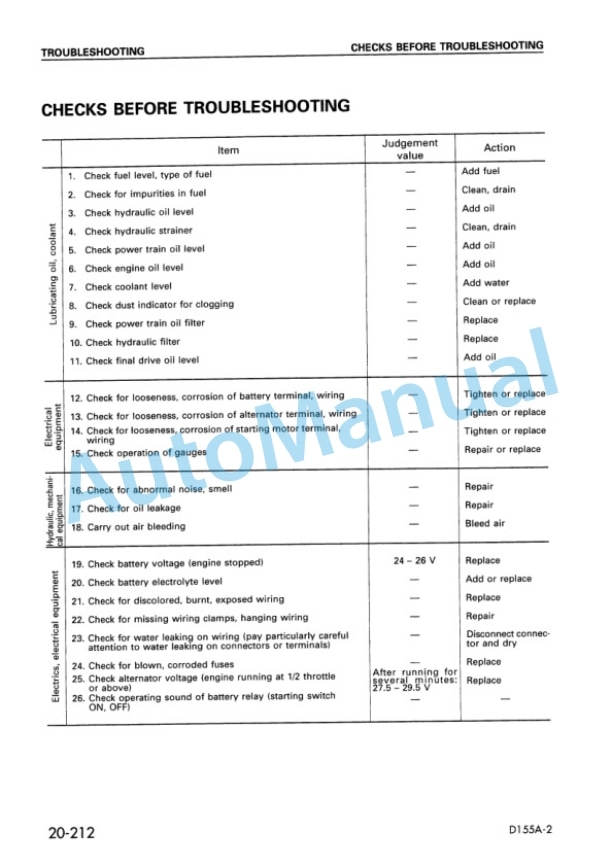

- 5.5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5.5. CONNECTOR TYPES AND CONNECTING EQUIPMENT AND PART NAMES

- 5.5.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.5.7. HOW TO FOLLOW THE TROUBLESHOOTING FLOW DIAGRAMS

- 5.5.8. TROUBLESHOOTING FOR ELECTRIC EQUIPMENT (EMODE)

- 5.5.9. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL EQUIPMENT (HMODE)

- 5.5.10. TROUBLESHOOTING FOR MONITOR PANEL AND RELATED PARTS (MMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. FUEL INJECTION PUMP ASSEMBLY

- 6.4.1. REMOVAL

- 6.4.2. INSTALLATION

- 6.5. CYLINDER HEAD ASSEMBLY

- 6.5.1. REMOVAL

- 6.5.2. INSTALLATION

- 6.6. RADIATOR GUARD ASSEMBLY

- 6.6.1. REMOVAL

- 6.6.2. INSTALLATION

- 6.7. RADIATOR,TORQUE CONVERTER OIL COOLER ASSEMBLY

- 6.8. FUEL TANK ASSEMBLY

- 6.8.1. REMOVAL

- 6.8.2. INSTALLATION

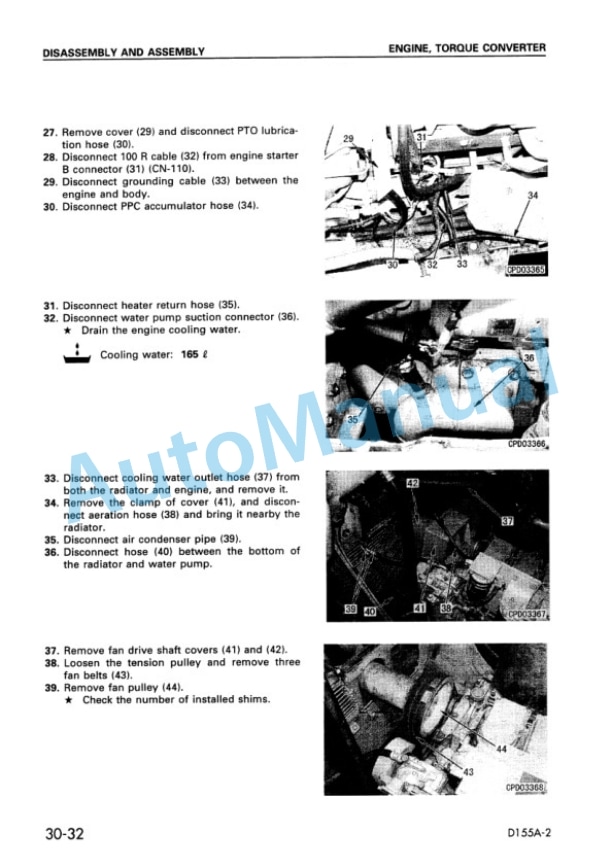

- 6.9. ENGINE,TORQUE CONVERTER ASSEMBLY

- 6.9.1. REMOVAL

- 6.9.2. INSTALLATION

- 6.10. TORQUE CONVERTER ASSEMBLY

- 6.10.1. REMOVAL

- 6.10.2. INSTALLATION

- 6.10.3. DISASSEMBLY

- 6.10.4. ASSEMBLY

- 6.11. TORQUE CONVERTER RELIEF VALVE ASSEMBLY

- 6.11.1. DISASSEMBLY

- 6.11.2. ASSEMBLY

- 6.12. TORQUE CONVERTER REGULATOR VALVE

- 6.12.1. DISASSEMBLY

- 6.12.2. ASSEMBLY

- 6.13. TRANSMISSION ASSEMBLY

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. TORQUE FLOW TRANSMISSION ASSEMBLY

- 6.14.1. DISASSEMBLY

- 6.14.2. ASSEMBLY

- 6.15. TRANSMISSION CONTROL VALVE ASSEMBLY

- 6.15.1. DISASSEMBLY

- 6.15.2. ASSEMBLY

- 6.16. TRANSMISSION LUBRICATION VALVE ASSEMBLY

- 6.16.1. DISASSEMBLY

- 6.16.2. ASSEMBLY

- 6.17. BEVEL GEAR SHAFT ASSEMBLY

- 6.17.1. DISASSEMBLY

- 6.17.2. ASSEMBLY

- 6.18. STEERING CLUTCH ASSEMBLY

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

- 6.18.3. DISASSEMBLY

- 6.18.4. ASSEMBLY

- 6.19. BRAKE BOOSTER ASSEMBLY

- 6.19.1. DISASSEMBLY

- 6.19.2. ASSEMBLY

- 6.20. STEERING RELIEF VALVE ASSEMBLY

- 6.20.1. DISASSEMBLY

- 6.20.2. ASSEMBLY

- 6.21. VALVE ASSEMBLY LINKED TO STEERING,BRAKE

- 6.21.1. DISASSEMBLY

- 6.21.2. ASSEMBLY

- 6.22. FIRST PINION ASSEMBLY

- 6.22.1. DISASSEMBLY

- 6.22.2. ASSEMBLY

- 6.23. FINAL DRIVE ASSEMBLY

- 6.23.1. DISASSEMBLY

- 6.23.2. ASSEMBLY

- 6.24. TRACK FRAME ASSEMBLY

- 6.24.1. REMOVAL

- 6.24.2. INSTALLATION

- 6.25. RECOIL SPRING ASSEMBLY

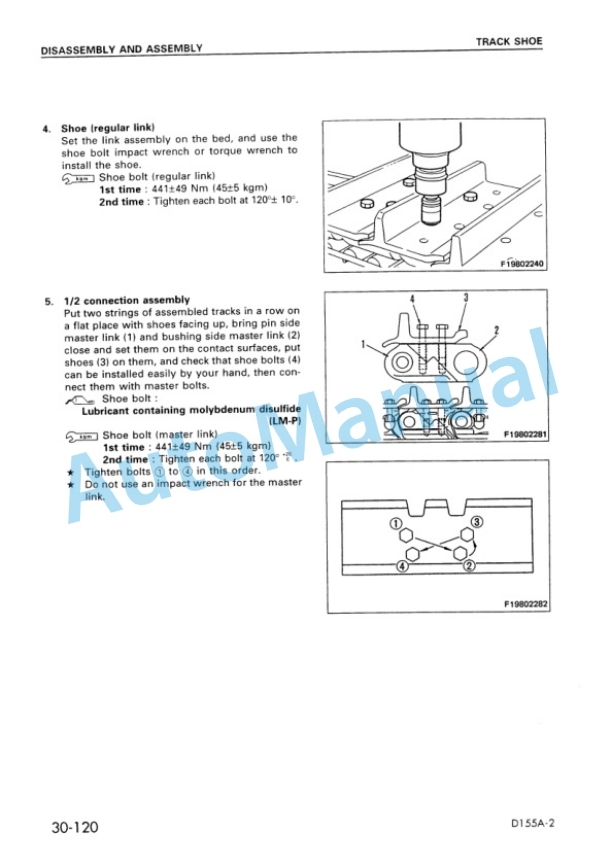

- 6.26. TRACK SHOE ASSEMBLY

- 6.26.1. REMOVAL

- 6.26.2. INSTALLATION

- 6.26.3. ENTIRE DISASSEMBLY

- 6.26.4. ENTIRE ASSEMBLY

- 6.27. LINK IN FIELD

- 6.28. BLADE,RIPPER CONTROL VALVE ASSEMBLY

- 6.28.1. DISASSEMBLY

- 6.28.2. ASSEMBLY

- 6.29. BLADE TILT CONTROL VAVLE

- 6.29.1. DISASSEMBLY

- 6.29.2. ASSEMBLY

- 6.30. RIPPER SELECTOR VALVE ASSEMBLY

- 6.30.1. DISASSEMBLY

- 6.30.2. ASSEMBLY

- 6.31. OIL CYLINDER ASSEMBLY

- 6.31.1. DISASSEMBLY

- 6.31.2. ASSEMBLY

- 6.32. PIN PULLER CYLINDER ASSEMBLY

- 6.32.1. DISASSEMBLY

- 6.32.2. ASSEMBLY

- 6.33. WORK MACHINE ASSEMBLY

- 6.33.1. REMOVAL

- 6.33.2. INSTALLATION

- 6.33.3. DISASSEMBLY

- 6.33.4. ASSEMBLY

- 6.34. RIPPER ASSEMBLY

- 6.35. CABIN FLOOR FRAME ASSEMBLY

- 6.35.1. REMOVAL

- 6.35.2. INSTALLATION

- 6.36. FLOOR FRAME ASSEMBLY

- 6.36.1. REMOVAL

- 6.36.2. INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. TORQUE CONVERTER

- 7.3. TRANSMISSION

- 7.4. TRANSMISSION CONTROL VALVE

- 7.5. TRANSMISSION LUBRICATION RELIEF VALVE

- 7.6. TRANSMISSION PUMP

- 7.7. BEVEL GEAR SHAFT

- 7.8. STEERING CLUTCH

- 7.9. STEERING PUMP

- 7.10. STEERING MAIN RELIEF VALVE

- 7.11. STEERING AND BRAKE CONTROL VALVE

- 7.12. STEERING BRAKE

- 7.13. SPRING ASSIST BRAKE CYLINDER

- 7.14. AUTOMATIC DRAIN VALVE

- 7.15. TRACK SHOE (DRY TYPE)

- 7.16. TRACK SHOE (SEALED AND LUBRICATED TYPE)

- 7.17. SUSPENSION

- 7.18. WORK EQUIPMENT PUMP

- 7.19. ROTARY SERVO VALVE (FOR BLADE LIFT)

- 7.20. MAIN CONTROL VALVE

- 7.21. BLADE TILT VALVE

- 7.22. RIPPER SELECTOR VALVE AND PILOT CHECK VALVE

- 7.23. WORK EQUIPMENT CYLINDER

- 7.24. QUICK DROP VALVE

- 7.25. CYLINDER STAY

- 7.26. WORK EQUIPMENT

- 8. OTHERS

- 8.1. ELECTRIC CIRCUIT DIAGRAM (SERIAL NO.5700157284)

- 8.2. ELECTRIC CIRCUIT DIAGRAM (SERIAL NO.57285 AND UP)

Rate this product

You may also like