Komatsu D21A-8, D21P-8, D21PL-8 Bull Dozer Shop Manual SEN06706-01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06706-01

- Format: PDF

- Size: 31.5MB

- Number of Pages: 457

Category: Komatsu Shop Manual PDF

-

Model List:

- D21A-8 Bull Dozer

- D21P-8 Bull Dozer

- D21PL-8 Bull Dozer

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 1. GENERAL

- 1.1. SPECIFICATION DRAWINGS

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. FUEL, COOLANT AND LUBRICANTS

- 2. STRUCTURE AND FUNCTION

- 2.1. ENGINE CONTROL

- 2.2. POWER TRAIN SYSTEM

- 2.3. POWER TRAIN SKELETON

- 2.4. POWER TRAIN HYDRAULIC PIPING

- 2.5. DAMPER AND UNIVERSAL JOINT

- 2.6. TRANSMISSION CONTROL

- 2.7. TRANSMISSION PUMP

- 2.8. HYDROSHIFT TRANSMISSION

- 2.9. TRANSMISSION CONTROL VALVE

- 2.10. STEERING CLUTCH AND BRAKE CONTROL

- 2.11. STEERING CYLINDER

- 2.12. BRAKE CYLINDER

- 2.13. PPC VALVE

- 2.14. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 2.15. STEERING BRAKE

- 2.16. FINAL DRIVE

- 2.17. TRACK FRAME

- 2.18. MAIN FRAME AND SUSPENSION

- 2.19. HYDRAULIC PIPING

- 2.20. HYDRAULIC CONTROL

- 2.21. HYDRAULIC TANK AND FILTER

- 2.22. HYDRAULIC CONTROL VALVE

- 2.23. OPERATION OF WORK EQUIPMENT CONTROL CIRCUIT

- 2.24. POWER ANGLE AND POWER TILTDOZER

- 2.25. STRAIGHT TILTDOZER

- 2.26. ENGINE CONTROL

- 2.27. MONITOR SYSTEM

- 2.28. SENSORS

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE FOR ENGINE

- 3.2. STANDARD VALUE TABLE FOR CHASSIS

- 3.3. TESTING AND ADJUSTING

- 3.3.1. LIST OF TESTING, ADJUSTING, AND TROUBLESHOOTING TOOLS

- 3.3.2. MEASURING ENGINE SPEED

- 3.3.3. MEASUREMENT OF EXHAUST GAS COLOR

- 3.3.4. ADJUSTING VALVE CLEARANCE

- 3.3.5. MEASURING COMPRESSION PRESSURE

- 3.3.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.3.7. BLEEDING AIR FROM FUEL CIRCUIT

- 3.3.8. MEASURING ENGINE OIL PRESSURE

- 3.3.9. TESTING AND ADJUSTING FAN BELT TENSION

- 3.3.10. ADJUSTING FUEL CONTROL LINKAGE

- 3.3.11. MEASURING POWER TRAIN OIL PRESSURE

- 3.3.12. ADJUSTING PPC VALVE

- 3.3.13. BLEEDING AIR FROM STEERING CIRCUIT

- 3.3.14. MEASURING AND ADJUSTING WORK EQUIPMENT MAIN RELIEF PRESSURE

- 3.3.15. BLEEDING AIR FROM HYDRAULIC CYLINDERS

- 3.3.16. BLEEDING AIR FROM ANGLE CYLINDERS CIRCUIT

- 3.3.17. ADJUSTING FUEL CONTROL LEVER

- 3.3.18. ADJUSTING TRAVEL OF INCHING PEDAL

- 3.3.19. ADJUSTING STEERING CONTROL LINKAGE

- 3.3.20. ADJUSTING BRAKE PEDAL, BRAKE CYLINDER

- 3.3.21. ADJUSTING BRAKE LINING CLEARANCE

- 3.4. TROUBLESHOOTING

- 3.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.4.4. CHECKS BEFORE TROUBLESHOOTING

- 3.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 3.4.6. TYPES AND LOCATIONS OF CONNECTORS

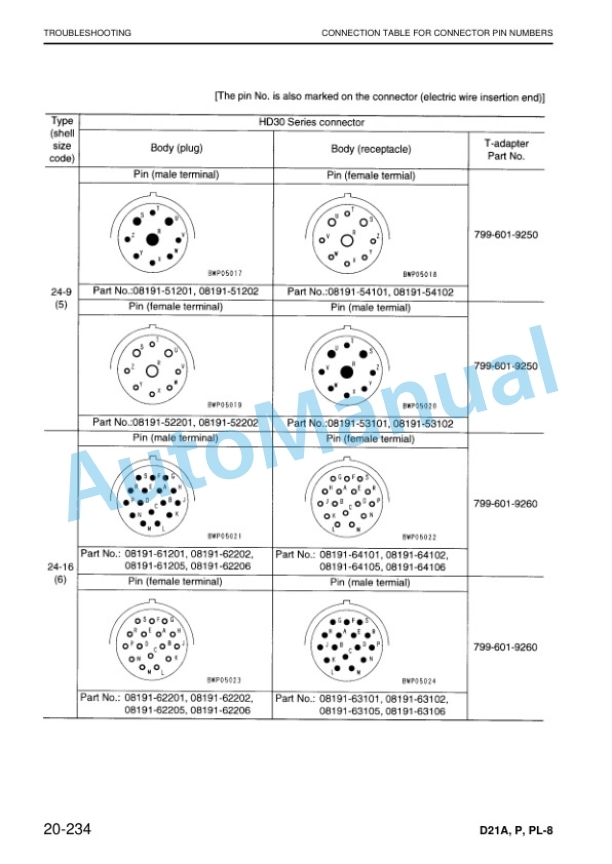

- 3.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.4.8. TBRANCH BOX AND TBRANCH TABLE

- 3.4.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 3.4.10. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 3.4.11. TROUBLESHOOTING OF ENGINE (S MODE)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.3. FUEL INJECTION PUMP

- 4.4. HYDROSHIFT TRANSMISSION

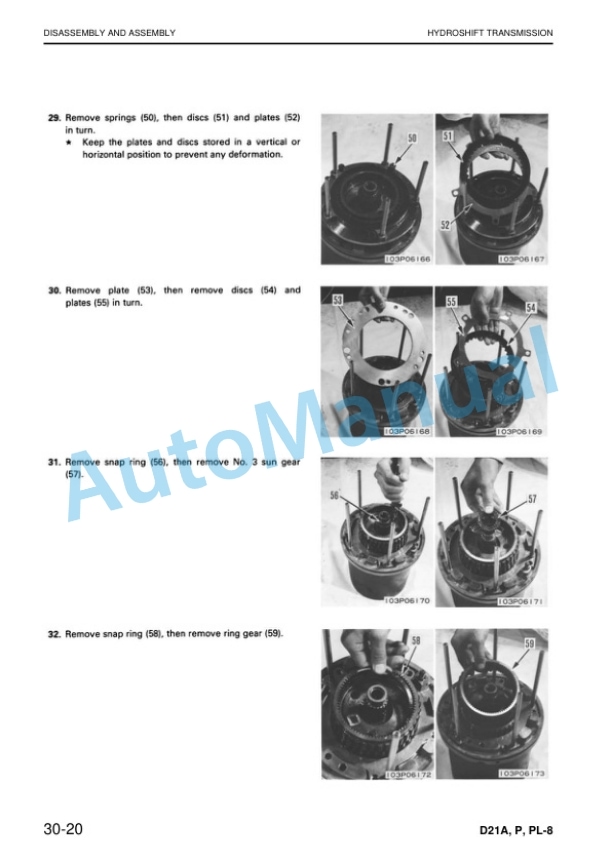

- 4.4.1. DISASSEMBLY

- 4.4.2. ASSEMBLY

- 4.5. MODULATING VALVE

- 4.5.1. ASSEMBLY

- 4.6. SELECTOR AND INCHING VALVE

- 4.6.1. ASSEMBLY

- 4.7. STEERING PPC VALVE

- 4.7.1. ASSEMBLY

- 4.8. STEERING CLUTCH

- 4.8.1. REMOVAL

- 4.8.2. INSTALLATION

- 4.8.3. DISASSEMBLY

- 4.8.4. ASSEMBLY

- 4.9. BEVEL GEAR SHAFT AND BEVEL GEAR

- 4.9.1. REMOVAL

- 4.9.2. INSTALLATION

- 4.10. FINAL DRIVE

- 4.10.1. REMOVAL AND INSTALLATION

- 4.11. FINAL DRIVE FIRST PINION

- 4.12. POWER TRAIN OIL COOLER

- 4.12.1. REMOVAL AND INSTALLATION

- 4.13. RECOIL SPRING

- 4.13.1. REMOVAL AND INSTALLATION

- 4.13.2. DISASSEMBLY AND ASSEMBLY

- 4.14. TRACK SHOE

- 4.14.1. REMOVAL AND INSTALLATION

- 4.15. HYDRAULIC CONTROL VALVE

- 4.15.1. ASSEMBLY

- 4.16. HYDRAULIC CYLINDER

- 4.16.1. ASSEMBLY

- 4.17. BLADE

- 4.17.1. REMOVAL AND INSTALLATION

- 5. MAINTENANCE STANDARD

- 5.1. DAMPER AND UNIVERSAL JOINT

- 5.2. HYDROSHIFT TRANSMISSION

- 5.3. TRANSMISSION CONTROL VALVE

- 5.4. TRANSMISSION AND STEERING PUMP

- 5.5. PPC VALVE

- 5.6. STEERING CYLINDER

- 5.7. BEVEL GEAR SHAFT

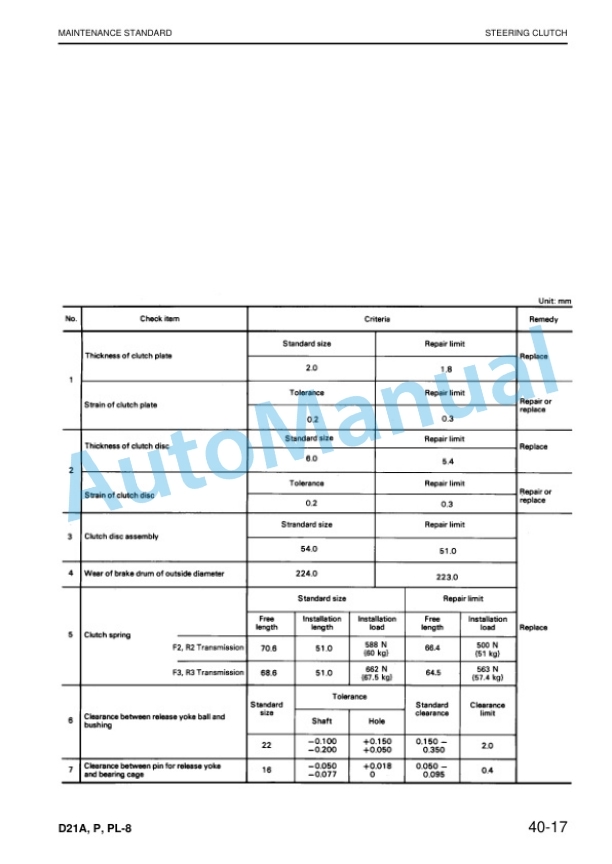

- 5.8. STEERING CLUTCH

- 5.9. TRACK SHOE (LUBRICATED TRACK LINK)

- 5.10. RUBBER CRAWLER

- 5.11. HYDRAULIC PUMP

- 5.12. HYDRAULIC CONTROL VALVE

- 5.13. HYDRAULIC CYLINDER

- 5.14. POWER ANGLE AND POWER TILTDOZER

- 5.15. STRAIGHT TILTDOZER

- 6. OTHERS

- 6.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM (F2, R2 TRANSMISSION)

- 6.2. POWER TRAIN HYDRAULIC SYSTEM (F2, R2 TRANSMISSION)

- 6.3. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM (F3, R3 TRANSMISSION)

- 6.4. POWER TRAIN HYDRAULIC SYSTEM (F3, R3 TRANSMISSION)

- 6.5. HYDRAULIC CIRCUIT DIAGRAM

- 6.6. HYDRAULIC CIRCUIT SYSTEM

- 6.7. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 6.8. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 6.9. ELECTRICAL WIRING DIAGRAM

- 6.10. CAB AND AIR CONDITIONER ELECTRICAL CIRCUIT

- 6.11. TRIMMING DOZER

- 6.11.1. CONTENTS

- 6.11.2. OUTLINE

- 6.11.3. STRUCTURE AND FUNCTION

- 6.11.4. MAINTENANCE STANDARD

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00