Komatsu D21A-8, D21P-8 Galeo Bull Dozer Shop Manual TEN00016-01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: TEN00016-01

- Format: PDF

- Size: 4.2MB

- Number of Pages: 207

Category: Komatsu Shop Manual PDF

-

Model List:

- D21A-8 Galeo Bull Dozer

- D21P-8 Galeo Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.4. NECESSARY INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. ENGINE SERIAL NO. PLATE

- 2.4.3. EMISSION CONTROL INFORMATION LABEL

- 2.4.4. POSITION OF SERVICE METER

- 2.4.5. TABLE OF ENTER SERIAL NO. AND DISTRIBUTOR

- 3. CONTENTS

- 4. SAFETY

- 4.1. SAFETY

- 4.2. SAFETY LABELS

- 4.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 4.2.2. SAFETY LABELS

- 4.3. GENERAL PRECAUTIONS

- 4.3.1. SAFETY RULES

- 4.3.2. IF PROBLEMS ARE FOUND

- 4.3.3. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 4.3.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.3.5. SAFETY FEATURES

- 4.3.6. KEEP MACHINE CLEAN

- 4.3.7. INSIDE OPERATORS COMPARTMENT

- 4.3.8. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 4.3.9. HANDRAILS AND STEPS

- 4.3.10. MOUNTING AND DISMOUNTING

- 4.3.11. NO PEOPLE ON ATTACHMENTS

- 4.3.12. CRUSHING OR CUTTING PREVENTION

- 4.3.13. PREVENTION OF BURNS

- 4.3.14. FIRE PREVENTION

- 4.3.15. ACTION IF FIRE OCCURS

- 4.3.16. WINDOW WASHER LIQUID

- 4.3.17. PRECAUTIONS WHEN USING ROPS (ROLL OVER PROTECTIVE STRUCTURE)

- 4.3.18. PRECAUTIONS FOR ATTACHMENTS

- 4.3.19. UNAUTHORIZED MODIFICATION

- 4.3.20. SAFETY AT WORKSITE

- 4.3.21. WORKING ON LOOSE GROUND

- 4.3.22. DO NOT GO CLOSE TO HIGHVOLTAGE CABLES

- 4.3.23. ENSURE GOOD VISIBILITY

- 4.3.24. VENTILATION FOR ENCLOSED AREAS

- 4.3.25. CHECKING SIGNALMANS SIGNALS AND SIGNS

- 4.3.26. EMERGENCY EXIT FROM OPERATORS CAB

- 4.3.27. BE CAREFUL ABOUT ASBESTOS DUST

- 4.4. PRECAUTIONS FOR OPERATION

- 4.4.1. STARTING ENGINE

- 4.4.1.1. CHECKS BEFORE STARTING ENGINE

- 4.4.1.2. PRECAUTIONS WHEN STARTING

- 4.4.1.3. PRECAUTIONS IN COLD AREAS

- 4.4.2. OPERATION

- 4.4.2.1. CHECKS BEFORE OPERATION

- 4.4.2.2. PRECAUTIONS FOR MOVING MACHINE FORWARD OR IN REVERSE

- 4.4.2.3. PRECAUTIONS WHEN TRAVELING

- 4.4.2.4. TRAVELING ON SLOPES

- 4.4.2.5. USING BRAKES

- 4.4.2.6. OPERATE CAREFULLY ON SNOW

- 4.4.2.7. PARKING MACHINE

- 4.4.3. TRANSPORTATION

- 4.4.3.1. LOADING AND UNLOADING

- 4.4.3.2. SHIPPING

- 4.4.4. BATTERY

- 4.4.4.1. BATTERY HAZARD PREVENTION

- 4.4.4.2. STARTING WITH BOOSTER CABLE

- 4.4.5. TOWING

- 4.4.5.1. WHEN TOWING

- 4.5. PRECAUTIONS FOR MAINTENANCE

- 4.5.1. WARNING TAG

- 4.5.2. KEEP WORK PLACE CLEAN AND TIDY

- 4.5.3. APPOINT LEADER WHEN WORKING WITH OTHERS

- 4.5.4. STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE

- 4.5.5. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 4.5.6. PROPER TOOLS

- 4.5.7. NO UNAUTHORIZED PERSONNEL INTO AREA

- 4.5.8. ATTACHMENTS

- 4.5.9. WORK UNDER THE MACHINE

- 4.5.10. NOISE

- 4.5.11. PRECAUTIONS WHEN USING HAMMER

- 4.5.12. REPAIR WELDING

- 4.5.13. REMOVING BATTERY TERMINAL

- 4.5.14. PRECAUTIONS WHEN USING HIGHPRESSURE GREASE TO ADJUST TRACK TENSION

- 4.5.15. DO NOT DISASSEMBLE RECOIL SPRING

- 4.5.16. PRECAUTION WITH HIGHPRESSURE OIL

- 4.5.17. HANDLING HIGHPRESSURE HOSES

- 4.5.18. WASTE MATERIAL

- 4.5.19. MAINTENANCE FOR AIR CONDITIONER

- 4.5.20. COMPRESSED AIR

- 4.5.21. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5. OPERATION

- 5.1. GENERAL VIEW

- 5.1.1. GENERAL VIEW OF MACHINE

- 5.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 5.2. EXPLANATION OF COMPONENTS

- 5.2.1. FRONT PANEL

- 5.2.2. SWITCHES

- 5.2.3. CONTROL LEVERS AND PEDALS

- 5.2.4. FUSE

- 5.2.5. FUSIBLE LINK

- 5.2.6. DOOR POCKET

- 5.3. OPERATION

- 5.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 5.3.2. STARTING ENGINE

- 5.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 5.3.4. STOPPING ENGINE

- 5.3.5. MACHINE OPERATION

- 5.3.6. SHIFTING GEARS

- 5.3.7. SHIFTING BETWEEN FORWARD AND REVERSE

- 5.3.8. STEERING MACHINE

- 5.3.9. PRECAUTIONS FOR OPERATION

- 5.3.10. WORK POSSIBLE USING BULLDOZER

- 5.3.11. PARKING MACHINE

- 5.3.12. CHECK AFTER FINISHING WORK

- 5.3.13. LOCKING

- 5.3.14. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 5.3.15. HANDLING RUBBER SHOES (RUBBER SHOES ONLY)

- 5.4. TRANSPORTATION

- 5.4.1. TRANSPORTATION MEANS

- 5.4.2. LOADING, UNLOADING WORK

- 5.4.3. LIFTING MACHINE

- 5.5. COLD WEATHER OPERATION

- 5.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.5.2. AFTER COMPLETION OF WORK

- 5.5.3. AFTER COLD WEATHER

- 5.6. LONGTERM STORAGE

- 5.6.1. BEFORE STORAGE

- 5.6.2. DURING STORAGE

- 5.6.3. AFTER STORAGE

- 5.7. TROUBLESHOOTING

- 5.7.1. AFTER RUNNING OUT OF FUEL

- 5.7.2. MACHINE TOWING METHOD

- 5.7.3. IF BATTERY IS DISCHARGED

- 5.7.4. OTHER TROUBLE

- 6. MAINTENANCE

- 6.1. GUIDE TO MAINTENANCE

- 6.2. OUTLINE OF SERVICE

- 6.2.1. OUTLINE OF OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 6.2.2. RELATING TO ELECTRIC SYSTEM

- 6.3. WEAR PARTS LIST

- 6.3.1. WEAR PARTS LIST

- 6.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 6.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 6.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 6.5.1. TORQUE LIST

- 6.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 6.6.1. SAFETY CRITICAL PARTS

- 6.7. MAINTENANCE SCHEDULE CHART

- 6.7.1. MAINTENANCE SCHEDULE CHART

- 6.8. SERVICE PROCEDURE

- 6.8.1. INITIAL 250 HOURS SERVICE(ONLY AFTER THE FIRST 250 HOURS)

- 6.8.2. WHEN REQUIRED

- 6.8.2.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 6.8.2.2. CLEAN INSIDE OF COOLING SYSTEM

- 6.8.2.3. CLEAN WATER SEPARATOR ELEMENT

- 6.8.2.4. CHECK AND ADJUST STEEL SHOE TENSION

- 6.8.2.5. CHECK AND TIGHTEN TRACK STEEL SHOE BOLTS

- 6.8.2.6. CHECK AND REPLACE RUBBER SHOES

- 6.8.2.7. CHECK AND ADJUST RUBBER SHOE TENSION

- 6.8.2.8. REPLACE RUBBER SHOES

- 6.8.2.9. REVERSE AND REPLACE END BITS AND CUTTING EDGES

- 6.8.2.10. BLEED AIR FROM HEAD END OF ANGLE CIRCUIT

- 6.8.2.11. ADJUST BRAKE PEDAL (TEST, ADJUST STEERING BRAKE)

- 6.8.2.12. ADJUST IDLER CLEARANCE

- 6.8.3. CHECK BEFORE STARTING

- 6.8.4. EVERY 50 HOURS SERVICE

- 6.8.4.1. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 6.8.5. EVERY 250 HOURS SERVICE

- 6.8.5.1. LUBRICATING

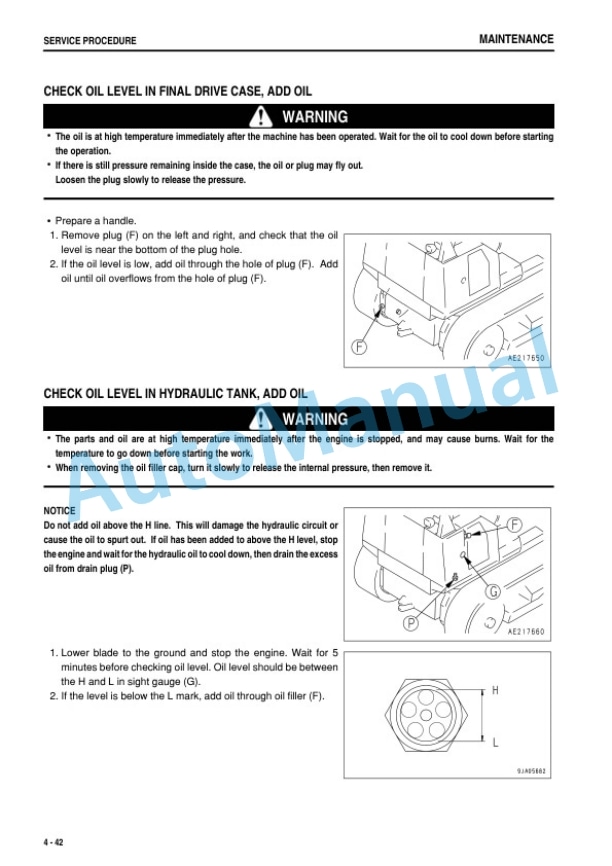

- 6.8.5.2. CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL

- 6.8.5.3. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 6.8.5.4. CHECK LEVEL OF BATTERY ELECTROLYTE

- 6.8.5.5. CHECK FAN BELT TENSION, ADJUST

- 6.8.6. EVERY 500 HOURS SERVICE

- 6.8.6.1. REPLACE FUEL FILTER CARTRIDGE

- 6.8.6.2. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE

- 6.8.6.3. CLEAN, CHECK RADIATOR FINS

- 6.8.6.4. CLEAN BREATHER

- 6.8.7. EVERY 1000 HOURS SERVICE

- 6.8.7.1. CHECK OIL LEVEL IN DAMPER CASE, ADD OIL

- 6.8.7.2. CHANGE OIL IN BEVEL GEAR CASE, TRANSFER CASE

- 6.8.7.3. CHANGE OIL IN TRANSMISSION CASE, CLEAN STRAINER

- 6.8.7.4. CHANGE OIL IN FINAL DRIVE CASE

- 6.8.7.5. CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC OIL FILTER CARTRIDGE

- 6.8.7.6. CHECK OIL IN UNDERCARRIAGE COMPONENTS

- 6.8.7.7. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 6.8.8. EVERY 2000 HOURS SERVICE

- 6.8.8.1. CHECK ALTERNATOR, STARTING MOTOR

- 6.8.9. EVERY 4000 HOURS SERVICE

- 6.8.9.1. CHECK WATER PUMP

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 8. ATTACHMENTS, OPTIONS

- 8.1. GENERAL PRECAUTIONS

- 8.1.1. PRECAUTIONS RELATED TO SAFETY

- 8.2. DECELERATOR PEDAL

- 8.3. SUSPENSION SEAT

- 8.3.1. ADJUSTMENT

- 8.3.2. SEAT BELT

- 8.4. HANDLING TRIMMING DOZER

- 8.4.1. GENERAL VIEW

- 8.4.2. EXPLANATION OF COMPONENTS

- 8.4.3. OPERATION

- 8.4.4. MAINTENANCE

- 8.4.5. SPECIFICATIONS

- 8.4.6. WEAR PARTS LIST

- 9. INDEX

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00