Komatsu D375A-5 Bull Dozer Operation and Maintenance Manual PEN00796-01

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN00796-01

- Format: PDF

- Size: 5.5MB

- Number of Pages: 251

-

Model List:

- D375A-5 Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.3.2. BREAKING IN THE MACHINE

- 2.4. NECESSARY INFORMATION

- 2.4.1. MACHINE SERIAL NO. PLATE AND POSITION

- 2.4.2. ENGINE SERIAL NO. PLATE AND POSITION

- 2.4.3. BLADE SERIAL NO. PLATE POSITION

- 2.4.4. RIPPER SERIAL NO. PLATE POSITION

- 2.4.5. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.2. SAFETY LABELS

- 3.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 3.2.2. SAFETY LABELS

- 3.3. GENERAL PRECAUTIONS

- 3.4. PRECAUTIONS FOR OPERATION

- 3.4.1. BEFORE STARTING ENGINE

- 3.4.2. OPERATION

- 3.4.3. TRANSPORTATION

- 3.4.4. BATTERY

- 3.4.5. TOWING

- 3.5. PRECAUTIONS FOR MAINTENANCE

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. GENERAL VIEW OF MACHINE

- 4.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

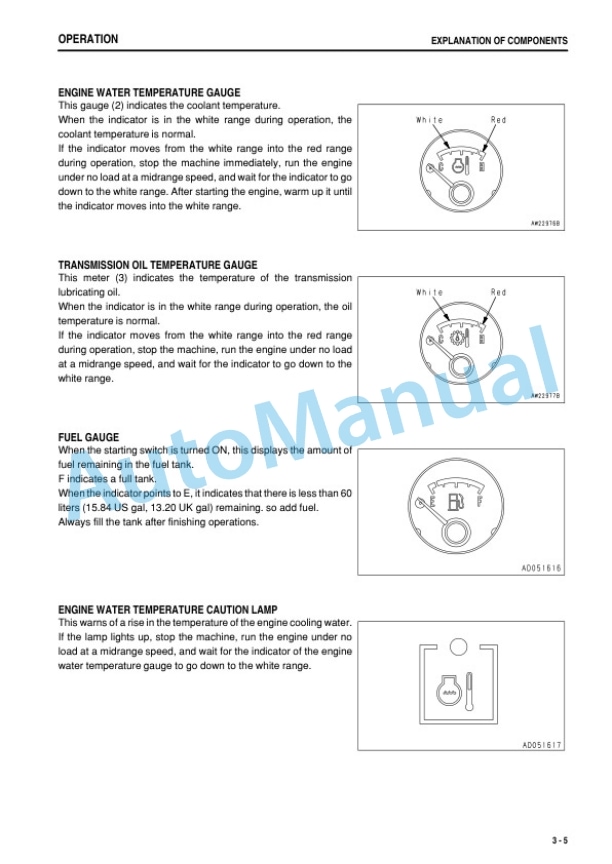

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. FRONT PANEL

- 4.2.2. MONITOR PANEL

- 4.2.3. SWITCHES

- 4.2.4. CONTROL LEVERS, PEDALS

- 4.2.5. POWER SOURCE

- 4.2.6. FUSE BOX

- 4.2.7. DOOR OPEN LOCK

- 4.2.8. SASH GLASS INTERMEDIATE LOCK

- 4.2.9. DOOR POCKET

- 4.2.10. ASHTRAY

- 4.2.11. TOOL BOX

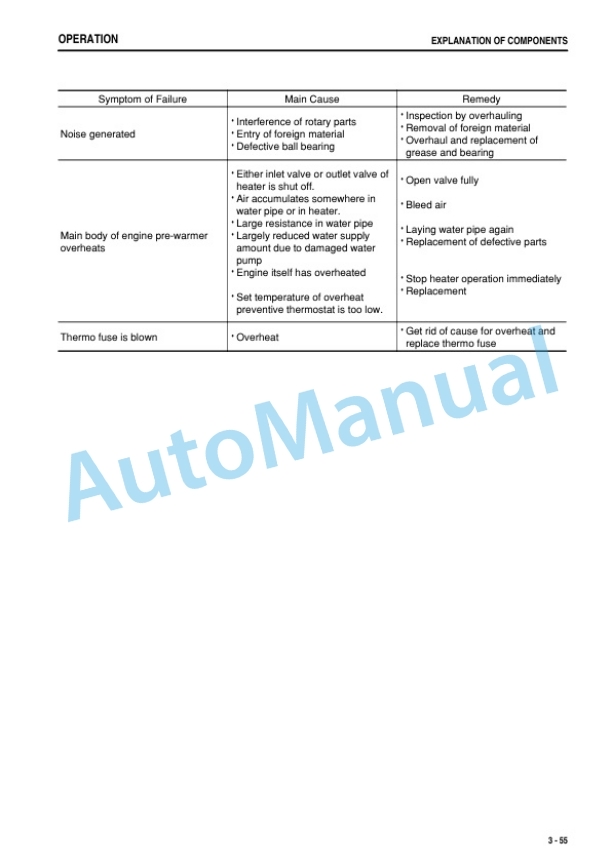

- 4.2.12. HANDLING HEATER

- 4.2.13. ADDITIONAL HEATER, HANDLING

- 4.2.14. ACCUMULATOR, HANDLING

- 4.2.15. BATTERY DISCONNECT SWITCH

- 4.2.16. HANDLING ENGINE SIDE COVER, ENGINE ROOM QUILTING

- 4.2.17. HANDLING INSPECTION LAMP

- 4.2.18. EXTERNAL POWER SOURCE TYPE ENGINE PREHEATING HEATER

- 4.2.19. HANDLING OF ONBOARD COMBUSTION PREHEATER

- 4.2.20. HANDLING OF FUEL STRAINER HEATER

- 4.3. OPERATION

- 4.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 4.3.2. STARTING ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 4.3.4. STOPPING ENGINE

- 4.3.5. CHECK AFTER STOPPING ENGINE

- 4.3.6. MACHINE OPERATION

- 4.3.7. STEERING MACHINE

- 4.3.8. PRECAUTIONS FOR OPERATION

- 4.3.9. PARKING MACHINE

- 4.3.10. CHECK AFTER FINISHING WORK

- 4.3.11. LOCKING

- 4.3.12. WORK POSSIBLE USING BULLDOZER

- 4.3.13. METHOD OF OPERATING PIN PULLER

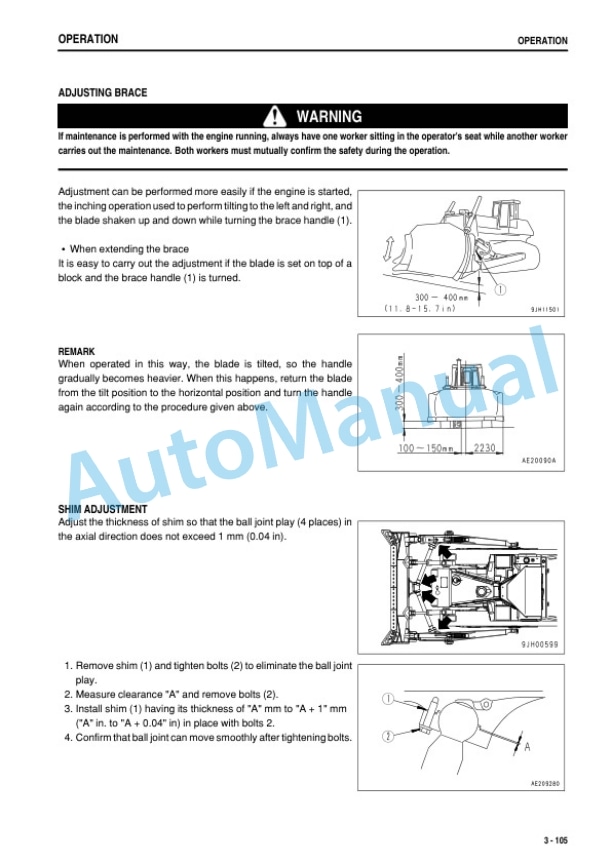

- 4.3.14. ADJUSTING POSTURE OF WORK EQUIPMENT

- 4.3.15. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 4.4. TRANSPORTATION

- 4.4.1. TRANSPORTATION PROCEDURE

- 4.4.2. PRECAUTIONS FOR LOADING

- 4.4.3. METHOD OF LIFTING MACHINE

- 4.4.4. PRECAUTIONS FOR TRANSPORTATION

- 4.4.5. TRAVELING ON ROADS

- 4.4.6. REMOVAL OF CAB

- 4.4.7. INSTALLATION OF CAB

- 4.5. COLD WEATHER OPERATION

- 4.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 4.5.2. AFTER COMPLETION OF WORK

- 4.5.3. AFTER COLD WEATHER

- 4.6. LONGTERM STORAGE

- 4.6.1. BEFORE STORAGE

- 4.6.2. DURING STORAGE

- 4.6.3. AFTER STORAGE

- 4.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 4.7. TROUBLESHOOTING

- 4.7.1. AFTER RUNNING OUT OF FUEL

- 4.7.2. METHOD OF TOWING MACHINE

- 4.7.3. IF BATTERY IS DISCHARGED

- 4.7.4. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. GUIDES TO MAINTENANCE

- 5.2. OUTLINES OF SERVICE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. OUTLINE OF ELECTRIC SYSTEM

- 5.3. WEAR PARTS

- 5.3.1. WEAR PARTS LIST

- 5.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 5.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 5.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 5.5.1. TORQUE LIST

- 5.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.6.1. SAFETY CRITICAL PARTS

- 5.7. MAINTENANCE SCHEDULE CHART

- 5.7.1. MAINTENANCE SCHEDULE CHART

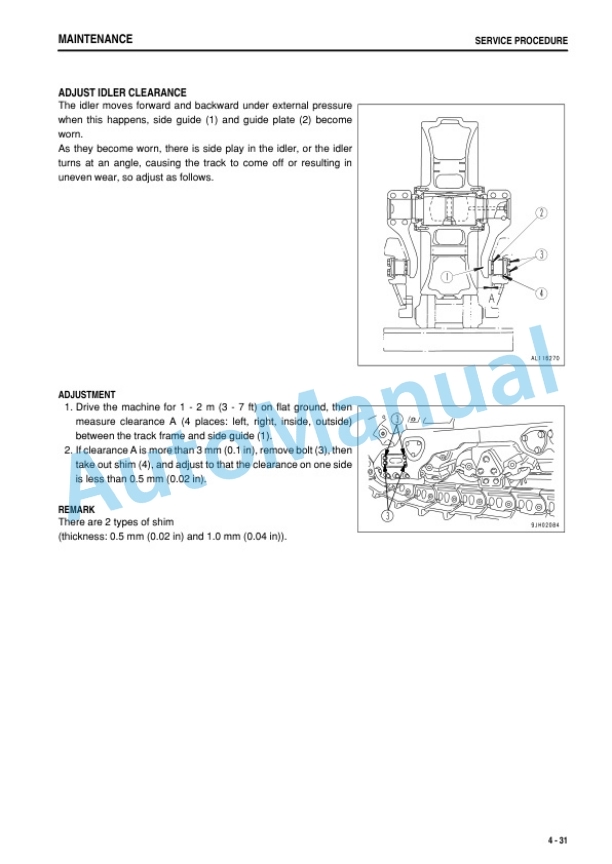

- 5.8. SERVICE PROCEDURE

- 5.8.1. INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)

- 5.8.2. WHEN REQUIRED

- 5.8.3. CHECK BEFORE STARTING

- 5.8.4. EVERY 250 HOURS SERVICE

- 5.8.5. EVERY 500 HOURS SERVICE

- 5.8.6. EVERY 1000 HOURS SERVICE

- 5.8.7. EVERY 2000 HOURS SERVICE

- 5.8.8. EVERY 4000 HOURS SERVICE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS, OPTIONS

- 7.1. GENERAL PRECAUTIONS

- 7.1.1. PRECAUTIONS RELATED TO SAFETY

- 7.2. SELECTION OF TRACK SHOE

- 7.2.1. SELECTION OF TRACK SHOES

- 7.3. PROCEDURE FOR SELECTING RIPPER POINT

- 7.3.1. PROCEDURE FOR SELECTING RIPPER POINT

- 7.4. CAP WITH LOCK, HANDLING

- 7.4.1. METHOD OF OPENING AND CLOSING CAP WITH LOCK

- 7.5. HANDLING MACHINES EQUIPPED WITH VHMS

- 7.5.1. VHMS INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED

- 7.5.2. VHMS AND COMMUNICATIONS TERMINAL INSTALLED

- 8. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual