Komatsu D375A-5 Bull Dozer Shop Manual SEBM035200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM035200

- Format: PDF

- Size: 37.4MB

- Number of Pages: 693

Category: Komatsu Shop Manual PDF

-

Model List:

- D375A-5 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. ENGINE CONTROL

- 4.2. POWER TRAIN

- 4.3. OVERALL DRAWING OF POWER TRAIN UNIT

- 4.4. POWER TRAIN HYDRAULIC PIPING DIAGRAM

- 4.5. POWER TRAIN HYDRAULIC CIRCUIT DRAWING

- 4.6. DAMPER, UNIVERSAL JOINT

- 4.7. TORQUE CONVERTER, PTO

- 4.8. TORQUE CONVERTER VALVE

- 4.9. TRANSMISSION CONTROL

- 4.10. TRANSMISSION

- 4.11. TRANSMISSION CONTROL VALVE

- 4.12. TRANSMISSION LUBRICATION RELIEF VALVE

- 4.13. SCAVENGING PUMP STRAINER

- 4.14. OVERFLOW VALVE

- 4.15. POWER TRAIN PUMP STRAINER

- 4.16. POWER TRAIN, LUBRICATING OIL FILTER

- 4.17. STEERING, BRAKE CONTROL

- 4.18. TRANSFER, BEVEL GEAR SHAFT, STEERING

- 4.19. STEERING CONTROL VALVE

- 4.20. FINAL DRIVE

- 4.21. TRACK FRAME

- 4.22. RECOIL SPRING

- 4.23. TRACK ROLLER BOGIE

- 4.24. MAIN FRAME

- 4.25. SUSPENSION

- 4.26. PPC CONTROL PIPING DIAGRAM

- 4.27. WORK EQUIPMENT CONTROL

- 4.28. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.29. HYDRAULIC TANK

- 4.30. PPC CHARGE VALVE

- 4.31. ACCUMULATOR

- 4.32. PPC LOCK VALVE

- 4.33. PISTON VALVE

- 4.34. QUICK DROP VALVE

- 4.35. PIN PULLER SWITCH

- 4.36. PIN PULLER SOLENOID VALVE

- 4.37. BLADE CONTROL KNOB

- 4.38. MAIN CONTROL VALVE

- 4.39. AIR CONDITIONER

- 4.40. MONITOR SYSTEM

- 4.41. SWITCH PANEL

- 4.42. FUSE BOX

- 4.43. ENGINE START SAFETY SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 5.4. STANDARD VALUE TABLE FOR MONITOR

- 5.5. TABLE OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.6. MEASURING ENGINE SPEED

- 5.7. MEASURING EXHAUST COLOR

- 5.8. ADJUSTING VALVE CLEARANCE

- 5.9. MEASURING COMPRESSION PRESSURE

- 5.10. MEASURING BLOWBY PRESSURE

- 5.11. MEASURING ENGINE OIL PRESSURE

- 5.12. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.13. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.14. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 5.15. MEASURING EXHAUST TEMPERATURE

- 5.16. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 5.17. MEASURING TORQUE CONVERTER STALL SPEED

- 5.18. MEASURING SPEED AT TORQUE CONVERTER STALL HYDRAULIC PUMP RELIEF (FULL STALL)

- 5.19. ADJUSTING FUEL CONTROL LINKAGE

- 5.20. ADJUSTING DECELERATOR PEDAL

- 5.21. ADJUSTING JOYSTICK (STEERING, DIRECTIONAL, SPEED CONTROL LEVER), PARKING BRAKE LEVEL LINKAGE

- 5.22. ADJUSTING BRAKE PEDAL LINKAGE

- 5.23. ADJUSTING WORK EQUIPMENT CONTROL LINKAGE

- 5.24. MEASURING POWER TRAIN OIL PRESSURE

- 5.25. MEASURING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.26. TESTING AND ADJUSTING WORK EQUIPMENT CONTROL CIRCUIT PRESSURE

- 5.27. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.28. ADJUSTING PPC VALVE

- 5.29. MEASURING ONOFF SOLENOID VALVE OUTPUT PRESSURE

- 5.30. BLEEDING AIR FROM HYDRAULIC CYLINDERS

- 5.31. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.32. CHECKING LOCATION OF CAUSE OF HYDRAULIC DRIFT OF BLADE AND RIPPER

- 5.33. MEASURING LEAKAGE INSIDE HYDRAULIC CYLINDER

- 5.34. ADJUSTING SEMI UTILTDOZER

- 5.35. ADJUSTING IDLER CLEARANCE

- 5.36. SIMPLE PROCEDURE FOR TESTING BRAKE PERFORMANCE

- 5.37. TROUBLESHOOTING

- 5.37.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.37.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.37.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.37.4. CHECKS BEFORE TROUBLESHOOTING

- 5.37.5. TYPE OF CONNECTOR AND POSITION OF INSTALLATION

- 5.37.6. CONNECTOR ARRANGEMENT DIAGRAM

- 5.37.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.37.8. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.37.9. TROUBLESHOOTING OF ENGING SYSTEM (S MODE)

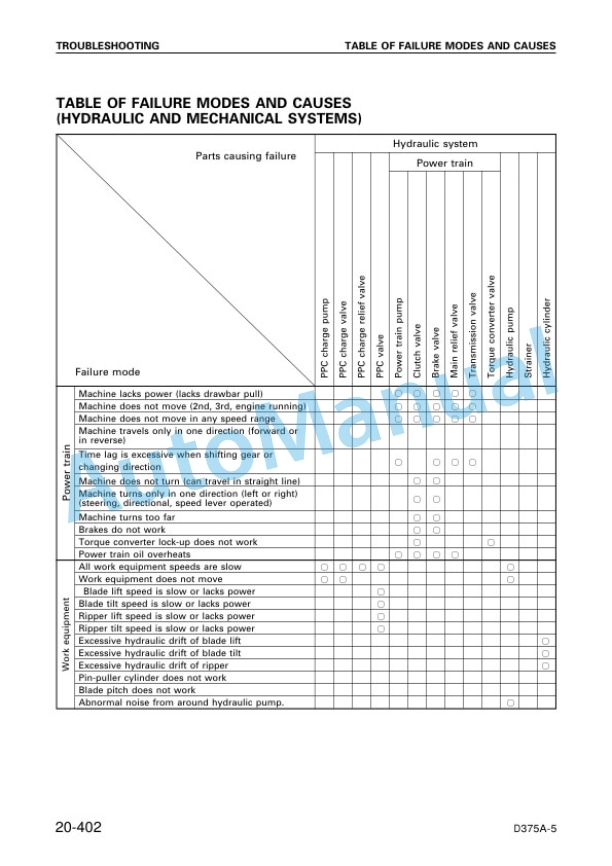

- 5.37.10. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 5.37.11. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 5.37.12. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCH OF SPECIAL TOOLS

- 6.5. ENGINE OIL COOLER

- 6.5.1. REMOVAL

- 6.5.2. INSTALLATION

- 6.6. FUEL INJECTION PUMP

- 6.7. AFTERCOOLER CORE

- 6.8. ENGINE FRONT SEAL

- 6.8.1. REMOVAL

- 6.8.2. INSTALLATION

- 6.9. ENGINE REAR SEAL

- 6.10. RADIATOR GUARD

- 6.11. POWER TRAIN UNIT

- 6.12. TORQUE CONVERTER

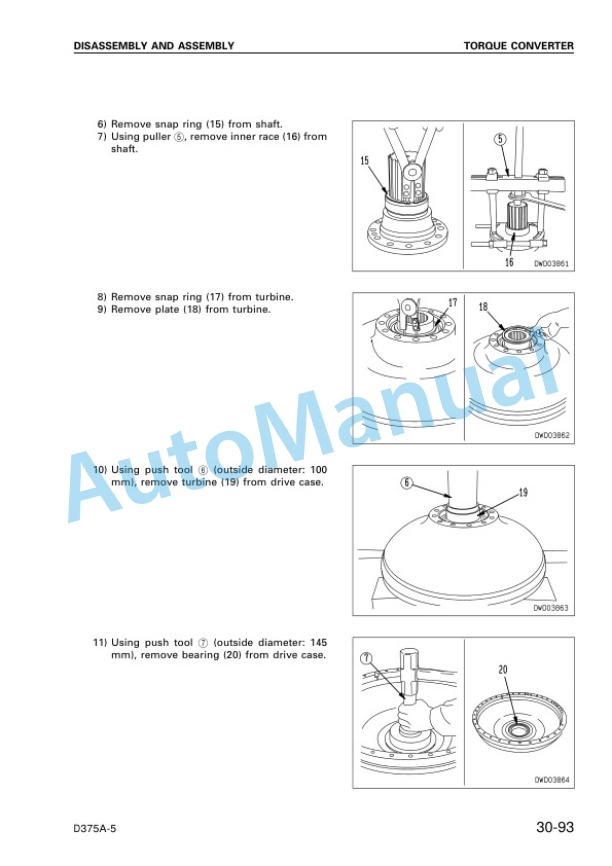

- 6.12.1. DISASSEMBLY

- 6.12.2. ASSEMBLY

- 6.13. TORQFLOW TRANSMISSION

- 6.14. POWER TRAIN,LUBRICATION PUMP

- 6.14.1. REMOVAL

- 6.14.2. INSTALLATION

- 6.15. SCAVENGING PUMP

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.16. TORQUE CONVERTER OIL COOLER

- 6.16.1. REMOVAL

- 6.16.2. INSTALLATION

- 6.17. TORQUE CONVERTER VALVE

- 6.17.1. REMOVAL

- 6.17.2. INSTALLATION

- 6.17.3. DISASSEMBLY

- 6.17.4. ASSEMBLY

- 6.18. TRANSMISSION CONTROL VALVE

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

- 6.18.3. DISASSEMBLY

- 6.18.4. ASSEMBLY

- 6.19. TRANSMISSION LUBRICATION VALVE

- 6.19.1. REMOVAL

- 6.19.2. INSTALLATION

- 6.19.3. DISASSEMBLY

- 6.19.4. ASSEMBLY

- 6.20. STEERING CONTROL VALVE

- 6.21. T BOGIE ASSEMBLY

- 6.21.1. REMOVAL

- 6.21.2. INSTALLATION

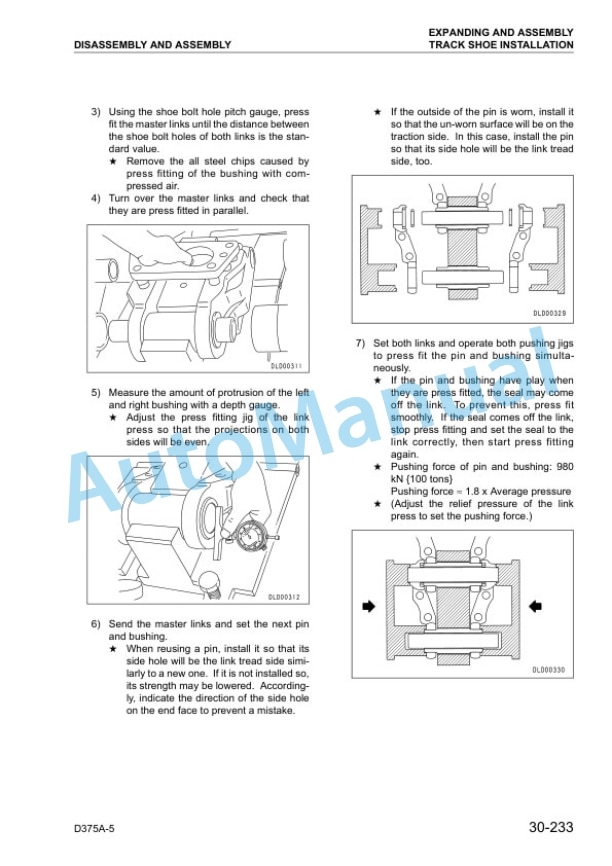

- 6.22. TRACK SHOE

- 6.22.1. CHECK BEFORE EXPANDING

- 6.22.2. EXPANDING

- 6.22.3. INSTALLATION

- 6.22.4. WHOLE DISASSEMBLY

- 6.22.5. WHOLE ASSEMBLY

- 6.22.6. WHEN RECYCLING FOR LUBRICATED TRACK

- 6.22.7. WHEN RECYCLING FOR GREASEFILLED TRACK

- 6.22.8. DIMENSIONS TABLE OF FITTING JIG OF LINK PRESS

- 6.23. ONE LINK

- 6.23.1. FIELD DISASSEMBLY

- 6.23.2. FIELD ASSEMBLY

- 6.24. MASTER LINK

- 6.24.1. FIELD DISASSEMBLY

- 6.24.2. FIELD ASSEMBLY

- 6.25. PIVOT SHAFT ASSEMBLY

- 6.26. EQUALIZER BAR BUSHING

- 6.27. WORK EQUIPMENT,PPC PUMP

- 6.27.1. REMOVAL

- 6.27.2. INSTALLATION

- 6.28. BLADE LIFT VALVE

- 6.28.1. REMOVAL

- 6.28.2. INSTALLATION

- 6.28.3. DISASSEMBLY

- 6.28.4. ASSEMBLY

- 6.29. BLADE TILT,RIPPER LO VALVE

- 6.29.1. REMOVAL

- 6.29.2. INSTALLATION

- 6.29.3. DISASSEMBLY

- 6.29.4. ASSEMBLY

- 6.30. RIPPER HI VALVE

- 6.30.1. REMOVAL

- 6.30.2. INSTALLATION

- 6.30.3. DISASSEMBLY

- 6.30.4. ASSEMBLY

- 6.31. PPC CHARGE VALVE

- 6.31.1. REMOVAL

- 6.31.2. INSTALLATION

- 6.31.3. DISASSEMBLY

- 6.31.4. ASSEMBLY

- 6.32. BLADE PPC VALVE

- 6.32.1. REMOVAL

- 6.32.2. INSTALLATION

- 6.32.3. DISASSEMBLY

- 6.32.4. ASSEMBLY

- 6.33. RIPPER PPC VALVE

- 6.33.1. REMOVAL

- 6.33.2. INSTALLATION

- 6.33.3. DISASSEMBLY

- 6.33.4. ASSEMBLY

- 6.34. BLADE LIFT CYLINDER

- 6.34.1. REMOVAL

- 6.34.2. INSTALLATION

- 6.35. BLADE TILT CYLINDER

- 6.35.1. REMOVAL

- 6.35.2. INSTALLATION

- 6.36. RIPPER LIFT CYLINDER

- 6.36.1. REMOVAL

- 6.36.2. INSTALLATION

- 6.37. RIPPER TILT CYLINDER

- 6.37.1. REMOVAL

- 6.37.2. INSTALLATION

- 6.38. HYDRAULIC CYLINDER

- 6.38.1. DISASSEMBLY

- 6.38.2. ASSEMBLY

- 6.39. RIPPER PINPULLER

- 6.40. AIR CONDITIONER COMPRESSOR

- 6.40.1. REMOVAL

- 6.40.2. INSTALLATION

- 6.41. AIR CONDITIONER CONDENSER

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. DAMPER, UNIVERSAL JOINT

- 7.3. TORQUE CONVERTER

- 7.4. TORQUE CONVERTER VALVE

- 7.5. TRANSMISSION

- 7.6. TRANSMISSION CONTROL VALVE

- 7.7. POWER TRAIN LUBRICATION POWER TRAIN PUMP

- 7.8. SCAVENGING PUMP

- 7.9. TRANSFER, BEVEL PINION

- 7.10. BEVEL GEAR SHAFT, STEERING CLUTCH, BRAKE

- 7.11. STEERING CONTROL VALVE

- 7.12. WORK EQUIPMENT PPC CHARGE PUMP

- 7.13. WORK EQUIPMENT CONTROL VALVE

- 7.14. PPC VALVE

- 7.15. PPC CHARGE VALVE

- 7.16. WORK EQUIPMENT CYLINDER

- 7.17. QUICK DROP VALVE

- 7.18. CYLINDER STAY

- 7.19. BLADE

- 7.20. RIPPER EQUIPMENT

- 8. OTHERS

- 8.1. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 8.2. ELECTRICAL CIRCUIT DIAGRAM (2/2)

Rate this product

You may also like